battery level indicator with lcd display factory

The CRISTEC battery monitor is the only one on the market with a large graphic LCD display for optimum data reading: 62 x 44 mm (built-in backlight). Its version includes a 250A shunt to simultaneously control the voltage, amperage and remaining capacity of a battery bank (i.e.: servitude) as well as the voltage of two other battery banks (i.e., starting and thruster).

By adding optional shunt kits it is possible to fully control 3 battery packs simultaneously (or the flow of power sources such as a wind turbine or solar panels – voltage & current) and 2 extra battery packs. This new battery gauge features an alarm that triggers when the preset low battery capacity threshold is reached and a dry contact for automatic control of a generating set.

Overcharging is terrible for your battery health as it can cause batteries to melt or swell. It could also be damaging to users if not controlled. Additionally, the casting of the battery could become too hot and cause flammable hydrogen to build up inside the sealed battery cells, leading to a bad battery. Luckily, there is a way to prevent overcharging from damaging your batteries: battery charge indicators. So, in this article, you’ll learn everything about battery charge indicators and how to make an easy battery charge indicatorcircuit.

Battery indicators are devices that show the status of a battery. Plus, battery indicators usually have a visual indication that accurately displays the battery’s state of charge.

Also, different technologies that require an ideal battery to operate always have an inbuilt battery indicator. Examples of such technology are mobile phones and computers.

Some mobile phone battery charge indicators are usually inbar graphs--which means the more bars you see, the better the battery charge status. Others indicate battery charge level through percentages.

Likewise, a battery charge display shows the battery in charge mode in portable computers that use rechargeable batteries. Also, you can see the amount of time and battery power you have left when your laptop is not charging.

Additionally, phones and computers aren’t the only devices with a battery charge indicator. Other electronic devices like power banks and smartwatches also have battery charge indicator lights that tell you when your battery is low or full.

Furthermore, asmart battery systemfeatures a controller that’s integrated with an interchangeable battery pack. This integration is capable of delivering a more accurate indication of the battery charge state.

There are various ways to make a battery charge indicator circuit that accurately shows the charge state. Some of the battery charge indicator circuits we’ll be discussing include a battery percentage indicator circuit, battery level indicator circuit using LM3914, and battery full charge indicator circuit employing two transistors.

This circuit is easy to show the current percentage of any battery. What’s more, the circuit is not expensive to build. Here’s the circuit diagram below:

This indicator circuit displays the battery percentage via the LEDs in ascending order. The first LED shows 20%, while the second shows 60%. Also, the third, fourth, fifth LEDs show 60%, 80%, and 100%, respectively.

For this circuit, you won’t need to connect resistors in series with the LEDs. Why? Well, the IC is capable of regulating current on its own. Check out the circuit diagram below:

The LEDs (D1 to D10) show the battery’s capacity in display or dot mode. You can select your preferred mode via the SW1 (external switch), which you should connect to pin 9 of the IC.

Furthermore, you can use different LED colors to show the battery status. So, connect the red LEDs (D1 - D3) to show when you have a low battery. Then, connect the green LEDs (D8 - D10) to show when the battery is 80% or fully charged. While the yellow LEDs will indicate the other power status. Thus, each LED in this circuit shows a 10% battery level.

Here’s an indicator circuit with a mini design that indicates when a battery charge is complete by lighting up an LED. Also, this circuit uses only two transistors as its major components. Take a look at the circuit diagram below:

This preset allows the circuit diagram above and will light up the LED once the connected battery is complete. So, to set up this circuit, you’ll have to supply the upper charge level you want and make adjustments to enable the LED to glow when it reaches the set level.

Setting up the above circuit is relatively easy. Like the power-on circuit, you’ll have to supply the voltage equal to the high charge level you want for the battery and then carefully tweak the circuit with a screwdriver to ensure the LED goes off at the level you want.

Battery level indicators are essential devices for all battery-powered devices. Without it, you won’t know when your batteries need charging or stop charging when full to prevent damages from overcharging.

It’s even more critical for battery electric vehicles as the health of car batteries are crucial. Most of these vehicles come with a battery condition meter (voltmeter) that helps you monitor the condition of yourstarter battery.

Now, most modern cars come withammetersthat show when the battery is charging or discharging. However, both the voltmeter and ammeter can show the state and charging system of an automobile or automotive battery.

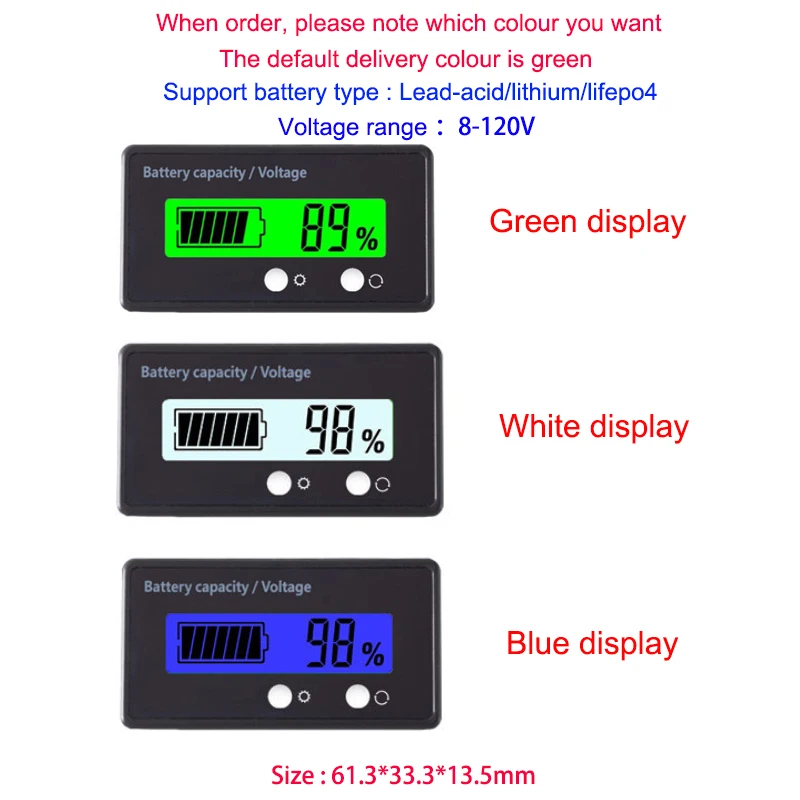

This product is a general instrument, adopts LCD color screen, can long-term display the battery, voltage, temperature (Selective assembly; sound-light alarm((Selective assembly) can be used in a variety of lighting conditions. The default parameters are suitable for lithium batteries, lead-acid batteries, lithium iron phosphate battery, Ni MH battery application field; through the development of programming, can be applied to any battery, simple wiring, convenient maintenance and disassembly using standard connector.

A lcd voltage indicator can be used for many purposes. For starters, it can help in determining the voltage of a charge-storage device, like a battery. This is especially useful if you are going to a place with no power so you can know whether to charge it or not. A lcd voltage indicator also helps you to know whether there is power in a circuit or not. If you want to check whether electronic devices are on or off, this device comes in handy. When you use it with a series of batteries, you can make a continuity checker. You can also use it to make an ohmmeter if you use a voltage divider with an unknown resistor. Lastly, a lcd voltage indicator can make an ammeter when measuring voltage over a shunt resistor.

When buying a lcd voltage indicator, there are various factors that you need to consider, including requirements, specifications, and total cost. When it comes to requirements, you need to determine whether you need a digital or analog voltmeter. Size also matters depending on where you are going to use it. Another factor that you need to consider when buying a lcd voltage indicator is the specifications of the device. One of the specifications is accuracy and measuring range. If you want to measure several parameters such as resistance, current, and voltage, consider buying a digital voltmeter. Lastly, look at the cost. Most of the time, the cost of the device depends on the number of features. The more the features, the more you pay.

For a wholesale lcd voltage indicator, visit Alibaba.com. This online shopping platform offers a wide range of voltage meters that suit your needs. Visit the website at any time and place your order.

Just connect the positive and negative wires of the Battery Percentage indicator to the positive and negative terminal of your battery and get an easy to read indication of the life of your battery.

The module (which is to be fitted on to the vehicle) serves to indicate to the vehicle operator/floor supervisor that the battery requires to be re-charged.

The BDI essentially monitors the rate of fall of the battery voltage (on discharge) and provides appropriate alarms and controls when the battery is discharged. This serves as an early warning indication that the battery needs to be re-charged.

The BDI provides a multi-colour (Green, Amber and Red) LED-based bar graph display which is indicative of the state of the battery, as well as an audible (buzzer) annunciation when battery is discharged to ~65% of its capacity. This serves as an indication that the battery needs to be re-charged.

The BDI also incorporates a relay who"s NO and NC contacts are brought out to provide an interlock with the lift motor – this enables the lift motor drive to be locked out when the Battery is discharged to below 80% of its capacity. This provides protection against over-discharging of the battery, thus prolonging battery service life.

The actual run-time of the vehicle (operational time) is displayed on the LCD display with a full-scale value of 99999.9 hours followed by a rollover to 0. The hour meter reading is non-volatile i.e, cannot be reset by the operator or by battery disconnection.

Using the push button switches, user can easily set the nominal battery voltage (24V*/30V/36V/48V/60V/72V/80V) and low batt. voltage level depending on the required rate of discharge from C2 to C10 in the universal model. The BDI will store these selected values in the non-volatile memory.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey