led lcd panel pinout quotation

You can get lcd panel pinout with an operation range that suits your specific application, choosing from a wide selection of suppliers. Source wholesale lcd panel pinout on Alibaba.com for your business and enjoy a wide variety and great deals.

With Alibaba.com, one of the world"s largest network of wholesale business suppliers, you can find the right shipment of wholesale lcd panel pinout. We have lcd screens for phone repairs available for all major brands and models. This includes models for which the manufacturer has discontinued replacement products, just look for old phone replacement lcd screens.

Explore the extensive selection of wholesale lcd panel pinout LCD displays, TFT, and HMI that can be used across a range of industries, including domestic, medical, industrial, automotive, and many others. You can choose from a number of standard industry sizes and find the lcd panels pinout that are applicable to your required use. If you would like options that allow a smaller environmental footprint due to low power consumption, you can browse the Chip-on-Glass (COG) LCDs. COGs are designed without PCBs so have a slimmer profile.

Liquid crystal display (LCD) is a flat panel display that uses the light modulating properties of liquid crystals. Liquid crystals do not produce light directly, instead using a backlight or reflector to produce images in colour or monochrome.

The EQUIFLUX® LED Display Graphics Lighting System is a high-powered LED linear light mounted on rigid metal PCB that provides bright, even lighting for retail and trade show display graphics. A variety of accessories are available to complete this plug-and-play solution, all available in multiple length options. These accessories make powering and installing the EQUIFLUX LED fixture quick and easy.

The Serial Monitor is a convenient way to view data from an Arduino, but what if you want to make your project portable and view sensor values without access to a computer? Liquid crystal displays (LCDs) are excellent for displaying a string of words or sensor data.

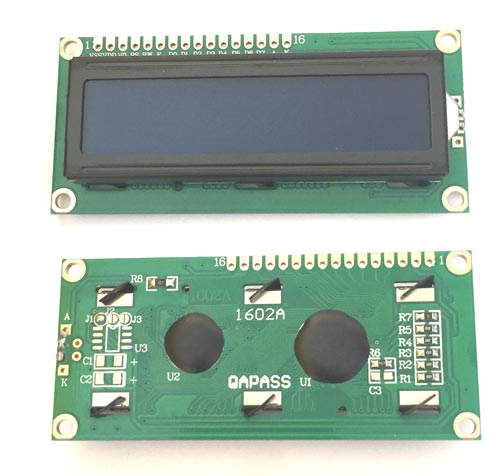

This guide will help you in getting your 16×2 character LCD up and running, as well as other character LCDs (such as 16×4, 16×1, 20×4, etc.) that use Hitachi’s LCD controller chip, the HD44780.

As the name suggests, these LCDs are ideal for displaying only characters. A 16×2 character LCD, for example, can display 32 ASCII characters across two rows.

Character LCDs are available in a variety of sizes and colors, including 16×1, 16×4, 20×4, white text on a blue background, black text on a green background, and many more.

One advantage of using any of these displays in your project is that they are “swappable,” meaning that you can easily replace them with another LCD of a different size or color. Your code will need to be tweaked slightly, but the wiring will remain the same!

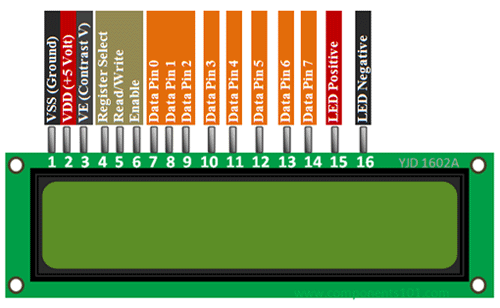

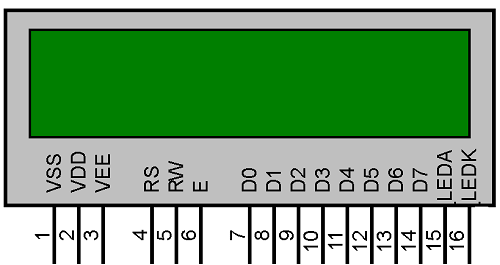

Before we get into the hookup and example code, let’s check out the pinout. A standard character LCD has 16 pins (except for an RGB LCD, which has 18 pins).

Vo (LCD Contrast) pin controls the contrast of the LCD. Using a simple voltage divider network and a potentiometer, we can make precise contrast adjustments.

RS (Register Select) pin is used to separate the commands (such as setting the cursor to a specific location, clearing the screen, etc.) from the data. The RS pin is set to LOW when sending commands to the LCD and HIGH when sending data.

R/W (Read/Write) pin allows you to read data from or write data to the LCD. Since the LCD is only used as an output device, this pin is typically held low. This forces the LCD into WRITE mode.

E (Enable) pin is used to enable the display. When this pin is set to LOW, the LCD ignores activity on the R/W, RS, and data bus lines; when it is set to HIGH, the LCD processes the incoming data.

The LCD has two separate power connections: one for the LCD (pins 1 and 2) and one for the LCD backlight (pins 15 and 16). Connect LCD pins 1 and 16 to GND and 2 and 15 to 5V.

Depending on the manufacturer, some LCDs include a current-limiting resistor for the backlight. It is located on the back of the LCD, close to pin 15. If your LCD does not contain this resistor or if you are unsure whether it does, you must add one between 5V and pin 15. It should be safe to use a 220 ohm resistor, although a value this high may make the backlight slightly dim. For better results, check the datasheet for the maximum backlight current and choose an appropriate resistor value.

Let’s connect a potentiometer to the display. This is necessary to fine-tune the contrast of the display for best visibility. Connect one side of the 10K potentiometer to 5V and the other to Ground, and connect the middle of the pot (wiper) to LCD pin 3.

That’s all. Now, turn on the Arduino. You will see the backlight light up. As you turn the potentiometer knob, you will see the first row of rectangles appear. If you have made it this far, Congratulations! Your LCD is functioning properly.

We know that data is sent to the LCD via eight data pins. However, HD44780-based LCDs are designed so that we can communicate with them using only four data pins (in 4-bit mode) rather than eight (in 8-bit mode). This helps us save 4 I/O pins!

The sketch begins by including the LiquidCrystal library. This library comes with the Arduino IDE and allows you to control Hitachi HD44780 driver-based LCD displays.

Next, an object of the LiquidCrystal class is created by passing as parameters the pin numbers to which the LCD’s RS, EN, and four data pins are connected.

In the setup, two functions are called. The first function is begin(). It is used to initialize the interface to the LCD screen and to specify the dimensions (columns and rows) of the display. If you’re using a 16×2 character LCD, you should pass 16 and 2; if you’re using a 20×4 LCD, you should pass 20 and 4.

In the loop, the print() function is used to print “Hello world!” to the LCD. Please remember to use quotation marks " " around the text. There is no need for quotation marks when printing numbers or variables.

The function setCursor() is then called to move the cursor to the second row. The cursor position specifies where you want the new text to appear on the LCD. It is assumed that the upper left corner is col=0 and row=0.

There are many useful functions you can use with LiquidCrystal Object. Some of them are listed below:lcd.home() function positions the cursor in the upper-left of the LCD without clearing the display.

lcd.scrollDisplayRight() function scrolls the contents of the display one space to the right. If you want the text to scroll continuously, you have to use this function inside a for loop.

lcd.scrollDisplayLeft() function scrolls the contents of the display one space to the left. Similar to the above function, use this inside a for loop for continuous scrolling.

lcd.display() function turns on the LCD display, after it’s been turned off with noDisplay(). This will restore the text (and cursor) that was on the display.

The CGROM stores the font that appears on a character LCD. When you instruct a character LCD to display the letter ‘A’, it needs to know which dots to turn on so that we see an ‘A’. This data is stored in the CGROM.

CGRAM is an additional memory for storing user-defined characters. This RAM is limited to 64 bytes. Therefore, for a 5×8 pixel LCD, only 8 user-defined characters can be stored in CGRAM, whereas for a 5×10 pixel LCD, only 4 can be stored.

Creating custom characters has never been easier! We’ve developed a small application called Custom Character Generator. Can you see the blue grid below? You can click on any pixel to set or clear that pixel. And as you click, the code for the character is generated next to the grid. This code can be used directly in your Arduino sketch.

After including the library and creating the LCD object, custom character arrays are defined. The array consists of 8 bytes, with each byte representing a row in a 5×8 matrix.

To complete the power supply circuit of a LED screen we will have to connect the LED cabinet with the electrical network. Let’s look at the most common types of power wiring installations:

To complete the power set up, you must feed the power supplies of each cabinet, by plugging it. To do this, you extend the cables from the electrical panel to the interior of the cabinets using the side holes. Contact a professional electrician to build the electrical panel. You must calculate the screen’s power consumption from the technical sheet (consumption per square meter) and specify the circuit breaker and the differential switches following the picture below.

The electrical panel of your screen requires several circuit breakers. The amount of circuit breakers will be determined by the size of your screen and the number of cabinets.

Liquid Crystal Displays or more commonly known as LCDs are one of the most common electronic components which help us interact with an equipment or a device. Most personal portable equipment and even gigantic industrial equipment utilize a custom segment display to display data. For many portable consumer electronics, a segment LCD display is one of the biggest contributors to the overall cost of the device, hence designing a custom segment display can drive the cost down while also utilizing the display area in the most optimum manner. These displays have the lowest cost per piece, low power requirements, and a low tooling fee too.

At first thought, designing a custom segment LCD might look like a Herculean task, but trust me that it is easier than it seems. In this article, we have summarised and compared the display types and available technologies which are required to construct a custom segment LCD. We have also provided a flowchart that can act as a step-by-step guide while you design your own custom LCD. We have also provided the process we followed, a require gathering sheet we used for communicating our needs to the manufacturer, and a few other data and the quotation we received from the manufacturer.

LCD Bias– It denotes the number of different voltage levels used in driving the segments, static drives (explained later in this article) only have 2 voltage levels or 2 bias voltage while multiplex drives have multiple voltage levels. For example, 1/3 will have 4 bias voltages.

LCDs utilizes the light modulating properties of liquid crystals which can be observed by using polarizing filters. Polarizing filters are special materials that have their molecules aligned in the same direction. If the light waves passing through polarisers have the same orientation as the filter, then the molecules of lights are absorbed by the filter, hence reducing the intensity of light passing through it, making it visible.

A custom LCD is important for maximizing the efficiency of the display area by adding custom symbols and characters. It also helps in reducing the cost and improving energy efficiency of the product. A higher number of custom symbols and specified placement of numerical and alphanumerical characters make the display more informative and readable for the user. This makes it look better than the plain old boring displays we get in the market. Furthermore, we can specify the viewing angle, contrast, and other specifications which can increase durability or give a better value for money for our intended usage. A typical Custom Segment display is shown below, we will also show you how to design and fabricate the same further in the article.

The LCD display doesn’t emit any light of its own, therefore it requires an external source of illumination or reflector to be readable in dark environments.

While designing a custom segment LCD display, we have the leverage of choosing a lot of parameters that affect the final product. From the color of the display to the illumination technique and color of illumination as well as the type of input pins. Some important considerations we need to take while designing a custom 7 segment display are - the type of display, i.e. positive or negative, illumination method, driving technique, polarising type, and connection method. All these design criteria are explained below:

So, which one should you choose? When the displays are to be used in areas with higher ambient light, we should select positive segment LCD display as it has better visibility than negative segment LCD displays without using a backlight.

As we know that LED displays don’t emit any light, hence to illuminate it and make it visible in a dark environment, we can use different methods of illumination. The most common LCD Illumination methods are compared below:

For displays that need to be used for budget-friendly devices that should be small and rugged, LED lights are preferred for the displays due to the high durability and low cost of operations. For high brightness, CCFL and Incandescent lights can be used.

A polarizer film is the most important component of an LCD display, which makes it possible to display characters by controlling the light. There are 3 types of polarizers that can be used in the LCD display, the properties and difference are given below:

If your products need to be used with a switchable backlight, then trans-reflective reflectors are best to be used for front reflectors. If the device has to be used without backlight, then we can select a reflective polarizer for the back-panel as it gives the best contrast ratio.

If your displays have fewer segments, then static LCD drive is preferred as it is easier to control and cheaper to construct, and has a better contrast ratio. But let’s say that if the number of segments in the display are more than 30-40 then a multiplex LCD drive should be preferred as it has multiple common pins, hence reducing the total number of pins required to drive the display.

Choosing a connector type!!! For the prototyping phase or if you need to connect your LCD display on a Microcontroller directly, a pin type connector is the best and most economical option you have. If you need to connect your LCD display in a final product with a high volume of production which also requires to be extremely durable, but at the same time should not take up a lot of space, a Flex type LCD Connector will work best for you

LCDs have limited viewing angles and when seen from an angle they lose contrast and are difficult to be observed. The viewing angle is defined by the angles perpendicular to the center of the display towards its right, left, up, and down which are denoted by the notations 3:00, 9:00, 12:00, and 6:00 respectively. The viewing angle of LCD can be defined as the angle w.r.t. to the bias angle at which the contrast of segments is legible.

To improve the viewing angle in an LCD, a Bias is incorporated in the design which shifts the nominal viewing angle with an offset. Another technique is to increase the Voltage, it affects the bias angle, making the display crisper when viewed from a direction.

For example, the viewing angle of a TN type TFT LCD is 45-65 degrees. Extra-wide polarising film (EWP) can increase the viewing angle by 10 degrees, using an O film polariser can make the viewing angles 75 degrees but these come at a cost of reduced contrast.

LCD Control chip or LCD driver chips can be mounted on the flex cable, display, or externally on a PCB. The placement of LCD control chip can affect the cost and size of the display. The 2 most common methods of chip placement are-Chip of Board (COB)and Chip on Glass(COG) which are described below:

We planned to design an air quality monitoring system for which we needed a custom segment LCD panel for an air quality monitoring device. Our product needs to display the following data: 2.5-micron and 10-micron particulate matter (PM) suspended in the air; the units should be in parts per million (PPM). CO2 in the air in PPM along with total volatile organic compounds present in the air in parts per billion (PPB). To make the product more usable, we included time in 24-hour format, Temperature in ºC, Battery status, loudspeaker status, Bluetooth status, and Wi-Fi status. And for some personal touch, we also added how good the air quality in the room is by using 3 different smileys.

We realized that it was impossible to provide all these data in a generic LCD available in the market, thus decided to build a custom LCD for our project.

A step-by-step flowchart is shown below to walk you through each and every step of selecting components and getting your custom segment LCD manufactured.

Usually, the displays are mounted at a height of 4.5 feet from the ground, thus the viewing direction was selected to be 12"O clock with an operating frequency of 64Hz. We selected a Transmissive polarizer for the front glass and a reflective polarizer for the rear glass so that the natural light can pass through the front panel and the display can achieve the maximum contrast without the need for backlighting and we opted for the pin type connectors as they are easy for prototyping and are suitable for harsh environment with a lot of vibrations and shocks which best suited our purpose.

We mailed our requirements to multiple LCD manufacturers, (you will find a lot of LCD manufacturers on the Internet). Most LCD manufacturers have competitive pricing, and reply within a week. A sample requirement sheet is shown above which a customer needs to fill to specify all the details to the manufacturer.

This is a sample Custom Segment LCD quotation we got from one of the manufacturers. As you can see, the cost is based on the quantity. Higher the quantity, lower the cost. Apart from the cost per quantity, there is one more component called tooling fees. Tooling fee is a one-time fee charged by the manufacturer. It is for the technical design, support, and customization of the product. Customization of PCB or tooling of LCD can drive the tooling price higher or lower.

The tooling time and cost depend on how detailed and accurate designs you sent to the manufacturer. They then send the exact dimensions and technical details of the product they will be manufacturing. Once you confirm the design, they manufacture and ship the product which might take 4-8 weeks to arrive depending on the size of the order and mode of transportation selected.

A custom segment LCD can help you personalize your product while also saving the overall cost of your product. The whole process will take you around 2-3 months, which will include the designing phase, prototyping phase, and getting your custom segment LCDs delivered to your doorstep. Higher ordering quantity will reduce the cost per piece of each unit, thus driving down the cost of your final product.

Color LCD module PS302-04043-00 is composed of the amorphous silicon thin film transistor liquid crystal display (a-Si TFT LCD) panel structure with driver LSIs for driving the TFT (Thin Film Transistor) array and a dual mode backlight. The a-Si TFT LCD panel structure is injected liquid crystal material into a narrow gap between the TFT array glass substrate and a color-filter glass substrate. Color (Red, Green, Blue) data signals from a host system (e.g. signal generator, etc.) are modulated into best form for active matrix system by a signal processing board, and sent to the driver LSIs which drive the individual TFT arrays. The TFT array as an electro-optical switch regulates the amount of transmitted light from the backlight assembly, when it is controlled by data signals. Color images are created by regulating the amount of transmitted light through the TFT array of red, green and blue dots.

LED backlighting is the most commonly used backlight for small, LCD panels. Light-emitting diodes, or LEDs, are practical components for a light source because of their small size. LED backlighting is popular due to its overall low cost, long life, variety of colors and high brightness.

LED backlights are housed in a light box that has a diffuser to evenly distribute the LED light. The light box is then mounted behind the LCD’s viewing area. The LED backlight comes in two configurations: array and edge lit. The array configuration has the LEDs mounted in a uniform, grid layout within the light box. This configuration gives off a very bright, even light. The disadvantage of an array configuration is that it requires a thick light box design to accommodate the number of LEDs required. The high number of LEDs in this configuration also means it consumes more power.

The other configuration for LED backlights is edge lit. An edge lit configuration is the most commonly used construction for LED backlights. This configuration mounts the LEDs along one edge of the light box. The layout results in a thin design. Edge lit also uses less LEDs overall and therefore consumes less power than an array configuration.

Another type of backlight options is the use of fiber optic technology. Fiber optic backlights use sheets of fiber optic woven cloth and are bundled by a ferrule (metal cap) to an LED or halogen light source. Advantages for the fiber optic technology includes low voltage, low power, and a very uniform brightness. This type of backlighting is ideal for custom display shapes or sizes however it is priced at a higher cost compared to other technologies available.

A third type of backlight option available uses an electroluminescent (EL) panel. The EL backlight is constructed of a series of different material layers that work together to create the light. The EL panel generates light when an electric current (AC power) is applied to its conductive surfaces. The advantage with EL backlighting is its low power consumption, no heat emission, and overall thin composition. EL backlighting is limiting in that it requires an invertor to generate the VAC needed to emit the light.

The last common backlight option available are cold cathode fluorescent lamps (CCFLs). CCFL backlights are a cost effective option typically found in graphic displays. The CCFL backlight for LCDs is usually configured with the lamp on the edge of a diffuser to distribute the light. An inverter is required to supply the voltage required by the fluorescent lamp. CCFLs offer a bright white light with low power consumption. This backlight option is not ideal for cold-temperature applications (less than 15°C) as the light output decreases with decreased ambient temperature.

There are many different backlight options available for your LCD. The most common types are LED, fiber optic, EL, and CCFL backlights. Cost and application of your product will have the highest influences on which backlight technology is best for your LCD.

One of these choices is deciding between an LCD display or an LED video wall. Continue reading to find out more about the basics, as well as the advantages and disadvantages of each solution.

Most people are familiar with LCD technology, which stands for Liquid Crystal Display. These types of displays have a massive presence in this world, used in living rooms to watch movies, fast-food restaurants to showcase menus, airports to show flight schedules, and everything in between. LCD technology was developed in the 1960s and has been used worldwide as a standard for roughly 20 years. It is a tried-and-true technology that has stood the test of time and will be around for the foreseeable future.

On an LCD screen, the panel is illuminated by a light source and works through reflection or transmission of light. Overall, LCD displays have better viewing angles and less glare than LED screens. This technology was designed to be energy efficient and tends to be lighter in weight.

An LCD video wall is made up of multiple LCD panel monitors mounted on a surface to create a digital canvas, which then work together to create a unified experience. They operate 24/7 at a high brightness and have thin bezels that help create a seamless look when the displays are placed next to one another.

Bezel thickness and the brightness rating are among key attributes to consider for an LCD video wall display. Here is what each of these means and why.

Nits:Brightness is measured in Nits. A higher Nit value means the display will be brighter. A brighter display is necessary in a room that sees plenty of direct sunlight, or if the intent is to draw in visitors from far away. With LCD video walls, the price of the hardware goes up as the display size and brightness increase, and the bezel width decreases.

The next item to consider is the type of content that will be displayed on your video wall. LCD displays have high resolution screens — modern 4K displays have over 8 million pixels! This means that the content being displayed is highly detailed and crystal-clear. A viewer could stand less than 1 foot away from the screen and be able to see exactly what is being shown on the screen.

Like previously mentioned with LCD video walls, an important consideration in the decision-making process is the type of content that will be displayed on the video wall. LED video walls suffer from image degradation and pixilation from up close, so fine details will be lost, and text will be illegible. If detail from up close is important, LCD displays are much better suited for that situation.Content examples that are well-suited for an LCD video wall:

Video walls are relatively new. But LCD technology has had decades of mainstream adoption, and with that comes both familiarity and lower costs. If those are important to you, then an LCD video wall is likely the right choice.

LED video walls are similar to LCD video walls, but the digital canvas is built using LED panels. Individual LED panels can be anywhere from 12”x12” to 36”x18”, which is much smaller than LCD displays. LED panels have a larger presence in this world than most might think—they are found indoors and outdoors at stadiums, arenas, concert venues, airports, and in use as large digital advertisements in iconic places such as Times Square.

The module is a small rectangular board that contains all the individual LEDs (light-emitting diodes).Unlike LCD, there is no glass or color filter on the LED video wall panels. The individual diodes that are placed on the modules produce both color and light.

One of the most impressive features of LED panels is that they can be combined to create almost any shape, without a bezel interrupting the digital canvas. LED video wall panels can be placed on curved surfaces, 90-degree edges, and other non-standard surfaces. The smaller size of the panels in relation to LCD video wall displays means they can fill more space on a surface—they aren’t limited to standard 46” and 55” sizes as are LCD video wall displays.

The most important factor to consider when scoping LED panels for a video wall is what is referred to as “pixel pitch.” The pixel pitch is effectively the distance between each pixel on the LED panel—a pixel pitch of 6mm means each pixel is spaced 6 millimeters away from the adjacent pixel. The smaller the pixel pitch, the smaller the distance is between each pixel, which means there are more pixels per square inch on the digital canvas.

Pixel pitch factors into viewing distance. When the pixels are close together, the image is more detailed and can be viewed comfortably by others from a close distance. But when the pixels are spaced further apart, a viewer needs to stand further away to view the image clearly.

Lastly, pixel pitch impacts the price of the LED video wall more than any other factor. For example, a 2mm pixel pitch LED video wall costs significantly more than its 10mm pixel pitch counterpart.

As is the case with an LCD video wall, an LED video wall will add exciting drama and premium value to showcase spaces. LED panel displays don’t enjoy the benefit of decades of mainstream adoption as do their LCD counterparts. However, the technology curve is increasing their availability and lowering their costs. At this time, an LED video wall will have higher upfront costs compared to an LCD video wall. If cost is the main concern, then an LED video wall system will not likely fit into your budget

An LED video wall would be well-suited and cost-justified if the intent of the video wall is to provide an immersive viewing experience from a further distance. This could be content with lots of movement, animation, imagery, and bright colors to draw viewers into your space or provide a unique experience.

Aside from LED video wall cost, there are other factors to consider which could make an LED video wall system the frontrunner for your project. Here are the advantages and disadvantages to consider:

Limitless shapes and sizes:the smaller size of LED panels allows them to be combined to create unique canvases, including curved, 90-degree edge, and other combinations not possible with LCD displays

Easy maintenance and service; high reliability:LED module replacement takes seconds with little effort; LED panels are rated with a lifetime of 80,000-100,000 hours, depending on the product

Low-Voltage Differential Signaling (LVDS) cables typically connect a flat panel display to its control board. While some panel and board combinations may work with a stock cable often a custom cable is needed. This is because each flat panel and control board has a unique pinout and connector required to mate with it. Our engineers will work with you to design your custom cable, to determine the connectors needed, the pinout required to properly connect the components, and any other items that may be needed such as EMI protection and shielding, etc.

Low Voltage Differential Signaling (LVDS) cables with twisted pairs. LVDS cables are custom made to interface between your LCD and Control/SBC or Embedded Mother Board. Shielding options available. Lengths vary from 3.00 inches, to as long as 15.00 feet. Fully Customized to meet your exact needs.

With all of the different LCD panel makers, board makers, Inverter and LED Driver makers out there, the endless variety of components and peripherals yield almost endless connector and pin mapping configurations. Our expertise that has made us an industry pioneer is connecting all of these various devices together with quality products. There are thousands of different connectors that appear on these difference devices. Finding a cable house that is tooled for all of these different parts is hard enough. Finding one with the experience and know how to design, scramble pin maps, maintain differential impedance, shield products to mitigate EMI, all while knowing what hidden aspects of the cable design to look for is our business. With well over 10,000 unique designs on file, all with unique bill of materials, and customized to each customers requirements, our experience helps to assist our customers on all levels of the cable design, and subsequent product support thereafter.

In some cases LCD panels will only have (1) connector on them which contains both data and backlight signals. This cable generally yields a "Y" or "V" shaped cable. This is because the SBC (single board computer), Controller or Embedded Motherboard generally has seperate DATA and BACKLIGHT connectors. Is you LCD panel 18bit or 24bit? PWM or Analog dimming? Do you know what screen orientation you need? Is your panel Dual, Single or even Quad Channel LVDS? All of these factors and many more yield the final cable design. This is where we come in. With over 10,000 unique cable designs that we can produce at an time we have the experience to help offer guidance and expertise where needed.

50in diagonal, UHD, ultra slim, LED backlight, 24x7 reliability, metal bezel, landscape and portrait, wide array of inputs, OPS slot, 500 nit brightness, speakers, RS232 and LAN control

55in. diagonal edge-lit LED professional LCD. 24x7 reliability. 1920x1080. 700 nits brightness. Data, video, HD-SDI inputs. RS-232, Ethernet control. Landscape and portrait. Requires at least 1.2 in. mount depth (Compatible with WMT-MXL only).

58in diagonal, UHD, ultra slim, LED backlight, 24x7 reliability, metal bezel, landscape and portrait, wide array of inputs, OPS slot, 500 nit brightness, speakers, RS232 and LAN control

65in diagonal, UHD, ultra slim, LED backlight, 24x7 reliability, metal bezel, landscape and portrait, wide array of inputs, OPS slot, 500 nit brightness, speakers, RS232 and LAN control

55in Transparent display, OLED panel, black, ERO bonded glass, HDMI x4, DP x1 inputs, FHD (1920x1080), landscape or portrait - inverted or tiling mounting possible, internal power, standard mount

55in Transparent display, OLED panel, black, ERO bonded glass, HDMI x4, DP x1 inputs, FHD (1920x1080), landscape or portrait - inverted or tiling mounting possible, internal power, straight mount

Clarity Matrix LX46HD: 46" 1920x1080, 450 nit LCD video wall system. Includes 1 LCD module, required power supply, quad controller electronics and mount. Landscape Only.

Clarity Matrix LX46HD with ERO: 46" 1920x1080, 450 nit LCD video wall system. Includes 1 LCD module, required power supply, quad controller electronics and mount. Landscape Only.

Clarity Matrix LX46HD: 46" 1920 x 1080, 450 nit LCD video wall system. Includes 1 LCD module, required power supply, quad controller electronics and mount. Portrait Only. Special Order Item Longer Lead time applies.

Clarity Matrix LX46 3D: 46" WXGA 3D LCD video wall system. Includes 1 LCD module, required power supply, quad controller electronics and mount. Landscape Only.

Clarity Matrix LX55HD: 55" 1920x1080, 450 nit LCD video wall system. Includes 1 LCD module, required power supply, quad controller electronics and mount. Landscape Only.

Clarity Matrix LX55HD with ERO: 55" 1920x1080, 450 nit LCD video wall system. Includes 1 LCD module, required power supply, quad controller electronics and mount. Landscape Only.

Clarity Matrix LX55HD with ERO: 55" 1920x1080, 450 nit LCD video wall system. Includes 1 LCD module, required power supply, quad controller electronics and mount. Portrait Only. Special Order Item Longer Lead time applies.

Clarity Matrix MX46HD: 46" 1920x1080 LCD video wall system. Includes 1 LCD module, required power supply, quad controller electronics and mount. Landscape Only.

Clarity Matrix MX55: 55" 1920x1080 LCD video wall system. Includes 1 LCD module, required power supply, quad controller electronics and mount. Landscape Only.

Clarity Matrix MX55 with ERO: 55" 1920x1080 LCD video wall system. Includes 1 LCD module, required power supply, quad controller electronics and mount. Landscape Only.

Clarity Matrix MX55: 55" 1920x1080 LCD video wall system. Includes 1 LCD module, required power supply, quad controller electronics and mount. Portrait Only. Special Order Item Longer Lead time applies.

46in diagonal, Full HD, ultra slim, LED backlight, 24x7 reliability, metal bezel, landscape/portrait mode, VGA, HDMI, DVI, Video inputs, RS232 control.

46in diagonal touchscreen, full HD, ultra slim, LED backlight, 24x7 reliability, metal bezel, landscape/portrait mode, VGA, HDMI, DVI, DisplayPort inputs, RS-232 control, speakers.

55in diagonal touchscreen, full HD, ultra slim, LED backlight, 24x7 reliability, metal bezel, landscape/portrait mode, VGA, HDMI, DVI, DisplayPort inputs, RS-232 control, speakers.

55 in. diagonal edge-lit LED professional LCD. Ultra slim, narrow bezel, low power, and lightweight. 1920x1080 resolution with 400 nits brightness . DVI, HDMI, Display Port, VGA inputs. Supports up to 10x10 Video Wall mode. IR, RS-232, and Ethernet control. Landscape and portrait.

15 inch Black HID Compliant 5-wire Resistive Touchscreen LCD, dual Serial and USB controller, VGA, external DC power supply, speakers, -3 to 25 degree tilt range, 75mm VESA compatible.

17 inch Black HID Compliant single-touch 5-wire resistive LED LCD, dual Serial and USB controller, VGA, internal power, DC power connector, speakers, -5 to 90 degree tilt range, 75 mm and 100mm VESA compatible.

17 inch Black HID Compliant 5-wire Resistive Touchscreen edge-lit LED LCD, USB controller, VGA, internal power, speakers, -5 to 90 degree tilt range, 100mm VESA compatible.

19" Black 5-Wire Resistive Touch Screen LCD with dual serial/USB Driver, Analog/DVI-D, internal power, speakers, 5 to 90 tilt - Supports MSR Kit 997-5618-00

32-inch wide black projected capacitive multi-touch FHD edge-lit LED LCD, USB controller, HDMI, DP, DVI-D and VGA inputs, Control via RS-232, internal power, speakers, 600 x 200 mm, 200 x 200 mm VESA compatible, no desk stand.

75in diagonal, UHD, D-LED backlight, 500 nit brightness, 24x7 reliability, single- or quad-source viewing, speakers, embedded ContentSmart media player, landscape and portrait

86in diagonal, UHD, D-LED backlight, 500 nit brightness, 24x7 reliability, single- or quad-source viewing, speakers, embedded ContentSmart media player, landscape and portrait

86in diagonal, UHD, D-LED backlight, 500 nit brightness, 24x7 reliability, single- or quad-source viewing, speakers, embedded ContentSmart media player, landscape and portrait, ERO with Gorilla Glass, 20 pt IR touch

98in diagonal, UHD, D-LED backlight, 400 nit brightness, 24x7 reliability, single- or quad-source viewing, speakers, embedded ContentSmart media player, landscape only

TD3200 LookThru 32 inch Transparent LCD Display Box, White, ERO(TM) Bonded Glass, HDMI Input, 1366x768 res, 29.5in x 17.5in x 15.0in (WxHxD), 200 x 200 mm VESA, External Power.

1) TWA Series 0.9mm LED Cabinet for MIDDLE/BOTTOM position with Integrated DUAL Power Supply, Leyard Control Software and power, control and video interconnects.

1) TWA Series 0.9mm LED Cabinet for MIDDLE/BOTTOM position with Integrated SINGLE Power Supply, Leyard Control Software and power, control and video interconnects.

1) TWA Series 0.9mm LED Cabinet for TOP position with DUAL Integrated Power Supply, Leyard Control Software and power, control and video interconnects.

1) TWA Series 0.9mm LED Cabinet for TOP position with SINGLE Integrated Power Supply, Leyard Control Software and power, control and video interconnects.

75in diagonal, UHD, D-LED backlight, 500 nit brightness, 24x7 reliability, MediaPlex Plus Processing, speakers, OPS slot, landscape and portrait, ERO with Gorilla Glass

75in diagonal, UHD, D-LED backlight, 500 nit brightness, 24x7 reliability, MediaPlex Plus Processing, speakers, OPS slot, landscape and portrait, ERO with Gorilla Glass, 32 pt IR touch

86in diagonal, UHD, D-LED backlight, 500 nit brightness, 24x7 reliability, MediaPlex Plus Processing, speakers, OPS slot, landscape and portrait, ERO with Gorilla Glass

86in diagonal, UHD, D-LED backlight, 500 nit brightness, 24x7 reliability, MediaPlex Plus Processing, speakers, OPS slot, landscape and portrait, ERO with Gorilla Glass, 32 pt IR touch. Single TouchMark key included.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey