4x4 lcd display free sample

You can use this royalty-free vector image "Green lcd display 4x4 settings gauge" for personal and commercial purposes according to the Standard or Extended License. The Standard License covers most use cases, including advertising, UI designs, and product packaging, and allows up to 500,000 print copies. The Extended License permits all use cases under the Standard License with unlimited print rights and allows you to use the downloaded vector files for merchandise, product resale, or free distribution.

The main difference between those two modules, is their pinouts, the LCD Backpack pinout is made to fit on an LCD with additional outputs for the backlight.

Since both the I2C port Expander and the I2C LCD Backpack are pretty much the same, couldn’t I just use the LCD Backpack to connect the Bourns encoder?

But if your project can make due with only 7 I/O pins then you can use the LCD Backpack as an I2C Expander since those other pins are properly connected.

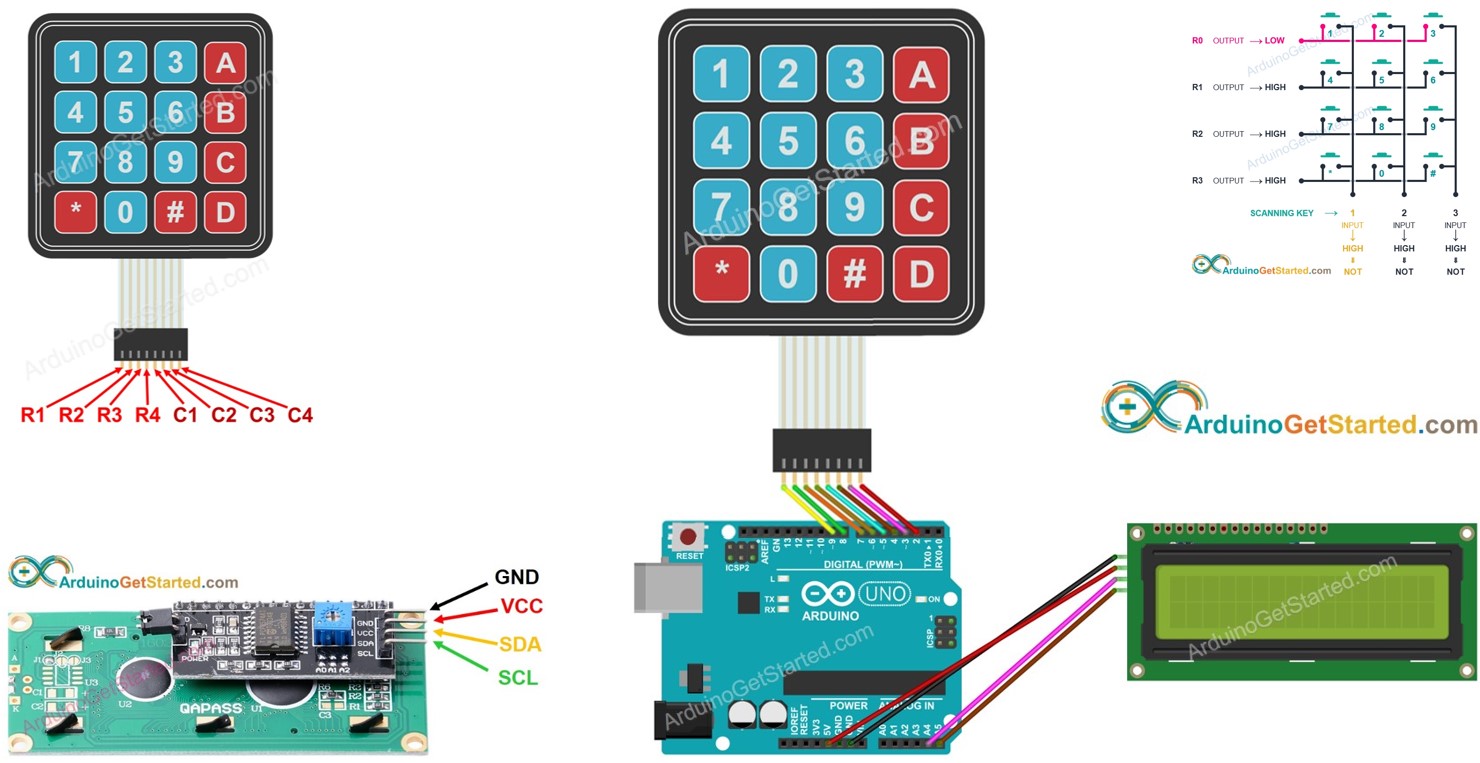

So instead of using 7 Pins on the Arduino, were’s using the I2C protocol and using only 2 Pins to read the Keypad as well as display the results on the LCD screen.

The main difference between those two modules, is their pinouts, the LCD Backpack pinout is made to fit on an LCD with additional outputs for the backlight.

Since both the I2C port Expander and the I2C LCD Backpack are pretty much the same, couldn’t I just use the LCD Backpack to connect the Bourns encoder?

But if your project can make due with only 7 I/O pins then you can use the LCD Backpack as an I2C Expander since those other pins are properly connected.

So instead of using 7 Pins on the Arduino, were’s using the I2C protocol and using only 2 Pins to read the Keypad as well as display the results on the LCD screen.

We have specific tutorials about keypad and LCD. Each tutorial contains detailed information and step-by-step instructions about hardware pinout, working principle, wiring connection to ESP32, ESP32 code... Learn more about them at the following links:

But it certainly is a viable choice, and we have used it before in the article about using LCD displays. The LCD display shield has a group of push buttons wired up in this exact fashion.

Load the sketch and open your serial monitor, making sure to observe the baud rate (it should be 9600 baud). Now press some keys on the keypad. You should observe the key values displayed on the serial monitor.

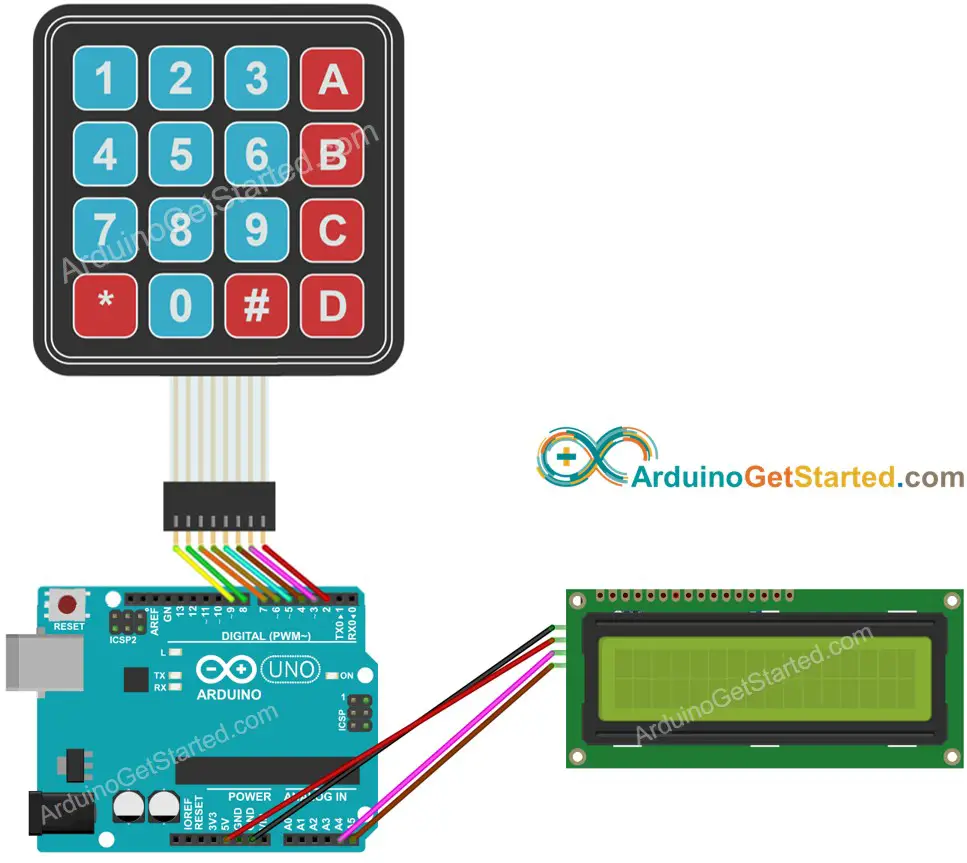

Our next experiment is just an extension of the first one. This time we will use an LCD display instead of the serial monitor to read keypress values.

To reduce the number of connections required we will be using an LCD display with an I2C backpack. This makes the hookup extremely simple, as illustrated below:

One difference, of course, is that we are including both the Wire Library for I2C and the new LiquidCrystal_I2C library that we just installed. Both of these libraries are required to use the LCD display with the I2C backpack.

In line 39 we create an object to represent our LCD display. The first parameter in the object is “0x3F”, which is the hexadecimal I2C address of the display. If you are using a display that has a different I2C address you will need to modify this parameter accordingly.

The Loop is almost identical to the previous sketch. Once again we get the value of the keypress and hold it in a character variable. Then we clear the LCD display and print the character to the display. It will remain on the display until the next key is pressed.

We start the Loop by placing the LCD cursor in the top left corner and printing “Enter Password:”. Then we look for a keypress, as we did in the previous sketches.

Once we have enough characters we compare theDataarray to theMasterarray. If the arrays are identical then we have the correct password and we activate the relay for 5 seconds. If it is incorrect we print “Incorrect” on the display and hold it there for a second.

You may have used an electronic device with a small Liquid Crystal Display (LCD) which has a textual hierarchical menu system for setting device configuration parameters. If you have tried writing menu code for your Arduino projects, you will recognise the challenge in developing a generic menu system for an open prototyping platform. This is because there are many input and display devices available, and a generic menu system must be independent of whichever input and display devices you wish to use. With our Arduino menu library, this independence is achieved by having the menu manager code use callback methods for handling user input and rendering the menu display.

To keep things simple, all coding examples have been targeted to work with an R3 Arduino Uno/Leonardo/Mega2560, and an LCD keypad shield similar to one illustrated above. There are numerous manufacturers of LCD keypad shields that have the same or similar pin connections, and you must ensure that the sample menu code uses the pin connections that are right for your shield. If the keypad buttons of your shield give different analog readings, you’ll need to make changes to file LcdKeypad.h. Bear in mind that the analog readings are not always consistent, which can lead to the occasional misreporting of a button press. Once you become familiar with the menu library, adapting it for use with other input and display devices should be straight-forward.

You can use the downloaded sample Arduino project as a starting point for your own coding requirements. You will need to write your own code in the body of method processMenuCommand(byte cmdId) to determine what must be done when a menu item is selected. The cmdId parameter is the Id you associate with a menu item in your menu Xml file. Callback method getNavAction() handles user input, and callback method refreshMenuDisplay(byte refreshMode) renders the menu. To work with other input and display devices you’ll need to re-write the code in these methods. Some LCD keypad shields are not suited for hardware PWM backlight control, and as such the coding example uses a soft PWM alternative.

The Select button on the LCD shield starts/stops a timer, with a long press resetting the timer. A long press of Up enters the menu. Up/Down/Right buttons are for navigating the menu, and Select for choosing a menu item. When an item is selected, Up/Down are used for changing values. When the Reset menu item is displayed, a long press of Select loads default configuration values. Digital pin 2 is used for activating a beeper for the alarm. Examining the source should give you good insight for using the menu system in your own projects. If you find this Arduino menu library guide useful, please share it.

The LCD module interface with a microcontroller is simple and it is a primitive means of adding a visual appeal to your embedded application. There are two basic types of LCD modules in the market they are, Character LCD and Graphics LCD. Character LCDs are the some of the cheapest means LCD displays available today.

This post is first of a series of four posts that walks through entire process of interfacing an LCD module with a (any) microcontroller with all the basic concepts dealt in detail. Subscribe to our posts and get free updates on these follow-up posts.LCD Module Basic Theory (LCD Controllers, CG&DD RAM, PIN description,Timing Diagram, Commands)

This post will cover the basic theory that you should have a clear understanding of, before getting started with the programming. Some of the sections below are not really essential for the interface but it is a good practice to have a thorough knowledge about what you are indulging in. Whereas some listed below are absolutely mandatory to understand how the LCD module works and to predict how it will behave for a given situation.

The LCD module has display controller that are used to receive the data from the controller and uses it to display the data in a legible format. These controllers have an embedded font set that can be addressed by sending the corresponding ASCII value of the the character to be printed.

Most LCD modules have a HD44780 or compatible controller which is specially designed to build LCDs with one or two lines with a maximum of 40 character positions each. They are ASIC (Application Specific Integrated Circuit). A single HD44780 is able to display two lines of 8 characters each.

This the most common configuration of LCD that most people prefer mostly due to reduced cost and small footprint. In a 16 x 2 line display LCD module, each the two lines have 40 character positions of which only 16 can be displayed at a time. The remaining positions are invisible and cannot be seen. To display the remaining 24 characters, the LCD has an option to move the window of characters displayed to the right or left so that; it appears as though the characters are scrolling. Here is a table of the DD RAM addresses that are within the visible data region. Note that in this module, DD RAM locations 10 to 27 on the first line and 51 to 67 are not covered by the displayable window of 16A character per line.Line/Col0123456789101112131415One000102030405060708090A0B0C0D0E0F

The 20 x 4 display module is a slight variant of the 16 x 2 Module such that, a single 40 character (of which 16 are displayable) line is split up into 2 halves of 20 displayable characters each to make 4 lines. Here the first line displays the first 20 DD RAM locations (00 - 13) and the third line displays the remaining 20 DD RAM locations (14 - 53) of the first line in the case of 16 x 2 LCD Module and the second line displays the first 20 DD RAM locations (40 - 53) and the fourth line displays the remaining 20 DD RAM locations (54 - 67) of the second line in the case of 16 x 2 LCD Module. This is the module that I am using in this post. It has the disadvantage of not being able to scroll but looks better with 4 displayable lines.Here is a table of the DD RAM addresses that are within the visible region.#000102030405060708090A0B0C0D0E0F101112131000102030405060708090A0B0C0D0E0F10111213

7DB0LCD Data Bus line. They are responsible for the parallel data transfer. DB7 is used to check the busy Flag.In 4 bit mode, DB0 to DB3 are not used and are left open.

There are two registers in an LCD, they are Instruction register and the Data register. The register select (RS) pin is used to select either of the two the registers. When held low, the Instruction register is selected and similarly, when it is high, the data register is selected. A write to the data register will write to the Display Data RAM (DD RAM) in the address last pointed by the address pointer. The address pointer is automatically incremented after each write operation.

In the 20 x 4 LCD Module, all the locations of the DD Ram are mapped on to a character position in the display. Hence a write to the data register with proper ASCII code will produce proper displayable character in the screen. You can find a good ASCII table here. Some of the values in the ASCII table are not printable and hence are not mapped on to any character. A write to the DD Ram with one such data will display some glyph that you cannot recognize.

The LCD datasheet comes with a lot of electrical and Mechanical specifications. Though they are not redundant, for now we will consider only the command sheet and the timing diagram without which it is impossible to interface the module.

The command sheet is a table which contains the various commands that can be issued to the LCD module so that it behaves as intended. I have not attached an image of the command sheet as I could not find any of a good readable resolution. So I created a HTML version of the command sheet that you could use at any resolution dYtm, You can find the Command Sheet here (or I should call it command page). The cells that are filled with absolute values have to be used as such and the ones that are having letters are variables and take either 0 or 1 based on the task it has to perform.

Here, D4 to D7 are 0, D3 is 1 and RS and R/W are held low. These are all constant values and hence have to be used as such. But the, bits D0 to D2 are all variables. Depending on the values return at positions B, C and D the following action are performed by the LCD controller,

According to this description, the value has to be written to the command register. That is if you want, display ON, cursor ON and the character at the cursor to be static, you have to write, 0x0E while holding the RS and RW lines Low.

As you know these LCDs have a built in font set and can be used by indexing the ASCII value of the corresponding character. It capable of operating on 8 data lines (D0 to D7) or on 4 data lines (D4 to D7). The upcoming posts will discuss the 8 bit and 4 bit mode of LCD interface. Other than the data lines the LCD needs 3 command lines - RS, R/W and EN. Therefore in total, an LCD interface will need 11 (8+3) or 7 (4+3) pins of the microcontroller.

It is possible to further reduce the total number of port pins required from 7 (4+3) to 6 (4+2) by shorting the R/W pin to ground. If the R/W pin is connected to the ground, the LCD can be used to write data only. Reading from it is not possible. So we are not able to read the busy flag from the module. To live with this disability, we are forced to provide ample amount of delay loops (and hence compromise on the speed of execution) so that the LCD is seldom busy doing thing when new data is given.

Introducing our custom 4x4 4K Video Wall package including 16ea 49” 1080P (4k /w Multi-Screen) Ultra Thin 1.75mm Bezel per side / 3.5mm total, Video Wall Displays & 1ea 4x4 4k Video Wall Controller, and 1ea 4x4 Aluminum Mounting bracket, allowing you to create an eye catching large scale 196" (diagonally) 4K display for your video content that is sure to grab the attention of any viewer.

These 4x4 4k Video Wall Systems are an ideal solution for environments that require an effective large scale medium for displaying your digital signage / video content such as Casinos, Sports Bars, Super Markets, Shopping Malls, Air Ports, Churches, Data Control Centre, Conference Rooms, and Education and Training.

Introducing Brightlink’s New 49” 1080P Video Wall Display with Ultra-narrow 1.75mm bezel / frame (3.5mm total with multiple displays) allowing seamless viewing when using in a multiple screen Video Wall set up.

These Video Wall Displays are designed to seamlessly fit together in configurations from 1x2, to 2x2, 2x3, 3x3, 4x4 and up, giving you a large scale, attention grabbing, medium to show your digital signage content.

When putting these 1080p displays together in a 2x2 configuration or up, you are able to display 4k (3840x2160p) content to give you an ultra sharp image. The 4k content gets divided over the 2x2 and up displays.

To distribute your 1080p or 4k source over your multi-screen configuration such as 2x2, 2x3, 3x3, 4x4, etc…, you can use one of our various Video Wall Controllers to easily achieve this by plugging your one HD source into the input and connecting each of your HD displays to the HDMI outputs via HDMI cables.

Introducing Brightlink’s New 4x4 4K Ultra UHD 3840x2160@60HZ HDMI 2.0 multi screen Video Wall Controller with 1x HDMI 2.0 in, 1x HDMI 1.4 in, & 1 x DP inputs.

The main function of this 4K Video Wall Controller is to display a 3840*2160 Ultra HD 4K image spread across 9 Displays in the default configuration of 4x4 to create a gigantic eye catching Video Wall that is sure to catch the attention of anyone who sees it.

This 4K Video Wall Controller is ideal for environments where superior performance and crisp clear high resolutions are required to display your video content / digital signage over many displays in large format.

Common application includes exhibition halls, trade shows, map display system, GPS positioning system, oil monitoring, satellite positioning, conference rooms, Education and tanning, Casinos, hotels, and many other environments where large format multi-screen displays are required while at the same time having a clear detailed image in order to show your content and information easily to any viewer at various distances.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey