define tft display quotation

The liquid crystal display (LCD) technology has been used in several electronic products over the years. There are more reasons for LCDs to be more endearing than CRTs.

A thin-film-transistor liquid-crystal display (TFT LCD) is a variant of a liquid-crystal display that uses thin-film-transistor technologyactive matrix LCD, in contrast to passive matrix LCDs or simple, direct-driven (i.e. with segments directly connected to electronics outside the LCD) LCDs with a few segments.

In February 1957, John Wallmark of RCA filed a patent for a thin film MOSFET. Paul K. Weimer, also of RCA implemented Wallmark"s ideas and developed the thin-film transistor (TFT) in 1962, a type of MOSFET distinct from the standard bulk MOSFET. It was made with thin films of cadmium selenide and cadmium sulfide. The idea of a TFT-based liquid-crystal display (LCD) was conceived by Bernard Lechner of RCA Laboratories in 1968. In 1971, Lechner, F. J. Marlowe, E. O. Nester and J. Tults demonstrated a 2-by-18 matrix display driven by a hybrid circuit using the dynamic scattering mode of LCDs.T. Peter Brody, J. A. Asars and G. D. Dixon at Westinghouse Research Laboratories developed a CdSe (cadmium selenide) TFT, which they used to demonstrate the first CdSe thin-film-transistor liquid-crystal display (TFT LCD).active-matrix liquid-crystal display (AM LCD) using CdSe TFTs in 1974, and then Brody coined the term "active matrix" in 1975.high-resolution and high-quality electronic visual display devices use TFT-based active matrix displays.

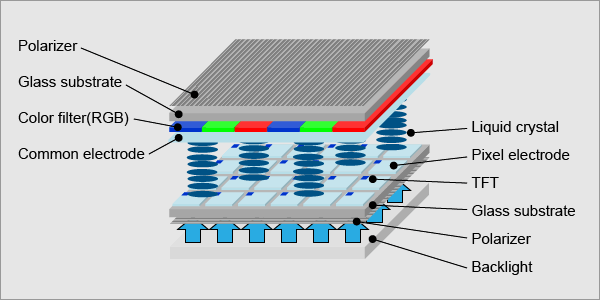

The liquid crystal displays used in calculators and other devices with similarly simple displays have direct-driven image elements, and therefore a voltage can be easily applied across just one segment of these types of displays without interfering with the other segments. This would be impractical for a large display, because it would have a large number of (color) picture elements (pixels), and thus it would require millions of connections, both top and bottom for each one of the three colors (red, green and blue) of every pixel. To avoid this issue, the pixels are addressed in rows and columns, reducing the connection count from millions down to thousands. The column and row wires attach to transistor switches, one for each pixel. The one-way current passing characteristic of the transistor prevents the charge that is being applied to each pixel from being drained between refreshes to a display"s image. Each pixel is a small capacitor with a layer of insulating liquid crystal sandwiched between transparent conductive ITO layers.

The circuit layout process of a TFT-LCD is very similar to that of semiconductor products. However, rather than fabricating the transistors from silicon, that is formed into a crystalline silicon wafer, they are made from a thin film of amorphous silicon that is deposited on a glass panel. The silicon layer for TFT-LCDs is typically deposited using the PECVD process.

Polycrystalline silicon is sometimes used in displays requiring higher TFT performance. Examples include small high-resolution displays such as those found in projectors or viewfinders. Amorphous silicon-based TFTs are by far the most common, due to their lower production cost, whereas polycrystalline silicon TFTs are more costly and much more difficult to produce.

The twisted nematic display is one of the oldest and frequently cheapest kind of LCD display technologies available. TN displays benefit from fast pixel response times and less smearing than other LCD display technology, but suffer from poor color reproduction and limited viewing angles, especially in the vertical direction. Colors will shift, potentially to the point of completely inverting, when viewed at an angle that is not perpendicular to the display. Modern, high end consumer products have developed methods to overcome the technology"s shortcomings, such as RTC (Response Time Compensation / Overdrive) technologies. Modern TN displays can look significantly better than older TN displays from decades earlier, but overall TN has inferior viewing angles and poor color in comparison to other technology.

Most TN panels can represent colors using only six bits per RGB channel, or 18 bit in total, and are unable to display the 16.7 million color shades (24-bit truecolor) that are available using 24-bit color. Instead, these panels display interpolated 24-bit color using a dithering method that combines adjacent pixels to simulate the desired shade. They can also use a form of temporal dithering called Frame Rate Control (FRC), which cycles between different shades with each new frame to simulate an intermediate shade. Such 18 bit panels with dithering are sometimes advertised as having "16.2 million colors". These color simulation methods are noticeable to many people and highly bothersome to some.gamut (often referred to as a percentage of the NTSC 1953 color gamut) are also due to backlighting technology. It is not uncommon for older displays to range from 10% to 26% of the NTSC color gamut, whereas other kind of displays, utilizing more complicated CCFL or LED phosphor formulations or RGB LED backlights, may extend past 100% of the NTSC color gamut, a difference quite perceivable by the human eye.

In 2004, Hydis Technologies Co., Ltd licensed its AFFS patent to Japan"s Hitachi Displays. Hitachi is using AFFS to manufacture high end panels in their product line. In 2006, Hydis also licensed its AFFS to Sanyo Epson Imaging Devices Corporation.

A technology developed by Samsung is Super PLS, which bears similarities to IPS panels, has wider viewing angles, better image quality, increased brightness, and lower production costs. PLS technology debuted in the PC display market with the release of the Samsung S27A850 and S24A850 monitors in September 2011.

TFT dual-transistor pixel or cell technology is a reflective-display technology for use in very-low-power-consumption applications such as electronic shelf labels (ESL), digital watches, or metering. DTP involves adding a secondary transistor gate in the single TFT cell to maintain the display of a pixel during a period of 1s without loss of image or without degrading the TFT transistors over time. By slowing the refresh rate of the standard frequency from 60 Hz to 1 Hz, DTP claims to increase the power efficiency by multiple orders of magnitude.

Due to the very high cost of building TFT factories, there are few major OEM panel vendors for large display panels. The glass panel suppliers are as follows:

External consumer display devices like a TFT LCD feature one or more analog VGA, DVI, HDMI, or DisplayPort interface, with many featuring a selection of these interfaces. Inside external display devices there is a controller board that will convert the video signal using color mapping and image scaling usually employing the discrete cosine transform (DCT) in order to convert any video source like CVBS, VGA, DVI, HDMI, etc. into digital RGB at the native resolution of the display panel. In a laptop the graphics chip will directly produce a signal suitable for connection to the built-in TFT display. A control mechanism for the backlight is usually included on the same controller board.

The low level interface of STN, DSTN, or TFT display panels use either single ended TTL 5 V signal for older displays or TTL 3.3 V for slightly newer displays that transmits the pixel clock, horizontal sync, vertical sync, digital red, digital green, digital blue in parallel. Some models (for example the AT070TN92) also feature input/display enable, horizontal scan direction and vertical scan direction signals.

New and large (>15") TFT displays often use LVDS signaling that transmits the same contents as the parallel interface (Hsync, Vsync, RGB) but will put control and RGB bits into a number of serial transmission lines synchronized to a clock whose rate is equal to the pixel rate. LVDS transmits seven bits per clock per data line, with six bits being data and one bit used to signal if the other six bits need to be inverted in order to maintain DC balance. Low-cost TFT displays often have three data lines and therefore only directly support 18 bits per pixel. Upscale displays have four or five data lines to support 24 bits per pixel (truecolor) or 30 bits per pixel respectively. Panel manufacturers are slowly replacing LVDS with Internal DisplayPort and Embedded DisplayPort, which allow sixfold reduction of the number of differential pairs.

The bare display panel will only accept a digital video signal at the resolution determined by the panel pixel matrix designed at manufacture. Some screen panels will ignore the LSB bits of the color information to present a consistent interface (8 bit -> 6 bit/color x3).

With analogue signals like VGA, the display controller also needs to perform a high speed analog to digital conversion. With digital input signals like DVI or HDMI some simple reordering of the bits is needed before feeding it to the rescaler if the input resolution doesn"t match the display panel resolution.

Kawamoto, H. (2012). "The Inventors of TFT Active-Matrix LCD Receive the 2011 IEEE Nishizawa Medal". Journal of Display Technology. 8 (1): 3–4. Bibcode:2012JDisT...8....3K. doi:10.1109/JDT.2011.2177740. ISSN 1551-319X.

Brody, T. Peter; Asars, J. A.; Dixon, G. D. (November 1973). "A 6 × 6 inch 20 lines-per-inch liquid-crystal display panel". 20 (11): 995–1001. Bibcode:1973ITED...20..995B. doi:10.1109/T-ED.1973.17780. ISSN 0018-9383.

K. H. Lee; H. Y. Kim; K. H. Park; S. J. Jang; I. C. Park & J. Y. Lee (June 2006). "A Novel Outdoor Readability of Portable TFT-LCD with AFFS Technology". SID Symposium Digest of Technical Papers. AIP. 37 (1): 1079–82. doi:10.1889/1.2433159. S2CID 129569963.

Kim, Sae-Bom; Kim, Woong-Ki; Chounlamany, Vanseng; Seo, Jaehwan; Yoo, Jisu; Jo, Hun-Je; Jung, Jinho (15 August 2012). "Identification of multi-level toxicity of liquid crystal display wastewater toward Daphnia magna and Moina macrocopa". Journal of Hazardous Materials. Seoul, Korea; Laos, Lao. 227–228: 327–333. doi:10.1016/j.jhazmat.2012.05.059. PMID 22677053.

A TFT is a type of transistor used in active-matrix LCD screens. TFT LCD screens use a separate transistor to control each pixel in the display. They allow the electrical current that controls each pixel to turn on and off quickly, which decreases response time and makes on-screen motion smoother. TFT LCDs are often used as computer monitors, televisions, mobile phone screens, and other flat-panel color displays.

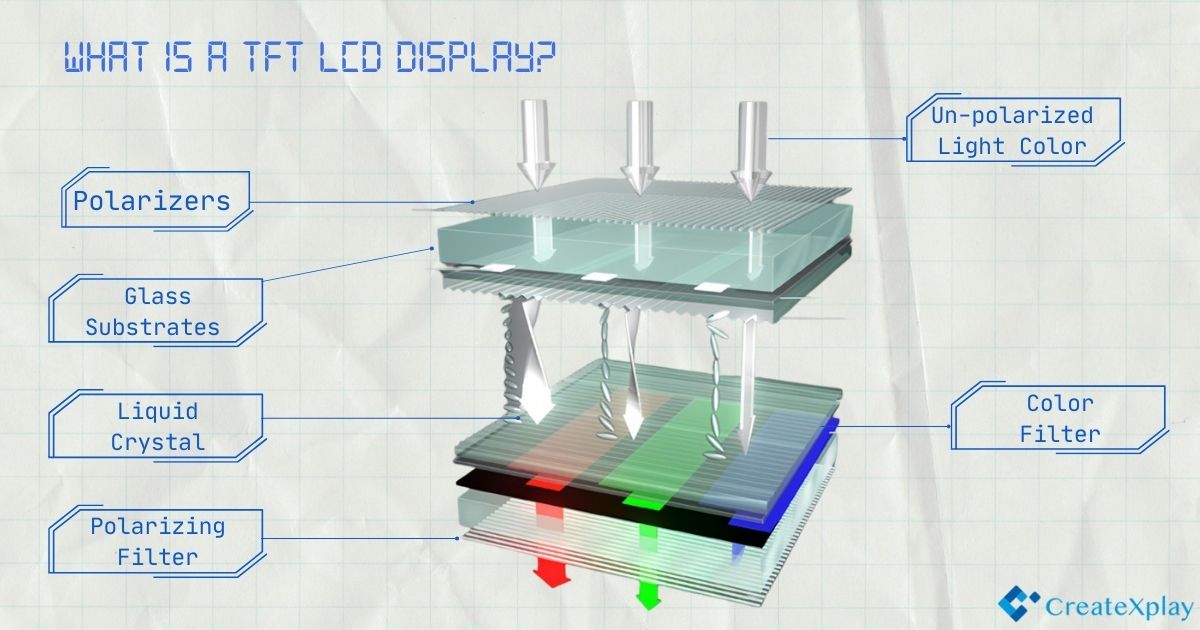

The name "Thin Film Transistor" is derived from the manufacturing process. The manufacturer first applies thin films of a semiconductor (like amorphous silicon) and dielectric materials to a flat, non-conductive surface (like glass). Unneeded silicon is etched away, leaving only a grid of transistors and the transparent glass surface. These transistor panels are thin enough to fit between a polarized backlight and the layer of liquid crystals. These transistors apply an electrical current to the liquid crystals, altering their arrangement to block light in certain ways. The light then passes through other layers of the screen, including a color filter and polarized light filter, to display the final image.

Not all TFT LCD screens are made the same. There are several types of TFT panels, made by distinct methods, and with different performance characteristics. The two most common types are TN and IPS.

Twisted Nematic (TN) panels contain liquid crystals that twist as an electric current is applied. As the crystals twist, they allow varying amounts of polarized light to pass through. TN panels are the easiest type of TFT LCD to produce and offer the quickest response times. However, TN panels don"t display colors as accurately as other types of panels, particularly when viewed at an angle.

TFT Liquid crystal display products are diversified, convenient and versatile, simple to keep up, upgrade, update, long service life, and have many alternative characteristics.

The display range covers the appliance range of all displays from one to forty inches and, therefore, the giant projection plane could be a large display terminal.

Display quality from the most straightforward monochrome character graphics to high resolution, high colour fidelity, high brightness, high contrast, the high response speed of various specifications of the video display models.

In particular, the emergence of TFT LCD electronic books and periodicals will bring humans into the era of paperless offices and paperless printing, triggering a revolution in the civilized way of human learning, dissemination, and recording.

It can be generally used in the temperature range from -20℃ to +50℃, and the temperature-hardened TFT LCD can operate at low temperatures up to -80 ℃. It can be used as a mobile terminal display or desktop terminal display and can be used as a large screen projection TV, which is a full-size video display terminal with excellent performance.

The manufacturing technology has a high degree of automation and sound characteristics of large-scale industrial production. TFT LCD industry technology is mature, with a more than 90% mass production rate.

From the beginning of flat glass plates, its display effect is flat right angles, letting a person have a refreshing feeling. LCDs are simple to achieve high resolution on small screens.

Leadtek has paid great efforts on research and development of TFT-LCM, especially on its application of consumable and industrial products. The sizes of LCM includes 1.4”, 2.4”, 3.5", 3.51", 4.3", 4", 5", 7", 8", 10.1” and 11.6". And among them the 3.5”, 4.3", 5", 7” and 10.1" LCM has achieved the leading level of the industry, and mainly applied to vehicle-applications, tablet PCs, smartphones, medical equipment, measurement equipment, E-books, EPC and industrial products, and provides powerful and reliable supports on supplies and qualities. We are cooperating with famous foreign companies on research and developments, and will bring out the series products of industrial control. Also, we explore the overseas market, and build up a long-term relationship with our overseas partners and agents, Leadtek products will be worldwide in the near future.

TFT displays have become increasingly common in our daily lives. They are used in cars, laptops, tablets, and smartphones, as well as in industrial applications and many more. But what are TFT displays and why are they so important?

A TFT (Thin Film Transistor) display is a type of display technology that uses a thin layer of transparent material to produce an image on the screen. The display is made up of thin layers of organic material called organic transistors, which are stacked together on a glass substrate and covered with a thin layer of plastic or metal oxide.

TFT displays are also used in many other industrial applications, such as industrial control systems, medical devices, automotive infotainment systems, and more.

The basic concept behind a TFT display is simple: it uses light to create an image on a screen. Light passes through the glass substrate and the organic transistors until it reaches the top layer of the display.

The number of pixels that can be displayed depends on how many organic transistors are used in each pixel or subpixel (a single-pixel is made up of multiple subpixels). For example, a 4-inch (10 cm) display has a pixel pitch of 0.0625 inches (1.57 mm).

The basic design of a TFT display has remained unchanged for more than 20 years. In this design, the sub-pixels are arranged in a grid pattern, with each subpixel connected to its neighbor by wires that form rows and columns.

The first large format TFT display was introduced in 1987 by NEC Corporation, which used a 1024×768 pixel screen for its PC monitor line, called CRT Professional Display System or “Videotronic” system. The technology was licensed to NEC’s competitors such as Hitachi and Toshiba for use in their own monitors and televisions. The system was marketed as “Super Video” and replaced the aging “Videotron” CRT monitors that were still being used at the time. The first LCD TV was also produced in 1987 by Sony.

In 1989, Sharp’s first TFT-LCD TV set was introduced with a resolution of 576×320 pixels, while the world’s first large format high definition screen with a resolution of 1024×768 pixels was introduced by NEC in 1994.

Over the years, TFT display technology has developed by leaps and bounds. It has been used in tablets, smartphones, notebooks, game consoles, and computer monitors. The technology is also used in digital cameras, camcorders, MP3 players, and GPS devices.

What does the TFT display technology comprise? From far, you can easily assume TFT to be a single unit. But in reality, it comprises different components that work together.

The backlight of the TFT display is a very important component. It provides the light for the pixels and is also responsible for illuminating the display. The light emitted by a backlight can be controlled by varying the amount of current running through it.

When it comes to LCD displays, there are two types of backlights; Active matrix and Passive matrix. Active matrix backlight has several layers of electrodes, which are used to control the amount of current flowing through them.

The pixel is the smallest unit in a TFT display. It is the basic unit of information that is displayed on the screen. The pixel consists of three sub-elements, namely; Red, Green, and Blue (RGB).

The number of sub-pixels that are used in each pixel varies with different display technologies. In full-color LCDs, there are three types of sub-pixel: red, green, and blue (RGB). Full color TFT displays use a combination of Red, Green, and Blue (RGB) sub-pixels to represent full color.

The light that is transmitted through each TFT is controlled by applying voltages of different values to each pixel in turn. To do this, a control circuit called a driver circuit is required. The driver circuit controls the voltage applied to each pixel with reference to a set of parameters known as “pixel information”.

This information includes color, brightness, and other characteristics that define how an individual pixel should be operated for display purposes. The parameters also include how many red, green and blue sub-pixels are used to produce each pixel.

The control system can be further divided into 3 sub-systems: the interface, the timing, and the data transfer system (DTS). These systems work together to provide all of the necessary functions for controlling TFT displays from external sources such as computers, printers, or TVs.

This is another component of a TFT display system. It consists of a liquid crystal material sandwiched between two glass plates. This material is responsible for controlling the light by changing its refractive index.

-Wide viewing angle: The viewing angle of the TFT display is larger than that of the CRT set. It is generally considered to be the best choice for applications requiring an extended viewing angle.

-Transparency: TFT display has better transparency than CRT set, which makes it more suitable for applications requiring high transparency such as window displays and computer monitors.

-High resolution: TFT display can produce higher resolution than CRT display. For example, the pixel density of TFT is about 3 million pixels per square inch (PPI), which is about three times that of conventional liquid crystal displays (LCDs) whose pixel density is about 100 ppi.

-Reliability: Since it uses no moving parts, the TFT screen does not need any maintenance or repair, and therefore the reliability is higher than that of LCDs and plasma displays.

-Power saving: TFT display consumes much less power than CRT. The power consumption of a mainstream TFT display is about 1/10 that of a typical LCD. In some applications, the power consumption can be reduced to 1/100 or less of that of a CRT.

-High brightness: The picture displayed on the screen can be bright enough to be seen in bright sunlight without any need for glare reduction filters.

-Compatibility: Since it uses no moving parts, the TFT screen does not have any mechanical problems such as screen flicker and image sticking problems found in plasma displays and LCDs.

-High resolution: Although the pixel density of TFT is about 3 million pixels per square inch (ppi), the resolution is more than 100 ppi which makes it more suitable for many applications where high resolution is needed.

-Consistency: Since it uses no moving parts, the image displayed on the TFT display is not affected by temperature and humidity, which makes it more consistent than LCDs and plasma displays.

-Cost: The cost of a TFT display is lower than that of LCDs and plasma displays. For example, in some applications where image quality is not critical, the cost of a TFT display may be only a few tens to a few hundreds of dollars while the cost of LCDs or plasma displays may be several thousand to several tens of thousands.

-Excellent color display: We can’t deny the fact that TFTs have a superior color display. This simply means that the color of pixels can be accurately reproduced.

-Very thin: When compared with LCDs and plasma displays, which are very thick, TFTs are very thin and lightweight. In addition, the cost of mounting a large size TFT screen to a wall panel is relatively low.

-No ghosting: ‘Ghosting’ refers to the fact that the display shows a bright spot on the screen when the screen is turned off. TFT screens do not show ghosting. TFTs produce a sharp image even when they are turned off.

-No geometric distortion: Geometric distortion refers to the shape of the display on a flat surface. TFTs produce a sharp image even when they are turned off.

-No radiation: TFTs do not emit any harmful radiation, and there is no need for shielding or shielding materials to protect people from harmful radiation.

Considering that TFTs use less power, it is possible to reduce energy consumption by up to 50% compared with LCDs. In addition, if you use LED backlights in TFT displays, you can reduce power consumption by up to 75% compared with conventional backlights.

If a product uses a backlight, there is a high possibility that the color of the screen will be affected after some time due to dust or dirt that comes into contact with it. But it is possible to prevent this problem by using TFTs with LED backlights, which have no problems such as those caused by dust and dirt.

Workability refers to the ease with which you can operate a product. When working with a screen that has TFTs, it is possible to increase the amount of information that can be displayed at one time. It is also possible to reduce the number of times you must change settings on a product by increasing its usability.

Design refers to what you can create with the use of a product. Using TFTs, it is possible to create products that have a thin profile and are lightweight, which makes them more convenient for transportation and storage.

Human interface refers to what you touch when using a product or what you see on the screen when using a product (e.g., buttons and other controls). By integrating the TFTs into the display part of a product, it is possible to make the human interface easier.

Amoled refers to a technology that replaces the traditional liquid crystal display (LCD) with an organic light-emitting diode (OLED). Modern TFTs are similar to Amoled in terms of their structure, but they differ from Amoled in terms of their performance.

The TFTs of the present invention have superior characteristics compared to Amoled, such as high contrast ratio and response speed. The TFTs also have superior characteristics compared to conventional display devices such as CRT and plasma display panels, which cannot be achieved by these conventional display devices.

IPS refers to a technology that replaces the traditional liquid crystal display (LCD) with in-plane switching technology. The IPS display has superior features to TFT due to its high contrast ratio, wide viewing angle, and high response speed.

There are certain limitations to TFTs. For example, there is a limit to the size of the display and the resolution of the image that can be displayed on a display. Also, because TFTs are considered to be a kind of organic semiconductor displays, they have a short life span and therefore need frequent replacement.

Because of their high resolution, TFT displays are used in display monitors. The type of TFT used in display monitors can be categorized as either active matrix or passive matrix. Active matrix TFTs use a thin film transistor (TFT) as its active component, whereas passive matrix uses a liquid crystal display (LCD).

TFTs are also being used in portable electronic devices such as mobile phones, personal digital assistants (PDAs), and cameras. These devices require high-resolution screens because the user must be able to view accurate images and text on the screen. TFTs are also being used in laptops, which have a much larger screen size than many other portable electronic devices.

Because of their size and high resolution, laptop computers use passive matrix TFT displays instead of LCDs for larger displays than those found on smaller-sized portable electronics devices that use LCDs for their displays (e.g., mobile phones and PDAs).

TFT displays are used in front-projection TVs. The type of TFT used in front-projection TVs can be categorized as either active matrix or passive matrix. Active matrix TFTs use a thin film transistor (TFT) as its active component, whereas passive matrix uses a liquid crystal display (LCD).

Head-mounted displays (HMDs) use liquid crystal on silicon technology to create small, inexpensive, low-power VR headsets that can be worn on the head. Some HMDs use active matrix TFT technology while others use passive matrix TFT technology. Active matrix HMDs use shorting bars or glass electrodes to control each pixel; passive matrix HMDs use a liquid crystal material that allows for the creation of an image by controlling the voltage applied to each pixel.

TFTs are used in projectors to create the on-screen image from the input signal. TFTs are used in both active matrix and passive matrix projectors. Active matrix projectors use shorting bars or glass electrodes to control each pixel, while passive matrix projectors use a liquid crystal material that allows for the creation of an image by controlling the voltage applied to each pixel.

CCDs are used in digital cameras and DV camcorders to capture still images and video, respectively. CCDs use a single array of photosites that each receives an electrical charge during exposure to light, resulting in an electrical signal that is output as an image. TFTs are used in CCDs as display circuits for previewing pictures.

TFTs are used in the display of gaming systems such as consoles, personal computers, and hand-held devices. TFTs are also used in the display of mobile telephones and in digital signs.

There are many factors to consider when buying a TFT display. The most important factors are the size of the display, the resolution of the display, and whether or not it is touch-sensitive.

It is also vital to consider where you are buying your TFT display system. A good place to buy a TFT display is from an authorized dealer or an online store. You should also consider whether or not the TFT display system you are looking for has a warranty.

At ICRFQ, we can connect you to the best TFT display suppliers and manufacturers in China. Just contact us and we will do what a reliable sourcing agent should do!

Display technology has moved forward at light speed. For years, even sophisticated equipment made do with numeric and alphanumeric display technology, buttons, and LEDs.

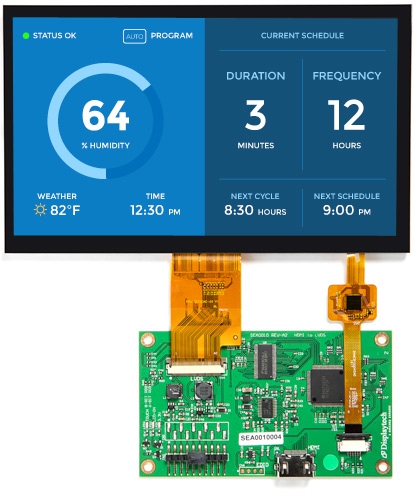

With mass production, manufacturing refinements, and competition, thin film transistor (TFT) displays have drastically dropped in price while dramatically improving in performance. They are the de facto standard to the point where it is not only expected, it is demanded that any modern user interface be full color, brightly backlit, touch sensitive, and have high video speeds and a good viewing angle.

While simple low-cost 8-bit microcontrollers could easily handle the multiplexed 7- and 14-segment LED and alphanumeric LCD displays, the memory, processor speeds, and peripheral resources needed to drive a TFT are more than most modest microcontrollers can handle. As a result, dedicated controller chips, embedded modules, or faster, denser, and more streamlined processor architectures are needed.

This article looks at the factors that make a good MCU-to-TFT interface. This includes memory depths and architectures, paging, data transfer, signaling levels, interfaces, and on-chip peripherals to look for when selecting a microcontroller for a TFT application. It examines the TFT technology and present day product offerings, which your designs will need to drive. It also looks at some microcontrollers that provide native support for color TFT displays, looking at their techniques, features, trade-offs, and limitations. All displays, microcontrollers, drivers, inverters, and development tools mentioned in this article are available from Digi-Key Corporation.

TFT displays are a type of liquid crystal display in which the transistor controlling the pixel’s crystal is etched into a layer of amorphous silicon deposited on the glass (see Figure 1). As in an IC process, very small transistors are geometrically formed. The small size of the transistor means it will not significantly attenuate the light passing through.

The advantage of TFTs is that they are fast enough for video, provide a large and smooth color palette, and are pixel addressable through an electronic two-dimensional control matrix (see Figure 2). Most low-cost displays use an amorphous silicon crystal layer deposited onto the glass through a plasma-enhanced chemical vapor deposition.

Figure 2: Electronically, a stable VCOM reference is used throughout the display, and the gamma corrected drive voltage passes through each transistor.

Many versions of TFT technologies have led us to the modern displays. Early complaints like poor viewing angles, poor contrast, and poor backlighting have been addressed. Better light sources, diffusers, and polarizers make many displays very vivid, some even claiming to be daylight readable. Modern day techniques like in-plane switching improve viewing angles by making the crystals move in a parallel direction to the display plane instead of vertically. Better speeds and contrasts of modern display make them high performance for a fairly low cost.

Since TFTs are not emissive devices, they require backlighting. The most commonly deployed backlight technology is cold cathode florescent lighting (CCFL). These devices were designed, chosen, and used because they are very efficient and have very long lives. Typically, a CCFL bulb is rated as having in the ball park of a 50,000 hour ‘half-life. ’ This means that after 50,000 hours, it still works, but with half the intensity when it was new.

Modern displays, especially the smaller ones, have transitioned to white LED-based backlights. These are easier to manufacture, do not require the high voltage inverter which CCFL bulbs need, and are approaching a lower cost point compared to CCFL technology. Both CCFL and LED technologies will use diffuser layers inside the stackup to evenly distribute light. LED-based backlights may actually be side lights and use a lightpipe structure to distribute the light.

Transflective technology is steadily improving and is available in some TFT displays. This is where both a backlight and ambient external light are used to make the display visible. Sunlight may make it viewable, but generally speaking the transflective displays are less transmissive. This means that the backlight will have to be brighter (and require more power) to be on par with a purely transmissive display that requires a backlight all the time.

With TFT and most color display technologies, an individual pixel contains a red, a green, and a blue picture element (pel). The relative intensity of each color will determine the resulting blended color.

Some displays will use dithering and alternating pixel colors to achieve a better blend of intermediate colors. Higher frame rates are also used since the persistence effect of phosphor-based displays does not carry over to LCDs. Determine the quality and smoothness of the display you will use. Not every frame rate control technique yields flicker- and jitter-free performance, especially at some resolutions. If you notice it, so will your customers and end users of your design.

The memory required to map the display image is key. While some micros will contain enough memory to hold a single page of display data (and not much else), you can see that a lot of memory is required for even a modest ¼ VGA display. This is more than what a typical microcontroller can house (see Table 1). As a result, an external bus interface to external RAM (SRAM, DRAM, or SDRAM) will be needed, especially if paging will be used.

Table 1: The memory required to map to a display is proportional to three times the square of the resolution because of the three color elements of each pixel.

Paging will allow better display quality since one page can be displayed while the next is being built in the background, then made live. This eliminates ghosting and image flicker when graphics are changing rapidly in effects like scrolling, moving sprites (graphical objects), color shade blending (for overlapping graphics as they move), etc.

A key feature when selecting a microcontroller for TFT interfacing is the DMA support. Multi-channel, flexible DMA will make a world of difference, especially when it comes to moving data between pages, character generator and rendering tables, animations and video. Along these lines, a preprogrammed and autonomous DMA functionality will allow you to refresh a display while the core microcontroller goes to sleep. This is a key power-reducing feature that can make a world of difference when operating from batteries.

One effective solution is to use the National Semiconductor LMH6640MF/NOPB which is a rail-to-rail (up to 16 volts), voltage feedback, high output (up to 100 ma) amplifier optimized for TFT transistor driving. The fast 170 V/µS slew rate yields a 28 MHz full power bandwidth (at five volts) and its small SOT-23 package can be fit into tight spaces (see Figure 3).

Also , the VCOM function and all its subtleties are often times integrated into more encompassing TFT driver chips like Texas Instruments’ LM8207MT/NOPB which combines an 18 channel gamma corrected driver with VCOM referencing buffer (see Figure 4). Note that the built-in VCOM buffer will allow a buffer tree to be created from a single reference for larger displays.

One approach to driving a TFT display without the need for a higher end processor is to use a discrete TFT controller chip that can be interfaced to a processor of lesser horsepower. An example is the Intersil TW8811-LD2-GR TFT controller chip (see Figure 5).

Aimed at a specific market segment, in this case automotive applications, the TW8811 combines control and even video standard (analog, RGB, S-Video, NTSC, PAL, and Secam) integration into a single chip controller. It supports and ties together different video sources to allow the same display to be used for navigation systems, engine displays, environmental control, in-car entertainment systems, backup cameras, etc.

The on-chip SDRAM interface provides the depth and cost-effective performance needed for displays up to WXGA resolutions, and the –40 to +85 degree temperature range makes this usable for a variety of harsh environment applications.

If a single microcontroller can control the task at hand as well as the embedded display, this is usually the most cost-effective solution. Most people will use a TFT module which already houses the VCOM, gamma correction, and TFT transistor drivers. As a result, the interface to the module is TTL, CMOS, or Low Voltage Differential Signaling (LVDS).

Thankfully, to help make TFT design tasks doable in a reasonable amount of time, the chip makers provide solutions targeted at display designs. Typically, these are higher-end, 32-bit, RISC-type processor architectures with streamlined peripherals and resources that handle both display-oriented and non-display-oriented functions such as communications, sensor interfacing, etc.

Devices like this need development environments and evaluation units and NXP is right there. The DK-57VTS-LPC2478 is a programmer’s development system that includes a 5.7 inch TFT with touch interface as well (see Figure 6). Note the 2M x 32 SDRAM for page buffering and graphic manipulations. NXP also offers the DK-57TS-LPC2478 which aims at sensor-based applications.

NXP Semiconductors is not alone by any means. Renesas Electronics America also provides processors with built-in support for TFTs. Take for example the DF2378RVFQ34V, an H8-based processor with advanced block transfer functionality built into the DMA. Like the NXP parts, it incorporates a slew of peripherals, Flash, memory interfaces, and I/O.

Not every processor needs to have a dedicated TFT interface to make it a viable candidate. For example, the TI TMS470R1B1MPGEA is a RISC-based 60 MHz ARM7 processor that can easily interface to a slew of TFT modules that are driven via a digital interface. While some modules need constant refreshing, others can be loaded with display data and generate all the timing and display data movement internally unburdening the host CPU. The CPU must be fast enough to keep up with any animations or video if this is the case.

Many displays are readily available as test vehicles. Many of these can be directly driven with the processors mentioned here. Many other processors can also be used, like offerings from Atmel (AT91SAM9261B-CU) and STMicroelectronics (STM32F107VBT6).

No matter how many data sheets you read, what it boils down to is this: a display is a visual device. What will ultimately make the decision is how it looks when you display your screens on it.

apron means a defined area, intended to accommodate aircraft for purposes of loading or unloading passengers, mail or cargo, fuelling, parking or maintenance;

IPS (In-Plane Switching) lcd is still a type of TFT LCD, IPS TFT is also called SFT LCD (supper fine tft ),different to regular tft in TN (Twisted Nematic) mode, theIPS LCD liquid crystal elements inside the tft lcd cell, they are arrayed in plane inside the lcd cell when power off, so the light can not transmit it via theIPS lcdwhen power off, When power on, the liquid crystal elements inside the IPS tft would switch in a small angle, then the light would go through the IPS lcd display, then the display on since light go through the IPS display, the switching angle is related to the input power, the switch angle is related to the input power value of IPS LCD, the more switch angle, the more light would transmit the IPS LCD, we call it negative display mode.

The regular tft lcd, it is a-si TN (Twisted Nematic) tft lcd, its liquid crystal elements are arrayed in vertical type, the light could transmit the regularTFT LCDwhen power off. When power on, the liquid crystal twist in some angle, then it block the light transmit the tft lcd, then make the display elements display on by this way, the liquid crystal twist angle is also related to the input power, the more twist angle, the more light would be blocked by the tft lcd, it is tft lcd working mode.

A TFT lcd display is vivid and colorful than a common monochrome lcd display. TFT refreshes more quickly response than a monochrome LCD display and shows motion more smoothly. TFT displays use more electricity in driving than monochrome LCD screens, so they not only cost more in the first place, but they are also more expensive to drive tft lcd screen.The two most common types of TFT LCDs are IPS and TN displays.

A thin-film transistor liquid crystal display (TFT LCD) is a type of liquid crystal display (LCD) that makes use of thin-film transistor technology in order to improve qualities such as contrast and addressability. TFT technology means that an individual transistor is used to drive each individual pixel, allowing for faster response times.

Thin-film transistor liquid crystal display technology uses "field-effect" transistors, which are built by layering thin films on a glass substrate, hence the name. This technique is commonly used for creating microprocessors. The TFT in the LCD controls individual pixels in the display by setting the level of the electric field across the three liquid crystal capacitors (one for each sub-pixel of red, green and blue) in the pixel in order to control the polarization of the crystal material. The amount of polarization in the crystal determines the amount of light that reaches the color filter from the backlight. Because of this ability to directly and quickly control each pixel, TFT is also called active-matrix LCD technology.

Phoenix Display International specializes in creating custom LCD displays for clients in a variety of business sectors. Our expert engineering team has extensive experience in creating custom displays based on your project’s final application, and will handpick and customize an LCD display module to fit the exact specifications of your project or product. In the process, we’re often able to create efficiencies and offer superior customer service that other LCD Screen manufacturers simply cannot, or will not, provide.

The process of designing your custom LCD display solution begins at our company headquarters, located in Phoenix, Arizona. Our team of engineers starts by taking a deep dive into your project, getting to know the product inside and out, learning the specifics, parameters, and end-use application. Based on this knowledge, we’re able to define or design the ideal LCD display, whether it is a character LCD display, a graphic LCD, a color LCD screen, or a completely custom LCD display solution.

From there, our team will design a custom electrical and mechanical interface for your LCD display, engineering in any extras your project may need, including controllers, converters, or touch-sensitive screens.

To learn more about our custom LCD displays and custom TFT displays, or to get a 24-hour quote for your project, contact Phoenix Display International today.

The DT022BTFT uses the same connections as the DT022CTFT, with the exception of the backlight (which has connections shown in the Displaytech datasheet).

The provided display driver example code is designed to work with Microchip, however it is generic enough to work with other micro-controllers. The code includes display reset sequence, initialization and example PutPixel() function. Keep the default values for all registers in the ILI9341, unless changed by the example code provided.

Note that the WR pin becomes the D/CX signal in serial mode. CS is used to initiate a data transfer by pulling it low. At the end of the data transfer, pull the CS pin high to complete the transaction. The timing diagram indicates that you can pull the CS pin high in between the command byte and data bytes within a transfer, but it is unlikely needed if the display is the only device on the SPI bus. To keep things simple, we suggest to leave it low during the entire transaction.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey