eaglecad tft lcd free sample

1.8\" TFT Display 128x160 Module ST7735S 1.44 V1.1 Series 128*128 TFT color screen 0.96\" I2C 128X64 OLED Display Module 0.96\" SPI Serial 128X64 OLED Display Module

The VeeCAN 800 is a 7" fully waterproof resistive touchscreen display. It features a WVGA 800 x 480 TFT LCD color display and two USB ports (one rear and one front accessible). The VeeCAN 800 also supports 14 analog inputs, four digital inputs, eight outputs, two CAN connections, as well as an Ethernet connection.

The VeeCAN 300R is a 3" round capacitive touchscreen display. It features a WVGA 432 x 432 LCD color display, and one USB port on the rear. The VeeCAN 300R also supports seven analog inputs, four digital inputs, one relay output, one CAN connection, as well as one RS-485 connection.

The VeeCAN 800 is a 7" fully waterproof resistive touchscreen display. It features a WVGA 800 x 480 TFT LCD color display and two USB ports (one rear and one front accessible). The VeeCAN 800 also supports 14 analog inputs, four digital inputs, eight outputs, two CAN connections, as well as an Ethernet connection.

The VeeCAN 700 is a 7" IP67 waterproof PCAP touchscreen display. It features a WVGA 800 x 480 TFT LCD color display and two USB ports. The VeeCAN 700 also supports one analog input, one digital input, one output, two CAN connections, as well as an Ethernet connection.

The VeeCAN 500 is a 5" IP67 waterproof PCAP touchscreen display. It features a WVGA 800 x 480 TFT LCD color display and two USB ports. The VeeCAN 500 also supports one analog input, one digital input, one output, two CAN connections, as well as an Ethernet connection.

The VeeCAN 300R is a 3" round IP67 waterproof PCAP touchscreen display. It features a WVGA 432 x 432 TFT LCD color display and one USB port. The VeeCAN 300R also supports six analog inputs, four digital inputs, one frequency output, and one CAN connection.

The KAntrak 1700 is a rugged 3" x 3" device containing a compact LCD display, perfect for harsh condition testing and diagnostics. It comes with GEM (Generic Engine Monitor) installed as standard.

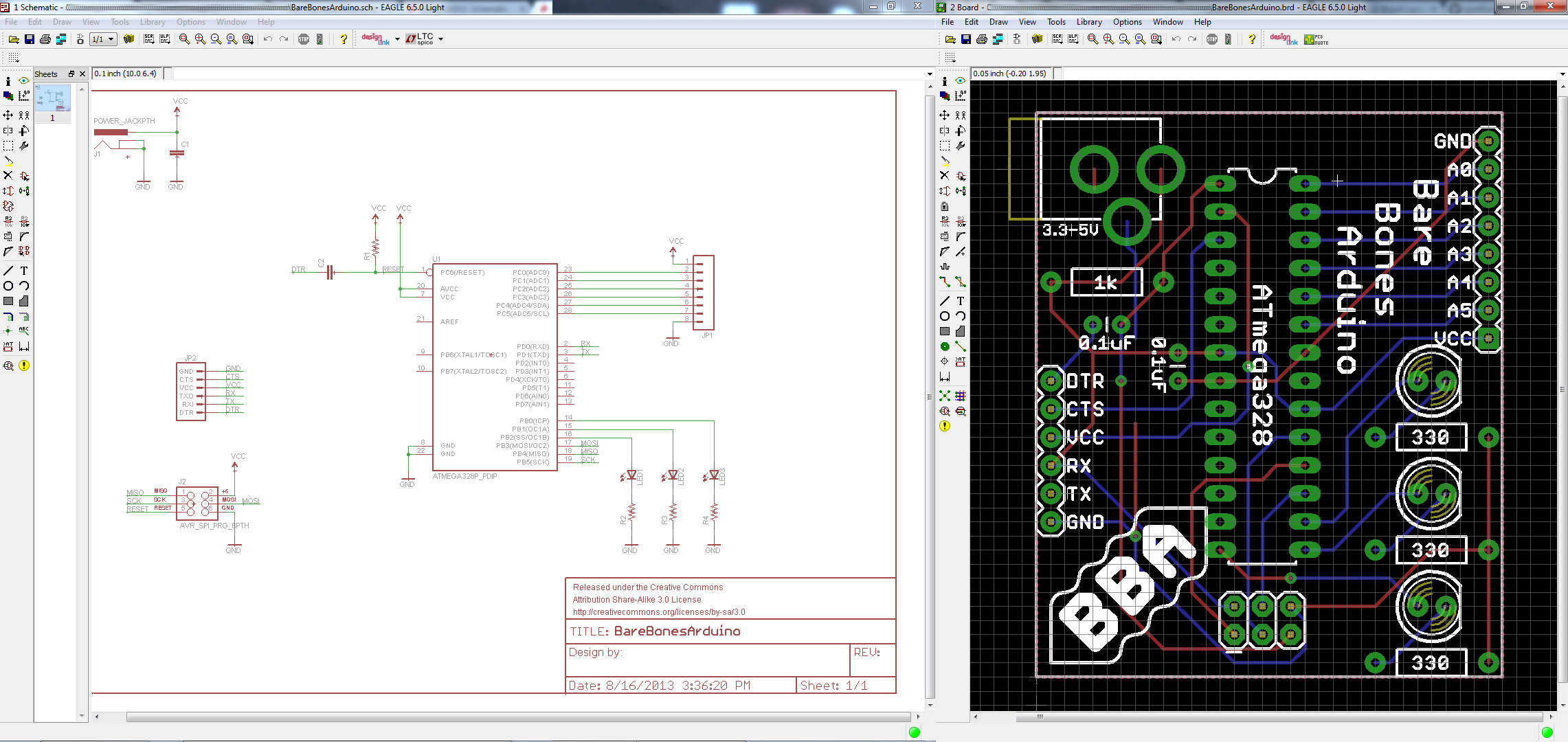

There are many CAD developed to assist the electronic designers during drawing of PCBs and schematics; often they are integrated in complete suite to project, simulate and realize a whole electronic system. Besides the many commercial versions, there are also free CADs available. Today we’d like to analyze one of the most diffused and known software: Eaglecad (eagle does not mean the powerful bird but it is the acronym of Easily Applicable Graphical Layout Editor) made by Cadsoft, actually at version 6.2.0. We have chosen this one because, as you know as an Arduino’s fan, the official pcbs and schematic files of the boards are developed and available free of charge to everybody in Eaglecad format; you can find also a lot of libraries and circuits made by famous DIY website (Sparkfun for first) available for free. Eaglecad is a professional software that have gained a lot of popularity due to the Arduino’s success. One of the most important difference between Eaglecad and its competitors is the availability of a version for every of the most common desktop OS: Windows, Linux, Mac. We have to specify that Eaglecad is not Free software but is a commercial one, which can be used in the free version (eaglecad light) only for evaluation purposes and by student but you can’t use the light version in any case when you earn or save money by using it. For further details about licenses and distributors have a look to the official Eaglecad website where you can find all the information you need. Remember that the light version has some limitations; anyway you can design circuit with a discrete complexity, as the one you can see at http://elmicro.com/en/kit12.html. The limitations are:

We can add other libraries like the Sparkfun one for example or we can also modify the ones which are provided by Eaglecad. Now select “Resistor”, “R-EU”: on the screen will appear a sub library where we can choose the kind of resistor we need (SMD,trough-hole) and its package.

For our example we’d like to use trough hole components so we’ll choose “R-EU_02_07/10” which is a 1/4W resistor horizontally mounted. Once a component has been chosen, on the right hand side of the window, Eaglecad shows the component symbol used in the schematic and beside the pcb pads of such component and the space required on the PCB. There is another window under the two we have seen before where there are details and notes that have been inserted during creation of the selected component.

We need 4 of such components so we click on “OK”, move on the schematic drawing area and put the element where we want by clicking again. Eaglecad automatically names resistors in a progressive way.

In this way it is easy to understand for every contact which is the related connector strip. Now insert the ground symbol and connect the LED cathodes to them (Eaglecad have available many kind of ground symbols: they are in the libraries “supply1” and “supply2”). We’ll choose “GND” available in the “supply1” library. Looking at the digital strips we can notice that they are in the “wrong” side of the schematic. To have a more easily access to the contact connections and to have a clear and readable schematic, we can use the”mirror” command to mirror the selected parts. Before apply this command, select the symbols of both connectors with the command “group” in order to reduce the number of required actions.

Once all the connections are done, select “Tool”, “Erc” to solve errors, if any, which will be shown in the “Erc errors” window where Eaglecad lists some issues: leds and switches have no value and the pins of the strips are not connected.

Wiring routing can be done automatically (autorouting function) or manually. In this short introduction we’ll use the hand routing in order to practice with Eaglecad. By selecting the “Route” icon it is possible to draw connections; the dimension, shape and width are visible on the top icon bar where is also possible to select the pcb side. The freeware version make possible to draw pcbs with only two sides, so we’ll find only “Top” and “Bottom”. In the same way you move components it is possible to define the printed circuit board dimensions; the white lines are the cutting boarder where the CNC will cut the pcb. Finally here a possible two sides pcb of our Arduino’s shield.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey