do lcd displays wear out supplier

I have a Samsung 19" lcd monitor for about two years now. This is the first LCD monitor I"ve owned. I mostly game with it and I"ve noticed that images from the games I play are begining to burn into the screen long after I"ve quit playing the game. Is this normal? Do LCD normally wear out like this?

LCD display screens are everywhere. You probably own one or more devices with an LCD display screen at home and at work. This includes your TV, computer monitor, watches, clocks, smartphones, and even calculators.

But have you ever wondered about how your LCD display screen works, its lifespan, components, and how it holds up to other emerging display technologies today?

Knowing all these things about your LCD display lets you appreciate your screen all the more. Caring for your device becomes easier when you’re armed with this knowledge.

LCD display screens make use of Liquid Crystal Display technology. The screen is embedded with liquid crystals, a substance that has properties in between a conventional liquid and a solid crystal. Liquid crystals can flow, but their molecules carry a crystal-like solid orientation.

Liquid crystals are responsible for producing an image flashed onto the LCD screen. They don’t emit light, though. Backlights are used to illuminate these crystals.

Now, in LCD displays, pixels are regulated by using liquid crystals for rotating polarized light. Polarized light denotes light waves with vibrations occurring in a single plane. In LCDs, this is achieved by using polarized layers.

When the liquid crystal is turned on, electricity flows through the nematic liquid crystals. They completely straighten out from their twisted state. The polarizing filter in front of the liquid crystal blocks out the light, resulting in the pixel turning off and becoming dark.

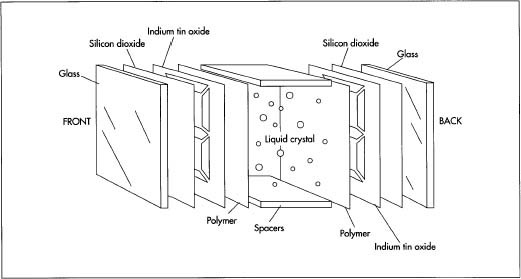

A single LCD contains millions of pixels, nematic liquid crystals, polarizing filters, and transistors. They all work together to create images on the screen.

Most LCD monitors have a lifespan ranging from 30,000 to 60,000 hours. That’s equivalent to 5-7 years using the monitor for 24 hours per day. It could also translate to 10-20 years with running the monitor for 8 hours a day, 5 days a week.

The backlight’s life expectancy is the biggest factor in determining the LCD display lifespan. It’s because liquid crystals do not give off light from themselves. The liquid crystals depend on the backlight for illuminating them. Hence, the LCD screen wears off when the backlights dim as it reaches its maximum lifespan.

The backlight serves as the illuminator of the entire LCD display device. Without a backlight, the LCD device remains darkened and hard to use. Backlights are installed directly behind the LCD panel to lighten up the display.

Simple devices such as pocket calculators don’t use a backlight for their LCD screens. Users rely on natural light to see the numbers displayed on such calculators. However, the majority of modern LCD screens such as televisions, computer monitors, smartphones, aviation screen panels, outdoor signages, and medical monitoring devices use backlights as their internal light source.

This type of backlight is the most popular and widely-used light source for LCDs today. Light-emitting diodes are semiconductors that emit light once electric current flows into it. Particles carrying the electric current are called electrons holes. These combine with electrons in the semiconductor, releasing photons (light particles).

White LED (WLED)– The LCD panel’s rear side is lit up with several white-colored LEDs. A diffuser is set in front of the LEDs to help evenly smooth out the light throughout the screen. Some computer monitors and large-screen LCD TVs use this LED technology.

ELP uses electroluminescent materials such as colored phosphors instead of heat to create light. This material is placed in between two conductor layers. The material emits light as a result of an electric current flowing through it. ELPs are mostly used in small LCD screens.

Computer monitors and TV screens predominantly used CCFLs for backlights. However, modern manufacturers opt for LED technology instead of CCFL for their devices’ backlights.

HCFL backlights have filaments that need to be heated to excite mercury atoms, cause the current to flow, and ultimately emit light. HCFLs are often used in LCD equipment such as medical devices, custom task-oriented lamps, scanners, and outdoor LCD signs.

Liquid crystals are the heart of an LCD display. This unique substance flows like a liquid but retains many characteristics of solid crystals. They have long and cylindrical-shaped molecules that can twist when changes in molecular orientation happen.

Different liquid crystal families are used in LCD displays. One requirement of such liquids is to exhibit mutual attraction. Also, the molecules in the liquid crystal need to be anisotropic. This means that the liquid crystal molecules have that average structural order along a molecular axis.

The nematic phase is characterized by the crystal molecules freely moving around the liquid. However, these molecules point themselves to one direction only, making it unique from pure liquid molecules. Nematic liquid crystals are the most common liquid used in LCD screens.

Color filters are found in between the liquid crystals. These filters determine whether the pixel shows red, green, or blue colors when activated. The filters work by independently controlling the pixel’s red, green, and blue sub-pixels. With this, the LCD screen can reproduce all possible colors found in the color space.

An LCD cell is made up of two polarizing filters. They enclose the LCD display and color filters. One polarizing filter is located in front of the backlight and is horizontal in orientation. The other one is found just beneath the pixel in front and is vertical in orientation. Polarizing filters are typically made of transparent crystals or glass substrates.

The role of polarizing filters is to control which light patterns can pass through the LCD screen. Without these filters, visual images generated by the LCD panel will have a poor contrast ratio and an inferior quality image.

Meanwhile, if the LCD display is arranged in a straightened way, the horizontal light waves that came from the first polarizing filter will be blocked from entering the vertical polarizing filter. The pixel is then turned off and no light illuminates it.

TFTs are responsible for providing electrical voltage to the LCD display. Each screen pixel has a corresponding transistor, enabling the pixels to easily be controlled in unison through changes in electrical current.

Using TFTs requires less charge and less power to operate the LCD display screen successfully. TFT use also leads to sharper images because each pixel has its own transistor controlling it. The charge given to a certain pixel can be actively maintained even if the screen is refreshed to display another image.

That’s all the basic information you need to know about LCD display screens. Now, you know how an LCD screen works, its possible lifespan, its components, and how it compares to other display technologies.

Armed with this information, you can better appreciate and take care of your LCD display devices. And in case you’re planning to add display devices to your business, the information you’ve learned will help you make educated choices regarding the display technologies you’ll utilize.

Much has been made of the longevity of LCD displays, at least compared to plasma monitors. The conventional wisdom is that LCD televisions last longer than their plasma TV counterparts, which is true. The problem is, a lot of people extrapolate from this that either (a) LCD displays last forever or (b) LCD monitors suffer no picture "wear" over time. Neither of these suppositions is correct.

Flat-panel LCD screen displays have a lifespan approaching 60,000 hours. The lifespan of an LCD display is generally longer than that of similar-sized plasma displays. Some manufacturers even claim that their LCDs can last upwards of 80,000 hours when used continuously under controlled conditions (e.g., in a room with "standard" lighting conditions and 77° temperatures throughout). Just how realistic such claims are is debatable. After all, whose living room has no windows and remains at a perfectly comfortable 77 degrees year-round?

In any case, the pictures on LCD displays will show some "wear" because they are generated by powerful lamps, which, like any lighting appliance, will dim over time and with use. The picture you see will dim ever so slightly as the lamp itself dims.

Therefore, the most important thing to consider when it comes to the lifespan of your LCD TV is the actual lifespan of the light source in your LCD. LCD TVs last as long as their lightsources do. So, the lightsource in your LCD monitor is the critical component of your LCD display unit.

The quality of your lightsource is particularly important for maintaining a proper white balance on your TV. As these florescent bulbs age, colors can become unbalanced, which could result in too much red, for example, in your picture. So, it pays to buy name-brand displays. You will definitely pay more for better LCD display brands like Sharp, Toshiba, JVC, or Sony than you will for cheap Chinese or Korean variety knock-offs, but you"ll get a backlighting bulb of higher quality and, in the end, a TV whose colors will stay truer longer.

To ensure the integrity of your lightsource for the duration of your LCD display"s lifespan, you will definitely want to adjust the CONTRAST setting of your LCD TV. Too high of a CONTRAST level will prematurely age your lightsource because it will have to work harder to maintain such light intensities. Your best bet is to keep your CONTRAST set appropriately for the conditions under which your view your LCD display. Higher light levels require slightly higher CONTRAST levels, while lower ambient light levels demand less CONTRAST.

You will also want to pay attention to the warranty for this particular feature, since it can be shorter than for the display as a whole. This means you might have to buy a whole new LCD monitor because the coverage on its backlight has expired. Moreover, some bulbs can be replaced, while others are built in to the unit itself. You should definitely do some research on the backlighting system, how it"s configured, and how it"s warranted.

Note: Sharp is currently the only manufacturer that makes LCD displays whose lamps can be changed out. This is definitely something to consider, given that LCD monitors dim as their lightsources do, so being able to replace its lamp will restore your picture to "like new" levels.

LCDs have a lifespan of about 50,000 hours, or 5 years — half the lifespan of LED. To help businesses transition from LCD to longer-lasting LED signage, Samsung has launched a trade-in program.

Flat-panel LCD TVs have a lifespan newly approaching 100,000 hours on average. The lifespan of an LCD TV is generally longer than that of similar-sized plasma televisions.

LED technology has improved drastically in recent years improving quality while driving costs down. LED is a bigger investment up front but generally has a lifespan of about 100,000 hours. LCD is cheaper and generally more familiar. A LCD screen typically has a lifespan of about 50,000 hours.

Most LCD monitors have a lifespan ranging from 30,000 to 60,000 hours. That"s equivalent to 5-7 years using the monitor for 24 hours per day. It could also translate to 10-20 years with running the monitor for 8 hours a day, 5 days a week.

In addition to humidity and temperature exposure, cyclic loadings and handling conditions (bending, repetitive shock, and drop loading) have been shown to cause failures in LCDs.

While LCDs are not susceptible to burn-in the same way CRT monitors are, LCDs suffer from what manufacturers call image persistence. Like the burn-in on CRTs, image persistence on LCD monitors is caused by the continuous display of static graphics on the screen for extended periods.

Lifespan. LG has said their OLED TVs have a lifespan of 100,000 hours to half brightness, a figure that"s similar to LED LCDs. Generally speaking, all modern TVs are quite reliable. Does that mean your new LCD or OLED will last for several decades like your parent"s last CRT (like the one pictured).

LED TVs are more energy-efficient as these models use light emitting diodes (LED) for backlighting. These TVs consume less power as compared to cold cathode fluorescent lamps (CCFL), which most LCD TVs use. This results in a power savings of up to 30%.

What does a life of 50,000 hours mean in the case of - LEDs? 50,000 hours would imply 5.7 years if the light is operated for 24 hours in a day, 7.6 years if the lights are on 18 hours per day and 11.4 years for 12 hours a day.

If you"re still wondering whether you should opt for an LCD or LED monitor, the answer is simple– LED displays are always the better choice, regardless of whether you"re looking for a better viewing angle, picture quality, or anti- eye fatigue features.

Is LED or LCD Better for the Eyes? An LED display provides the option to dim the backlight, along with other eye comfort features. Not only that, it provides a wider viewing angle without harming image quality. Therefore, an LED display is far better for your eyes than an LCD.

Turns out there is. According to research performed by Harvard Medical School, participants who used curved monitors reported experiencing less eye strain than subjects who used flat monitors. Blurred vision was also 4x less common in users of curved monitors than users of flat monitors.

On average LCD flat-screen TV is slated to have a half-life of roughly around 60,000 hours. LG LCD TVs fit squarely in with this statistic, as they last for anywhere between 40-60,000 hours, which would translate to 5 to 7 years.

An LCD or LED TV may not perform well under extreme temperature conditions. In the cold, the response time of an HDTV picture may lag. For this reason, many LCD and LED television manuals will specify a safe-operating-temperature range. In most HDTVs, this range is about 50–90°F.

Quite simply, the QN90B is one of the best LCD TVs you can buy, so it"s especially good that this TV is available in such a wide range of screen sizes. Like the Hisense U8H, the Samsung QN90B achieves excellent picture quality by way of mini-LED backlighting, local dimming, quantum dot color, and a 120 Hz refresh rate.

OLEDs are true emissive components that produce light on their own and do not require a light source. Meaning they produce a light that"s more natural and less harsh on your eyes. OLED TVs also provide excellent color and contrast because they do not use light from other sources to display colors, as LCD/LED TVs do.

In looking at standard 4K LED TVs vs 4K OLED TVs, both offer great viewing experiences and improvements over 1080p. But LG OLED technology will truly transform your home entertainment experience with superior blacks, cinematic colors and High Dynamic Range with Dolby Vision support.

When it comes to picture quality, full-array LED monitors are almost always superior to LCD monitors. But bear in mind that only full-array LEDs are superior. Edge-lit LEDs may actually be inferior to LCD monitors.

Liquid Crystal Displays (LCD) remain a popular choice for televisions and computer monitors. Unfortunately, these can be affected by a defect called backlight bleeding. Occurring when light isn"t entirely blocked around a display"s bezels, the imperfection is fixable in some cases, although not always.

I"m using this (https://smile.amazon.com/gp/product/B07 ... UTF8&psc=1) 4 line LCD display. Does this type of display have a problem with burn in or anything like that? I"m trying to decide if I need to limit the time the display is on or if I can leave it on 24/7.

LCD panels will fade with time, but the device is likely to last a decade or more before you notice the fade, at least speaking from personal experience with monitors that are on 24/7 for the last decade at my place of employment.

One widely cited problem is that OLED displays don"t last as long: degradation of the organic molecules meant that early versions of OLEDs tended to wear out around four times faster than conventional LCDs or LED displays. Manufacturers have been working hard to address this and it"s much less of a problem than it used to be.

There are a lot of tricks that OLED TVs (and presumably mobile phones) are documented as doing to reduce the wear on OLED pixels, such as "resting" individual pixels by subtly dimming some whilst brightening adjacent ones and applying slight blurs or colour changes where lack of detail won"t be noticed. For example the whole "reduce blue light in the evening because it helps you sleep" colour shift may well be a chance for the display to give the blue OLED pixels a bit of a break as much as anything else

Traditional LCD display"s like you linked will work for many decades as long as they are not in direct sunlight and kept between 15°C and 40°C at less than 90%RH. Other environmental conditions can shorten the life span significantly. The LED"s used for backlighting, when used at moderate brightness, will also be usable for decades before dimming is noticeable.

The small inexpensive OLED displays do burn out rather quickly compared to other technologies. This statement from Adafruit for one they sell is dead on IME. https://www.adafruit.com/product/326

Please note that OLED displays are made of hundreds of...OLEDs! That means each pixel is a little organic LED, and if it"s kept on for over 1000 hours it"ll start to dim. If you want to keep the display uniformly bright, please turn off the display (set the pixels off) when it isn"t needed to keep them from dimming.

Have you ever left your TV or monitor on for days, stuck on the same image? You return to your screen, only to find an image burned into the display. No matter what you do, it won"t go away. It is a permanent image burn.

Why do monitors and TVs get image burn? Why can"t manufacturers prevent LCDs and plasma screens from a burnt image imprint? Moreover, what can you do to fix an image burn?

Before flat-screens and crystal displays, most TVs and monitors featured CRT (Cathode Ray Tube) technology. In CRTs, individual pixels comprise a red, blue, and green phosphor component. Depending on the intensity of each phosphor component, the pixel appears to the human eye as a unique color.

Plasma displays use plasma, a gaseous substance containing free-flowing ions. When the plasma is not in use, the particles in the plasma are uncharged and display nothing. With the introduction of an electric current, the ions become charged and begin colliding, releasing photons of light.

LCD and LED do not work in the same way as CRTs, either. LCD and LED screens use backlit liquid crystals to display colors. Although manufacturers market screens using LED and LCD, an LED screen is still a type of LCD. The white backlight filters through the liquid crystals, which extract particular colors per pixel.

LCD and LED displays don"t suffer from the same type of image burn as CRTs and plasma screens. They"re not completely clear, though. LCD and LED screens suffer from image persistence. Read on to find out more about image persistence.

Before you can fix screen burn-in, take a second to understand why these images burn in the first place. LCDs and LEDs don"t suffer from burn-in as seriously as plasma screens. But static images can leave an imprint on both display types if left alone for too long. So, why does image burn happen?

First, let"s tackle plasma screen burn-in. Remember why CRTs experience image burn? When a still image remains on the screen for too long, the phosphor components in each pixel wear out at different rates. The uneven burn rates leave behind a ghost image, forever etched into the screen.

LCD and LED screens can also experience image burn, though the image burn process can take longer to develop into a permanent issue. In addition, LCD and LED screens suffer from another issue, known as image retention (also known as image persistence or an LCD shadow).

Image retention is a temporary issue that you are more likely to notice before it becomes a permanent issue. However, proper image burn can still affect LCD, LED, and OLED screens.

When you load up the video game on the screen, you can still see the faint outline of the steam train on the screen. The steam train image will remain for a short while, but the movement and color changes of the video game (or film, TV show, or other media type) should erase the retained image.

Issues arise when a screen shows a single news channel 24 hours a day, every day, causing channel logos to burn-in, along with the outline of the scrolling news ticker and so on. News channels are a well-known source of television burn-in, no matter the screen type.

Image burn-in fixes exist for LCD and plasma screens. How effective an image burn-in fix is depends on the screen damage. Depending on the length and severity of the image burn, some displays may have permanent damage.

My personal rule of thumb is to turn off the display if I plan on being away for more than 15 minutes. That way, it is difficult to get caught out, plus you save yourself money on electricity costs and monitor or TV wear and tear.

If your plasma or LCD screen already has image burn-in, you can try turning on white static for 12 to 24 hours. The constant moving of white-and-black across your screen in random patterns can help remove the ghost image from your screen.

Unfortunately, this won"t work for extreme cases. Some TVs will have a built-in pattern swiping option that basically accomplishes the same thing (filling your screen with random patterns).

Pixel-shift constantly slightly adjusts the image on your screen, which varies the pixel usage to counteract image burn. You might have to enable a pixel or screen shift option in your screen settings. Pixel-shift is a handy feature for LED and OLED screens that cannot recover from image burn and should help counteract an LCD shadow.

While the Deluxe version uses advanced algorithms to repair burned screens and prolong plasma and LCD longevity, the official site is no longer up and running, and there is no way to download the full version officially.

You can find the free version of the Deluxe app online, but it is limited to 20 minutes running at a time. Furthermore, we"re not going to link out to the versions you can find online as we cannot verify the security of these installations. If you do use the Deluxe version, you do so at your own risk.

How long will your LED display last? In nearly every industry, from retail businesses to concert halls to corporate centers, decision makers need to evaluate the return on investment (ROI) of their LED signage. In most cases, potential buyers go straight to the obvious place: the LED manufacturer’s spec sheet. The industry standard for LED lifespan is 100,000 hours, or about 10 years, and most people assume that’s how long their display will last. But it’s not quite that simple.

“The reality is, your screen can often last significantly longer than 100,000 hours,” says Kevin Izatt, a senior product manager in Samsung’s Display division. “We’ve had displays that have been up for 15-plus years with more than adequate brightness. Because the diode is actually only one factor in the lifespan of your LED display.”

The biggest contributor to diode degradation is heat. As you increase a diode’s brightness, it produces more heat. Your display’s physical environment also contributes to the temperature of the diodes, especially for outdoor displays.

“Fans are mechanical; they break down,” explains Izatt. “And similar to your computer, the electrical components don’t last forever. Together, these factors all contribute to the lifespan of an LED display. Looking at just the diode lifespan doesn’t give you the complete story — almost always, another part will go out first.”

“Something like airflow is very important,” says Izatt. “You need a screen that has good cooling, and a design that allows heat to flow out of the back through vents.”

It’s easy to see why: The circuit boards powering the display release heat, and that heat needs to go somewhere. Without a strong design, thermal stress will degrade the life of the display, except for the highest-quality parts — optimal conditions notwithstanding.

“Lots of variations on the color and brightness you use will impact the life of the diode,” explains Izatt. “For instance, black doesn’t use any of the diodes at all. And if your content is using lots of gray, that’s a much lower power output than white.”

That’s not to say you should hold back on displaying rich, vibrant colors — after all, that’s what LED does best. But it does factor into your product’s life expectancy.

To help businesses transition from LCD to longer-lasting LED signage, Samsung has launched a trade-in program. Samsung will come on site to remove your existing display and provide a discount on a new LED bundle kit.

Traded-in LCD displays that are still operating will be refurbished and resold, and your business will receive a cash rebate. Nonworking displays will be recycled and their parts reused.

You can’t rely on the number on the diode spec sheet; the lifespan of your LED display depends on many more factors. “Overall quality has a tremendous impact on the life of the display that diode specs just don’t take into account,” says Izatt. Your best bet is to look at the purchase holistically and invest in a top-tier product.

As you plan your LED signage rollout — or an upgrade — learn how to configure and tailor your screens’ real-time messaging with an integrated CMS in thisfree guide. And if you haven’t decided what kind of display is best suited to your current project, compare all ofSamsung’s LED displays.

Liquid crystal displays (LCD) have become an essential component to the industry of display technology. Involved in a variety of contexts beyond the indoors like LCD TVs and home/office automation devices, the LCD has expanded its usage to many environments, such as cars and digital signage, and, thus, many temperature variations as well.

As with any substance that requires a specific molecular characteristic or behavior, LCDs have an operating temperature range in which the device, if within, can continue to function properly and well. In addition to that, there is also an ideal storage temperature range to preserve the device until used.

This operating temperature range affects the electronic portion within the device, seen as falling outside the range can cause LCD technology to overheat in hot temperatures or slow down in the cold. As for the liquid crystal layer, it can deteriorate if put in high heat, rendering it and the display itself defective.

In order for the LCD panel to avoid defects, a standard commercial LCD’s operation range and storage range should be kept in mind. Without adaptive features, a typical LCD TV has an operating range from its cold limit of 0°C (32°F) to its heat limit of 50°C (122°F) (other LCD devices’ ranges may vary a bit from these numbers).

The storage range is a bit wider, from -20°C (-4°F) to 60°C (140°F). Though these ranges are quite reasonable for many indoor and even outdoor areas, there are also quite a few regions where temperatures can drop below 0°C or rise above 32°C, and in these conditions, LCDs must be adapted to ensure functionality.

Heat, can greatly affect the electronics and liquid crystals under an LCD screen. In consideration of heat, both external heat and internally generated heat must be taken into consideration.

Seen as the liquid crystals are manipulated in a device by altering their orientations and alignments, heat can disrupt this by randomizing what is meant to be controlled. If this happens, the LCD electronics cannot command a certain formation of the liquid crystal layer under a pixel, and the LED backlighting will not pass through as expected, which can often lead to dark spots, if not an entirely dark image. This inevitably disrupts the display’s readability.

Depending on the upper limit of the operation temperature range, LCD device can be permanently damaged by extreme heat. With long exposure to extreme heat, besides the destruction of the liquid crystals, battery life can shorten, hardware can crack or even melt, response time may slow to prevent even more heat generation from the device.

The LED backlight and the internal circuitry, typically TFT-based in the common TFT LCDs, are components that can generate heat that damages the device and its display. To address this concern with overheating, many devices use cooling fans paired with vents.

Some devices that are used in extremely high ambient temperatures may even require air conditioning. With air vents to carry the heat out, the device can expel it into the surroundings.

In the opposite direction is extreme cold. What typically occurs in the cold is “ghosting” (the burning of an image in the screen through discoloration) and the gradual slowing and lagging of response times. Like heat-affected LCD modules, the extreme temperature can affect the liquid crystals. This layer is a medium between the liquid and solid state, so it is still susceptible to freezing.

An LCD device can be left in freezing temperatures because it will likely not be permanently damaged like in the heat, but it is important to understand the device’s limits and how to take precautions when storing the device. The standard and most common lower-bound storage range limit is -20°C, below freezing, but if possible, it would be best to keep it above that limit, or else there is still a risk of permanent damage.

Display types have a lot of variation. Choices like alphanumeric or graphic LCD, human-machine interactive LCD modules and touchscreen panels capabilities, the width of the viewing angle, level of contrast ratios, types of backlighting, and liquid crystal alignment methods are often considered. For example, the twisted nematic LCD provides for the fastest response time at the lowest cost, but cannot offer the highest contrast ratio or widest viewing angle.

Environment-based factors must consider things besides the obvious temperature like UV exposure and humidity/moisture, as they all are necessary in finding the perfect fit extreme temperature LCD module.

Besides the LCD modules, recent new products have opened doors in wide temperature range displays, such as OLED displays. OLED displays offer better displays in regard to contrast, brightness, response times, viewing angles, and even power consumption in comparison to traditional LCD displays.

These benefits, in addition to its ability to achieve a wide temperature range, provide more options for consumers in search of high quality displays for extreme climates.

Touch screen is a kind of HMI (Human Machine Interface). Before 2007, not many people paid attention to it. But after 2007, touch panels are used in all kinds of smart phones and tablets, it has become household name. Let’s talk a little bit about its recent story first.

It’s no secret that Steve Jobs had a huge impact on the world of technology, but perhaps his legacy will be felt most significantly in mobile. No matter the smartphone, it works the way it does now because back in 2007 Steve Jobs stood on a stage before a throng of reporters and said, “Who wants a stylus? … Yuck!”. Apple was not the first company who created the touch screen, but it was the first to make it really work on cellphones.

Indeed, Steve Jobs almost missed out capacitive touch technology on the iPhone and iPad altogether. That’s because he didn’t see “any value to the idea” of multi-touch: the breakthrough in touch screen display technology which makes iOS regulars like “pinch-to-zoom” possible.

And it was left up to Ive and a few other core Apple employees to save it. Multi-touch at Apple began with a demo from Greg Christie and Bas Ording, who spent several months in 2004 creating a working prototype of an iPad-like screen, the size of a conference table. On it, a person could use two hands to move folders around, activate icons, shrink and enlarge documents, and “scroll” vertically and horizontally using swipes. They presented the tech to top Apple executives by projecting it onto a video screen. Jobs had been excited about creating a tablet, but he was less than impressed by the demo.

After thinking about the idea for a few days, however, Jobs came around — and ran it past a number of Apple executives whose opinions he trusted. Jobs wasn’t immediately convinced he could make a go of a tablet as a mass-market product, but as a phone he could certainly see the application. He told Tony Fadell to “go figure out how to add this multi-touch interface to the screen of a phone. A really cool, really small, really thin phone.”

In 1965, E.A Johnson at Royal Radar Establishment in Malvern, UK was considered as the first inventor who invented capacitive touch screen. He published his article about the touch screen technology in Ergonomics in 1967.

We have to classify the “wear” physically or electrically. Physically, it is difficult to wear out your touch screen unless you use keys or diamond to scratch the touchscreen. The surface hardness of different touchscreens are different. Some low end touch can be as “soft” as 2H, but iPhone surface can be as hard as 9H made by chemically tempered glass panel.

Screen burn-in, image burn-in, ghost image, or shadow image, is a permanent discoloration of areas on an electronic display such as a cathode ray tube (CRT) in an old computer monitor or television set. It is caused by cumulative non-uniform use of the screen.

With phosphor-based electronic displays (for example CRT-type computer monitors, oscilloscope screens or plasma displays), non-uniform use of specific areas, such as prolonged display of non-moving images (text or graphics), repetitive contents in gaming graphics, or certain broadcasts with tickers and flags, can create a permanent ghost-like image of these objects or otherwise degrade image quality. This is because the phosphor compounds which emit light to produce images lose their luminance with use. This wear results in uneven light output over time, and in severe cases can create a ghost image of previous content. Even if ghost images are not recognizable, the effects of screen burn are an immediate and continual degradation of image quality.

The length of time required for noticeable screen burn to develop varies due to many factors, ranging from the quality of the phosphors employed, to the degree of non-uniformity of sub-pixel use. It can take as little as a few weeks for noticeable ghosting to set in, especially if the screen displays a certain image (example: a menu bar at the top or bottom of the screen) constantly and displays it continually over time. In the rare case when horizontal or vertical deflection circuits fail, all output energy is concentrated to a vertical or horizontal line on the display which causes almost instant screen burn.

Phosphor burn-in is particularly prevalent with monochromatic CRT screens, such as the amber or green monochrome monitors common on older computer systems and dumb terminal stations. This is partly because those screens displayed mostly non-moving images, and at one intensity: fully on. Yellow screens are more susceptible than either green or white screens because the yellow phosphor is less efficient and thus requires a higher beam current. Color screens, by contrast, use three separate phosphors (red, green, and blue), mixed in varying intensities to achieve specific colors, and in typical usage patterns such as "traditional" TV viewing (non-gaming, non-converged TV usage, non-Internet browsing, broadcasts without tickers or flags, no prolonged or permanent letterboxing) are used for operations where colors and on-screen object placement approach uniformity.

Modern CRT displays are less susceptible than older CRTs prior to the 1960s because they have a layer of aluminum behind the phosphor which offers some protection. The aluminum layer was provided to reflect more light from the phosphor towards the viewer. As a bonus, the aluminum layer also prevented ion burn of the phosphor and the ion trap, common to older monochrome televisions, was no longer required.

A nearly two-year-old LCD television showing extreme burn-in of CNN"s circa 2008 digital on-screen graphic; this television is in a McDonald"s restaurant where CNN is permanently turned on and displayed throughout the business day.

In the case of LCDs, the physics of burn-in are different than plasma and OLED, which develop burn-in from luminance degradation of the light-emitting pixels. For LCDs, burn-in develops in some cases because pixels permanently lose their ability to return to their relaxed state after a continued static use profile. In most typical usage profiles, this image persistence in LCD is only transient.

Both plasma-type and LCD-type displays exhibit a similar phenomenon called transient image persistence, which is similar to screen burn but is not permanent. In the case of plasma-type displays, transient image persistence is caused by charge build-up in the pixel cells (not cumulative luminance degradation as with burn-in), which can be seen sometimes when a bright image that was set against a dark background is replaced by a dark background only; this image retention is usually released once a typical-brightness image is displayed and does not inhibit the display"s typical viewing image quality.

In many cases, the use of a screensaver is impractical. Most plasma-type display manufacturers include methods for reducing the rate of burn-in by moving the image slightly,Android Wear watches with OLED displays can request that Android Wear enable "burn protection techniques" that periodically shift the contents of the screen by a few pixels.

Other examples: Apple"s iPhone X and Samsung"s Galaxy series both mitigate or delay the onset of burn-in by shifting the pixels every minute or so for the battery, Wi-Fi, location, and service bars. Also, parallax scrolling may be enabled for the home screen to give icons a 3D-like effect, a setting Apple refers to as "perspective zoom". AG Neovo patented Anti-burn-in technology is also using pixel shifting to activate the pixels to move by the designed time interval to prevent burn in effect on LCD monitors.

Google requests that when these techniques are enabled, watch face developers do not use large blocks of pixels so that different pixels are burned in with each shift, reducing the overall wear of the pixels.

Photo: A trick of the polarized light: rotate one pair of polarizing sunglasses past another and you can block out virtually all the light that normally passes through.

Photo: Prove to yourself that an LCD display uses polarized light. Simply put on a pair of polarizing sunglasses and rotate your head (or the display). You"ll see the display at its brightest at one angle and at its darkest at exactly 90 degrees to that angle.

Planning for LCD display obsolescence is undoubtedly one of the last things on your to-do list. But how do you know when it’s time to get involved? There are three major signs to look out for that can help you decide.

However, if you begin to notice lead times becoming even longer than typical and random, you may have an issue of potential obsolescence. Longer or unpredictable lead times typically relate to supply chain issues with a particular component, or set of components, of the display.

Despite the volumes for your particular project, ifglobal demanddoes not support the continuation of production, you may see the beginning signs of obsolescence through these lead-time variations.

Another leading indicator of potential display obsolescence relates to the quality of the product. A significant shift downward in quality may be an indicator of upstream supply chain challenges.

A great example of this relates to LCD backlights. By 2000, the improved cost and performance of white LEDs surpassed the long CFL bulbs in small-format displays. Small-format displays all began using the LED backlight instead of small CFL tubes.

This continuance of cost reductions, combined with the improved performance of LEDs, enabled the LED backlight to displace the CFL backlight on larger and larger platforms. Today, all LCD displays—from small format to large, flat-panel televisions—now employ an LED backlight. Any older, small-format or large, CFL-based displays are now obsolete.

For example, in the late 1990s, cellphonesfrom monochrome to color LCD displays. As a result, the largest display manufacturers (Sharp, Hitachi, Samsung, NEC, etc.) began to exit the monochrome LCD business to focus on the small-format color LCD market. This left behind a wake of obsolete, name-brand, monochrome display configurations.

The cell phone market caused another shift around 2014, when the high-volume cell phone market became dominated by the two main suppliers, Apple and Samsung, and reduced the number of small-platform, color LCD projects available. This drove a big exit of the small-format color TFT manufacturers in this market that had to retool their business model to support the more profitable flat-panel TV market.

In our vision, there’s a market trend towards OLED displays for TVs and cell phones. But even still, the higher cost of the OLED panel does not quite justify the performance advantages over the existing small-format TFT market. This will change as OLED production increases and OLED costs get closer to that of the TFT equivalent.

Another trend involveswhich are becoming much more commonplace and are using both OLED and some E-ink technologies. As these displays become more widespread, they will be able to take advantage of the economies of scale and obtain more competitive lower costs.

Keeping the lines of communication open with your supplier can give you important insights into the lifecycle of your displays. Knowing about obsolescence ahead of time helps you plan your next move, such as stocking and transition strategies to stay one step ahead of the market.

Deciding when it’s time to replace your digital display can be tough. After all, you want to get as much use as possible out of your investment. But even the best displays don’t last forever. It’s important to consider upgrading your LED display to not only remain competitive and compliant, but also to avoid having to use more power to keep it running. With a newer setup, you can ensure lower energy costs and worry less about downtime.

You should also consider how long your manufacturer stated your board would last. Perhaps your specific board was quoted as a 10- to 12-year lifespan. If you’re approaching the end of that range, it may be time to look into an upgrade — while you still have the luxury of time. With age also comes warranty concerns. If your display has aged out of its warranty, any issues that arise can be costly to fix.

Even with the best maintenance, displays are subject to mechanical issues and failure. Older displays, especially those outdoors, receive a lot of environmental wear and tear over the years. Sunlight fades and degrades individual diodes, decreasing display brightness and picture consistency. With an inconsistent picture, your display is less valuable to both you and your advertisers. And as with any aging product, parts can fail. It happens, and without a warranty to replace or repair, those parts can be a big hit to your budget — if you can find obsolete parts at all.

With rapid advancements in display technology, an upgrade may be necessary to stay competitive or compliant. Samsung’s MagicINFO, an all-in-one digital signage platform, is also an option that can help you manage the software and the hardware of your LED displays and optimize their performance, all from one place.

The types of LCD displays you purchase depend largely on the nature of the applications for which you’re planning on using them. Rugged LCD displays have unique features that make them the most suitable and logical choice for usage in extreme environmental conditions. Extreme environmental conditions don’t necessarily mean outdoor usage—although, that’s certainly included.

They can include dangerous or life-threatening situations during which the displays will be exposed to direct or indirect shock, vibrations, harsh usage, and extremely low or high temperature fluctuations. Industrial display monitors are specifically designed to function in these types of conditions without interruption, even when they sustain a few minor damages.

Industrial rugged Marine displays are typically designed with “all-weather” capabilities that make them resistant and impervious to a variety of environmental conditions that are beyond the control of the user. Extended operational temperature ranges, dimmable capabilities, optically bonded glass, and capacitive or resistive touchscreen options are all available to meet various application requirements.

Screen adaptability can make a big difference when completing particularly risky or dangerous missions. Manufacturers typically offer a wide range of customization options to make optimal usability more accessible for users of all technological and physical capacities. Adaptable industrial screens, monitors, and displays are crucial for aiding in the successful completion of a mission or task by providing flexible visibility, angles, and usage options.

Given the fact that Marines are usually wearing protective tactical gear that sometimes include heavy-duty gloves, it’s important to have options in terms of the type of touchscreen capabilities that are featured in their industrial display monitors. Resistive touchscreens are the ideal choice for this type of environment because they allow the user to wear gloves while operating the display.

As mentioned, industrial display monitors are frequently subjected to harsh weather conditions, including extreme cold and heat. Cold temperatures can cause the external chassis and other hardware to harden. Under these conditions, commercial monitors would show advanced signs of wear and tear or start to crack. Industrial displays, however, are perfectly capable of withstanding these extreme conditions without so much as suffering a hairline fracture.

Considering the harsh conditions that rugged Marine displays are constantly exposed to, manufacturers and distributors usually offer extensive warranty options that go well beyond the typical manufacturer’s defect warranties.

When it comes to rugged LCD displays and monitors in North America, there’s only one name that’s synonymous with high quality and reliability—Nauticomp Inc.Over the past 20+ years, our engineers have cultivated the art and science behind designing some of the most advanced rugged Marine and military displays on the market.Contact ustoday to learn more about our products or to place an order.

Industrial LCD displays and computer monitors are generally very low maintenance, but they do need a good cleaning every once in a while to make the viewing experience more enjoyable and extend their lifespan. But it’s important that you learn the proper ways to clean LCD screens to avoid damaging them in the process. Keep reading to learn how to clean a monitor screen the right way, so that you can get the most use out of it and remove smudges, dirt, and germs.

Make sure to turn the monitor off before you start cleaning it as wiping it with a damp cloth while it’s on can damage the pixels. Plus, it’s easier to see the dust, smudges, and dust particles when the screen is off and completely black. That way, you can make sure you get a thorough clean without damaging the screen. Turning off touchscreen devices before cleaning is also highly recommended so you can avoid accidental touches that perform the wrong actions or functions.

LCD screens have protective anti-glare and anti-reflective coatings on them to improve visibility. Touchscreens also have oleophobic coatings that prevent fingerprint oil smudges from appearing on the screen. Store-bought glass cleaners contain harsh chemicals such as alcohol and ammonia, which can penetrate the surface of the screen and severely damage its internal mechanism after wearing down the protective coatings. It’s best to stay away from using household cleaners on your industrial LCD displays unless you have the greenlight from the manufacturer.

Microfiber cloths are also a great option because they usually have grooves that gently capture and remove stuck-on particles while also removing smudges on the screen without damaging them.

If blasting the screen with canned air or wiping it down with a microfiber cloth doesn’t work, then your next best option is cleaning it with distilled water. Unlike tap water, distilled water isn’t fortified with mineral deposits that can scratch or damage industrial display monitors. Many manufacturers advise against spraying the water directly onto the screen for obvious reasons. Instead, spray a small amount onto a microfiber cloth until it’s just damp and gently spot wipe the parts of the display that need it.

For more tips on how to clean a monitor screen and keep it in tiptop shape, contact Nauticomp Inc. We’re one of the leading suppliers of industrial computer monitors and displays around the globe.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey