character lcd module datasheet free sample

16×2 LCD is named so because; it has 16 Columns and 2 Rows. There are a lot of combinations available like, 8×1, 8×2, 10×2, 16×1, etc. But the most used one is the 16*2 LCD, hence we are using it here.

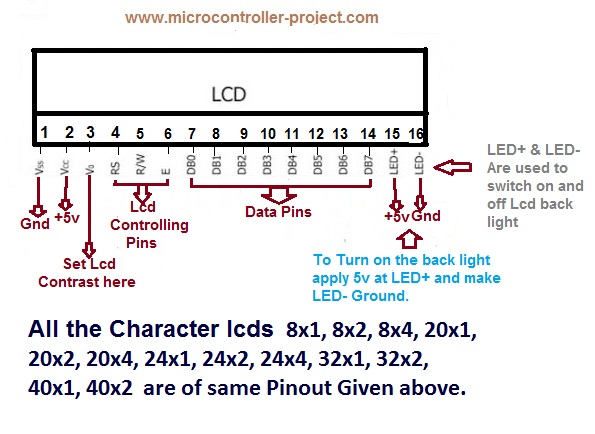

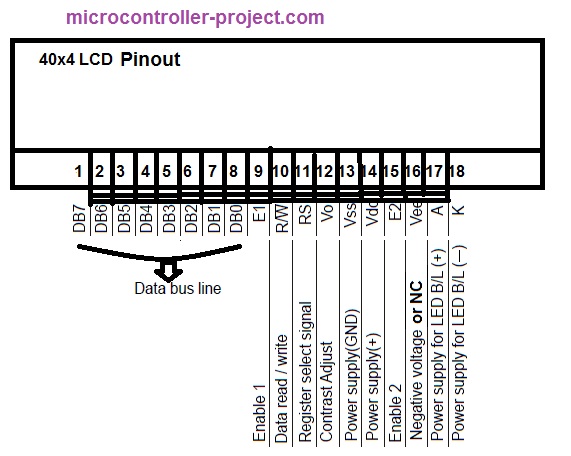

All the above mentioned LCD display will have 16 Pins and the programming approach is also the same and hence the choice is left to you. Below is the Pinout and Pin Description of 16x2 LCD Module:

These black circles consist of an interface IC and its associated components to help us use this LCD with the MCU. Because our LCD is a 16*2 Dot matrix LCD and so it will have (16*2=32) 32 characters in total and each character will be made of 5*8 Pixel Dots. A Single character with all its Pixels enabled is shown in the below picture.

So Now, we know that each character has (5*8=40) 40 Pixels and for 32 Characters we will have (32*40) 1280 Pixels. Further, the LCD should also be instructed about the Position of the Pixels.

It will be a hectic task to handle everything with the help of MCU, hence an Interface IC like HD44780 is used, which is mounted on LCD Module itself. The function of this IC is to get the Commands and Data from the MCU and process them to display meaningful information onto our LCD Screen.

The LCD can work in two different modes, namely the 4-bit mode and the 8-bit mode. In 4 bit mode we send the data nibble by nibble, first upper nibble and then lower nibble. For those of you who don’t know what a nibble is: a nibble is a group of four bits, so the lower four bits (D0-D3) of a byte form the lower nibble while the upper four bits (D4-D7) of a byte form the higher nibble. This enables us to send 8 bit data.

As said, the LCD itself consists of an Interface IC. The MCU can either read or write to this interface IC. Most of the times we will be just writing to the IC, since reading will make it more complex and such scenarios are very rare. Information like position of cursor, status completion interrupts etc. can be read if required, but it is out of the scope of this tutorial.

The Interface IC present in most of the LCD is HD44780U,in order to program our LCD we should learn the complete datasheet of the IC. The datasheet is given here.

There are some preset commands instructions in LCD, which we need to send to LCD through some microcontroller. Some important command instructions are given below:

The Displaytech 162J series is a lineup of 16x2 character LCD modules. These modules have an 80x36 mm outer dimension with 66x16 mm viewing area on the display. The 162J 16x2 LCD displays are available in STN or FSTN LCD modes with or without an LED backlight. The backlight color options include yellow green, white, blue, pure green, or amber color. Get a free quote direct from Displaytech for a 16x2 character LCD display from the 162J series.

The Displaytech 162H series is a lineup of 16x2 character LCD modules. These modules have an 84x44 mm outer dimension with a 66x16 mm viewing area on the display. The 162H 16x2 LCD displays are available in STN or FSTN LCD modes with or without an LED backlight. The backlight color options include yellow green, white, blue, pure green, or amber color. Get a free quote direct from Displaytech for a 16x2 character LCD display from the 162H series.

The Serial Monitor is a convenient way to view data from an Arduino, but what if you want to make your project portable and view sensor values without access to a computer? Liquid crystal displays (LCDs) are excellent for displaying a string of words or sensor data.

This guide will help you in getting your 16×2 character LCD up and running, as well as other character LCDs (such as 16×4, 16×1, 20×4, etc.) that use Hitachi’s LCD controller chip, the HD44780.

When activated by an electric current, these liquid crystals become opaque, blocking the backlight that is located behind the screen. As a result, that area will be darker than the rest. By activating the liquid crystal layer in specific pixels, characters can be generated.

As the name suggests, these LCDs are ideal for displaying only characters. A 16×2 character LCD, for example, can display 32 ASCII characters across two rows.

If you look closely, you can see tiny rectangles for each character on the screen as well as the pixels that make up a character. Each of these rectangles is a grid of 5×8 pixels.

Character LCDs are available in a variety of sizes and colors, including 16×1, 16×4, 20×4, white text on a blue background, black text on a green background, and many more.

One advantage of using any of these displays in your project is that they are “swappable,” meaning that you can easily replace them with another LCD of a different size or color. Your code will need to be tweaked slightly, but the wiring will remain the same!

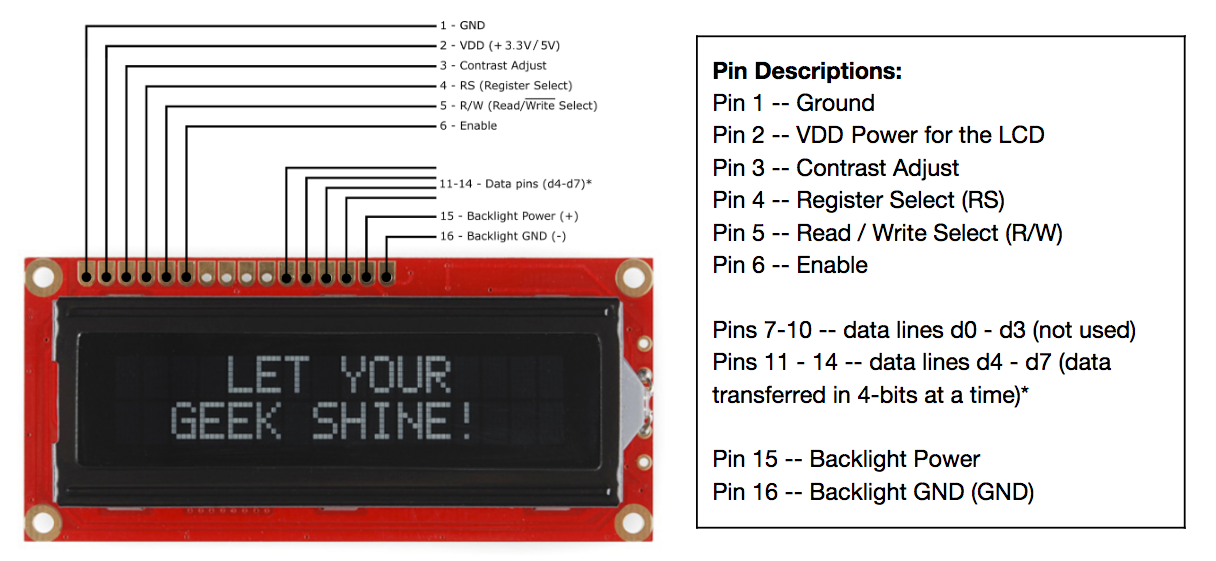

Before we get into the hookup and example code, let’s check out the pinout. A standard character LCD has 16 pins (except for an RGB LCD, which has 18 pins).

Vo (LCD Contrast) pin controls the contrast of the LCD. Using a simple voltage divider network and a potentiometer, we can make precise contrast adjustments.

RS (Register Select) pin is used to separate the commands (such as setting the cursor to a specific location, clearing the screen, etc.) from the data. The RS pin is set to LOW when sending commands to the LCD and HIGH when sending data.

R/W (Read/Write) pin allows you to read data from or write data to the LCD. Since the LCD is only used as an output device, this pin is typically held low. This forces the LCD into WRITE mode.

E (Enable) pin is used to enable the display. When this pin is set to LOW, the LCD ignores activity on the R/W, RS, and data bus lines; when it is set to HIGH, the LCD processes the incoming data.

D0-D7 (Data Bus) pins carry the 8 bit data we send to the display. To see an uppercase ‘A’ character on the display, for example, we set these pins to 0100 0001 (as per the ASCII table).

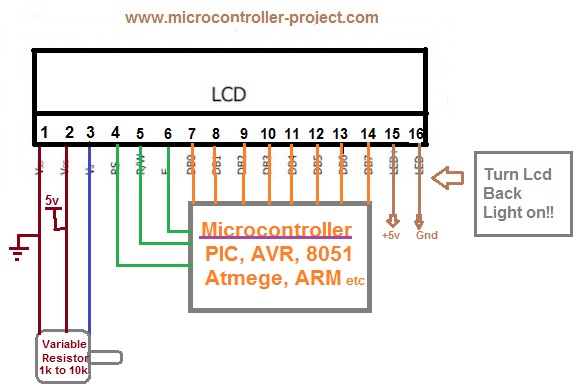

The LCD has two separate power connections: one for the LCD (pins 1 and 2) and one for the LCD backlight (pins 15 and 16). Connect LCD pins 1 and 16 to GND and 2 and 15 to 5V.

Depending on the manufacturer, some LCDs include a current-limiting resistor for the backlight. It is located on the back of the LCD, close to pin 15. If your LCD does not contain this resistor or if you are unsure whether it does, you must add one between 5V and pin 15. It should be safe to use a 220 ohm resistor, although a value this high may make the backlight slightly dim. For better results, check the datasheet for the maximum backlight current and choose an appropriate resistor value.

Let’s connect a potentiometer to the display. This is necessary to fine-tune the contrast of the display for best visibility. Connect one side of the 10K potentiometer to 5V and the other to Ground, and connect the middle of the pot (wiper) to LCD pin 3.

That’s all. Now, turn on the Arduino. You will see the backlight light up. As you turn the potentiometer knob, you will see the first row of rectangles appear. If you have made it this far, Congratulations! Your LCD is functioning properly.

We know that data is sent to the LCD via eight data pins. However, HD44780-based LCDs are designed so that we can communicate with them using only four data pins (in 4-bit mode) rather than eight (in 8-bit mode). This helps us save 4 I/O pins!

The sketch begins by including the LiquidCrystal library. This library comes with the Arduino IDE and allows you to control Hitachi HD44780 driver-based LCD displays.

Next, an object of the LiquidCrystal class is created by passing as parameters the pin numbers to which the LCD’s RS, EN, and four data pins are connected.

In the setup, two functions are called. The first function is begin(). It is used to initialize the interface to the LCD screen and to specify the dimensions (columns and rows) of the display. If you’re using a 16×2 character LCD, you should pass 16 and 2; if you’re using a 20×4 LCD, you should pass 20 and 4.

In the loop, the print() function is used to print “Hello world!” to the LCD. Please remember to use quotation marks " " around the text. There is no need for quotation marks when printing numbers or variables.

The function setCursor() is then called to move the cursor to the second row. The cursor position specifies where you want the new text to appear on the LCD. It is assumed that the upper left corner is col=0 and row=0.

There are many useful functions you can use with LiquidCrystal Object. Some of them are listed below:lcd.home() function positions the cursor in the upper-left of the LCD without clearing the display.

lcd.scrollDisplayRight() function scrolls the contents of the display one space to the right. If you want the text to scroll continuously, you have to use this function inside a for loop.

lcd.scrollDisplayLeft() function scrolls the contents of the display one space to the left. Similar to the above function, use this inside a for loop for continuous scrolling.

lcd.display() function turns on the LCD display, after it’s been turned off with noDisplay(). This will restore the text (and cursor) that was on the display.

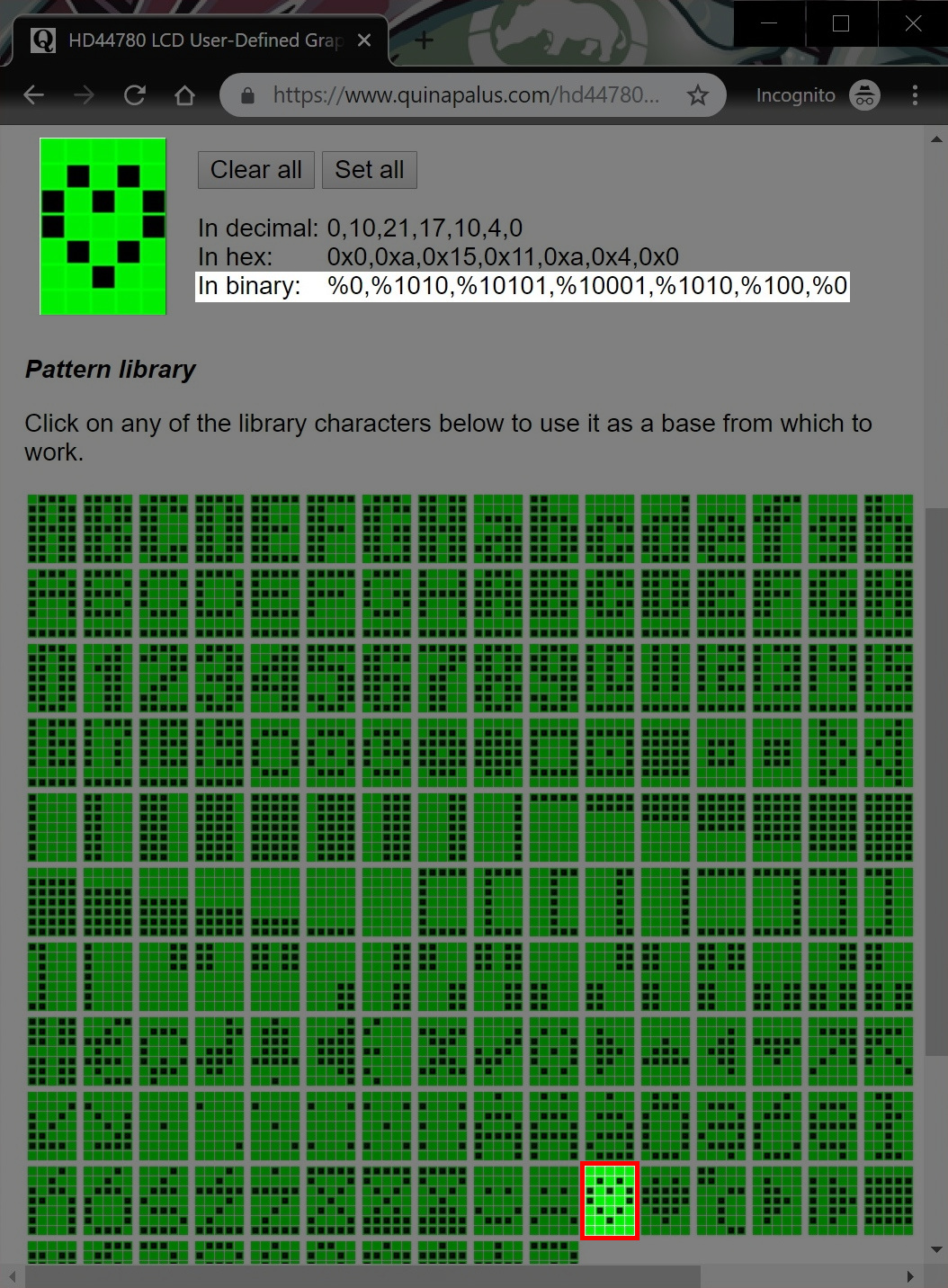

If you find the default font uninteresting, you can create your own custom characters (glyphs) and symbols. They come in handy when you need to display a character that isn’t in the standard ASCII character set.

As previously discussed in this tutorial, a character is made up of a 5×8 pixel matrix; therefore, you must define your custom character within this matrix. You can define a character by using the createChar() function.

The CGROM stores the font that appears on a character LCD. When you instruct a character LCD to display the letter ‘A’, it needs to know which dots to turn on so that we see an ‘A’. This data is stored in the CGROM.

CGRAM is an additional memory for storing user-defined characters. This RAM is limited to 64 bytes. Therefore, for a 5×8 pixel LCD, only 8 user-defined characters can be stored in CGRAM, whereas for a 5×10 pixel LCD, only 4 can be stored.

Creating custom characters has never been easier! We’ve developed a small application called Custom Character Generator. Can you see the blue grid below? You can click on any pixel to set or clear that pixel. And as you click, the code for the character is generated next to the grid. This code can be used directly in your Arduino sketch.

There’s no limit to what you can create. The only limitation is that the LiquidCrystal library only supports eight custom characters. But don’t be sad, look at the bright side; at least we have eight characters.

After including the library and creating the LCD object, custom character arrays are defined. The array consists of 8 bytes, with each byte representing a row in a 5×8 matrix.

This sketch contains eight custom-characters. Take, for example, the Heart[8] array. You can see that the bits (0s and 1s) are forming the shape of a heart. 0 turns the pixel off, and 1 turns it on.

In the setup, we use the createChar() function to create a custom character. This function accepts two parameters: a number between 0 and 7 to reserve one of the eight supported custom characters, and the name of the array.

ERM1601SYG-2 is 16 characters wide,1 row character lcd module,SPLC780C controller (Industry-standard HD44780 compatible controller),6800 4/8-bit parallel interface,single led backlight with yellow green color included can be dimmed easily with a resistor or PWM,stn-lcd positive,dark blue text on the yellow green color,wide operating temperature range,rohs compliant,built in character set supports English/Japanese text, see the SPLC780C datasheet for the full character set. It"s optional for pin header connection,5V or 3.3V power supply and I2C adapter board for arduino.

Of course, we wouldn"t just leave you with a datasheet and a "good luck!".For 8051 microcontroller user,we prepared the detailed tutorial such as interfacing, demo code and Development Kit at the bottom of this page.

Newhaven 16x2 character Liquid Crystal Display shows characters with dark pixels on a bright yellow/green background when powered on. This transflective LCD Display is visible with ambient light or a backlight while offering a wide operating temperature range from -20 to 70 degrees Celsius. This NHD-0216HZ-FL-YBW-C display has an optimal view of 6:00 and comes with a temperature compensation circuit. This display operates at 5V supply voltage and is RoHS compliant.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey