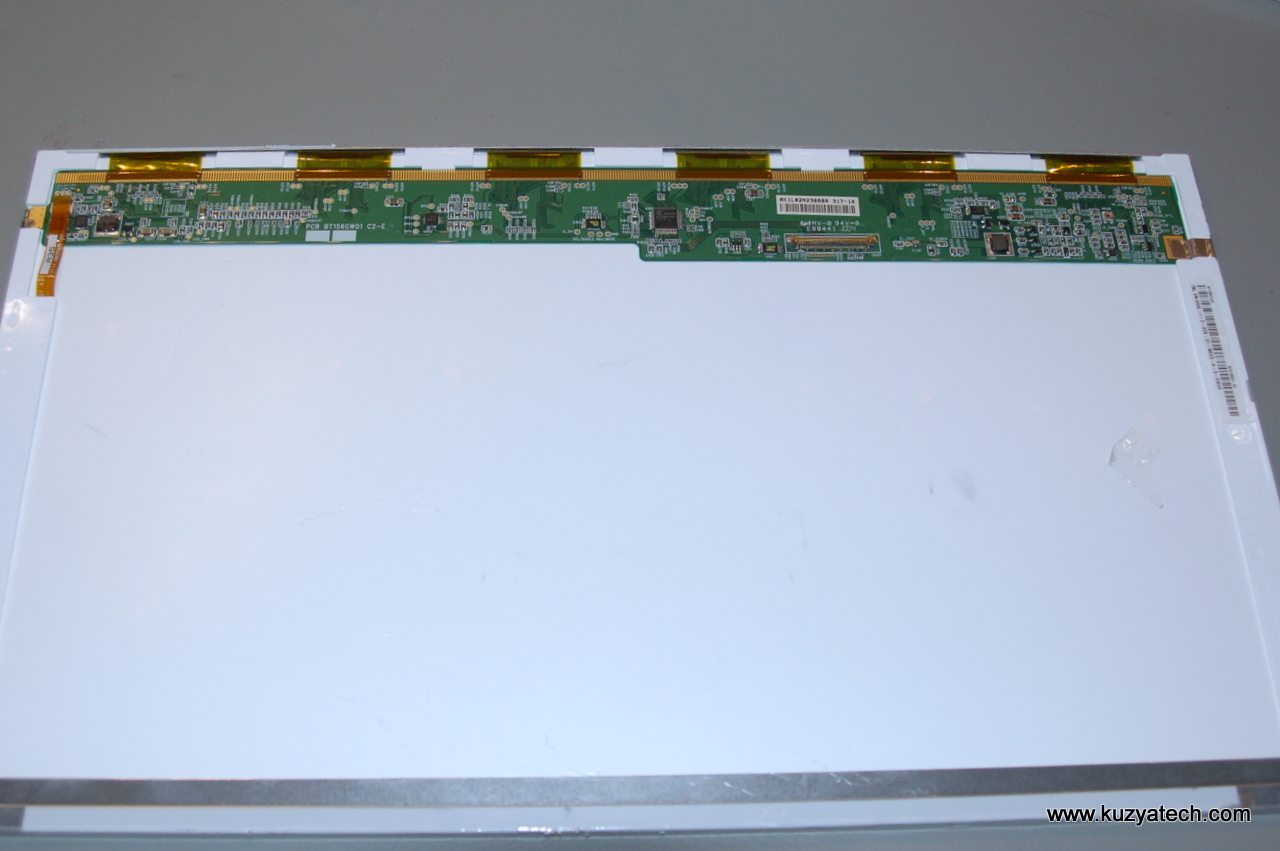

tft display teardown price

Over the years, LCD modules and LCD displays have grown in popularity. Companies in many different industries, including but not limited to the medical, automotive, consumer, food services, industrial, and technology sectors rely on at least one TFT LCD module or TFT LCD display on a daily basis. Although touchscreens are very durable and designed to withstand the hands of time, older modules and displays sometimes need to be repaired. When weighing the cost of having your displays repaired, you should take the time to consider your options.

After doing some research on the cost of repairs, many business owners find that it makes more sense to have their TFT LCDs replaced. Although units may cost less to repair initially, the cost of having to repair your older displays over and over again can add up. This is because older units may need to be repaired more than once. Even if multiple repairs will not cost any additional money, repairs lead to downtime and can have a tremendous impact on your business.

Older units in need of repair can have a long-term impact on a company’s bottom line. This is because outdated displays do not perform as well as new and improved displays. As many business owners have come to discover, new and improved touchscreen technology can increase efficiency, boost productivity, and improve customer satisfaction. This a top reason why so many companies decide to have a TFT LCD display or module replaced.

If you are thinking about having your older touchscreens repaired, then you should consider how having newer technology in place will help your business grow. Focusing strictly on the cost of replacing your displays can have a long-term impact on your business in more ways than one. For better results, you should consider all of the benefits of having new custom touchscreens specifically manufactured for your business. Ultimately, having new and improved displays in place for your employees and customers to use will be a business decision that pays for itself over time.

Question re: "Interestingly enough, the Thunderbolt cable that routes into the display also plugs into a standard Thunderbolt socket on the logic board."

We got the warm fuzzies when we found out that no proprietary tools were required to dissect Apple’s colossal display. In fact, all you really need to pull the guts out of this machine are some heavy duty suction cups, Torx T6 and T10 screwdrivers, and maybe a spudger here and there.

All in all, we were struck by the Thunderbolt Display’s ease of disassembly, and its 8 out of 10 repairability score reflects our admiration. But what did we find inside? Lots and lots of goodies that usually don’t come standard with an LCD monitor. Although monitors usually don’t cost as much as a laptop, either.

The LG display found inside is model number LM270WQ1. It’s the same display found in the iMac Intel 27″ from October of 2009, as well as the same basic LG display found in Dell’s competing 27″ monitor—though the Apple version uses LED backlights as opposed to Dell’s traditional CCFL. Dell’s version is also matte, something that lots of Mac users have been complaining about since the old 30″ Cinema Display was discontinued.

The 27-inch (diagonal) TFT active-matrix LCD has a resolution of 2560 by 1440 pixels, the standard for displays of this size and price. Its 12 ms response time and 16.7 million colors, however, fall short of the 6 ms response time and 1.07 billion colors of Dell’s comparable display. We might be splitting hairs here, but those hairs would be viewed with 1,053,300,000 less colors on Apple’s display. Just saying.

The fan is easily removed simply by detaching a couple of connectors and unfastening a few screws. Apple has, as usual, chosen to go with a large, brushless fan to keep the colossal Thunderbolt Display cool and quiet.

Interestingly enough, the Thunderbolt cable that routes into the display also plugs into a standard Thunderbolt socket on the logic board. Apple could have just soldered the cable wires to the board, but instead chose to implement a cover that prevents the cable from being detached from the logic board’s Thunderbolt socket.

We found some massive speaker enclosures near the side edges of the Thunderbolt Display and eagerly removed the screws holding them in place. Turns out the Thunderbolt Display comes with a 49 Watt 2-speaker sound system, including a miniature subwoofer.

Reports suggest that Apple is getting closer to implementing MicroLED in its future product releases, including the Apple Watch, with the display technology potentially offering a number of benefits compared to other methods. AppleInsider explains how the current TFT and OLED display technologies work, and how MicroLED differs.

MicroLED shows promise as a display technology, potentially offering power savings and a reduced screen thickness when put beside current-generation display panels. Apple has recognized the potential, and has invested heavily into developing the technology over the last few years, with a view to using it in the company"s future products.

To understand fully how MicroLED can benefit Apple, it is worth understanding how the commonly-used display technologies work in the first place, before examining how different MicroLED really is in a comparison.

The most common display technology used by consumer products today, and the oldest of the technologies examined in this article, TFT"s full name of TFT LCD stands for Thin-film-transistor liquid-crystal display. This technology is extensively used by Apple in its products, found in iPads, iPhones, MacBooks, and iMac lines.

The LCD part relates to the concept of defining small translucent or transparent areas in a thin and flexible liquid crystal-filled panel, like the displays used in calculators. Passing current through the segment changes the molecular properties of the defined segment area, allowing it to switch between being see-through or opaque.

TFT takes this a stage further, by effectively covering an entire panel with a grid of isolated liquid crystal segments, which again can vary between opaque and transparent based on the level of electrical current. In this case, there are far more segments needed to make up the display than with a normal calculator.

Polarizing filters on either side of the TFT display sandwich are used to prevent light from passing through directly, with the liquid crystal reaction of each segment affecting polarized light passing through the first filter to go through the second.

Sometimes these types of display are known as "LED," but this somewhat of a misnomer, as this actually refers to the use of Light Emitting Diodes as a light source. The LED backlight shines light through the various layers making up the TFT LCD.

Displays that use collections of LEDs as individual pixels do exist, but it isn"t usually found in consumer products. LED screens are commonly used for billboards, in attractions, and as a large-scale display for events.

TFT LCD screens continue to be widely used in production for a number of reasons. Manufacturers have spent a long time perfecting the production of the display panels to make it as cheap as possible, while its high usage allows it to benefit from economies of scale.

Used in consumer devices in a similar way to TFT LCD, OLED (Organic Light-Emitting Diode) is a display technology that is similar in the basic concept, but differs considerably in its execution. Again, the idea is for a thin panel to be divided up into segments, with charge applied to each section to alter its molecular properties, but that"s where the techniques diverge.

These self-emitting pixels gives OLED a considerable advantage over LCD-based systems in a number of areas. Most obviously, by not needing a backlight, OLED panels can be made far thinner than an equivalent LCD-based display, allowing for the production of thinner devices or more internal area for other components, like a larger battery.

The power efficiency of OLED panels can be far greater, as while a TFT screen requires an always-on backlight, the brightness of OLED pixels themselves determine power usage, with a black pixel consuming no power at all. OLED screens are also faster to respond than LCD displays, making them more useful for VR displays, where response time needs to be as rapid as possible.

This also allows OLED to provide superior contrast ratios compared to TFT, as the lack of backlight bleed-through that occurs in TFT simply doesn"t happen in OLED.

OLED also can be produced on plastic substrates instead of glass, allowing it to be used to create flexible displays. While this is currently embodied in curved and other non-flat screens in some devices, it has the potential to be employed in foldable smartphones or rolled up for storage, an area Apple is also allegedly examining.

Despite the advantages, OLED is still lagging behind TFT in terms of adoption. The cost of production is far higher, in part due to the need for extremely clean environments, as a single speck of dust can potentially ruining a display during fabrication.

OLED panels are also affected by the presence of water, both in production and in use. Small amounts of water contacting the organic substrate can cause immediate damage to the display, rendering parts of the screen useless.

Thought to be the next big thing in display technology, MicroLED basically takes the idea of using LEDs for pixels in a large stadium-style screen and miniaturizes it all.

Using extremely small LEDs, three MicroLEDs are put together to create each pixel, with each subpixel emitting a different color from the usual red, blue, and green selection. As each LED emits light, there is no need for a backlight as used in TFT screens.

MicroLED doesn"t use an organic compound to produce light, making it less susceptible to failure compared to OLED. Just like OLED, it can be applied onto a flexible material, allowing it to be used for curved displays or non-stationary components, like a watch strap, and can result in an extremely thin display panel.

MicroLED offers the same lower power consumption and high contrast ratio benefits as OLED when compared to TFT. However, MicroLED is also capable of producing a far brighter image than OLED, up to 30 times brighter, and is in theory more efficient in converting electricity into light.

As a relatively new and in-development technology, the cost of MicroLED production is extremely high in comparison to the more established OLED and TFT mass production lines, in part due to lower than required yields. Manufacturing equipment vendors have produced hardware for MicroLED production that cuts defects in half and reduces deposition deviance from 3 nanometers down to 1 nanometer, but it is unclear if this is enough to help mass production move forward.

While MicroLED is an attractive proposition for Apple, it is not the only technology under development by the company"s engineers. Apple has previously filed patent applications for a technology described as "Quantum Dot LED and OLED Integration for High Efficiency Displays."

Quantum Dots are photoluminescent particles included in an LED-backed TFT display that can produce brighter and more vibrant colors, with the colors produced depending on their size. While available in current QLED televisions, the technology is only really being used to enhance the backlight, rather than being used to illuminate individual pixels.

Image: Lee, Changhee & BAE, Wanki & KWAK, Jeonghun. (2014). "Quantum Dot LED (QLED) Emerging as a Next-generation Display Technology" in Physics and High Technology

The technology in theory can create an even thinner display than OLED, along with a more streamlined manufacturing process. True QD displays are also capable of high pixel densities of up to 1,000ppi, multiple times the density required to be called a Retina-quality display, and based on Apple"s hybrid invention, will also boast the response times of OLED technology.

The QD patent application certainly shows Apple is thinking about display technology in multiple ways, and how it can be applied to future devices, but short of getting firm supply chain information or an official announcement from Apple directly, it is difficult to confirm which direction it will be heading.

Apple has been interested in using the technology for some time now, with the first notable sign being its acquisition of LuxVue in May 2014, alongside assorted related patents. A MicroLED specialist, LuxVue was rumored to have been the display producer for the ill-fated Google Glass headset, but was also the holder of assorted patents in the LED display field, including MicroLED.

At the time, the acquisition was thought to be an attempt by Apple to bring part of its display technology development in-house, with suggestions the MicroLED technology would be used in another rumored-at-the-time device, the Apple Watch. A more recent report suggests Apple is working with TSMC to make small panels for a future premium Apple Watch, potentially starting mass production by the end of the year.

The facility is also claimed to be sufficient in size to perform small scale manufacturing of display panels, allowing the company to keep development and testing in-house without involving third-parties. Considering Apple"s previous history in developing technologies before issuing information to manufacturing partners, it is possible that Apple is trying to work out the kinks in production before suppliers even attempt to make MicroLED panels.

The rumored small screen production may be for the Apple Watch now, but it may also benefit another often-rumored device, namely the VR or AR headset. This type of hardware relies on light components to keep the weight off the user"s head and neck, as well as displays with a high refresh rate and as close to perfect color reproduction as possible.

Apple is also apparently planning to use the technology in larger displays, said to be bigger in size than those in the MacBook Pro lines. This could be an iMac or iMac Pro, or even an external display, but ultimately there"s no real indication of Apple"s plans at this point, regardless of the scale of the screen.

Reports from last year also suggest Apple"s investment in MicroLED was a cause for concern for Samsung, LG, and other South Korean suppliers who provide display panels for the company"s products. Owning the process for MicroLED manufacturing could allow Apple to migrate away from its existing display suppliers in the coming years, reducing revenues and profits.

Aside from Apple"s development, there has been little in the way of announcements from other firms for products using the technology that could be bought by consumers in the coming months. The exception is Samsung, Apple"s main rival in the mobile marketplace and a major supplier of display panels, but its usage of MicroLED is not aimed at producing smaller screens.

The impending use of the technology in a high-priced consumer product could be considered proof that MicroLED display technology is maturing enough for use in devices. If the reports claiming Apple is getting close to mass producing panels is true, the inclusion of MicroLED in the Apple Watch could end up being the first mainstream usage of the technology.

The new mini-LED display technology validates LCD technology can still move forward and compete with the OLED displays. Mini-LEDs are physically smaller than backlight LEDs used in the typical LCD. The mini-LED size allows more LEDs (in theory almost 5x more) to be used in a display design, delivering better colors. And even though there are more LEDs in a mini-LED display, mini-LED displays will have better power efficiency than the same LCD.

Linda Lin covers large-sized thin-film-transistor LCD panels and is in charge of survey reports covering manufacturers and vendors in the notebook panel supply chain. With her many years of experience, Linda has developed first-rate relationships throughout her extensive network of contacts and connections in the display industry.

Linda previously worked at LCD market research firm WitsView, leading research on panels and downstream products, including monitors and TVs. At the Market Intelligence & Consulting Institute, Taiwan’s chief information and communications technology market research group, she oversaw regional research for South and East Asia. It was during this time that Linda decided to make large-sized displays her main focus. Linda has a master’s degree in business administration from National Yunlin University of Science and Technology in Taiwan.

He has been working various analyzes with cost, structure and supply chain of electronic devices for over 10 years, and he has performed more than 300 devices for teardowns. Paul specializes a various teardown device who focused mobile device, display device (television, automotive), and semiconductor. He also has done a lot of commissioned project with trend and patent analysis in order to provide specific insights to customer. Especially he is good at 4G and 5G RF part analysis for telecommunication. Prior to joining Informa Tech, Paul has been working in cost benchmarking team at IHS Markit(now S&P Global) and he has experience in variety of workplaces at consumer & electronics industry for 20 years.

Queenie Jiang is a research analyst in the Displays team at Omdia and based in Shanghai, China. She covers display components research with a specific focus on China; she analyzes the market, prices, supply chains, and technologies.

Kimi is a senior analyst for display (TFT LCD and OLED) touch and user interface at Omdia. He covers display price, supply chain, fingerprint, cover lens, shipment forecasts, and emerging technologies.

Stacy is an experienced analyst in Omdia’s display research team, covering small and medium displays. She focuses on automotive displays, smartphone displays, and wearable displays. As a Principal Analyst, she covers small and medium display shipments, supply chain, pricing, and business strategy analysis. She is the lead analyst of the automotive display intelligent service.

Prior to her role, Stacy served as the manager of the market intelligence department of Delta Electronics Group and led the team to provide market insights to the senior management team. She was also a senior analyst responsible for the large area display market at iSuppli. During her tenure, she established a comprehensive industry network and delivered several speeches. She was awarded the iSuppli Idol Award in 2008. She holds a master"s degree in international marketing from the University of Strathclyde in the UK and a bachelor"s degree in business administration from National Chengchi University in Taiwan.

As part of Omdia’s small/medium displays practice, Joy covers displays under 9 inches in size utilized in smartphones, tablets, wearables, and automotive displays. Her research touches areas such as the AMOLED ecosystem, new trends in smartphone panel displays, and the supply chain in China for smartphone displays.

Joy brings 17 years of experience to the subjects she covers. She worked previously at BOE, the giant Chinese display manufacturer, as a product manager for medical and industrial displays. She started her career at Tianma Group as an LCD module design engineer, then became manager of product design and development. She transferred to the marketing department as an analyst for mobile phone displays and then for automotive displays. Joy has a bachelor’s degree in automation from Beihang University, a major public research institution in China. She also holds a master’s degree in business management from Renmin University of China.

Mr. Hidetoshi Himuro is a Director at Omdia. He previously worked at DisplaySearch, a leader in primary research and forecasting on the global display market. At DisplaySearch, he served as director of IT & FPD market research. He was responsible for market research and analysis of large-area LCD applications, including monitor, notebook PCs and public display/digital signage. He also forecasted monthly large-area LCD panel pricing. With his background in engineering, he covered the LCD panel technology roadmap.

Prior to DisplaySearch, Mr. Himuro held a number of positions at NEC in both Japan and the US. At NEC, his diverse responsibilities included strategic planning, project management, LCD panel and monitor set procurement, design verification, vendor relationships and hardware development for notebook PCs and LCD monitors and their LCD panels. He has a bachelor"s degree in Electrical Engineering from Tokyo University of Science, Japan.

Peter Su conducts research on large-sized displays, tracking supply-and-demand dynamics, market trends, and product roadmaps on panels sized more than 9 inches measured diagonally and used in tablets, notebooks, monitors, and televisions.

Previously, Peter was at DisplaySearch, where he worked with large displays as well. At AU Optronics, he was in panel sales and strategic product marketing in the notebook PC and tablet business units. There, he was also involved in PC capacity planning, technology investment projects, and both upstream and downstream channels for panels and mobile PCs. Peter has a bachelor"s degree in economics from the University of Victoria in Canada, and a master’s degree in business administration from Concordia University Wisconsin in Mequon, Wisconsin.

Mr. Hisakazu Torii is a Research and Analysis Executive Director, TV, Consumer Electronics and Devices, at Omdia. Previously he worked at DisplaySearch, a leader in primary research and forecasting on the global display market. At DisplaySearch, he served as vice president of Japanese TV market research. With 18 years of display industry experience, he was responsible for covering all Japanese TV brands across Asia Pacific.

Before DisplaySearch, Mr. Torii worked at Mitsubishi Electric where he conducted market research for product groups, business planning and new product development in all major display applications, including TVs, notebook PCs, monitors, mobile phones, digital still cameras, digital video recorders, automotive displays and industrial applications. He earned a degree from the Department of Law at Waseda University in Tokyo, Japan.

Tadashi Uno covers various aspects of displays, including the display glass, the display panel for smartphones and tablets, and the cost model for large-sized displays.

Before joining the company in 2014, he was with DisplaySearch, a leader in primary research and forecasting on the global display market, where he served as director of display materials and components. Previously, Tadashi was manager of the planning division for display component operations at Dai Nippon Printing in Tokyo, where he was responsible for the company’s display components and relationship with glass manufacturers and driver integrated circuit makers. He has a bachelor"s degree from the University of Kyoto-Sangyo in Kyoto, Japan.

Mr. Hiroshi Hayase is a Senior Director at Omdia. He previously worked at DisplaySearch and Solarbuzz, leading providers of display and solar market intelligence. With nearly 30 years of experience in the LCD industry, he brings an unparalleled focus to sales, marketing management, production, product engineering and market research and analysis.

At DisplaySearch, Mr. Hayase served as vice president of small and medium displays. Before that, he was responsible for sales and market research at a Taiwanese LCD panel/module manufacturer, Wintek Japan Corporation. Earlier, he served as sales manager with Applied Komatsu Technology (AKT), where he was responsible for sales of CVD systems to major Japanese panel producers. He also has 13 years of experience in sales management and production engineering across the full range of LCD production processes with Seiko Epson. Mr. Hayase holds a bachelor"s degree in Mechanical Engineering from Shizuoka University, Japan.

He previously worked at DisplaySearch and Solarbuzz, leading providers of display and solar market intelligence. Mr. Annis is a leading expert in flat panel display research and served in a dual role as vice president of manufacturing research at DisplaySearch as well as at its sister company of Solarbuzz. At DisplaySearch, he was responsible for analyzing emerging technologies, tracking and forecasting flat panel display investments, and researching equipment, materials and process trends. At Solarbuzz, he developed the company"s proprietary polysilicon, wafer and cell manufacturing databases and authored related reports.

Prior to DisplaySearch, Mr. Annis spent six years at Photon Dynamics (now Orbotech), the leading provider of yield management solutions to the FPD industry and served as an international business manager for SAMCO International, a Japanese semiconductor equipment manufacturer. He holds a master"s degree in Business Law from Ryukoku University in Kyoto, Japan, and a bachelor"s degree from Pomona College in Claremont, California, US. He is based in Japan.

Mr. Robin Wu is a Principal Analyst at Omdia. Previously he worked at DisplaySearch, a leader in primary research and forecasting on the global display market. At DisplaySearch, he served as a PC and TFT analyst, specializing in trend analysis of China"s PC, monitor, and panel markets. He also acted as vice chair of the VESA monitor task group in 2010 and has focused on monitor/panel standardization since early 2009.

Prior to DisplaySearch, Mr. Wu spent nearly seven years at the leading IT brand IBM/Lenovo. There, he focused on monitor/TFT business, delivering industry-leading green ThinkVision products and managing panel sourcing and qualifications. In addition to providing support to the desktop/AIO business, he acted as a liaison in the industry, building strong relationships with leading PC monitor OEMs in China. Mr. Wu has a bachelor"s degree in Mechanics & Electronics and a master"s degree in Micro-Electro-Mechanical Systems from Huazhong University of Science and Technology, China.

Before joining the company, Jay was at EverDisplay Optronics—also known as Hehui Optoelectronics—in Shanghai, where he worked for six years in OLED R&D, flexible display design, and new products. He holds a doctorate in material science from the South China University of Technology in Guangdong, China.

Jeff Lin is a longtime analyst and researcher in the field of displays, having previously worked at DisplaySearch, a leader in primary research and forecasting on the global display market. At DisplaySearch, he worked as an analyst covering Taiwan"s display market and was responsible for market research and analysis of the PC monitor value chain and large-area panel roadmap.

Before DisplaySearch, Jeff gained valuable experience handling panel sourcing and desktop monitor market analysis at BenQ Corporation. Prior to that, he served as a key monitor account sales manager at Samsung Electronics Taiwan, where he formed key relationships with leading PC monitor company and OEMs in the country. Before Samsung, he was an engineer at Chunghwa Picture Tubes (CPT), where he led TV panel development projects and planned TV panel roadmaps.

Jimmy Kim conducts research on a broad—and disparate—array of subject areas in display materials and components, including cost modeling for OLED displays, new developments in mini LED technology, and the emergence of new display form factors, such as rollables and foldables.

Jimmy joined the company in 2014 following the acquisition of DisplaySearch, where he served as a senior analyst covering display materials and LED analysis. Jimmy also worked at Samsung—first at Samsung LED, and then at Samsung Electronics. There, he led several R&D projects on new light sources for LCD backlighting and new BLU structures.

Jerry Kang is responsible for the OLED display market analysis at IHS. His main focus is the AMOLED panel and the next generation display market including flexible and transparent display with AMOLED.

With more than 10 years of industry experience, Jerry is known for his professional analysis and strategic insights on the technology and market for OLED display. He is frequently quoted in media, and is invited to speak at major conferences worldwide.

Prior to joining IHS in 2011, Jerry worked as an OLED development engineer at Samsung SDI and Samsung Mobile Display, in charge of operational circuit designing for OLED and LCD.

David Hsieh is a noted expert in research and analysis of the TFT LCD, and LCD TV value chain for Mainland China and Taiwan. As head of the Displays team, he oversees the division’s end-to-end research on displays, covering the supply chain, materials and components, supply-and-demand dynamics, pricing and cost modeling, revenue and shipment forecasts, and emerging technologies.

In an earlier stint at DisplaySearch, he led the company’s primary research and forecasting on the global display market while concurrently serving as vice president of the greater China market. David also worked at HannStar Display, a leading manufacturer of TFT LCD panels, as a key account manager, production planner, and production engineer for the HannStar TFT LCD module line.

In his previous roles at the company, Jusy led the research team on TV technology and ecosystems, which included the panel display market for TVs and large-sized LCDs. He has also worked on the global monitor and public information markets.

Jusy’s work is currently concentrated in the areas of demand forecasting, competitive analysis, pricing, and new-trend analysis. He also serves as project manager for numerous consultancy missions centered on display technology for industry-leading manufacturers, government institutions, and investment companies.

Irene has tracked the display industry’s parts and materials market for many years. She worked for a year in 2007 at the company’s Yokohama office, where the human networks she built during that period remain a great asset for her optical-film-related research.

He joined IHS in November 2014, when IHS acquired DisplaySearch, a leader in primary research and forecasting on the global display market. At DisplaySearch, he served as director of large-area displays & FPD materials analysis in the company"s Korea office. He is a recognized display expert and has been invited to speak on large-area displays, especially on PDP technology, at many Korean FPD forums.

Prior to DisplaySearch, Mr. Chung spent 10 years on the R&D and marketing teams of Samsung SDI"s CRT and PDP Division. There, he managed PDP product planning and technology marketing, led the FPD benchmarking team in the PDP Division and taught Samsung SDI"s new employees about display history and technologies. Mr. Chung has a bachelor"s degree from Kookmin University in Seoul, South Korea.

The Eizo ColorEdge 243W is basically made up of two shells, the first made of plastic, which is what we see on the monitor, and the second made of metal that serves as support for the rest of the components: a TFT-LCD panel LG Display LM240WU4-SLB3, an Eizo 5P23049 Power Supply board (which is also used for other models such as the SX2462W), an LCD inverter and an Eizo Main Board.

User-Interface-Focused iPad Changes the Game in Electronic Design, iSuppli Teardown RevealsEl Segundo, Calif., April 7, 2010—With more than 40 percent of its Bill of Materials (BOM) dedicated to the display, touch screen and other user interface components, Apple Inc.’s iPad represents a radical departure in electronic design compared to conventional products, according to a teardown conducted by iSuppli Corp.

“While the iPad has the potential to change the game in the computing, wireless and consumer worlds, it already has changed the game of how many electronic products are—and will be– designed,” said Andrew Rassweiler, director and principal analyst and teardown services manager for iSuppli. “The iPad’s design represents a new paradigm in terms of electronics cost structure and electronic content. Conventional notebook PCs are ‘motherboard-centric,’ with all the other functions in the system—such as the display, the keyboard and audio—peripheral to the central microprocessor and the main Printed Circuit Board (PCB) at the core. With the iPad, this is reversed. Everything is human-machine-interface-centric, with the PCB and Integrated Circuits (ICs) all there to facilitate the display of content as well as user inputs.”

Based on its physical teardown, iSuppli estimates the BOM of the low-end 16Gbyte, non-3G iPad at $250.60. When manufacturing expenses are added, the cost rises to $259.60.

This cost is higher than iSuppli’s virtual teardown estimate issued in February of a $219.35 BOM and $229.35 manufacturing cost. Cost for the display, the battery, the user interface chips and the power management Integrated Circuits (ICs) all exceeded iSuppli’s initial estimates, driving up the total BOM.

Please note that the teardown costs account only for hardware and manufacturing and do not include other expenses such as software, royalties and licensing fees.

The single most expensive component in the iPad is the display, priced at $65 and representing 25.9 percent of the product’s BOM. The display is a 9.7-inch diagonal, 262,000-color TFT-LCD with a resolution of 1024 by 768 pixels. It employs In-Plane Switching (IPS) technology, which supports a wider viewing angle and better picture quality in terms of presentation of color than a conventional LCD.

“The display represents a customized implementation of an IPS panel, driving up its cost relative to a more commoditized netbook panel,” Rassweiler said.

In the specific iPad torn down by iSuppli, the IPS TFT-LCD was supplied by LG Display. However, iSuppli believes Apple has qualified two other suppliers for the display, with more possible in the future.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey