arduino tft display menu factory

In the oscilloscope, signal data is read from Arduino’s pin A5. This data value is mapped to display coordinates. Then the value is used to draw each pixel to create the waveform of the signal

In the RGB Mixer, when a slider is touched, map the touch cordinates to display cordinates. Then draw a black box in the slider’s current position. After that, draw the colour box again with the new display cordinates. Map the display position to a value between 0 and 255 and create the RGB colour combination to show in the top right corner of the screen.

Sticking to the principle of "Super Quality, Satisfactory service" ,We are striving to be a good business partner of you for Menu Tft Arduino, Lcd Liquid Crystal Display, High Brightness Tft, Active Matrix Tft Lcd,Mobile Lcd. Special emphasis around the packaging of merchandise to avoid any damage during transportation,Detailed interest into the useful feedback and strategies of our esteemed shoppers. The product will supply to all over the world, such as Europe, America, Australia,Grenada, Mexico,Croatia, Kyrgyzstan.We care about every steps of our services, from factory selection, product development & design, price negotiation, inspection, shipping to aftermarket. We have implemented a strict and complete quality control system, which ensures that each product can meet quality requirements of customers. Besides, all of our products have been strictly inspected before shipment. Your Success, Our Glory: Our aim is to help customers realize their goals. We are making great efforts to achieve this win-win situation and sincerely welcome you to join us.

In electronics world today, Arduino is an open-source hardware and software company, project and user community that designs and manufactures single-board microcontrollers and microcontroller kits for building digital devices. Arduino board designs use a variety of microprocessors and controllers. The boards are equipped with sets of digital and analog input/output (I/O) pins that may be interfaced to various expansion boards (‘shields’) or breadboards (for prototyping) and other circuits.

The boards feature serial communications interfaces, including Universal Serial Bus (USB) on some models, which are also used for loading programs. The microcontrollers can be programmed using the C and C++ programming languages, using a standard API which is also known as the “Arduino language”. In addition to using traditional compiler toolchains, the Arduino project provides an integrated development environment (IDE) and a command line tool developed in Go. It aims to provide a low-cost and easy way for hobbyist and professionals to create devices that interact with their environment using sensors and actuators. Common examples of such devices intended for beginner hobbyists include simple robots, thermostats and motion detectors.

In order to follow the market tread, Orient Display engineers have developed several Arduino TFT LCD displays and Arduino OLED displays which are favored by hobbyists and professionals.

Although Orient Display provides many standard small size OLED, TN and IPS Arduino TFT displays, custom made solutions are provided with larger size displays or even with capacitive touch panel.

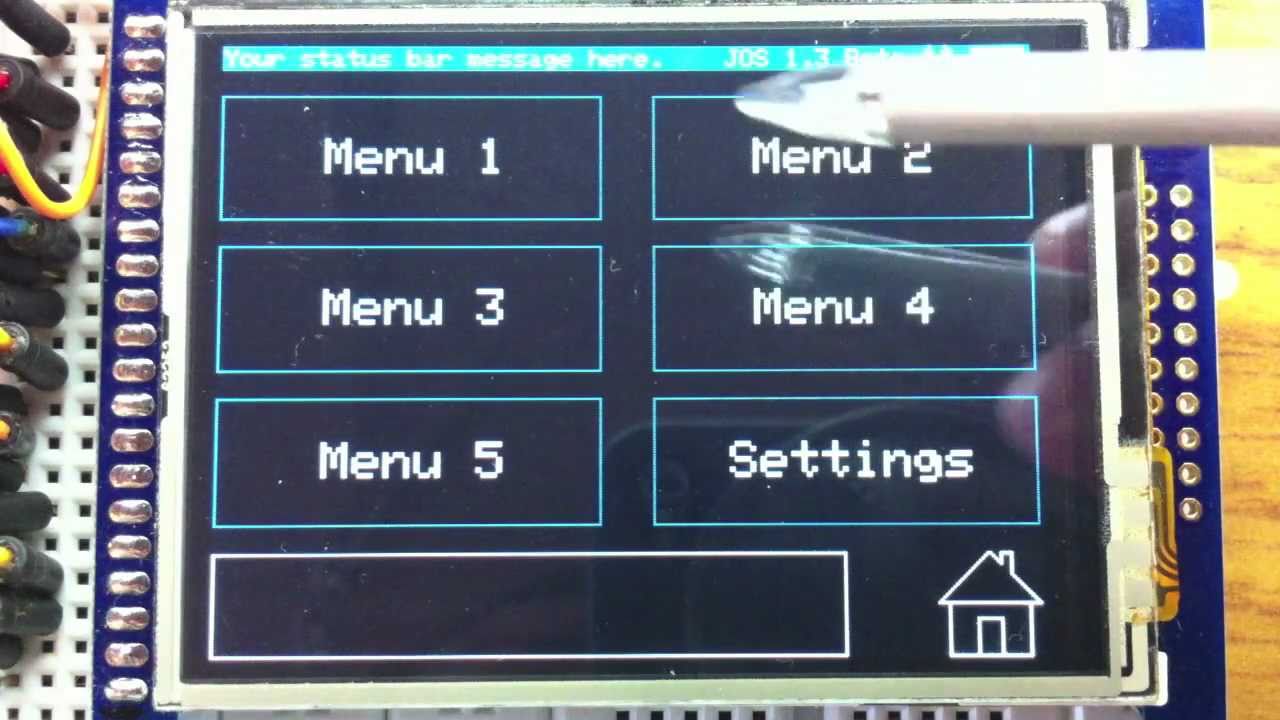

Hi! A menu on a TFT LCD display shield using Arduino would be nice right ? Here’s a demo of a simple menu I created. The complete code is available too.

In the oscilloscope, signal data is read from Arduino’s pin A5. This data value is mapped to display coordinates. Then the value is used to draw each pixel to create the waveform of the signal

In the RGB Mixer, when a slider is touched, map the touch cordinates to display cordinates. Then draw a black box in the slider’s current position. After that, draw the colour box again with the new display cordinates. Map the display position to a value between 0 and 255 and create the RGB colour combination to show in the top right corner of the screen.

To interface TFT LCD Display with Arduino, for designing custom HMI TFT LCD Display provide rich colours, detailed images, and bright graphics with their full-colour RGB mode it comes in different pixels 128 x 160 pixels, 320×240 pixels and many more.

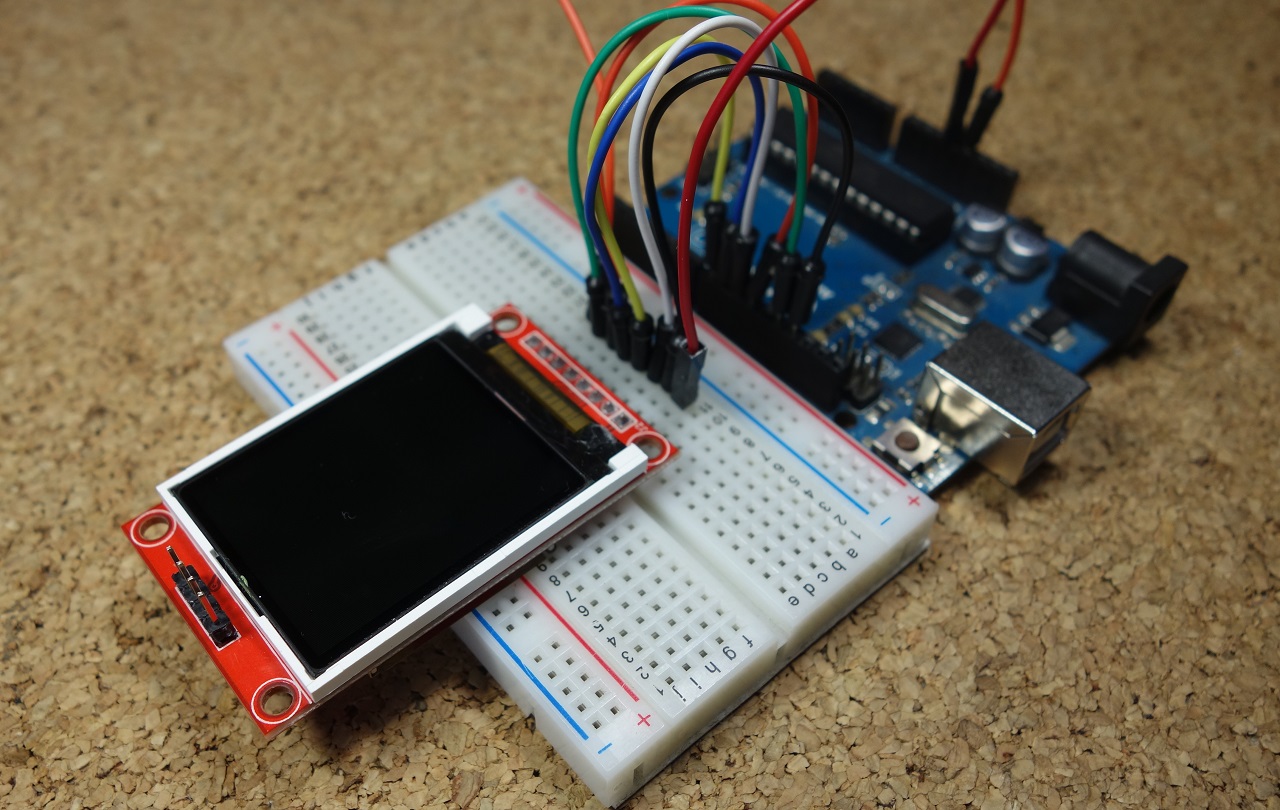

In this tutorial, we’ll interface the 1.8 TFT LCD display with Arduino Uno. You’ll learn how to interface the TFT LCD with Arduino to write text on this LCD. This tutorial presents the coding, wiring diagram and components list required for the LCD display.

Creating an interface between the user and the system is very important. This interface can be created by displaying useful data, and menus. There are several components to achieving this. LEDs, 7-segments, OLEDs, and full-color TFT LCDs. The right component for your projects depends on the amount of data to be displayed, and the type of user interaction.

TFT LCD is a variant of a liquid-crystal display (LCD) that uses thin-film-transistor (TFT) technology to improve image qualities such as addressability and contrast. In the case of Arduino, the processor frequency is low. So it is not possible to display complex and high-speed motions. Therefore, full-colour TFT LCDs can only be used to display simple data and commands. This TFT has 128 x 160 pixels. 1.8 TFT display can load images from an SD card. It has an SD card slot at the back. You can see the front and back views of the TFT LCD in the figures below.

TFT is an abbreviation of “Thin Film Transistor”. It has transistors made up of thin films of Amorphous silicon. It serves as a control valve to provide an appropriate voltage onto liquid crystals for individual sub-pixels. The working principle is very simple the TFT LCD composes of many pixels that can emit light of any colour. The desired image achieves by controlling each pixel to display the corresponding colour. In TFT LCD, the backlight technology is generally used. In order to accurately control the colour and brightness of each pixel, it is necessary to install a shutter-like switch after each pixel. When the “blinds” are opened, light can pass through them. When the shutters are closed, light cannot pass through them.

Connect your PC to Arduino and open Arduino IDE. For the very first steps, you can refer to Connecting Windows PC with Arduino tutorial. You can get the .ino code and libraries from my download area with the following link:

This is the section before setup which uses for globe variables defining and libraries additions. TFT.h is the library for TFT LCD Display and uses for writing and drawing on the display. The TFT display communicates with the Arduino via SPI communication, so you need to include the SPI library.

This is the setup section in which Serial.begin(9600) initialize. TFTscreen.begin() is use to initialize the library. TFTscreen.background(0, 0, 0) is use to customize the screen background color here TFTscreen.background(0, 0, 0) means the background colour is black. TFTscreen.setTextSize(2) is use to set the font size.

In the loop section first, we will print the “Hi_peppe8o!” in the centre of the LCD and this will be in three different colours (Red, Green, Blue) you can choose any colour using the different colour codes. After 300 milliseconds a straight line will be displayed, after 300 milliseconds a square will be displayed, after 300 milliseconds a circle will be displayed, and after 300 milliseconds screen will be black/ erase and these all shapes and the text will be repeated in the void loop.

The LCD displays the text of “Hi_peppe80” and after that displays the line, square, and circle and then erases everything after completing this sequence. The command used for clearing all the data is TFTscreen.background(0,0,0):

TFT LCD screens combined with Human Machine Interface (HMI) technology result in exciting project ideas applicable to a wide variety of industries. STONE HMI TFT LCD Arduino project ideas. After all, HMI is a smart technology that uses touch to draw out information from both the human user and the display machine.

And when high-quality display screen modules such as STONE Tech’s TFT LCD products are laden with HMI technology, the result is outstanding machine performance capable of bringing out the best in every customer and business.

Now, this article will feature STONE HMI. Furthermore, we will also present some exciting project development initiatives carried out by the company using its vast range of TFT LCD modules paired with HMI technology, and the TFT LCD Arduino project.

The interface with which HMI works consists of both hardware and software. These two work together to let users input signals using direct or indirect touch (such as by using a special screen stylus) on the machine display. Once the touch signals have been inputted, the machine recognizes them and sends them to the software to begin interpretation. The machine then responds by showing the desired information to the human user.

Medical equipment in hospital settings uses HMI to display pertinent information regarding a patient. For instance, a ventilator machine can display data such as vital signs and a selection of possible breathing patterns for the patient. It can also alert medical practitioners when there is a problem with the patient or the machine through alarms and sounds.

Another HMI machine used in daily life is the car dashboard. An on-board car control panel using an intelligent touch screen can be used to display important car information like speed, gas levels, and time. The screen dashboard can also be used to toggle many functions like turning the AC and beam on or off using a single touch.

HMIs are user-friendly by nature. Graphics and colors can easily be added to the display to communicate with the end-users. Any problems arising from the HMI screen can also be detected easily using color codes, alarms, and sounds. Furthermore, you’ll need only a few touches to fix any issues detected by an HMI device.

What makes HMI a good choice for industrial use is that it is fully flexible and customizable to fit several industrial needs. The TFT LCD screen sizes can be tailor-made to suit the HMI’s application. Furthermore, the software that comes with the machines can be adjusted as well.

STONE Technologies is a proud manufacturer of superior quality TFT LCD modules and LCD screens. The company also provides intelligent HMI solutions that perfectly fit in with its excellent hardware offerings.

STONE TFT LCD modules come with a microcontroller unit that has a cortex-m4 32-bit CPU. Such a module can easily be transformed into an HMI screen. Simple hexadecimal instructions can be used to control the module through the UART port. Furthermore, you can seamlessly develop STONE TFT LCD color user interface modules and add touch control, features to it.

You can also use a peripheral MCU to serially connect STONE’s HMI display via TTL. This way, your HMI display can supply event notifications and the peripheral MCU can then execute them. Moreover, this TTL-connected HMI display can further be linked to microcontrollers such as:

Each customizable TFT-LCD HMI display module comes with free access to STONE’s dedicated design software. STONE TOOLBox software is an easy-to-use program that allows you to set up graphical user interface functions such as:

HMI projects can quickly be done with Stone’s HMI-ready display modules. As previously mentioned, STONEprovides complete modules that include hardware and a free downloadable GUI design software – everything you need to get started on your HMI concept.

Also, STONE manufactures several TFT LCD touch screen sizes that range from 3.5 to 15.1 inches. Customized options are also available depending on your needs. There are also plenty of options and models for each screen size.

Indeed, STONE produces a plethora of HMI-ready TFT LCD screens. You won’t have a hard time finding the right display module compatible with your microcontroller projects.

STONE developed an oxygen monitor for an Italian customer. The monitor uses Stone’s 7-inch TFT LCD screen and was connected to an oxygen tank for medical use.

The finished product displays information about the connected oxygen tank such as concentration levels and other advanced data. All these data are displayed on a streamlined interface developed using TOOLBox software.

The end-product featured a touch screen display where fan functions such as speed, dose, and RF are controlled. Moreover, the resulting fan control board can operate at temperatures ranging from -20°C to 70°C, making it a simple yet heavy-duty device.

STONE’s display screen was connected to the Arduino development board through UART. But this required a level conversion achieved by the MAX3232. Meanwhile, the same Arduino board was wired to the MAX30100 module through an IIC interface.

Some modifications to the MAX30100 module were made, specifically to the IIC pull-up resistor. The remainder of the project was finished using Arduino codes to finally create a responsive display for heart rate and blood oxygen monitoring.

This project aims to create a fingerprint door lock that can enter, scan, compare, and delete fingerprints. It utilized an STM32 development board, fingerprint identification module, and Stone’s STVC050WT-01 LCD display.

STONE LCD screen’s role here is to display the fingerprint module’s status. As with all other projects, STONE TOOLBox software was used to generate the user interface flashed on the screen. Meanwhile, Stone’s LCD screen was connected to the development board and fingerprint identification module with MCU through UART-TTL signals.

The idea for this project is a real-time display of pictures collected by the camera on the LCD display screen. The TFT LCD STONE module used for this project is a 7-inch serial display module with 800×480 resolution. A camera module, development board, and some wires are needed to complete the project.

The user interface was designed using STONE TOOLBox and Adobe Photoshop. Then, the hardware parts were wired together; some parts needed welding. After that, a simple program was written following MCU to the command control TFT-LCD module.

This particular project used a STONE serial LCD touch display screen. This functions as the main display for the coffee machine. With the screen installed, you can:

RGB lamps that can be controlled through a touch display – this is the aim of this project idea. STONE’s 7-inch TFT LCD display module in STVC070WT-01 was used to connect and control an RGB lamp.

Last but not least is a basic appliance controller made using STONE’s 7-inch TFT LCD touch screen and an STM32 development board. The touch screen controls lights for various parts of the house. The finished product also collects data about humidity, temperature (indoor and outdoor), and air quality.

STONE’s TFT LCD intelligent touch modules can be paired with Arduino technology to automate a variety of processes. This project clearly demonstrates this.

Here, a sensor directly connected to Arduino Uno is monitored by the display screen in real-time. Moreover, two light bulbs connected to Arduino are directly controlled by the display screen as well.

This project is all about making a car display dashboard using a 10.1-inch STONE LCD touch screen. The on-board display interface for a used car contains the following:

We presented an overview of what HMI technology is, how it works, and which applications use it. Also, we covered Stone’s range of HMI-capable TFT LCD display modules. Furthermore, we discussed a lengthy list of exciting project ideas made using Stone’s superior quality HMI displays.

STONE Technologies is truly your best bet for powering your HMI-driven development ideas(projects based on TFT LCD Arduino, STM32, ESP, etc.). Take inspiration from the actual examples we’ve shown you and build your very own HMI display device today.

Beijing STONE Technology co., ltd was established in 2010 and devoted itself to manufacturing and developing high-quality intelligent TFT LCD display modules.

Our vision is to become one of the world"s top display manufacturers in the industrial intelligent field. And providing top-quality products and professional technical services to customers all over the world.

Our core TFT LCD display modules integrate a CPU, flash memory, and touch screen in the hardware unit. Paired with an easy-to-use free GUI design software and complete instruction set, customers can avoid time-consuming accessories selection and system integration tasks. These units greatly reduce the workload in HMI development and make the entire process faster and easier.

The modules come with a UART TFT serial interface that can be controlled by any MCU through the simple but powerful instruction set like the 8051 series, AVR series, MSP430 Series, STM32 series, MC9S12, and Arduino series, among others.

Each TFT display LCD module has a wide range of applications, such as automated system control, vending machine functionality, intelligent lockers, electricity equipment (oiling machine, EV charger), elevators, smart home and office, precision instruments, and much more.

To date, we have delivered custom display solutions to over 3000 customers around the world. Our TFT LCD modules have been widely praised for their quality and performance and that is in large part thanks to our partners, including NI, Siemens, ThyssenKrupp, and many others. These long-term cooperative relationships have been mutually beneficial and we hope to continue a long history of success.

We covered the basics of accelerometer previously inUsing Arduino with Parts and Sensors – Accelerometer Part 1andUsing Arduino with Parts and Sensors – Accelerometer Part 2. Today we’ll be testing KX022-1020 accelerometer using TFT liquid crystal panel. We’ll discuss how to control the TFT LCD in more detail in the next article. In addition, we’ll further exploreArduino Create. For more information about Arduino Create, please refer back tothisarticle.

We’ll continue using Arduino Create Web Editor as we did in our lasttutorial. To add the library, you can upload the zip file by selecting it from “Libraries” on the left menu and clicking on “ADD ZIP LIBRARY.”

Now the sample program is working fine, let’s try to display the values on a 1.8 inch TFT LCD monitor. Although this TFT liquid crystal monitor has a resolution slightly smaller than 126 x 160 px, it’ll be quite useful when displaying numbers or letters with Arduino etc.

In the past, we used 7-segment LED to display numerical values only. But this time, I tried to display the graph along with the values obtained from the accelerometer.

When using the TFT monitor, the connection method and the library used in the program may be different depending on the specification of each TFT monitor. The TFT monitor used in this tutorial is a monitorSainSmart ST7735R. In addition to Arduino, the monitor is also compatible with Raspberry.

In order to use the monitor to run the program in Arduino, we’ll have to modify the downloaded library a little bit.We’ll go over how to control the TFT LCD in more detail in the next article. Once everything is set, you will be able to output numerical values in the monitor as shown in the video below:

In the next part, we’ll create a simple device using the same accelerometer and TFT monitor. We’ll show how to create graphs and display the values obtained from the accelerometer on the TFT monitor.

Add some dazzle to your project with this 1.45" diagonal graphic TFT display module. This small display packs 128x128 full-color pixels into one square inch of active display area. It is a great choice when you need color and sharp detail while using minimal front panel space. At less than 5 grams, the display adds very little weight to handheld devices.

Thanks to the integrated Sitronix ST7735S or compatible controller, a single 3.3v source powers everything. The SPI host interface allows full read and write control of the display while using only 10 pins. The single bright white LED backlight has anode (A,+) and cathode (K, -) pins brought out on the Flexible Printed Circuit (FPC) tail. To connect, all you need is a standard 10-conductor, 0.5 mm ZIF socket such as Omron Electronics

While the SPI interface requires only a few lines to control this TFT LCD module, it is still possible to transfer data at a rate that supports 20 FPS (Frames Per Second) screen updates -- fast enough to play a full-motion video as shown in our videos.

To get started, download the datasheet and SPI sample code. And of course Crystalfontz is always here to help you when you integrate this display into your application.

The new line of 3.5” TFT displays with IPS technology is now available! Three touchscreen options are available: capacitive, resistive, or without a touchscreen.

For over 20 years Newhaven Display has been one of the most trusted suppliers in the digital display industry. We’ve earned this reputation by providing top quality products, services, and custom design solutions to customers worldwide.

In addition to a serial/usb/host interface, Marlin also includes a menu-based user interface for inexpensive character and graphical LCD controllers. Rotate a knob or use buttons to navigate menu items, edit values, and make other adjustments. Click the knob or press a button to choose menu items, exit adjustment screens, and perform other actions.

Note: In low-level contexts we refer to the first extruder as E0, the second as E1, etc. However, at “user level” in the LCD menus, we refer to the first extruder as E1, the second as E2, etc. (Marlin 2.0 includes an option to show the first extruder as E0.)

The Tune menu is only available during active printing. Most items in this menu are editable values. Item Description Requirements Speed: -–- Feed Rate Multiplier

The move axis sub-menu was reorganized for Marlin 1.1. To use the move commands, first select the axis to move, then select the move distance. Use the controller wheel (or arrow buttons) to adjust the axis position. For larger move sizes, Marlin waits until you stop moving the controller for 1/2 second before it starts the move, giving you an opportunity to catch overshoot. Item Description Requirements Free XY Move Z down to safe-zone DELTA (above safe zone)

The Bed Leveling menu groups together commands for calibrating the nozzle-to-bed distance. Different options will appear depending on your setup and the type of leveling you’ve enabled. Level Bed runs the default G29 procedure. For auto bed leveling this will deploy the probe, measure all points, and stop. For manual leveling (PROBE_MANUALLY or MESH_BED_LEVELING) you’ll be taken through a step-by-step process. Item Description Requirements Free XY Move Z down to safe-zone DELTA (above safe zone)

The Unified Bed Leveling menu groups together commands for leveling and mesh editing. Since this menu is very large and complex, it will be described in a separate document - coming soon.

Set the fan speed plus bed and/or nozzle temperature to the preset “PLA” settings. Use M145 S0 ... to change the temperatures and fan speed used for this menu. Item Description Requirements Preheat PLA Active Extruder, fan, bed HOTENDS == 1

Set the fan speed plus bed and/or nozzle temperature to the preset “ABS” settings. Use M145 S1 ... to change the temperatures and fan speed used for this menu. Item Description Requirements Preheat ABS Active Extruder, fan, bed HOTENDS == 1

The Control sub-menu includes the Temperature, Motion, and Filament sub-menus and Settings/EEPROM commands, plus a few other miscellanous hardware control commands. Item Description Requirements LCD Contrast » HAS_LCD_CONTRAST

Use this sub-menu to set the target temperature for nozzles and the bed, fan speed, AUTOTEMP, PID factors, and material preheat settings. Item Description Requirements Nozzle: -–- Current E Target Temperature HOTENDS == 1

When the ANTCLABS BLTouch probe acts up you can use the items in this sub-menu to reset and test the probe. Item Description Requirements Reset BLTouch Revive after an error

Take-screenshot function allows to create BMP image of currently displayed LCD screen and saves it in File List with specified name. Screenshots without file name are not saved, screenshots with an existing file name are overwritten.

Interfaces menu provide configuration for interface display timing in Stat Slideshow. Up to 10 additional (non-physical) interfaces can be added to the LCD.

A Page is an screen that can contain up to 12 interface bar graphs. Sub-menu allows to configure which interfaces are shown in a page. Up to 5 pages can be added to all interface graph screen and up to 12 interfaces per page. To add an interface to a page, it first must be added under /lcd interfaces sub-menu.

PIN code number allows to protect sensitive menus on the LCD screen. The PIN number will be asked if Read-Only mode is disabled and you add an IP address, reset or reboot the router. Default PIN is 1234

Since v6.0, LCD has a menu structure. Menu screens consist of buttons that are used to navigate the menus. A scrollbar is shown on the right side of the screen if it does not fit on the actual display. The screen can be dragged up or down to access more options if they are available. At the top of each menu screen is a "Back" button that jumps to the previous screen.

Interfaces menu displays all the Ethernet and Wireless interfaces. Bandwidth usage is shown similar to the All interface graph screen. From the Interfaces screen you can choose a specific interface to look at.

Registration Table (only for wireless) - menu which shows all the registered clients for the wireless interface and their respective signal strengths;

Stat Slideshow screen is similar to the "Stats" screen, but the interfaces are switched after they timeout. Settings for slideshow are stored in RouterOS submenu /lcd interface

Voltage type: 5v or 3v voltage input voltage,input is selectable. Because TFT can only work under 3.3 V voltage, so when the input voltage VIN is 5V, need through the 3.3 V voltage regulator IC step down to 3.3V , when the input voltage of 3.3 V, you need to use the zero resistance make J2 short , is equivalent to not through the voltage regulator IC for module and power supply directly.

Display screen is everywhere nowadays. Do you still remember the TVs or computer monitors 20 years ago? They were quadrate, huge and heavy. Now let’s look at the flat, thin and light screen in front of you, have you ever wondered why is there such a big difference?

Actually, the monitors 20 year ago were CRT (Cathode Ray Tube) displays, which requires a large space to run the inner component. And now the screen here in your presence is the LCD (Liquid Crystal Display) screen.

As mentioned above, LCD is the abbreviation of Liquid Crystal Display. It’s a new display technology making use of the optical-electrical characteristic of liquid crystal.

Liquid crystal is a state of substance that has both the characteristics of liquid and solid crystal. It don’t emit light itself, but it can let the light pass perfectly in specific direction. Meanwhile, liquid crystal molecule will rotate under the influence of a electric field, and then the light goes through it will rotate too. That said, liquid crystal can be a switch of light, which is the key in display technology.

STN LCD: STN is for Super-twisted Nematic. The liquid crystal in STN LCD rotate more angles than that in TN LCD, and have a different electrical feature, allowing STN LCD to display more information. There are many improved version of STN LCD like DSTN LCD (double layer) and CSTN LCD (color). This LCD is used in many early phones, computers and outdoor devices.

TFT LCD: TFT is for Thin Film Transistor. It’s the latest generation of LCD technology and has been applied in all the displaying scenario including electronic devices, motor cars, industrial machines, etc. When you see the word ‘transistor’, you may realize there’s integrated circuits in TFT LCD. That’s correct and the secret that TFT LCD has the advantage of high resolution and full color display.

In a simple way, we can divide TFT LCD into three parts, from bottom to top they are: light system, circuit system and light and color control system.In manufacturing process, we’ll start from inner light and color control system and then stretch out to whole module.

It’s accustomed to divide TFT LCD manufacturing process into three main part: array, cell and module. The former two steps are about the production of light and color control system, which contains TFT, CF (color filter) and LC (liquid crystal), named a cell. And the last step is the assembly of cell, circuit and light system.

Now let’s turn to the production of TFT and CF. Here is a common method called PR (photoresist) method. The whole process of PR method will be demonstrated in TFT production.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey