battery level indicator with lcd display free sample

In this project, I will show you how to design a simple Battery Level Indicator Circuit using easily available components. Battery level indicator indicates the status of the battery just by glowing LED’s. For example six LED’s are glowing means battery capacity 60% remains.

This article explains you how design battery level indicator. You can use this circuit to check car battery or inverter. So by using this circuit, we can increase the lifetime of battery.

The heart of this battery level indicator circuit is LM3914 IC. This IC takes input analog voltage and drives 10 LED’s linearly according to the input analog voltage. In this circuit, there is no need of resistors in series with LEDs because the current is regulated by the IC.

In this circuit LED’s (D1-D10) displays the capacity of the battery in either dot mode or display mode. This mode is selected by the external switch sw1 which is connected to 9th pin of IC. 6th and 7th pins of IC are connected to the ground through a resistor. This resistor controls the brightness of LED’s. Here resistor R3 and POT RV1 forms potential divider circuit. Here pot RV1 is used for calibration. There is no need of any external power supply to this circuit.

The circuit is designed to monitor 10V to 15V DC. The circuit will work even if the battery voltage is 3V. The operating voltage of this IC is 3v to 25v DC. Lm3914 drives led’s, LCDs and vacuum fluorescents. The IC contains adjustable reference and accurate 10-steps divider. This IC can also acts as sequencer.

We can also connect different color led’s to indicate the status. Connect D1 to D3 red LED’s which indicates shut down stage of your battery and use D8-D10 green color LED’s which indicates 80 to 100 percentage of the battery and use yellow color for remaining.

With a little modification we can use this circuit to measure other voltage ranges also. For this remove the resistor R2 and connect upper voltage level to the input. Now vary the resistance of Pot RV1 till the D10 LED glows. Now remove upper voltage level at the input and connect lower voltage level. Connect a high value variable resistor in the place of resistor R2 and vary it till the D1 LED glows. Now disconnect the pot, measure the resistance across it and connect resistor of same value in place of R2. Now the circuit is ready to monitor other voltage ranges.

This circuit is most suitable for indicating 12V battery level. In this circuit each led indicates 10 percent battery level. We can extend this circuit to 100 steps by cascading lm3914 IC’s.

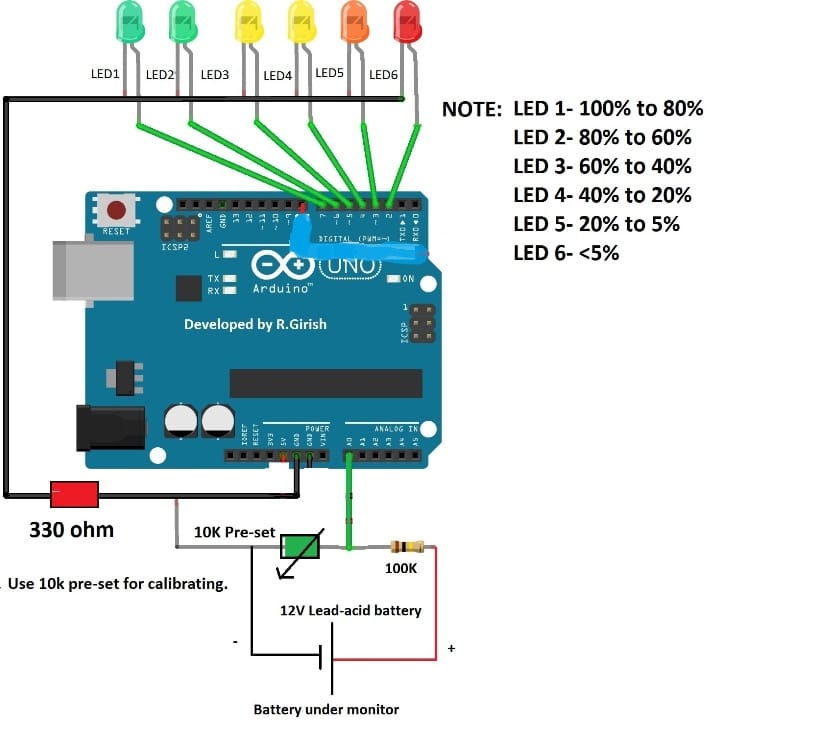

In this post, we are going to construct an Arduino based battery level indicator, where a series of 6 LEDs show the level of the battery. If you are interested in monitoring and maintenance of your 12V battery, this circuit might become handy.

Being electronics enthusiasts, we all might have a battery for testing our prototype circuits. Since we concentrate on the prototype during experiment, we care less on the battery.

The proposed battery charger circuit will show you how much energy left in the battery, this circuit may be connected to battery, while you prototyping your circuits. When this circuit indicates low battery, you may put the battery to charge. The circuit has 6 LEDs, one LED glow at a time to indicate the voltage level of the battery.

The circuit consists of Arduino which is the brain of the system, a potential divider which helps the Arduino to sample the input voltage. A pre-set resistor is used to calibrate the above setup. The series of 6 LEDs will indicate the battery level.

The Arduino measures a narrow range of voltage from 12.70V to 11.90V. A fully charged battery should have voltage above 12.70V after disconnecting from charger. A low battery voltage must not go below 11.90V for a 12V sealed lead-acid battery.

The calibration for this Arduino 6 LED battery level indicator circuit must be done carefully, if you did not calibrate correctly, the circuit will show incorrect voltage level of the battery.

When you turn on the circuit, it starts with LED test, where the LEDs glow up sequentially with some delay. This might help you to debug errors while arranging the LEDs.

Just connect the positive and negative wires of the Battery Percentage indicator to the positive and negative terminal of your battery and get an easy to read indication of the life of your battery.

This is a simple Arduino library to monitor battery consumption of your battery powered projects, being LiPo, LiIon, NiCd or any other battery type, single or multiple cells: if it can power your Arduino you can monitor it!

The big assumption here is that battery capacity is linearly correlated to its voltage: the assumption itself is wrong, but in most cases it"s close enough to reality, especially when it comes to the battery higher capacity side.

In reality, the relation between battery capacity and its voltage is better represented by a curve and there are many factors affecting it: current drawn, temperature, age, etc...

The library requires at least 1 analog pin (we will call this the sense pin) and no less than 2 pieces of info on your battery: the voltage you will consider the minimum acceptable level, below which your project/product becomes unreliable and should be shut down, and the maximum voltage you can expect when the battery is fully charged.

Additionally, you can provide a second pin (either analog or digital) to activate the battery measurement circuit (we call it the activation pin), useful in all those situations where you can sacrifice a pin to further increase your battery duration.

The sense pin wiring can vary depending on your battery configuration, but here are a few examples based on the assumption you are using a 5V board: in case of a 3.3V board you should be performing the necessary adjustments.

Voltage sources made of single cell LiPo or LiIon, along with some single or multi-cell NiCd configurations (like up to 3 AA or AAA), are not able to provide the suggested 5.0 volts input to your board and a voltage booster can solve your problem.

What does that mean when it comes to measuring your battery level? We need to measure the battery voltage before it gets boosted, which means your sense pin must be connected between the battery positive terminal and the booster positive input and we don"t need any additional components as the voltage is already in the acceptable range:

Voltage sources made of multiple cells LiPo or LiIon, along with some single or multi-cell NiCd configurations (like up the classic 9V battery or 4+ AA or AAA), provide voltages above the 5.0 volts input: most of the Arduino boards are equipped with voltage regulators able to dissipate into heat all the excess.

To measure such batteries we need to hook our sense pin before it gets regulated, between the battery positive terminal and the Arduino unregulated input VIN or RAW, but we require two resistors to reduce the voltage to acceptable values:

Because the resistors in this configuration will constantly draw power out of your battery, you shouldn"t pick values under 1k Ohm, or you"ll deplete your batteries much faster than normal. On the other end, going too high on the resistor values will impede the library from getting accurate readings.

Once again, to measure such batteries we need to hook our sense pin before it gets regulated, between the battery positive terminal and the voltage regulator positive input VIN or RAW and, as before, we require two resistors to reduce the voltage to acceptable values:

Batteries are a precious resource and you want to prolong their life as much as you can so, deplete your battery to determine its capacity is not desirable.

As a consequence of connecting the battery terminals through two resistors we are drawing some energy out of the battery: for a 9V battery and 1k Ohm for R1 and R2, you will be adding a constant 4.5mA current consumption to your circuit. Not a huge amount, but definitely not desirable.

If you have an unused pin on your Arduino it will be easy to limit this additional current consumption to be drawn only when needed: during battery measurement. We will be turning the activation pin HIGH during battery measurement so that the voltage divider will be disconnected most of the time:

Whenever your battery voltage is above your board voltage you need a voltage divider to constraint your readings within the 0-5V range allowed by your Arduino and you will have to provide this library with its ratio.

If you use a 22k Ohm resistor for R1 and a 10k Ohm for R2 than your voltage ratio will be 3.2 and you will be able to safely monitor a 12-15V battery.

You must select the resistors in order to get a ratio which will produce values between the 0-5V range (or 0-3.3V for 3.3V devices) at all the times and to obtain that the process is quite simple: divide your battery maximum voltage by 5V and you"ll get the absolute minimum value for the voltage ratio, then pick any two resistors values whose combination produce a ratio equal or higher than the absolute minimum. For a 12V battery the absolute minimum voltage ratio is 12/5=2.4, meaning you can"t use a split supply divider made of two equal resistors: you need R1 to be a higher value than R2! Get this wrong and you will probably burn your sense pin.

You can use this nice website to find some appropriate values for the resistors setting your battery maximum voltage as Voltage source and aiming at obtaining a Output voltage value lesser than your board voltage (5V or 3.3V) but as close as possible.

The voltage divider total resistance, made of R1 + R2, will determine the current drawn from your battery by the sensing circuit: lower is the total resistance and more accurate are your readings, higher the resistance and less current is drawn from your battery (Ohm"s law rulez!). My suggestion is to keep this value within 20k-22k Ohm when using an always-connected circuit and under 10k Ohm if you use an on-demand configuration.

When determining the ratio don"t stick with the resistors nominal values, instead, if possible, use a multimeter to actually measure their resistance so to improve your results: a 4.7kΩ resistor could easily be a 4.75kΩ in reality!

The level available functions aim at providing an approximation of the remaining battery capacity in percentage. This is not an easy task when you want to achieve reliable values and it is something the industry of mobile devices invests a decent amount of resources.

After collecting a few data points on battery voltage vs. battery capacity, I"ve used the https://mycurvefit.com/ and https://www.desmos.com online tools to calculate the math functions best representing the data I"ve collected.

In the above plot I represent the battery percentage (Y axis) as a function of the difference between the current battery voltage and the minimum value (X axis): the graph represents a battery with a voltage swing of 1200mV from full to empty, but the functions scale accordingly to the minVoltage and maxVoltage parameters.

linear is the default one (dashed red), probably the least accurate but the easiest to understand. It"s main drawback is, for most chemistries, it will very quickly go from 25-20% to 0%, meaning you have to select the minVoltage parameter for your battery accordingly. As an example, a typical Li-Ion battery having a 3V to 4.2V range, you want to specify a 3.3V configuration value as minimum voltage.

sigmoidal (in blue) is a good compromise between computational effort and approximation, modeled after the tipical discharge curve of Li-Ion and Li-Poly chemistries. It"s more representative of the remaining charge on the lower end of the spectrum, meaning you can set the minimum voltage accordingly to the battery safe discharge limit (typically 3V for a Li-Ion or Li-Poly).

asymmetric sigmoidal (in green) is probably the best approximation when you only look at battery voltage, but it"s more computational expensive compared to sigmoidal function and, in most cases, it doesn"t provide a great advantage over it"s simmetric counterpart.

I strongly encourage you to determine the function that best matches your particular battery chemistry/producer when you want to use this library in your product.

As an example, for a single cell Li-Ion battery (4.2V - 3.7V) powering a 3.3V MCU, you"ll need to use a voltage divider with a ratio no less than 1.3. Considering only E6 resistors, you can use a 4.7kΩ (R1) and a 10kΩ (R2) to set a ratio of 1.47: this allows to measure batteries with a maximum voltage of 4.85V, well within the swing of a Li-Ion. It"s a little too current hungry for my tastes in an always-connected configuration, but still ok. Considering the chemistry maps pretty well to our sigmoidal approximation function I"m going to set it accordingly along with the minimum voltage which lowest safe value clearly is 3.0V (if a Li-Ion is drained below 3.0V the risk of permanent damage is high), so your code should look like:

For a double cell Li-Ion battery (8.4V - 7.4V) powering a 5V MCU, you"ll need to use a voltage divider with a ratio no less than 1.68: you can use a 6.8kΩ (R1) and a 10kΩ (R2) to set the ratio precisely at 1.68, perfect for our 8.4V battery pack. The circuit will continuously draw 0.5mA in an always-connected configuration, if you can live with that. As we don"t want to ruin our battery pack and we don"t want to rush from 20% to empty in afew seconds, we"ll have to set the minimum voltage to 6.8V (with a linear mapping) to avoid the risk of permanent damage, meaning your code should look like:

Another classic example might be a single 9V Alkaline battery (9V - 6V) powering a 5V MCU. In this case, you"ll need to use a voltage divider with a ratio no less than 1.8 and, for sake of simplicity, we"ll go for a nice round 2 ratio. Using a nice 10kΩ both for R1 and R2 we"ll be able to measure batteries with a maximum voltage of 10V consuming only 0.45mA. The trick here is to determine when our battery should be considered empty: a 9V Alkaline, being a non-rechargeable one, can potentially go down to 0V, but it"s hard our board can still be alive when this occurs. Assuming we are using a linear regulator to step down the battery voltage to power our board we"ll have to account for the regulator voltage drop: assuming it"s a 1.2V drop, we might safely consider our battery empty when it reaches 6.2V (5V + 1.2V), leading to the following code:

NOTE: Most 5V MCU can actually continue to operate when receiving 4.8V or even less: if you want to squeeze out as much energy as you can you can fine tune the low end, but also consider there is not much juice left when a battery voltage drops that much.

Under the condition of power off, long-press the button on the back of the module (do not release) and power up the module. The monitor will display the battery specification, then press the button again to choose the battery specification. After choosing the specification you need, cut off the power and then power up the module again. The adjustment is finished.

The App is an excellent complement to the Pico device. It makes the initial setup of the Pico MUCH easier and faster than doing it from the Pico’s screen. The displayed menus are very similar than the Pico and the settings are presented in the same order, so it’s super easy to find everything.

The iOS app seems to works flawlessy, but we had a hard time figuring how to use the Android app (our phone just couldn’t establish communication with the Pico). The only way to make it work is to set the Pico in STA mode: instead of creating it’s own WiFi network (you read it right: the Pico communicates via WiFi not via Bluetooth), in STA mode the Pico join an existing router (in our case, our Verizon JetPack). Once setup this way, we could use the app on our Android phone.

Overcharging is terrible for your battery health as it can cause batteries to melt or swell. It could also be damaging to users if not controlled. Additionally, the casting of the battery could become too hot and cause flammable hydrogen to build up inside the sealed battery cells, leading to a bad battery. Luckily, there is a way to prevent overcharging from damaging your batteries: battery charge indicators. So, in this article, you’ll learn everything about battery charge indicators and how to make an easy battery charge indicatorcircuit.

Battery indicators are devices that show the status of a battery. Plus, battery indicators usually have a visual indication that accurately displays the battery’s state of charge.

Also, different technologies that require an ideal battery to operate always have an inbuilt battery indicator. Examples of such technology are mobile phones and computers.

Some mobile phone battery charge indicators are usually inbar graphs--which means the more bars you see, the better the battery charge status. Others indicate battery charge level through percentages.

Likewise, a battery charge display shows the battery in charge mode in portable computers that use rechargeable batteries. Also, you can see the amount of time and battery power you have left when your laptop is not charging.

Additionally, phones and computers aren’t the only devices with a battery charge indicator. Other electronic devices like power banks and smartwatches also have battery charge indicator lights that tell you when your battery is low or full.

Furthermore, asmart battery systemfeatures a controller that’s integrated with an interchangeable battery pack. This integration is capable of delivering a more accurate indication of the battery charge state.

There are various ways to make a battery charge indicator circuit that accurately shows the charge state. Some of the battery charge indicator circuits we’ll be discussing include a battery percentage indicator circuit, battery level indicator circuit using LM3914, and battery full charge indicator circuit employing two transistors.

This circuit is easy to show the current percentage of any battery. What’s more, the circuit is not expensive to build. Here’s the circuit diagram below:

This indicator circuit displays the battery percentage via the LEDs in ascending order. The first LED shows 20%, while the second shows 60%. Also, the third, fourth, fifth LEDs show 60%, 80%, and 100%, respectively.

For this circuit, you won’t need to connect resistors in series with the LEDs. Why? Well, the IC is capable of regulating current on its own. Check out the circuit diagram below:

The LEDs (D1 to D10) show the battery’s capacity in display or dot mode. You can select your preferred mode via the SW1 (external switch), which you should connect to pin 9 of the IC.

Furthermore, you can use different LED colors to show the battery status. So, connect the red LEDs (D1 - D3) to show when you have a low battery. Then, connect the green LEDs (D8 - D10) to show when the battery is 80% or fully charged. While the yellow LEDs will indicate the other power status. Thus, each LED in this circuit shows a 10% battery level.

Here’s an indicator circuit with a mini design that indicates when a battery charge is complete by lighting up an LED. Also, this circuit uses only two transistors as its major components. Take a look at the circuit diagram below:

This preset allows the circuit diagram above and will light up the LED once the connected battery is complete. So, to set up this circuit, you’ll have to supply the upper charge level you want and make adjustments to enable the LED to glow when it reaches the set level.

Setting up the above circuit is relatively easy. Like the power-on circuit, you’ll have to supply the voltage equal to the high charge level you want for the battery and then carefully tweak the circuit with a screwdriver to ensure the LED goes off at the level you want.

Battery level indicators are essential devices for all battery-powered devices. Without it, you won’t know when your batteries need charging or stop charging when full to prevent damages from overcharging.

It’s even more critical for battery electric vehicles as the health of car batteries are crucial. Most of these vehicles come with a battery condition meter (voltmeter) that helps you monitor the condition of yourstarter battery.

Now, most modern cars come withammetersthat show when the battery is charging or discharging. However, both the voltmeter and ammeter can show the state and charging system of an automobile or automotive battery.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey