lcd screen material manufacturer

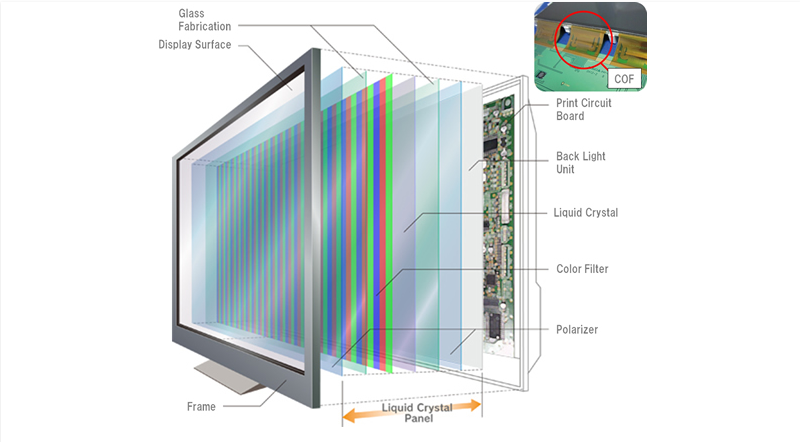

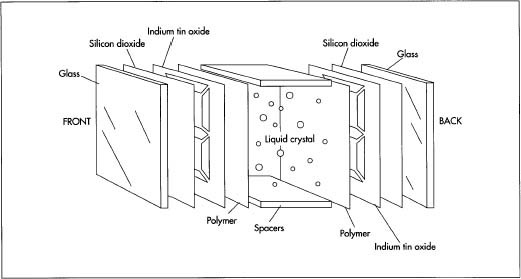

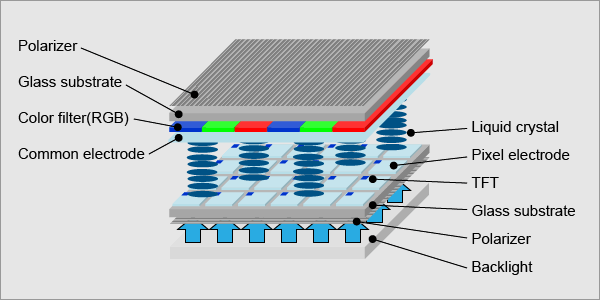

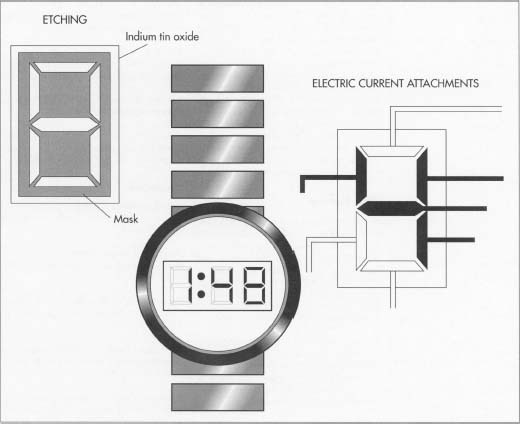

Flat-panel displays are thin panels of glass or plastic used for electronically displaying text, images, or video. Liquid crystal displays (LCD), OLED (organic light emitting diode) and microLED displays are not quite the same; since LCD uses a liquid crystal that reacts to an electric current blocking light or allowing it to pass through the panel, whereas OLED/microLED displays consist of electroluminescent organic/inorganic materials that generate light when a current is passed through the material. LCD, OLED and microLED displays are driven using LTPS, IGZO, LTPO, and A-Si TFT transistor technologies as their backplane using ITO to supply current to the transistors and in turn to the liquid crystal or electroluminescent material. Segment and passive OLED and LCD displays do not use a backplane but use indium tin oxide (ITO), a transparent conductive material, to pass current to the electroluminescent material or liquid crystal. In LCDs, there is an even layer of liquid crystal throughout the panel whereas an OLED display has the electroluminescent material only where it is meant to light up. OLEDs, LCDs and microLEDs can be made flexible and transparent, but LCDs require a backlight because they cannot emit light on their own like OLEDs and microLEDs.

Liquid-crystal display (or LCD) is a thin, flat panel used for electronically displaying information such as text, images, and moving pictures. They are usually made of glass but they can also be made out of plastic. Some manufacturers make transparent LCD panels and special sequential color segment LCDs that have higher than usual refresh rates and an RGB backlight. The backlight is synchronized with the display so that the colors will show up as needed. The list of LCD manufacturers:

Organic light emitting diode (or OLED displays) is a thin, flat panel made of glass or plastic used for electronically displaying information such as text, images, and moving pictures. OLED panels can also take the shape of a light panel, where red, green and blue light emitting materials are stacked to create a white light panel. OLED displays can also be made transparent and/or flexible and these transparent panels are available on the market and are widely used in smartphones with under-display optical fingerprint sensors. LCD and OLED displays are available in different shapes, the most prominent of which is a circular display, which is used in smartwatches. The list of OLED display manufacturers:

MicroLED displays is an emerging flat-panel display technology consisting of arrays of microscopic LEDs forming the individual pixel elements. Like OLED, microLED offers infinite contrast ratio, but unlike OLED, microLED is immune to screen burn-in, and consumes less power while having higher light output, as it uses LEDs instead of organic electroluminescent materials, The list of MicroLED display manufacturers:

LCDs are made in a glass substrate. For OLED, the substrate can also be plastic. The size of the substrates are specified in generations, with each generation using a larger substrate. For example, a 4th generation substrate is larger in size than a 3rd generation substrate. A larger substrate allows for more panels to be cut from a single substrate, or for larger panels to be made, akin to increasing wafer sizes in the semiconductor industry.

"Samsung Display has halted local Gen-8 LCD lines: sources". THE ELEC, Korea Electronics Industry Media. August 16, 2019. Archived from the original on April 3, 2020. Retrieved December 18, 2019.

"TCL to Build World"s Largest Gen 11 LCD Panel Factory". www.businesswire.com. May 19, 2016. Archived from the original on April 2, 2018. Retrieved April 1, 2018.

"Panel Manufacturers Start to Operate Their New 8th Generation LCD Lines". 대한민국 IT포털의 중심! 이티뉴스. June 19, 2017. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"Samsung Display Considering Halting Some LCD Production Lines". 비즈니스코리아 - BusinessKorea. August 16, 2019. Archived from the original on April 5, 2020. Retrieved December 19, 2019.

Herald, The Korea (July 6, 2016). "Samsung Display accelerates transition from LCD to OLED". www.koreaherald.com. Archived from the original on April 1, 2018. Retrieved April 1, 2018.

"China"s BOE to have world"s largest TFT-LCD+AMOLED capacity in 2019". ihsmarkit.com. 2017-03-22. Archived from the original on 2019-08-16. Retrieved 2019-08-17.

STONE Technologies is a proud manufacturer of superior quality TFT LCD modules and LCD screens. The company also provides intelligent HMI solutions that perfectly fit in with its excellent hardware offerings.

STONE TFT LCD modules come with a microcontroller unit that has a 1GHz Cortex-A8 CPU. Such a module can easily be transformed into an HMI screen. Simple hexadecimal instructions can be used to control the module through the UART port. Furthermore, you can seamlessly develop STONE TFT LCD color user interface modules and add touch control, features to them.

Becoming a reputable TFT LCD manufacturer is no piece of cake. It requires a company to pay attention to detail, have excellent manufacturing processes, the right TFT display technology, and have a consumer mindset.

Now, we list down 10 of the best famous LCD manufacturers globally. We’ll also explore why they became among the top 10 LCD display Manufacturers in the world.

LG Display is a leading manufacturer of thin-film transistor liquid crystal displays (TFT-LCD) panels, OLED, and flexible displays.LG Display began developing TFT-LCD in 1987 and currently offers Display panels in a variety of sizes and specifications using different cutting-edge technologies (IPS, OLED, and flexible technology).

With innovative and differentiated technologies, QINNOOptoelectronics provides advanced display integration solutions, including 4K2K ultra-high resolution, 3D naked eye, IGZO, LTPS, AMOLED, OLED, and touch solutions. Qinnooptoelectronics sets specifications and leads the market. A wide range of product line is across all kinds of TFT LCD panel modules, touch modules, for example, TV panel, desktop and laptop computer monitor with panels, small and medium scale “panels, medical, automotive, etc., the supply of cutting-edge information and consumer electronics customers around the world, for the world TFT – LCD (thin-film transistor liquid crystal display) leading manufacturers.

AU Optronics Co., LTD., formerly AU Optronics Corporation, was founded in August 1996. It changed its name to AU Optronics after its merger with UNIOPtronics in 2001. Through two mergers, AU has been able to have a full range of generations of production lines for panels of all sizes.Au Optronics is a TFT-LCD design, manufacturing, and r&d company. Since 2008, au Optronics has entered the green energy industry, providing customers with high-efficiency solar energy solutions.

Sharp has been called the “father of LCD panels”.Since its founding in 1912, Sharp developed the world’s first calculator and LIQUID crystal display, represented by the living pencil, which was invented as the company name. At the same time, Sharp is actively expanding into new areas to improve people’s living standards and social progress. Made a contribution.

BYD IT products and businesses mainly include rechargeable batteries, plastic mechanism parts, metal parts, hardware electronic products, cell phone keys, microelectronics products, LCD modules, optoelectronics products, flexible circuit boards, chargers, connectors, uninterruptible power supplies, DC power supplies, solar products, cell phone decoration, cell phone ODM, cell phone testing, cell phone assembly business, notebook computer ODM, testing and manufacturing and assembly business, etc.

Kyocera was founded in 1959 as a manufacturer of technical ceramics. Industrial ceramics is a series of advanced materials with unique physical, chemical, and electronic properties. Today, most of Kyocera’s products are related to telecommunications, including semiconductor components, RF and microwave packaging, passive electronic components, wireless mobile phones and network equipment, crystal oscillators and connectors, and optoelectronic products for optoelectronic communication networks.

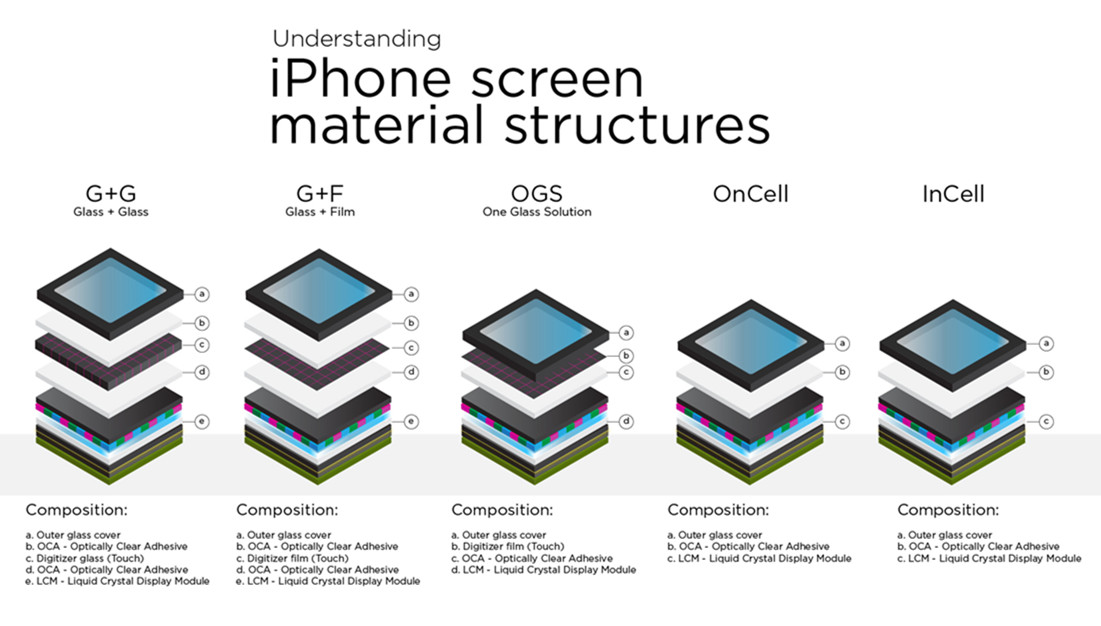

Tianma microelectronics co., LTD., founded in 1983, the company focus on smartphones, tablets, represented by high order laptop display market of consumer goods and automotive, medical, POS, HMI, etc., represented by professional display market, and actively layout smart home, intelligent wear, AR/VR, unmanned aerial vehicles (UAVs) and other emerging markets, to provide customers with the best product experience.IN terms of technology, the company has independently mastered leading technologies such as LTPS-TFT, AMOLED, flexible display, Oxide-TFT, 3D display, transparent display, and in-cell/on-cell integrated touch control. TFT-LCD key Materials and Technologies National Engineering Laboratory, national enterprise Technology Center, post-doctoral mobile workstation, and undertake national Development and Reform Commission, The Ministry of Science and Technology, the Ministry of Industry and Information Technology, and other major national thematic projects. The company’s long-term accumulation and continuous investment in advanced technology lay the foundation for innovation and development in the field of application.

We have thousands of standard products that are in stock and available from our Seattle, WA and Hong Kong warehouses to support fast product development and preproduction without MOQ. The stock covers TN, STN LCD display panels, COB, COG character LCD display, graphic LCD display, PMOLED, AMOLED display, TFT display, IPS display, high brightness and transflective, blanview sunlight readable display, super high contrast ratio display, lightning fast response displays, efficient low power consumption display, extreme temperature range display, HMI display, HDMI display, Raspberry Pi Display, Arduino display, embedded display, capacitive touch screen, LED backlight etc. Customers can easily purchase samples directly from our website to avoid time delays with setting up accounts and credit terms and shipping within 24 hours.

Many of our customers require customized OEM display solutions. With over two decades of experience, we apply our understanding of available display solutions to meet our customer’s requirements and assist from project concept to mass production. Using your ideas and requirements as a foundation, we work side by side with you to develop ideas/concepts into drawings, build prototypes and to final production seamlessly. In order to meet the fast changing world, we can provide the fastest turnaround in the industry, it takes only 3-4 weeks to produce LCD panels samples and 4-6 weeks for LCD display module, TFT LCD, IPS LCD display, and touch screen samples. The production time is only 4-5 weeks for LCD panels and 5-8 weeks for LCD display module, TFT LCD, IPS LCD display, and touch screen.

With the rapid development of my country’s display industry, the global display industry structure has undergone major changes. At present, the LCD industry is mainly concentrated in China, Japan, and South Korea. With the release of the new production capacity of mainland panel manufacturers, mainland China will become the world’s largest LCD production area shortly. So, what are the top ten LCD manufacturers in the world, and how do they rank?

LG Display (Chinese name is LG Display) is currently the world’s No. 1 LCD panel manufacturer, affiliated to LG Group, headquartered in Seoul, South Korea, with R&D, production, and trading institutions in China, Japan, South Korea, and the United States and Europe.

Innolux is a professional TFT-LCD panel manufacturing company founded by Foxconn Technology Group in 2003. The factory is located in Shenzhen Longhua Foxconn Technology Park, with an initial investment of RMB 10 billion. Innolux has a strong display technology research and development team, coupled with Foxconn’s strong manufacturing capabilities, and effectively exerts the benefits of vertical integration, which will make a significant contribution to improving the level of the world’s flat-panel display industry.

Innolux conducts production and sales operations in a one-stop manner and provides overall solutions for group system customers. Innolux attaches great importance to the research and development of new products. Star products such as mobile phones, portable and car-mounted DVDs, digital cameras, game consoles, and PDA LCD screens have been put into mass production, and they have quickly seized the market to win market opportunities. Several patents have been obtained.

AU Optronics was formerly known as Daqi Technology and was established in August 1996. In 2001, it merged with Lianyou Optoelectronics and changed its name to AU Optronics. In 2006, it acquired Guanghui Electronics again. After the merger, AUO has a complete production line for all generations of large, medium, and small LCD panels. AU Optronics is also the world’s first TFT-LCD design, manufacturing, and R&D company to be publicly listed on the New York Stock Exchange (NYSE). AU Optronics took the lead in introducing an energy management platform and was the first manufacturer in the world to obtain ISO50001 energy management system certification and ISO14045 eco-efficiency assessment product system verification, and was selected as the Dow Jones Sustainability World in 2010/2011 and 2011/2012. Index constituent stocks set an important milestone for the industry.

At present, BOE’s shipments in notebook LCD screens, flat-panel LCD screens, mobile phone LCD screens, and other fields have reached the world’s first place. Its successful entry into Apple’s supply chain will become the world’s top three LCD panel manufacturers soon.

Sharp is known as the “Father of LCD Panels.” Since its establishment in 1912, Sharp Corporation has developed the world’s first calculator and liquid crystal display, represented by the invention of the live pencil, which is the origin of the current company’s name. At the same time, Sharp is actively expanding into new areas to improve the living standards of human beings and society. Contribute to progress.

The company independently masters leading technologies including LTPS-TFT, AMOLED, flexible display, Oxide-TFT, 3D display, transparent display, and IN-CELL/ON-CELL integrated touch control. The company has a national engineering laboratory for TFT-LCD key materials and technology, a national-level enterprise technology center, a post-doctoral mobile workstation, and undertakes many major national-level special projects such as the National Development and Reform Commission, the Ministry of Science and Technology, and the Ministry of Industry and Information Technology. The company’s strong technology and scientific research capabilities have become the cornerstone of the company’s sustainable development.

Kyocera Corporation was established in 1959 as a manufacturer of technical ceramics. Technical ceramics refers to a series of advanced materials with unique physical, chemical, and electronic properties. Today, most of Kyocera’s products are related to telecommunications, including semiconductor components, radiofrequency and microwave product packages, passive electronic components, wireless mobile phones and network equipment, crystal oscillators and connectors, and optoelectronic products used in optoelectronic communication networks.

Established in 1998, Winstar Display Co., Ltd. is a reliable LCD Display Module Manufacturer and LCD Panel Supplier. Winstar has development of high-quality display module products. We operate worldwide, configure, service products, and also provide logistics support to deliver products and services competitively. We provide LCM Modules including monochrome TN/STN/FSTN LCM, COG LCD, TFT LCM / TFT panels, FSC-LCD, graphic LCM, character LCD displays, OLED display modules (PMOLED), custom LCD displays, OLED and LCD panel.

New Vision Display is a custom LCD display manufacturer serving OEMs across diverse markets. One of the things that sets us apart from other LCD screen manufacturers is the diversity of products and customizations we offer. Our LCD portfolio ranges from low-cost monochrome LCDs to high-resolution, high-brightness color TFT LCDs – and pretty much everything in between. We also have extensive experience integrating LCD screen displays into complete assemblies with touch and cover lens.

Sunlight readable, ultra-low power, bistable (“paper-like”) LCDs. Automotive grade, wide operating/storage temperatures, and wide viewing angles. Low tooling costs.

Among the many advantages of working with NVD as your LCD screen manufacturer is the extensive technical expertise of our engineering team. From concept to product, our sales and technical staff provide expert recommendations and attentive support to ensure the right solution for your project.

As a leading LCD panel manufacturer, NVD manufactures custom LCD display solutions for a variety of end-user applications: Medical devices, industrial equipment, household appliances, consumer electronics, and many others. Our state-of-the-art LCD factories are equipped to build custom LCDs for optimal performance in even the most challenging environments. Whether your product will be used in the great outdoors or a hospital operating room, we can build the right custom LCD solution for your needs. Learn more about the markets we serve below.

For over 20 years we"ve been helping clients worldwide by designing, developing, & manufacturing custom LCD displays, screens, and panels across all industries.

Newhaven Display has extensive experience manufacturing a wide array of digital display products, including TFT, IPS, character displays, graphic displays, LCD modules, COG displays, and LCD panels. Along with these products, we specialize in creating high-quality and affordable custom LCD solutions. While our focus is on high-quality LCD products, we also have a variety of graphic and character OLED displays we manufacture.

As a longtime leader in LCD manufacturing, producing top-quality LCD modules and panels is our highest priority. At Newhaven Display, we’re also incredibly proud to uphold our reputation as a trusted and friendly custom LCD manufacturing company.

As a custom LCD manufacturing company, we ensure complete control of our custom displays" reliability by providing the industry"s highest quality standards. Our design, development, production, and quality engineers work closely to help our clients bring their products to life with a fully custom display solution.

Customer support requests sent by phone, email, or on our support forum will typically receive a response within 24 hours. For custom LCD project inquiries, our response time can take a few days or weeks, depending on the complexity of your display customization requirements. With different production facilities and a robust supply chain, we are able to deliver thefastest turnaround times for display customizations.

Our excellent in-house support and custom display modifications set Newhaven Display apart from other LCD display manufacturers. From TFTs, IPS, sunlight readable displays, HDMI modules, EVE2 modules, to COG, character, and graphic LCDs, our modifications in the customization process are completed at our Illinois facility, allowing us to provide quality and fast turnaround times.

As a display manufacturer, distributor, and wholesaler, we are able to deliver the best quality displays at the best prices. Design, manufacturing, and product assembly are completed at our headquarters in Elgin, Illinois. Newhaven Display International ensures the best quality LCD products in the industry in this newly expanded facility with a renovated production and manufacturing space.

As the electronic display market continues to evolve, consumer demand is pushing manufacturers to develop higher-quality, brighter, more flexible and adaptable screens, for applications ranging from handheld devices and smartphones to large-format TVs to the automotive, signage and many other markets.

DuPont is a leading supplier of innovative materials and processes that enable enhancements to advanced flat-panel display (FPD), liquid crystal display (LCD) and organic light-emitting diode (OLED) display technologies. By putting science to work, we can help you succeed with innovative and sustainable solutions that improve performance while reducing your manufacturing costs for electronic displays.

OLED materials and process technologies designed to enable cost-effective OLED TVs and future OLED lighting applications, e.g., red, green and blue emissive materials

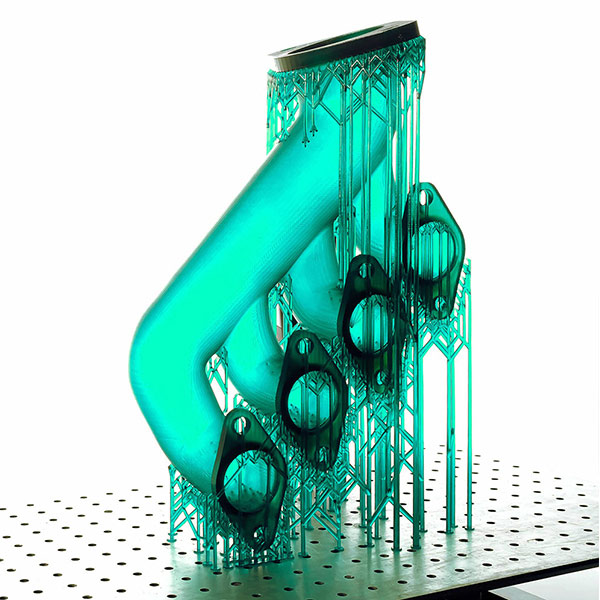

Flexible displays require advanced polyimides to become truly ubiquitous. In addition, our polyimide films and liquids, we are developing hard coat materials and impact-protecting elastomeric materials to address this market demand.

Manufacturer of optical coatings, flat panel/LCD glass, instrument glass, & CRT filter glass. Products include anti-reflective/anti-glare coatings, transparent conductive coatings, fiber optic coatings, beam splitters, cover glass, etched glass, heater glass, glass sandwiches, lighting wedges, & circular polarizers. Applications include EMI/RFI protection, contrast adjustment, & optical instruments. Capabilities include precision glass cutting to tolerances of plus/minus .005 in. & precision glass edging to tolerances of plus/minus .002 in. Additional capabilities include custom manufacturing of laminated products. Services & products meet Military Spec.

Kingtech is one of the leading TFT LCD display OEM/ODM manufacturers in China since 2003. Customization is allowed for projects such as industrial devices, medical, POS, logistics devices, smart home applications and etc.

To provide a one-stop LCD display solution. During the last 17 years, based on LCD manufacturing as our center, we gradually expand to the TFT capacitive touchscreen, driving board, software hardware design, and complete industrial computer solution.

As a professional LCD screen supplier/ LCD display supplier/ LCD panel company/ LCD module manufacturer, Kingtech LCD aims to provide a one-stop service and solve your problems. With a strong LCD Display module R & D team and strict quality management of IS09001, IS01400ATF16949 certificates.

In recent time, China domestic companies like BOE have overtaken LCD manufacturers from Korea and Japan. For the first three quarters of 2020, China LCD companies shipped 97.01 million square meters TFT LCD. And China"s LCD display manufacturers expect to grab 70% global LCD panel shipments very soon.

BOE started LCD manufacturing in 1994, and has grown into the largest LCD manufacturers in the world. Who has the 1st generation 10.5 TFT LCD production line. BOE"s LCD products are widely used in areas like TV, monitor, mobile phone, laptop computer etc.

TianMa Microelectronics is a professional LCD and LCM manufacturer. The company owns generation 4.5 TFT LCD production lines, mainly focuses on making medium to small size LCD product. TianMa works on consult, design and manufacturing of LCD display. Its LCDs are used in medical, instrument, telecommunication and auto industries.

TCL CSOT (TCL China Star Optoelectronics Technology Co., Ltd), established in November, 2009. TCL has six LCD panel production lines commissioned, providing panels and modules for TV and mobile products. The products range from large, small & medium display panel and touch modules.

Established in 1996, Topway is a high-tech enterprise specializing in the design and manufacturing of industrial LCD module. Topway"s TFT LCD displays are known worldwide for their flexible use, reliable quality and reliable support. More than 20 years expertise coupled with longevity of LCD modules make Topway a trustworthy partner for decades. CMRC (market research institution belonged to Statistics China before) named Topway one of the top 10 LCD manufactures in China.

Founded in 2006, K&D Technology makes TFT-LCM, touch screen, finger print recognition and backlight. Its products are used in smart phone, tablet computer, laptop computer and so on.

Established in 2013, Eternal Material Technology is committed to the research, development and manufacturing of electronic materials and providing technical services. EMT is leading the industry with its products of OLED and color photoresist materials.

The Company engages in the R&D, manufacturing, and sale of LCD panels. It offers LCD panels for notebook computers, desktop computer monitors, LCD TV sets, vehicle-mounted IPC, consumer electronics products, mobile devices, tablet PCs, desktop PCs, and industrial displays.

The global display market reached a value of US$ 151.5 Billion in 2021. As per the analysis by IMARC Group, the top manufacturers in the display industry are focused on manufacturing advanced display variants in different sizes that are equipped with speakers, built-in cameras, and video calling features. They are also making heavy investments in the advancement of display technologies, such as liquid crystal display (LCD), cathode ray tube (CRT), light-emitting diode (LED), organic LED (OLED), gas plasma, quantum dot, and e-paper. Along with this, the development of smart displays integrated with innovative technologies, such as the Internet of Things (IoT) and artificial intelligence (AI) that assist in real-time monitoring and provide remote access, is offering lucrative opportunities to key players. Furthermore, the leading manufacturers are entering into partnerships and collaborations and focusing on research and development (R&D) activities to launch technologically advanced displays. Apart from this, the introduction of interactive and flexible displays that offer enhanced brightness, flexibility, and low power consumption is creating a positive market outlook. Looking forward, the market value is expected to reach US$ 197.3 Billion by 2027, growing at a CAGR of 4.10% during the forecast period (2022-2027).

Corning Incorporated is one of the leading innovators in materials science worldwide that specializes in glass, ceramics, and concrete manufacturing. The company’s industry-leading products include damage-resistant cover glass for mobile devices; precision glass for advanced displays; optical fiber, wireless technologies, and connectivity solutions for state-of-the-art communications networks; trusted products to accelerate drug discovery and delivery; and clean-air technologies for cars and trucks. It operates through five segments, including display technologies, optical communications, environmental technologies, specialty materials, and life sciences.

DuPont de Nemours Inc. is a global innovation and technology leader, serving the semiconductor, display, circuit board, digital and flexographic printing, healthcare, aerospace, industrial, and transportation industries. The company is a leading supplier of innovative display materials and processes that enable enhancements to advanced flat-panel display (FPD), liquid crystal display (LCD), and organic light-emitting diode (OLED) display technologies. It operates several manufacturing facilities and offices in around 40 countries across the globe, including the United States, China, Taiwan, Singapore, Indonesia, India, Japan, Mexico, Australia, Canada, Korea, France, Germany, United Kingdom, Italy, Spain, Philippines, Thailand, Vietnam, Belgium, and Brazil.

E Ink Holdings Inc. is the originator, pioneer, and leader in ePaper technology. It delivers its advanced display products to the leading brands and manufacturers across the globe, allowing them to install extremely durable, low-power displays in previously impossible or unimaginable applications and environments. It also develops, manufactures, and markets thin-film transistor liquid crystal displays (TFT-LCDs). At present, the company has operations in Taiwan, China, North America, Japan, and Korea.

Innolux Corporation is a global leader in display technology engaged in producing and supplying TFT-LCD, liquid crystal panel modules, and touch modules. It provides advanced display integration solutions with innovative and differentiated technologies, such as 8K4K ultra-high-resolution, active-matrix AM miniLED, AM microLED, LTPS, and touch solutions. The company also covers a range of display application products, including TV panels, desktop monitors and notebook computer panels, small and medium-sized panels, medical panels, and automotive panels.

Leyard Optoelectronic Co., Ltd. is a global leader in audio-visual technology. It operates through four segments, including intelligent display, international business, nightscape lighting, cultural tourism, and VR entertainment. In addition, the company offers a variety of display products, such as small pitch LED, conventional LED, LCD products, creative LED, LED leasing, LED modular, and conference and commercial display products.

Qisda Corporation is an ODM/OEM leader engaged in manufacturing electronic products for consumer, commercial, medical, and industrial applications. It has a diverse product portfolio, consisting of LCD monitors, digital signage and professional displays, projectors, scanners, multifunctional printers, 3G/4G smartphones, medical gateways, medical imaging and telecare, automobile infotainment devices, e-reader, and tablets. Moreover, the company owns and operates manufacturing facilities in China, Mexico, and Taiwan.

Sharp Corporation is a Japanese multinational corporation primarily engaged in the manufacturing and sales of electric and electronic application equipment, electronic components, and telecommunications equipment. The company operates through three segments, including smart life, 8K ecosystem, and ICT. It has a diverse product portfolio, consisting of display modules, LCD TVs, semiconductor lasers, sensor modules, audio equipment, in-vehicle cameras, multi-function printers, information displays, and business projectors.

Sony Corporation is a Japanese multinational conglomerate corporation that manufactures electronic products, semiconductor solutions, and imaging and sensing solutions. It also offers a wide range of professional displays, including LCD, HDR, LED, and OLED display technologies, ideal for digital signage, screen mirroring, and various professional solutions. The company currently has operations across several countries and regions worldwide, including Japan, the United States, Europe, China, India, Australia, Indonesia, Malaysia, New Zealand, Philippines, Singapore, Thailand, and Vietnam.

The cutting-edge G10 production line is a result of cutting-edge technology. To consistently manufacture LCD panels using the G10 glass substrates, each individual manufacturing process incorporates a range of unique know-how. Developed in collaboration with several world-leading production equipment manufacturers, SDP"s large-scale, one-of-a-kind manufacturing equipment delivers state-of-the-art accuracy and performance levels. One example is the photolithography machine, which is about the size of a tennis court. Our master-craftsmen operate and monitor this machine with the utmost care, to manufacture next-generation products.

In the design of the substrate, photolithography is used to form circuits and wiring. First, a coater system is used to apply photosensitive material—called “photoresist”—rapidly and uniformly across the entire glass substrate. Next, using a photolithography machine, the glass substrate is irradiated with ultraviolet light, transferring onto it a high-precision TFT pattern via a mask. A developing system uses developer fluid to dissolve and remove the photoresist previously applied using the photolithography machine, and only the resist that forms the TFT pattern remains.

The market for LCD displays is undergoing rapid growth centered on notebook computers, cellular phones and LCD televisions. LCD televisions, in particular, are becoming larger and less expensive thanks to technological innovations and the ramping up of mass production. With the appearance of 8K TV sets etc, the consumer appetite for LCD televisions is growing, so demand is expected to continue to expand going forward. CoorsTek provides a variety of materials that are essential to the LCD display manufacturing process and help raise production efficiency.

CoorsTek has developed and supplies a variety of fine ceramic products that are needed to manufacture semiconductors, including quartz glass, carbon products, and silicon carbide products. The purification, processing and evaluation technologies we have developed out of this are highly competitive when applied to the manufacturing process for LCD displays as well, which is quite similar.

We provide a diverse array of materials for the manufacturing processes to help rationalize and streamline LCD production. Products that have earned a strong reputation with our customers include synthetic quartz photomask substrates, a strategic product that improves the exposure precision of micro-circuitry, vacuum breaking filters and silicon carbide materials sintered under atmospheric pressure.

As LCD displays have become larger in recent years, the glass substrates that make up the displays have been growing in stride. Around 2000, the 730 x 920 mm size, called the fourth generation, was mainstream. By 2005, mass production had been initiated for the seventh generation (1,870 x 2,200 mm) and, in 2006, mass production began on 2,160 x 2,400 mm displays, the eighth generation, as the move to larger sizes has accelerated.

In conjunction with this evolution, greater precision and proprietary expertise has come to be required for materials production as well. We already have a system in place to accommodate growth in the size of photomask substrates thanks to our synthetic quartz purification and polishing technologies and unique know-how in the area of mass production, so are ready to meet the rising demand to come.

This ceramic material is next in hardness to diamonds while also being lightweight. It is highly regarded as a material for ultra-flat, lightweight platforms that do not bend or warp, making possible accurate exposure.

Quartz chambers are used as batch furnaces inside heat treatment systems for thin film transistor (TFT) array substrates, which are main type of LCD display using the active matrix method. Compared to metal, quartz is capable of restricting the occurrence of particles to an absolute minimum and it helps prevent metallic contamination.

... and dusty conditions. Plus, the protective glass serves to protect the display against sharp foreign objects, meaning the screen is still operable even with scratches on the surface.

... be used on the screen to maximize safety and hygiene. Plus, white-colored housing makes it easy for users to detect and remove dust or any other foreign substances.

... with a complete digital advertising solution. The wall-mounted outdoor display combines a high-bright screen with a weatherproof body. The 1,500 NITS screen captures attention, and auto-dimming keeps ...

... engaging digital signage in any weather. The high-brightness LCD screen keeps your content clear in direct sunlight, for maximum customer engagement. An IP54/NEMA 4 enclosure protects the screen ...

... turn-key system solutions in a stainless steel enclosure as wall, floor or ceiling mounting versions. The screen of the POLARIS Remote 15"" is a TFT display with an XGA resolution (1024 x 768 pixels) ...

... the main display for applications requiring a small screen. End-cap shelf displays in retail settings or as personal gaming screens as part of a larger interactive gaming table benefit from the features and design of ...

An LCD monitor is a flat screen using liquid crystal technology to create the display. It is used in place of CRT (cathode ray tube) monitors to display all types of verbal or graphic information.

These monitors are used wherever displays are necessary, including numerical control screens for machine tools, human-machine interfaces (HMI) or simply as industrial computer screens.

LCD monitors are among those that control the transmission or reflection of a separate light source rather than generating their own. The various technologies include twisted nematic (TN), super twisted nematic (STN), film compensated super twisted nematic (FSTN) and thin film transistor (TFT).

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey