tft lcd pcb connection fpc made in china

The modern technological china lcd display fpc units on Alibaba.com have high-density integration. These products have a high-quality output with robust yet flexible for easy folding. The diverse layering of circuits allows for more power and efficient working. The electronic gadgets have several contact pins for better connectivity. The large storage china lcd display fpc are suitable for multiple electronic items such as telecommunication and children"s toys.

Technologically advanced china lcd display fpc units have small-sized platforms, and that saves space for other items. Efficiency helps the users to save money on human resource hiring since the work can be done electronically. These products are durable and easy to handle with simple guidance from professionals. The high adaptability of terminal pins makes signals flow freely. With better connectivity, the users will enjoy the high-frequency performance from their electronics.

When looking for efficient china lcd display fpc units on Alibaba.com, users must check on what board size and thickness are compatible with the gadgets in question. The copper thickness should also be ideal. The layering type dictates where and how the connections will be. The integrated capacity is essential for any free flow of transmission frequencies. Soldering patterns and surface finishing show good work and better connectivity.

Better working capacities allow for better results. The connecting electronic gadgets have better construction designs for durability. The verified suppliers and comprehensive catalogs enhance trust and transparency in the market. Competitive china lcd display fpc make the purchasing journey enjoyable. Find the products on Alibaba.com for significant experiences.

As shown in fig. 1, a composite display integrating a TFT module and a VA liquid crystal panel includes a VA-type LCD panel 1, a TFT liquid crystal panel 4, a left LED backlight 6, and a right LED backlight 7, wherein the TFT liquid crystal panel 4 is attached to a central area below the VA-type LCD panel 1; the left LED backlight 6 and the right LED backlight 7 are attached to the left side and the right side below the VA type LCD screen 1.

The utility model also comprises a PCB circuit board 12, the PCB circuit board 12 is fixed below the TFT LCD screen 4 and the left LED backlight and the right LED backlight 6 and 7; the PCB 12 is attached to the VA mode LCD 1 and the TFT module 4 on the PCB 12 by means of the high viscosity foam 11 attached to the periphery of the PCB.

As shown in fig. 2, the circuit structure on the PCB circuit board 12 includes: the main control MCU is connected with a VA-LCD driving chip, a left LED backlight driving circuit and a right LED backlight driving circuit which are connected with ports of the main control MCU.

As shown in fig. 1-2, the VA LCD panel 1 is provided with a left FPC2 and a right FPC3, and the ports of the VA-LCD driver chip are respectively connected to the left FPC2 of the VA LCD panel through the left FPC socket of the VA-LCD and connected to the right FPC3 of the VA LCD panel through the right FPC socket of the VA-LCD.

And a driving IC is bound on the TFT liquid crystal screen 4, and a TFT-LED backlight 8 is also arranged at the bottom of the TFT liquid crystal screen 4.

The circuit structure on the PCB 12 further comprises a TFT LED backlight driving circuit, and a port of the main control MCU is directly connected with an FPC jack of the TFT liquid crystal screen and is connected to a driving IC of the TFT liquid crystal screen through the jack; the LED backlight driving circuit of the TFT has one end connected to the power supply and the other end connected to the FPC jack of the TFT LCD, and is connected to the TFT-LED backlight 8 of the TFT LCD via the FPC5 of the TFT LCD and the jack.

VA type LCD screen 1 is dot matrix LCD screen, the utility model discloses a circuit structure on PCB circuit board 12 still includes VA-LCD line drive enable circuit and VA-LCD row drive enable circuit that is connected with master control MCU, VA-LCD line drive enable circuit and VA-LCD row drive enable circuit are respectively through the left FPC of VA-LCD left side FPC socket connection VA type LCD screen, through the right FPC of VA-LCD right side FPC socket connection VA type LCD screen, line drive and row drive are used for the line and the display control who arranges to dot matrix type LCD screen-VA type LCD screen 1.

Like fig. 3-10, for in fig. 2 the utility model discloses an actual design of each chip and circuit of PCB circuit board, in fig. 3, main control MCU adopts STM32 singlechip, 32 bit ARM microcontroller, Cortex-M3 kernel, the highest operating frequency 72 MHz. And FLASH and SRAM are built in. The support sets are ADC, SPI, USB, I2C and UART, and their connection relationships with other chips and circuits are described in the foregoing description of fig. 2, and the port numbers of STM32 correspond to the interconnection port numbers of other chips one to one, which can be recognized by those skilled in the art and will not be described in detail.

In fig. 4, the VA-LCD driving chip of the present embodiment is ST7072LQFP80, and P32-P35 are ports connected to the main control MCU through I2C, corresponding to fig. 3. SEG0-SEG33 are port numbers corresponding to port numbers on the VA-LCD left FPC jack of fig. 8 and the 9VA-LCD right FPC jack of fig. 8, respectively.

Fig. 5-6 show the driving circuits of the left LED backlight 6, the right LED backlight 7 and the TFT-LED backlight 8, which are all driving circuits formed by transistors (Q3 drives the TFT-LED backlight 8, Q4 drives the left LED backlight 6, Q5 drives the right LED backlight 7), the power supply terminal VCC3.3V is connected to the base of the transistor, the backlight power output terminal VLEDK3(2, 1) is connected to the collector of the transistor, the emitter of the transistor is grounded, and the backlight power supply is connected between VCC3.3V and VLEDK3(2, 1).

Fig. 7 shows a VA-LCD row driving enable circuit and a VA-LCD column driving enable circuit of this embodiment, which are formed by transistors (Q1 and Q2 drive rows and columns, respectively), the base control terminals P15 and P16 of the transistors are connected to the master MCU port, and the collector output terminals TCOM and TSEG are connected to the VA-LCD left FPC socket of fig. 8 and 9 and the VA-LCD right FPC socket of fig. 9, respectively.

The FPC jack of the TFT liquid crystal panel of fig. 10 has a driving port VLEDK1 for the TFT-LED backlight in addition to a connection port to the main control MCU.

The LCD Panel Industry is always in change, many displays were out of production due to the materials shortage, we are willing to help our customers to find alternative suppliers to maintain the stability of their projects. We have established a good partnership with some Brand OLED Manufacturers, and we hope to be your long-term TFT LCD Display/OLED Screen Partner.

Hundreds, Thousands, Small batches are no problem. Not only TFT&OLED, Mono PMOLED, OLED, STN, but FSTN Displays are also welcome, we will try our best to help you.

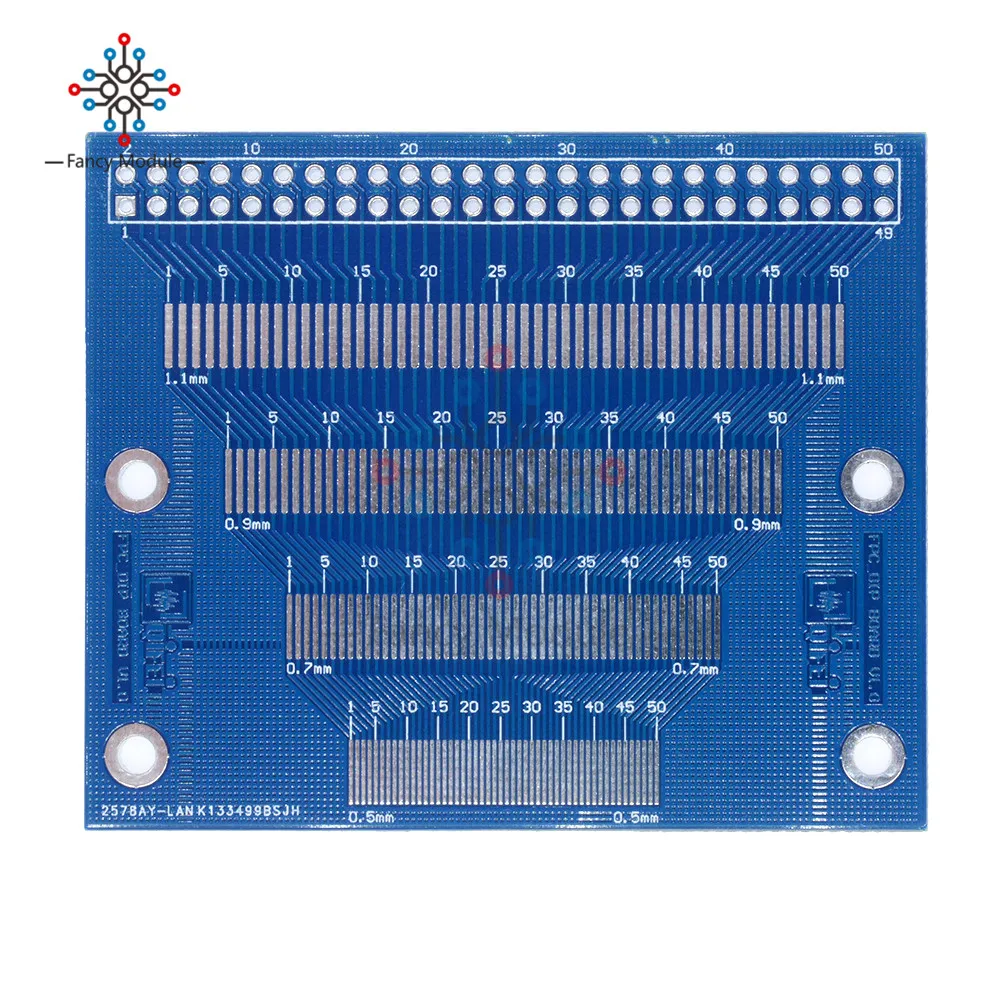

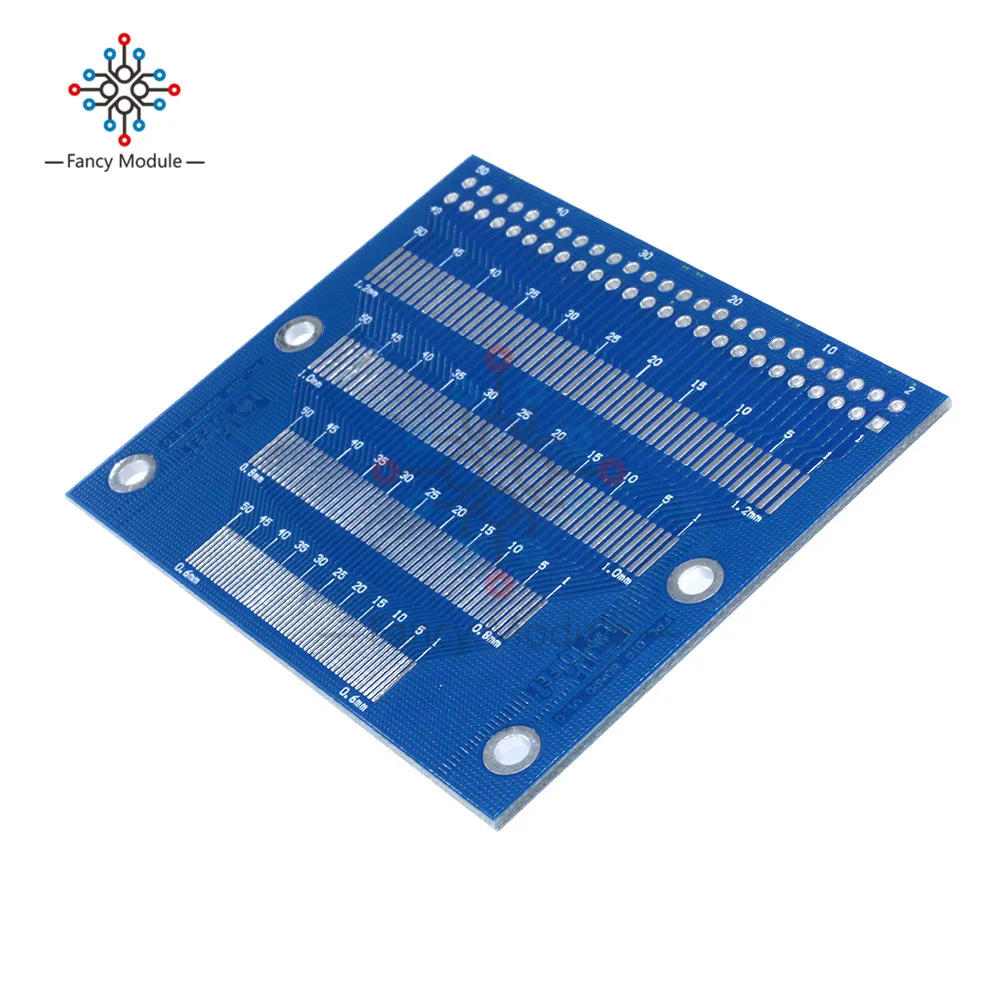

The easy-on FFC, FPC connector with a 0.5 mm pitch interface supports different applications. The surface mount, right-angle orientation with Nylon material has a ranging temperature of -20° to +85°C, current of 0.5 A, and a maximum voltage of 50 V.

Adjust the length, position, and pinout of your cables or add additional connectors. Get a cable solution that’s precisely designed to make your connections streamlined and secure.

Choose from a wide selection of changes including shape, size, pinout, and component layout of your PCB to make it a perfect fit for your application.

For me, it"s about a TFT + touch + controller solution that we"ll have a little more control over (quality and repeatability). Cost is of some concern, but if we can build a better unit for $80 than the current $50 one from China I"d be happy with that.

The LCDs themselves seem reasonably common, but having only one or two sources for the completed unit with PCB worries me too. I"d also remove the features we don"t need (SD card slot and flash memory) and replace the 2 female headers with 1 male one so we can use easier-to-make female-female IDC cables.

FPCs are typically used with a ZIF connector to connect to a PCB. When looking for a compatible ZIF connector for a given FPC, it is important to consider the pitch (spacing of the pins), the number of pins, whether the connector has contacts on the top, bottom, or both, and the material of the connectors on the FPC and the ZIF connector.

To satisfy the high demand for flexible printed circuits,flexible printed circuit board manufacturers must play their role effectively. Predictably, the high number of flex circuit board manufacturers globally can make it difficult for you to choose the right partner for your flex PCB manufacturing needs.

But since it is of the essence to get the right partner for your flex PCB manufacturing needs, you must understand how to go about it. Additionally, it helps to know the top 10 flexible printed circuit board manufacturers globally. So please read on to get it right when you are looking for your next flex circuit manufacturer.

Flex circuits, despite some history, have become popular in recent times. Flex PCBs have a complicated manufacturing processcompared to conventional rigid circuit boards. It arises because of their intricate nature. You, therefore, need to get the ideal manufacturer possessing the right manufacturing equipment, highly skilled staff, the correct processes (including quality assuranceand testing), an acceptable industry pedigree, etc., to get it right. The high number of manufacturers also complicates your selection process further. But as always, you can always navigate this minefield if you consider the following.

If you want to identify the correct manufacturing partner for yourflex PCB, check whether they have the latest equipment and technologies. Such a capacity helps in producing high-quality flexible PCBs for your needs. Most reliableflex PCB makersendeavor to maintain quality and enhance efficiency. As a result, such companies invest in their production facilities. Check for drilling tools, place board testers, surface finishing tools, imaging equipment, etc.

Flexible PCBs require advanced processes when it comes to their manufacturing. Further, plenty of steps get into the manufacturing process, and not every manufacturer qualifies in producing high-quality flex PCB.

Most reputable manufacturers have skilled technicians who can handle your flex PCB manufacturing needs. Therefore, if a potential manufacturer lacks such a group of skilled technicians, you had a better look elsewhere.

Quality is significant when it comes to flex PCBs. Therefore, check and ascertain that your potential flex PCB partner produces high-quality flex circuits of the desired standards. The flex PCB products should have long-term durability, high-speed communication lines, high-density design, high conductivity, etc. Further, you can always resort to E-tests to ensure the quality of the flex PCB boards.

Design standards and quality often determine the production cost of flex PCBs. Additionally, some factors like base material or solder mask material can vary. Such factors can heavily weigh on your final product’s price or cost. Therefore, you must find a decent balance between cost and quality before placing your order. Therefore, do not pay or contract a manufacturer before considering this.

Flex PCBs have the uncanny ability to fit most applications. It, therefore, implies that it comes in diverse sizes and shapes. When it comes to your flex circuit manufacturing needs, your ideal partner must demonstrate the capacity to produce your desired form. For example, if you want a flexible PCB for military applications, you will need a flex circuit markedly different from a medical application. Most standup manufacturers will have the capacity to manufacture various forms and sizes of flex PCB for your use.

One vital step in the manufacturing process entails testing. For your Flex printed circuit, the company needs to have robust and updated techniques to ensure the integrity and functionality of the board upon deployment. A lack of elaborate testing can lead to mass failures of Flex PCBs. In testing the Flex printed circuit boards, the manufacturer identifies faults and corrects them early.

You can always get different flexible PCB designs from manufacturers. However, this primarily depends on your needs. It can entail multi-layer flex PCBs, double-sided flex PCBs, and single-sided flex circuits. But for a top-tier manufacturer, the type of flex PCB should never become an issue. The manufacturer needs to demonstrate the capacity to fabricate all the types based on your needs.

Most reputable companies ensure the development and testing of a prototype before the mass production of a flex PCB. The cost of identifying an error later in post-production can prove grave and costly. As an engineer or designer, it can work best for you if you get a prototype from the company before production. In this manner, you can suggest and have them incorporate ideas.

If you want a top-quality flexible PCB, you may want to consider hiring a top-tier flex PCB manufacturer. But armed with the knowledge of the aspects to consider in picking a quality PCB manufacturer, it is time to narrow down and zero in on the ideal option. However, to save you from all the hustle, we have sampled the best ten FPC manufacturers all over the world.

It is a famous and industry-setting flex PCB manufacturer. Unimicron also gets inferred to be a World-leading PCB Company. The company prides itself in guaranteeing you its commitment to delivering quality flex PCBs. You also get to enjoy the manufacturer’s extra focus on quickening the manufacturing process.

The manufacturer has its headquarters in Taiwan and a demonstrated history of 31 years since 1990. It possesses a global pedigree and provides world-class facilities, machinery, and workforce to serve its international clientele diligently. The company not only fabricates flexible PCBs but offersintegrated circuit carriers, rigid-flex PCBs, HDI or high-density interconnections, testing, andburn-in services.

RayMing PCB & Assembly is an excellent option you can choose when it comes to your flexible printed circuit. The RayMing PCB and Assembly company, unlike other manufacturers, provide full turnkey services ranging from prototyping to assembly and packaging. Additionally, if you want a customization of your flex PCB, you can always rely on the company.

Provide fabrication and assembly for both partial and full turnkey flexible printed circuits. The layer number of flex PCB includes 1-12 layers with diverse material choices and board thickness.

Full and partial turnkey flex PCB fabrication while also encompassing assembly for your printed circuit board design. Partial turnkey flex production entails providing the boards and some components for your flex PCB design. But beyond this point, the company carries out all the other activities to ensure a functional and efficient flex PCB product. On the other side, full turnkey will involve the company undertaking all the activities from procurement, design, testing, and quality monitoring of PCB production.

DSBJ comes as a unique flex PCB manufacturer that understands the meaning of diversification into different sectors like AI. It is an important quality that acts as its main selling point. DSBJ has a long industry experience spanning over 40 years since 1980, when it started as a small stamping and sheet metal factory. It then morphed into Suzhou Dong Shan Ban Jin company eight years later. As they say, everything from this point onwards is history.

The company has continued evolving over the last few years through consistent innovations and concepts in designing, manufacturing, and prototype PCBs. The realization of this can also get credited to meaningful collaborations and the acquisition of some franchises and companies. In addition, it helped expand DSBJ’s manufacturing services in diverse areas of the globe. For instance, the acquisition of Multek in 2018 expanded the scope of manufacturing in terms of global geographical locations.

The Taiwan-based company comes as a reputable flex PCB manufacturer specializing in designing, fabrication, and assembly of rigid printed circuit boards. It is equipped with world-class manufacturing processes that ensure high-quality PCBs.

Tripod Technology deals in other electronic back-end equipment products despite primarily indulging in PCB development and manufacture. It includes a topping machine, test handler, target hole drilling, etc. It prides itself on sustainable environmental protection, especially in the production process. You will find its business model unique as it is developed around R&D (research and development). Such a strategy propels it above competitors in global PCB manufacturing, which is a notch higher.

The company has a remarkable reputation for manufacturing incredible and quality flex printed circuits. Zhen Ding Tech believes in investing in more materials to better facilitate Flex and otherPCB designtypes. In addition, it combines theIoT (Internet of Things), Internet of Vehicles, AI, and 5G technology to offer several customized solutions.

You get to enjoy simplifying their printed circuit board fabrication or manufacturing process into vital aspects. The first step entails the design phase before further research through the R&D department. After this, the Flex or other PCB type gets manufactured before delivery for your use.

The company has a distinct collaborative approach to developing or manufacturing flex circuit boards for you. Kinwong comes as one of those manufacturers that will not rest until your PCB needs to get met. Further, it prides itself on excellent craft with attention to your design to provide a true-to-type or improved version of your expectations.

If you have not encountered the bizarre, this company will shock you slightly. It is not your standard PCB order and manufacturing company, but one that specializes in designing and evolving new PCB design trends to fruition. Shennan Circuits got incepted in 1984 and have over 37 years of experience in the field. It is global, with production sites in China and North America. It also has R&D sites located in Europe as an integral aspect of its commitment to manufacturing.

Diverse approaches in providing world-class electronic circuit solutions and technology include a 3-in-1 PCB design process encompassing design, substrate packaging, and assembly. The approach can also involve a full PCB value chain, including scheme design, micro-assembly, PCB testing, manufacturing, etc.

If you have a large flex PCB order, then Suntak PCB can prove the ideal solutions partner for you. The company has a demonstrated history and pedigree of manufacturing PCBs since 1995. Coupled with a skilled staff of over 4500 and a 3 million sq. m factory space, you will hardly get disappointed. What is more? The company commits to providing high-caliber PCBs to its clients or customers.

The company is an industry leader when it comes to PCB technology innovation. The belief entails using the correct technology whenever the desire encompasses getting more opportunities in the industry. Because of this, the manufacturer prides on this mantra for the two decades it has existed. Further, customer satisfaction ranks highly, thus their commitment to ensuring quality PCB service delivery.

China has emerged as a global powerhouse when it comes to PCB manufacturing. Additionally, the labor is highly skilled and cheap compared to North American and European companies. As a result, the quality of PCBs by Chinese manufacturers proves high and withlower costs which rank them highly.

If you want a quality flexible PCB, finding the correct flexible printed circuit board manufacturer becomes of the essence. It thus becomes prudent to understand the aspects discussed to pick the best-suited manufacturer for your flex PCB needs. But starting your discrimination with the highlighted flex PCB manufacturers will make it easier for you, would it not? Best of luck.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey