do lcd displays wear out factory

Samsung Display will stop producing LCD panels by the end of the year. The display maker currently runs two LCD production lines in South Korea and two in China, according to Reuters. Samsung tells The Verge that the decision will accelerate the company’s move towards quantum dot displays, while ZDNetreports that its future quantum dot TVs will use OLED rather than LCD panels.

The decision comes as LCD panel prices are said to be falling worldwide. Last year, Nikkei reported that Chinese competitors are ramping up production of LCD screens, even as demand for TVs weakens globally. Samsung Display isn’t the only manufacturer to have closed down LCD production lines. LG Display announced it would be ending LCD production in South Korea by the end of the 2020 as well.

Last October Samsung Display announced a five-year 13.1 trillion won (around $10.7 billion) investment in quantum dot technology for its upcoming TVs, as it shifts production away from LCDs. However, Samsung’s existing quantum dot or QLED TVs still use LCD panels behind their quantum dot layer. Samsung is also working on developing self-emissive quantum-dot diodes, which would remove the need for a separate layer.

Samsung’s investment in OLED TVs has also been reported by The Elec. The company is no stranger to OLED technology for handhelds, but it exited the large OLED panel market half a decade ago, allowing rival LG Display to dominate ever since.

Although Samsung Display says that it will be able to continue supplying its existing LCD orders through the end of the year, there are questions about what Samsung Electronics, the largest TV manufacturer in the world, will use in its LCD TVs going forward. Samsung told The Vergethat it does not expect the shutdown to affect its LCD-based QLED TV lineup. So for the near-term, nothing changes.

One alternative is that Samsung buys its LCD panels from suppliers like TCL-owned CSOT and AUO, which already supply panels for Samsung TVs. Last year The Elec reported that Samsung could close all its South Korean LCD production lines, and make up the difference with panels bought from Chinese manufacturers like CSOT, which Samsung Display has invested in.

I have a Samsung 19" lcd monitor for about two years now. This is the first LCD monitor I"ve owned. I mostly game with it and I"ve noticed that images from the games I play are begining to burn into the screen long after I"ve quit playing the game. Is this normal? Do LCD normally wear out like this?

How long will your LED display last? In nearly every industry, from retail businesses to concert halls to corporate centers, decision makers need to evaluate the return on investment (ROI) of their LED signage. In most cases, potential buyers go straight to the obvious place: the LED manufacturer’s spec sheet. The industry standard for LED lifespan is 100,000 hours, or about 10 years, and most people assume that’s how long their display will last. But it’s not quite that simple.

“The reality is, your screen can often last significantly longer than 100,000 hours,” says Kevin Izatt, a senior product manager in Samsung’s Display division. “We’ve had displays that have been up for 15-plus years with more than adequate brightness. Because the diode is actually only one factor in the lifespan of your LED display.”

The biggest contributor to diode degradation is heat. As you increase a diode’s brightness, it produces more heat. Your display’s physical environment also contributes to the temperature of the diodes, especially for outdoor displays.

“Fans are mechanical; they break down,” explains Izatt. “And similar to your computer, the electrical components don’t last forever. Together, these factors all contribute to the lifespan of an LED display. Looking at just the diode lifespan doesn’t give you the complete story — almost always, another part will go out first.”

“Something like airflow is very important,” says Izatt. “You need a screen that has good cooling, and a design that allows heat to flow out of the back through vents.”

It’s easy to see why: The circuit boards powering the display release heat, and that heat needs to go somewhere. Without a strong design, thermal stress will degrade the life of the display, except for the highest-quality parts — optimal conditions notwithstanding.

“Lots of variations on the color and brightness you use will impact the life of the diode,” explains Izatt. “For instance, black doesn’t use any of the diodes at all. And if your content is using lots of gray, that’s a much lower power output than white.”

That’s not to say you should hold back on displaying rich, vibrant colors — after all, that’s what LED does best. But it does factor into your product’s life expectancy.

To help businesses transition from LCD to longer-lasting LED signage, Samsung has launched a trade-in program. Samsung will come on site to remove your existing display and provide a discount on a new LED bundle kit.

Traded-in LCD displays that are still operating will be refurbished and resold, and your business will receive a cash rebate. Nonworking displays will be recycled and their parts reused.

You can’t rely on the number on the diode spec sheet; the lifespan of your LED display depends on many more factors. “Overall quality has a tremendous impact on the life of the display that diode specs just don’t take into account,” says Izatt. Your best bet is to look at the purchase holistically and invest in a top-tier product.

As you plan your LED signage rollout — or an upgrade — learn how to configure and tailor your screens’ real-time messaging with an integrated CMS in thisfree guide. And if you haven’t decided what kind of display is best suited to your current project, compare all ofSamsung’s LED displays.

The human cognitive ability to perceive and process data from several heterogeneous outputs and react correctly to the information is greatly enhanced with the proper representation of graphical data. Large format displays allow for the consolidation of multiple heterogeneous displays, fonts, dials, gauges, numbers, into a single homogeneous representation of situational awareness.

For example, for many years, firemen first to arrive on scene have been met with screeching fire alarms, indicator lights on a fire panel and “as built” drawings locked in a cabinet with a special key. Today they could now be greeted by a large format LCD with a 3D view of the building, smoke flow diagrams, and other information to help them understand the situation and make better decisions faster. Occupants leaving a building can also benefit from graphical mass notification information which can be tailored for the situation.

Similarities exist on industrial control systems where several CRTs or smaller LCDs are being replaced by a large LCD with clever graphics designed for human factors and perception.

The challenge of these applications is the proper integration of the COTS LCD technology to meet requirements of availability, reliability, and intended use.

Large LCD panels are coming out of the factory with brilliant colors and near perfect viewing angles using ASV (Advanced Super View) and IPS (In Plane Switching) innovations driven by consumer TV requirements. The challenge is ruggedizing a display to preserve as much of this as possible, this while shielding against objects, liquids, sunlight and EMI. These surface choices may adversely affect the optics of the panel, which can be reduced through bonding techniques to eliminate air gaps.

Depending on its intended use, mission critical displays may be required to operate in an environment subject to dust, sand, fog, chemicals, falling or spraying liquids (broken pipes, sprinklers, etc). Protection of the LCD panel involves designing an outer enclosure capable of keeping dust and liquids out while keeping the display operating in its proper temperature range.

The transition of display backlights from CCFL to LED has also helped reduce the amount of energy in a panel, which has been a great benefit to thermal management. Displays that are used in direct sunlight, however, have to deal with solar gain which can add as much as 1000W /m2 to the problem on a sunny, cloudless day at high noon. The amount absorbed depends on the enclosure’s material and color, but typically blocking IR films or a laminar flow of air over the display are used to prevent the display from “blacking out”. In sub freezing environments, such as outdoor, or non temperature controlled areas, supplemental heaters may be required to prevent slow response of the LCDs due to low temperature.

The deployment of large screen LCDs in control rooms, ships, industrial areas, or public venues requires consideration of tampering, vibration, and shock. It is important to understand the nature of the vibration or shock in magnitude and frequency to which the screen may be subjected. Sources can be motors, conveyors, engines, propeller blades or even seismic events. In many industries, there are published standards, which represent shock and vibration experienced by the display in both transit and operation. Some of the component considerations when designing a display requiring ruggedization are listed in Table 3.

There are several touchscreen technologies available, each having its own set of strengths and weaknesses. It is important to understand the end use and user to choose the best solutions. For instance, using an infrared touch screen in an outdoor location at night can attract insects which can actually cause false touches if they land on the screen and break the IR light beam. Other touch screen technologies such as capacitive are sensitive to metal enclosures making them difficult choices for very rugged applications. Some of the more popular technologies and their strengths and weaknesses are listed in Table 4.

Parts within a large screen display are considered to have a large Mean Time Between Failures (MTBF) usually measured in tens of thousands of hours or higher. The first reaction is to divide this number by 8760 hours per year and feel assured your 24X7 display will last that many years before it fails. However the MTBF is just a probability of failure and is calculated during the “useful life” of a part, typically at room temperature. As a part starts to wear out, or gets used at high temperature, its reliability can decrease rapidly. Solid-state components such as ICs are thought of as lasting virtually forever, but within an LCD there are several components that, when routinely maintained or changed out, will keep the reliability at its maximum. The use of intelligent health monitoring such as temperature, brightness, fan speed or air flow to trigger maintenance events will increase overall reliability and availability.

Leveraging the performance and value of large format commercial off the shelf (COTS) displays requires careful attention and understanding of the environment and operation by the end user. Using this information to develop specific design requirements, engineering a design that meet these requirements, and finally developing test steps that validate the product meets these requirements will ensure a successful large format COTS display implementation.

How much DSE you see depends partly on the model you purchased. Pricier models generally feature improved better uniformity, mostly because manufacturers use more rigorous quality standards for their high-end products. But, no matter how much you spend, uniformity is unique to every individual unit, meaning you don"t really know how much DSE you"re getting until you see it in person.

Still, DSE may afflict cheaper versions, particularly if the anti-reflective coating on the glass that overlays the screen is of low quality or poorly applied. Furthermore, as the display ages, the phosphors in the screen may begin to wear out or malfunction, all of which can contribute to less uniform images, which is often apparent particular in scenes with fast panning shots.

In LCD and LED TVs, DSE is typically a bigger issue, one that"s due to the way these units are illuminated. Before we proceed, it"s worth mentioning that although marketing-speak often treats LED and LCD TVs as completely different technologies, they"re not different beasts.

LED units could be more accurately described as "LED-backlit LCD televisions," but salespeople and consumers alike are too lazy to utter that tongue-wearying phrase while haggling in a big-box store. What"s important to realize is that both categories rely on LCDs (liquid crystal displays), which act as shutters that either block light or allow it to pass, depending on the image that"s being rendered on the screen.

There are a variety of factors that affect LCD quality, notably illumination source. Older LCD TVs, for example, used multiple cold cathode fluorescent lamps (CCFL) to light LCDs from the rear. They provide generally smooth and even illumination, but they make the final product rather bulky.

Regardless of the lighting source, sometimes it"s not the technology itself that results in DSE. It might be due to the way the display was handled at the factory or even en route to your home.

If you"ve ever pressed a little too hard on your smartphone or computer screen, you"ve likely witnessed a bit of discoloration, clear evidence of how sensitive LCDs are to physical pressure. Now, picture a huge manufacturing facility that cranks out thousands of these units per week. It"s easy to see how a bit of mishandling could alter the screen"s consistency.

The same goes for shipping. Some units travel long distances in cargo boxes, and then take bouncy rides in your car to their final resting place on your living room wall. That"s a lot of opportunities for tiny mishaps to affect LCD uniformity.

Photo: A trick of the polarized light: rotate one pair of polarizing sunglasses past another and you can block out virtually all the light that normally passes through.

Photo: Prove to yourself that an LCD display uses polarized light. Simply put on a pair of polarizing sunglasses and rotate your head (or the display). You"ll see the display at its brightest at one angle and at its darkest at exactly 90 degrees to that angle.

Important technical improvements of LCD, such as LED backlighting and wide viewing Angle, are directly related to LCD. And account for an LCD display 80% of the cost of the LCD panel, enough to show that the LCD panel is the core part of the entire display, the quality of the LCD panel, can be said to directly determine the quality of an LCD display.

The production of civil LCD displays is just an assembly process. The LCD panel, the main control circuit, shell, and other parts of the main assembly, basically will not have too complex technical problems.

Does this mean that LCDS are low-tech products? In fact, it is not. The production and manufacturing process of the LCD panels is very complicated, requiring at least 300 process processes. The whole process needs to be carried out in a dust-free environment and with precise technology.

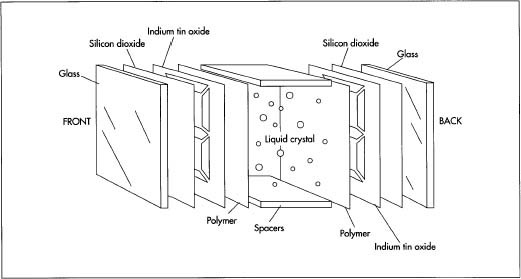

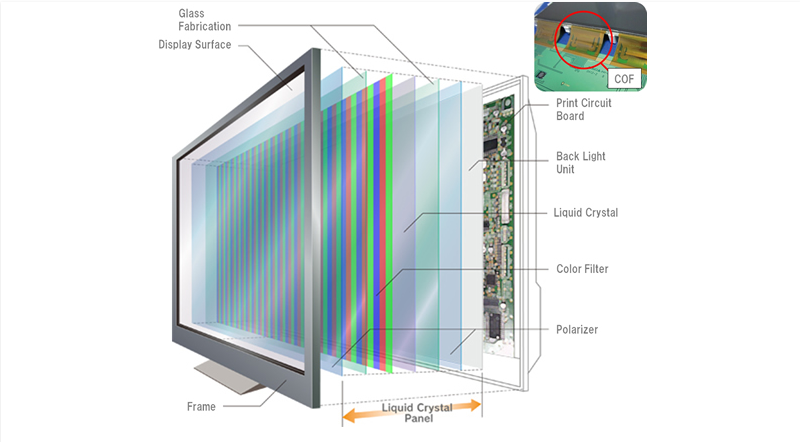

The general structure of the LCD panel is not very complex, now the structure of the LCD panel is divided into two parts: the LCD panel and the backlight system.

Due to the LCD does not shine, so you need to use another light source to illuminate, the function of the backlight system is to this, but currently used CCFL lamp or LED backlight, don’t have the characteristics of the surface light source, so you need to guide plate, spreadsheet components, such as linear or point sources of light evenly across the surface, in order to make the entire LCD panel on the differences of luminous intensity is the same, but it is very difficult, to achieve the ideal state can be to try to reduce brightness non-uniformity, the backlight system has a lot to the test of design and workmanship.

In addition, there is a driving IC and printed circuit board beside the LCD panel, which is mainly used to control the rotation of LCD molecules in the LCD panel and the transmission of display signals. The LCD plate is thin and translucent without electricity. It is roughly shaped like a sandwich, with an LCD sandwiched between a layer of TFT glass and a layer of colored filters.

LCD with light refraction properties of solid crystals, with fluid flow characteristics at the same time, under the drive of the electrode, can be arranged in a way that, in accordance with the master want to control the strength of the light through, and then on the color filter, through the red, green, blue three colors of each pixel toning, eventually get the full-screen image.

According to the functional division, the LCD panel can be divided into the LCD panel and the backlight system. However, to produce an LCD panel, it needs to go through three complicated processes, namely, the manufacturing process of the front segment Array,the manufacturing process of the middle segment Cell, and the assembly of the rear segment module. Today we will be here, for you in detail to introduce the production of the LCD panel manufacturing process.

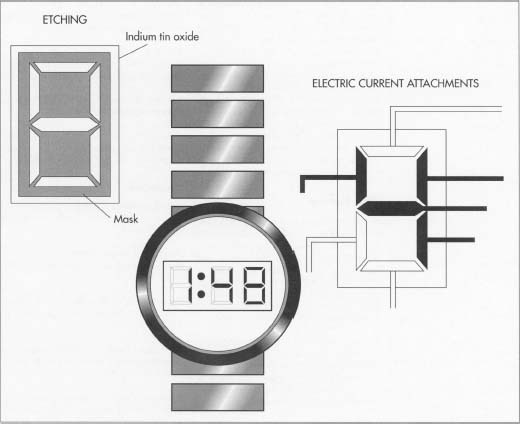

The manufacturing process of the LCD panel Array is mainly composed of four parts: film, yellow light, etch and peel film. If we just look at it in this way, many netizens do not understand the specific meaning of these four steps and why they do so.

First of all, the motion and arrangement of LCD molecules need electrons to drive them. Therefore, on the TFT glass, the carrier of LCD, there must be conductive parts to control the motion of LCD. In this case, we use ITO (Indium Tin Oxide) to do this.ITO is transparent and also acts as a thin-film conductive crystal so that it doesn’t block the backlight.

The different arrangement of LCD molecules and the rapid motion change can ensure that each pixel displays the corresponding color accurately and the image changes accurately and quickly, which requires the precision of LCD molecule control.ITO film needs special treatment, just like printing the circuit on the PCB board, drawing the conductive circuit on the whole LCD board.

Then etch off the ITO film without photoresist covering with appropriate acid etching solution, and only retain the ITO film under the photoresist. ITO glass is conductive glass (In2O3 and SnO2). The ITO film not covered by photoresist is easy to react with acid, while the ITO film covered by photoresist can be retained to obtain the corresponding wire electrode.

This completes the previous Array process. It is not difficult to see from the whole process that ITO film is deposited, photoresist coated, exposed, developed, and etched on TFT glass, and finally, ITO electrode pattern designed in the early stage is formed on TFT glass to control the movement of LCD molecules on the glass. The general steps of the whole production process are not complicated, but the technical details and precautions are very complicated, so we will not introduce them here. Interested friends can consult relevant materials by themselves.

The glass that the LCD board uses makes a craft also very exquisite. (The manufacturing process flow of the LCD display screen)At present, the world’s largest LCD panel glass, mainly by the United States Corning, Japan Asahi glass manufacturers, located in the upstream of the production of LCD panel, these manufacturers have mastered the glass production technology patents. A few months ago, the earthquake caused a corning glass furnace shutdown incident, which has caused a certain impact on the LCD panel industry, you can see its position in the industry.

As mentioned earlier, the LCD panel is structured like a sandwich, with an LCD sandwiched between the lower TFT glass and the upper color filter. The terminal Cell process in LCD panel manufacturing involves the TFT glass being glued to the top and bottom of a colored filter, but this is not a simple bonding process that requires a lot of technical detail.

As you can see from the figure above, the glass is divided into 6 pieces of the same size. In other words, the LCD made from this glass is finally cut into 6 pieces, and the size of each piece is the final size. When the glass is cast, the specifications and sizes of each glass have been designed in advance.

Directional friction:Flannelette material is used to rub the surface of the layer in a specific direction so that the LCD molecules can be arranged along the friction direction of the aligned layer in the future to ensure the consistency of the arrangement of LCD molecules. After the alignment friction, there will be some contaminants such as flannelette thread, which need to be washed away through a special cleaning process.

After the TFT glass substrate is cleaned, a sealant coating is applied to allow the TFT glass substrate to be bonded to the color filter and to prevent LCD outflow.

Finally, the conductive adhesive is applied to the frame in the bonding direction of the glass of the color filter to ensure that external electrons can flow into the LCD layer. Then, according to the bonding mark on the TFT glass substrate and the color filter, two pieces of glass are bonded together, and the bonding material is solidified at high temperatures to make the upper and lower glasses fit statically.

Color filters are very important components of LCD panels. Manufacturers of color filters, like glass substrate manufacturers, are upstream of LCD panel manufacturers. Their oversupply or undersupply can directly affect the production schedule of LCD panels and indirectly affect the end market.

As can be seen from the above figure, each LCD panel is left with two edges after cutting. What is it used for? You can find the answer in the later module process

Finally, a polarizer is placed on both sides of each LCD substrate, with the horizontal polarizer facing outwards and the vertical polarizer facing inwards.

When making LCD panel, must up and down each use one, and presents the alternating direction, when has the electric field and does not have the electric field, causes the light to produce the phase difference and to present the light and dark state, uses in the display subtitle or the pattern.

The rear Module manufacturing process is mainly the integration of the drive IC pressing of the LCD substrate and the printed circuit board. This part can transmit the display signal received from the main control circuit to the drive IC to drive the LCD molecules to rotate and display the image. In addition, the backlight part will be integrated with the LCD substrate at this stage, and the complete LCD panel is completed.

Firstly, the heteroconductive adhesive is pressed on the two edges, which allows external electrons to enter the LCD substrate layer and acts as a bridge for electronic transmission

Next is the drive IC press. The main function of the drive IC is to output the required voltage to each pixel and control the degree of torsion of the LCD molecules. The drive IC is divided into two types. The source drive IC located in the X-axis is responsible for the input of data. It is characterized by high frequency and has an image function. The gate drive IC located in the Y-axis is responsible for the degree and speed of torsion of LCD molecules, which directly affects the response time of the LCD display. However, there are already many LCD panels that only have driving IC in the X-axis direction, perhaps because the Y-axis drive IC function has been integrated and simplified.

The press of the flexible circuit board can transmit data signals and act as the bridge between the external printed circuit and LCD. It can be bent and thus becomes a flexible or flexible circuit board

The manufacturing process of the LCD substrate still has a lot of details and matters needing attention, for example, rinse with clean, dry, dry, dry, ultrasonic cleaning, exposure, development and so on and so on, all have very strict technical details and requirements, so as to produce qualified eyes panel, interested friends can consult relevant technical information by a search engine.

LCD (LC) is a kind of LCD, which has the properties of light transmission and refraction of solid Crystal, as well as the flow property of Liquid. It is because of this property that it will be applied to the display field.

However, LCD does not emit light autonomously, so the display equipment using LCD as the display medium needs to be equipped with another backlight system.

First, a backplate is needed as the carrier of the light source. The common light source for LCD display equipment is CCFL cold cathode backlight, but it has started to switch to an LED backlight, but either one needs a backplate as the carrier.

CCFL backlight has been with LCD for a long time. Compared with LED backlight, CCFL backlight has many defects. However, it has gradually evolved to save 50% of the lamp and enhance the transmittance of the LCD panel, so as to achieve the purpose of energy-saving.

With the rapid development of LED in the field of lighting, the cost has been greatly reduced.LCD panels have also started to use LED as the backlight on a large scale. Currently, in order to control costs, an LED backlight is placed on the side rather than on the backplate, which can reduce the number of LED grains.

At the top of the diffusion plate, there will be 3~4 diffuser pieces, constantly uniform light to the whole surface, improve the uniformity of light, which is directly related to the LCD panel display effect. Professional LCD in order to better control the brightness uniformity of the screen, panel procurement, the later backlight control circuit, will make great efforts to ensure the quality of the panel.

Since the LCD substrate and the backlight system are not fixed by bonding, a metal or rubber frame is needed to be added to the outer layer to fix the LCD substrate and the backlight system.

After the period of the Module, the process is completed in LCM (LCDModule) factory, the core of this part of the basic does not involve the use of LCD manufacturing technology, mainly is some assembly work, so some machine panel factories such as chi mei, Korea department such as Samsung panel factory, all set with LCM factories in mainland China, Duan Mo group after the LCD panel assembly, so that we can convenient mainland area each big monitor procurement contract with LCD TV manufacturers, can reduce the human in the whole manufacturing and transportation costs.

However, neither Taiwan nor Korea has any intention to set up factories in mainland China for the LCD panel front and middle manufacturing process involving core technologies. Therefore, there is still a long way to go for China to have its own LCD panel industry.

Liquid-crystal-display televisions (LCD TVs) are television sets that use liquid-crystal displays to produce images. They are, by far, the most widely produced and sold television display type. LCD TVs are thin and light, but have some disadvantages compared to other display types such as high power consumption, poorer contrast ratio, and inferior color gamut.

LCD TVs rose in popularity in the early years of the 21st century, surpassing sales of cathode ray tube televisions worldwide in 2007.plasma display panels and rear-projection television.

Passive matrix LCDs first became common as portable computer displays in the 1980s, competing for market share with plasma displays. The LCDs had very slow refresh rates that blurred the screen even with scrolling text, but their light weight and low cost were major benefits. Screens using reflective LCDs required no internal light source, making them particularly well suited to laptop computers. Refresh rates of early devices were too slow to be useful for television.

Portable televisions were a target application for LCDs. LCDs consumed far less battery power than even the miniature tubes used in portable televisions of the era. In 1980, Hattori Seiko"s R&D group began development on color LCD pocket televisions. In 1982, Seiko Epson released the first LCD television, the Epson TV Watch, a small wrist-worn active-matrix LCD television. Sharp Corporation introduced the dot matrix TN-LCD in 1983, and Casio introduced its TV-10 portable TV.Citizen Watch introduced the Citizen Pocket TV, a 2.7-inch color LCD TV, with the first commercial TFT LCD display.

Throughout this period, screen sizes over 30" were rare as these formats would start to appear blocky at normal seating distances when viewed on larger screens. LCD projection systems were generally limited to situations where the image had to be viewed by a larger audience. At the same time, plasma displays could easily offer the performance needed to make a high quality display, but suffered from low brightness and very high power consumption. Still, some experimentation with LCD televisions took place during this period. In 1988, Sharp introduced a 14-inch active-matrix full-color full-motion TFT-LCD. These were offered primarily as high-end items, and were not aimed at the general market. This led to Japan launching an LCD industry, which developed larger-size LCDs, including TFT computer monitors and LCD televisions. Epson developed the 3LCD projection technology in the 1980s, and licensed it for use in projectors in 1988. Epson"s VPJ-700, released in January 1989, was the world"s first compact, full-color LCD projector.

In 2006, LCD prices started to fall rapidly and their screen sizes increased, although plasma televisions maintained a slight edge in picture quality and a price advantage for sets at the critical 42" size and larger. By late 2006, several vendors were offering 42" LCDs, albeit at a premium price, encroaching upon plasma"s only stronghold. More decisively, LCDs offered higher resolutions and true 1080p support, while plasmas were stuck at 720p, which made up for the price difference.

Predictions that prices for LCDs would rapidly drop through 2007 led to a "wait and see" attitude in the market, and sales of all large-screen televisions stagnated while customers watched to see if this would happen.Christmas sales season.

When the sales figures for the 2007 Christmas season were finally tallied, analysts were surprised to find that not only had LCD outsold plasma, but CRTs as well, during the same period.Pioneer Electronics was ending production of the plasma screens was widely considered the tipping point in that technology"s history as well.

In spite of LCD"s dominance of the television field, other technologies continued to be developed to address its shortcomings. Whereas LCDs produce an image by selectively blocking a backlight, organic LED, microLED, field-emission display and surface-conduction electron-emitter display technologies all produce an illuminated image directly. In comparison to LCDs all of these technologies offer better viewing angles, much higher brightness and contrast ratio (as much as 5,000,000:1), and better color saturation and accuracy. They also use less power, and in theory they are less complex and less expensive to build.

Manufacturing these screens proved to be more difficult than originally thought, however. Sony abandoned their field-emission display project in March 2009,

If the picture responds to input but displays a messy image, such as jumbled multicolored squares, the AV (audio visual) board may be damaged. This is usually a rectangular circuit board located near the audio and visual cables. Replace obviously damaged parts using a soldering iron, or order a replacement board and carefully install it to the same screws and ribbon cables.

We can service the battery in your iPad or Apple Pencil for a service fee. Our warranty doesn’t cover batteries that wear down from normal use. We"ll test your iPad to see if it has a battery issue or a different power issue.

The current out-of-warranty battery service fee will apply until the end of February 2023. Effective March 1, 2023, the out-of-warranty battery service fee will be increased by $ 20 for the following iPad models: iPad Pro 12.9” (5th generation and prior), iPad Pro 11” (3rd generation and prior), iPad Pro 10.5”, iPad Pro 9.7”, iPad mini (6th generation and prior), and iPad Air (5th generation and prior).

The polarizer plate used in the display surface can be easily damaged. Do not touch, press, or rub the display panel with hard tools or objects such as tweezers.

The liquid inside the panel (liquid crystal) is a harmful substance. If the crystal panel becomes damaged do not ingest any of the liquid crystal which may leak out. If the liquid crystal makes contact with skin or clothing, wash with soap and rinse.

It is commonly held that a team at the RCA David Sarnoff Research Center in Princeton, NJ under the leadership of George H. Heilmeier did the initial development of liquid crystal displays (LCDs), in particular of the Dynamic Scattering Mode (DSM) LCD.

In 2002, a comprehensive history of LCDsSharp Corporation, a major competitor of Casio Computer Co., and some "survivorship bias" concerning persons and institutions still engaged in LCD work, had an influence on the sources used.

As the very first Member of Technical Staff doing work on LCDs at the Brown, Boveri Research Center in Baden, Switzerland, I have recently become personally motivated to give my account of less known events that took place while I was employed by BBC from 1969 to 1980. First, some personal background:

I was born and raised in St. Gallen, a town in German speaking East Switzerland. During high school we had to learn French and English. I was better at mathematics and physics. I never imagined that I would end up marrying a girl from South America and speak first French and then Spanish with her !

In 1959 I started my studies in electrical engineering at the Swiss Federal Institute of Technology in Zurich (ETH Zurich). There were only two tracks to choose from at that time: power electrical engineering and what was called Schwachstromtechnik, which translated means low-current technology. This was basically an electronics curriculum and my preference. Part of the program was a mandatory internship in industry of at least half a year through which I was to gain some practical experience. I fulfilled this requirement as well as military service during my vacations. That way I did not have to sacrifice an entire year in order to accomplish the internship and military service, which is still compulsory for all Swiss men up to this day. In hindsight, my thesis was very much at the forefront of ultrasound medical instrumentation. My thesis partner and I had to develop the circuitry for a device to measure the flow in blood vessels with pulsed ultrasonic waves. This work was done within the high-frequency electronics department of Fritz E. Borgnis. I graduated as Diplomingenieur at the end of 1963.

My mother had spent an entire year in California during the 1930s. These had been were very challenging times due to a long recession, and I remember her telling us a lot about her interesting experiences. Years later, she still maintained contact with friends in the US and, as a result, a family in Oregon became my sponsor to obtain a visa, when I moved to California looking for a job early in 1965. My poor English and limited experience made it difficult. I was subjected to all kinds of (for me) harrowing tests during interviews. I can recall specifically a written test that needed to be completed within a certain time limit with myself nervously watching the ticking clock. Also, my degree from the ETH Zurich (which ranks as the best university in continental Europe today) did not impress potential employers, as this excellent European university was hardly known in the US at that time.

Later that year, I joined Beckman Instruments in the East Bay across from San Francisco as a design engineer working on electronic measuring equipment. My choice had to do with the proximity of UC Berkeley (Cal), where I took extension classes in the evenings to improve my English and learn FORTRAN programming.

A new facility for its research center was opened in the Stanford Industrial Park at Hillview Avenue in Palo Alto. I moved to Palo Alto and drove across the Bay Bridge to attend classes at CAL. While I was studying at Berkeley from 1966 to 1968, political student activities on the campus were in full bloom, but these were for me not more than a sideshow. At Friden I conceived a potential electronic replacement for the magnetic wire memory in the desktop electronic calculator. Transistors were relatively expensive. Therefore, using flip-flops with two transistors to store bits was not an option. I proposed a type of dynamic shift register using basically one transistor and capacitor per stage in 1967. Unlike the concept of a Bucket Brigade for analog voltages as first published by Philips researchers in 1969 and later implemented as Charge-Coupled Devices, my circuit was intended to shift digital bit information in a serial memory. This is when I learned about the US custom of writing an invention report. It made me aware of the importance of patent notebooks and filings during my later work on LCDs (see section Patents).

Luckily, I could do my thesis at work choosing a topic of interest to both the company and my research adviser Martin Graham Oral History, Martin H. Graham. This was an exemplary cooperation between university and industry already at that time! The name of my final report was A Vector Generator for CRT Displays. I got the M.Sc. degree as a straight-A student, which gave me quite a feeling of satisfaction after my initial difficulties in the US. Now the doors were open. I got job offers from Bell Labs, Murray Hill, NJ, and the Singer Librascope Division in the Bay Area, but I decided to move back to Switzerland in 1968.

In May 1969 BBC entered a formal cooperation with Hoffmann-La Roche (Roche) entitled Medical Electronics, in which various common projects were studied, such as a new mobile intensive care unit. I was asked by F. K. von Willisen to look into display technologies as part of the BBC side of the cooperation. On December 11th 1969 I gave an overview of state-of-the-art display technologies including RCA"s work on LCDs at an internal BBC symposium. At the same venue Gerhard Meier of the Fraunhofer Institute in Freiburg, Germany, explained liquid crystals in detail. This institute already had a tradition of LC research. There was an exchange of staff and knowledge between this institute and a team at the Kent State University LC Institute, where Alfred Saupe and Juergen Nehring worked at the time.

In following with the conclusions of internal reports by both sides, LCDs were established as a common research project. I became the very first person at BBC to work full time on LCDs, while Roche assigned organic chemists and hired additional physicists. Roche concentrated on the synthesis of LC substances suitable for LCDs and the physics of electrooptical effects in LC structures. BBC developed the corresponding cell technology, explored applications and driving electronics. It was a truly interdisciplinary effort. I set up a small team with a young electrical engineer and a couple of technical assistants to develop a suitable cell technology. We used a pyrolytic process to deposit metaloxyd transparent electrodes on glass substrates. The disadvantage of this approach was that edging of electrode patterns was difficult. It was exiting to work with our first LCDs exhibiting the Dynamic Scattering Mode (DSM) discovered by RCA. A common project with ROCHE called for patient monitoring to indicate crucial measurements as part of new life support equipment, so we studied bar graph displays.

We found that we needed an array of several quasi-analog bar displays side-by-side, which led us to study simple matrix displays. We certainly were among the first to study the limitations of matrix-addressed LCDs, and I disclosed some of the results at conferences later-on. In an experimental unit we connected a discrete capacitor in parallel to each LC segment and decoupled the segment with a diode from the driving electronics when not selected.TFT) and a storage capacitor at each pixel.

Early on I did measurements of the electrooptic threshold voltage in LCDs. As a simple matrix LCD requires sequential addressing of rows (scanning, multiplexing) with a periodic refresh, pulsed voltages have to be applied to the segments/pixels. In 1972, I found by varying the pulse width that the threshold, measured as RMS voltage, remains nearly constant.

A major milestone was the discovery of the 90-degree Twisted Nematic field effect (TN cell) and its properties by Wolfgang Helfrich and Martin Schadt, physicists at Roche. The corresponding patent application was filed on December 4th, 1970 (see section Patents). When new LC substances were developed for TN LCDs by chemists at Roche, we demonstrated the good cooperation by publishing the result together.

I probably did the first public demonstration of a working Twisted Nematic LCD, at least in Europe, at the IEE Conference on Displays organized by the University of Loughborough, UK, in September 1971. It was a transparent, quasi-analog bar TN LCD that I put on an overhead projector to show it to the audience. By varying the voltage applied, the bar moved up and down. It aroused much interest, and a I received a question from a participant about small, noticeably inhomogeneous areas, which were later identified as domains of reverse twist.

Unfortunately the common projects with Roche came to an end as early as March 1972. Roche had bought Electro-Médicine Dassault, France, which maintained some activities that were directly competing with some of the work at BBC (not related to LCDs). Our management considered this as a breach of confidence. Thereafter Roche became a supplier of LC substances to BBC. I played a role in evaluating Roche mixtures for our displays.

Early on Georges Keller, head of the electronic components division of BBC, became interested in LCDs. He provided the support of his glass technology experts at the tube division. Since initially we used a Schiff-base LC mixture for our TN displays, we had to hermetically seal our cells with glass frit bonding along the edges at high temperatures to avoid humidity entering the cell. This prevented us from using the common technique of orienting the LC molecules by rubbing an organic layer (a surfactant) on the glass surface. We employed a vacuum-deposited layer of SiO instead, where the structure for orientation is defined by the evaporation angle. The electrodes were manufactured with a new vacuum deposition process optimized by Balzers Ltd. in the neighboring Principality of Liechtenstein.

Prototype displays were made for a joint-effort wristwatch project that we did together with Ebauches SA, the major Swiss watch movements manufacturer (now part of the Swatch Group) and Faselec, the Swiss IC subsidiary of Philips. A working quartz digital wristwatch was shown at the MUBA fair in March 1973. It contained chips made by Faselec and our 8-digit TN LCD.

Georges Keller asked me to provide the technology part for a business plan to industrially manufacture LCDs. The main customers envisioned were wristwatch manufacturers. A pilot line was set up at the BBC tube factory in Birrfeld during 1973. Top management approved the business plan and credit to construct a brand new plant in Lenzburg.

As far as I know, it was the first dedicated factory worldwide, built from scratch, measuring 39,000 square feet, exclusively to manufacture TN LCDs in volume. ILIXCO had a small-scale operation in the US (comparable to a pilot line), and Sharp of Japan started with DSM LCDs for their calculators about at the same time. BBC built an additional LCD factory of 47,000 square feet in 1978.

Nobody knew in 1973 whether the new LCDs would have a sufficient operating life expectancy. I was charged to set up and supervise accelerated tests at elevated temperatures and voltages to get some clues. As a result, we improved our cell technology. I left the research center and joined the new LCD division in the capacity of deputy head to develop applications and manage part of the activities such as custom design of new LCDs, contacts with LC substance suppliers, IC manufacturers, testing and patent matters.

During the following years a lot of effort was needed to automate manufacturing. Labor costs in Switzerland were (and still are) high. The process chosen initially was not well suited for larger substrates and low-cost manufacturing. BBC was not any more willing to finance expansion in an area not important to its basic business. Therefore, a 50/50 joint venture was set up with Philips of The Netherlands at the beginning of 1980, called Videlec AG. Philips had a strong interest in display technologies for their consumer products, in particular the potential use of LCDs in TV sets.

In addition to our Swiss wristwatch customers and Timex Corp. in the US, Casio Computer Co. became an important client in 1974. It is worthwhile to recall how this relationship evolved. I do not know how the initial contacts were established. BBC had a small subsidiary in Japan already. However, dealing with an important client in this new high-tech field meant that help was needed. In Japan, there are network organizations, where companies from different industries collaborate. These powerful associations are called Keiretsu. Many Keiretsu include at least one major bank and a major trading company.Oki Electric Industry, the Fuyo Keiretsu got involved. I recall a meeting in Zurich with a representative of Marubeni, the corresponding trading company, and a visit of a top manager of the Yasuda group at the BBC Research Center.

The Japanese officer of Oki Electric from Germany, who was with us on that day, took a bow nearly to the ground when he greeted this influential man from the center of his Keiretsu. OKI Electric was interesting for us as a partner because they had a CMOS fab in Japan and were in line to become an LSI supplier for Casio wristwatches. Casio planned to diversify into quartz watches, where similar components were needed as in electronic pocket calculators. After many discussions and the evaluation of our LCD samples, we were chosen to be the LCD supplier for the new wristwatches. On one occasion we had the honor of being invited for dinner at a typically Japanese restaurant in Tokyo by Mr. Kashio, one of the founding brothers. In 1974 our new factory for TN LCDs became operational. The Casiotron digital wristwatch with some interesting new features was released with our custom made LCD in October 1974. Not everything went smoothly. We encountered yield and delivery problems which required several trips to Tokyo to see Casio people.

Due to price pressure and the fact that customers were mainly in Asia, BBC started an LCD assembly line in Hongkong. I had to travel to HK to instruct local employees, first for final testing, then for doing custom designs.

We probably were among the first to develop backlit TN LCDs. Since LCDs do not emit light themselves, they need ambient light or a dedicated light source for viewing. Wristwatches in particular cannot be read in the dark without some form of illumination. Therefore, at our laboratory we developed a suitable backlighting scheme, taking into account the limited space available in a wristwatch with a digital liquid crystal display. Our patented solution included a thin plastic diffuser plate behind the LCD with a miniature incandescent light bulb at its side.edge-lit in present-day flatscreen LCD television sets using LEDs as light sources.

The major difference is that the backlight is continuously on during the operation of an LCD TV set, whereas in wristwatches the backlight is only used while pushing a button in order to save battery power. When enough ambient light is available, the display is used in its reflective mode. This combination is called a transflective display.

A different solution was developed for panel-mounted meters that were proposed by BBC for power and industrial control centers. Reflective TN LCDs were conceived as bargraph replacements for conventional electromechanical meters, but were difficult to read under low ambient light, as they are mounted vertically. Therefore, we used a cold-cathode fluorescent lamp (CCFL) and a diffuser to backlight our bargraph display as shown on the right-hand side of the picture. This was much easier to read than the purely reflective type on the left.

Switzerland. The Swiss authorities only examined strictly new developments in the watch and textile machine sectors. Otherwise patents were granted rather freely, but could be challenged later-on at a trial. When RCA defended their patent application with a broad claim for digital electronic wristwatches containing a battery, quartz crystal, frequency divider and LCD, I was asked by the Bulova Watch Co. to testify against this claim. We showed that, based on the disclosed information, it was not possible to make a wristwatch with an adequate temperature range on the priority date. Therefore the patent was not granted in Switzerland.

Germany. The German patent authority had rules requiring publication of a patent application in the submitted form within 18 months as Offenlegungsschrift (laid open to public inspection). Many foreign applications were also filed in Germany within one year of filing in another country. This provided a good window to see what others were doing. After the examination by a German patent examiner, a revised Auslegeschrift, including claims allowed by the examiner, was published. Opponents could intervene within 3 months by introducing additional prior art or other facts until a definite patent (Patentschrift) was granted or rejected.

USA. In the US, the examination process was not public and the duration unpredictable until a patent was granted and published. In addition, priority could be established before the filing date, if relevant patent notebook entries or other evidence was presented by the inventor. This opportunity did not exist in Europe. A famous case was the invention of the twisted nematic, field effect LCD. Roche filed this patent application on December 4th, 1970 in Switzerland establishing thereby a priority. James Fergason followed more than four months later filing a similar patent application in the US on April 22nd, 1971. However, Fergason presented patent notebook entries, witnessed by colleagues, predating the priority date of Roche. In my opinion this gave unfair advantage to US filers.

For Roche as well as BBC (which after the merger with ASEA from Sweden in 1987 changed their name to ABB) royalty income from their LCD patents became a substantial source of income.

Working at the forefront of a new technology is exciting. I could attend many conferences, learned to make presentations and was invited to lecture on topics relating to my work on LCDs. Early recognition was evident in that I received invitations to make presentations at UC Berkeley, at the IEEE EUROCON conference and organize a panel discussion at the École Polytechnique de l"Université de Lausanne (EPUL) in 1972. During several years I gave a lecture at the Technische Akademie Esslingen near Stuttgart, Germany. As the only Swiss among many German lecturers, it was gratifying to get good ratings by participants from industry.

I left BBC in 1980 to work in the field of telecommunications. In 1983 my former colleagues from the BBC Research Center invented the Super-Twisted Nematic LCD (STN-LCD), which made it possible to have passive-matrix flat-panel displays with many pixels and reasonably high resolution for the first time.Game Boy, cellular phones, viewfinders of cameras, etc. I like to believe that this invention was a successful follow-up of our earlier focus on improving matrix addressing of LCDs. The corresponding patent brought in millions from licenses. Shortly thereafter Videlec in Lenzburg ceased operations, and the LC staff at the BBC Research Center was reduced to a skeleton.

P. J. Wild, P. U. Schulthess: "Liquid Crystal Bar Graph Displays," Conference on Displays, IEE Conference Publication no. 80, pp. 161-164, Sept. 1971.

Patent US4096550: "Illuminating Arrangement for a Field-effect Liquid-crystal Display as well as Fabrication and Application of the Illuminating Arrangement," filed Oct. 15, 1976, published June 20, 1978, inventors: W. Boller, M. Donati, J. Fingerle, P. Wild.

Tech observers and investors revel in lively discussions about the latest, greatest gadget and whose bottom line will get the greatest bounce. They enjoy debating the intricacies and details of materials that contribute to these devices, and the related trends and developments. For us at Corning, materials innovators for 165 years, it’s been great to see a recent uptick in discussions about OLED versus LCD display panel technology - a genuine #GlassAge debate.

Corning.com staff sat down with Mike Kunigonis, business director for Corning’s High Performance Displays Group, to understand key differences between OLED and LCD display technology.

Corning.com: Thanks for your time today, Mike. Let’s start with a key question: In the context of display panels, how does OLED technology work and what are the main differences between it and LCD technology?

MK: OLED stands for Organic Light-Emitting Diode, or Organic LED. It’s an alternative to LCDs for consumer electronic devices that range in size from wearable to TVs. Like LCD, OLED is a type of panel that enables the displays on device screens. An OLED display picture is generated by turning on and off millions of tiny individual LEDs, each forming the individual pixels of a display. Compare this to LCD, where an always-on backlight projects light through a liquid crystal, sandwiched between two pieces of glass. When the liquid crystal is excited by an electrical current, it lets the light of an individual pixel pass through like a shutter. LCD and OLED display panels both excel at delivering vibrant consumer displays, each in its own unique way.

Corning.com: We’ve heard industry analysts with varying opinions on the benefits an OLED device offers. So why would a consumer prefer a device with an OLED display over an LCD display?

MK: Adoption of OLED displays on smaller, mobile devices is the driver behind most of today’s OLED industry growth, so let me focus on that. A handheld OLED display is attractive to consumers because of the industrial design and display attributes that this technology can support. For example, OLED displays can be curved, or be thinner, or have narrower bezels – or no bezels at all – or flex and bend. Plus, an OLED display will be a great solution for virtual reality applications because it can provide high resolution and superior response time and latency.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey