tft lcd pcb connection fpc price

Elastomeric connectors, also known as ZEBRA strips, are a common connection type for LCDs with surface mount connections. A ZEBRA strip connector is comprised of a malleable insulation strip with alternating conduction lines and can be used as a substitute for a hardwire connection. These connectors get their name from their alternating conduction lines that appear as stripes, similar to a Zebra.

ZEBRA strips are positioned between a display’s connection ports and its controller. They then require a bezel to ensure a proper connection with the display. Once the bezel has been applied, the ZEBRA strips compress against an LCD’s surface mount connection ports. The resulting pressure from the bezel allows for a solid connection between the conductive strips and the display.

This connection type is a good option for testing and prototyping displays as there is no need to permanently connect pins to the display. ZEBRA strips are also a good option for thin, compact LCD and PCB designs. For example, if limited space is available within the enclosure, a ZEBRA strip can be used as an alternative to metal pins or ZIF connectors. ZEBRA connectors can also often be a cheaper alternative to other connection types.

Flexible printed circuit (FPC) and flexible flat circuit (FFC) cables (hereinafter both interchangeably referred to as “FPC” or “FPC Cable”) are widely used connectors that provide access to the internal circuitry embedded in the display. Such connectors are standard in laptops and mobile phone displays.

FPC cables reduce the amount of area required by pins to interface with a display and can be integrated into PCB with minimal space and complexity by routing the signals through this cable.

FPC cables are directly routed to the embedded liquid crystal driver and the internal circuits required to drive the display. To access the contacts on an FPC, a ZIF connection port can be used to hold the cable in place and prevent damage to circuitry. The end of an FPC cable is placed into a ZIF connection port and locked into place by a clasp or plastic holder.

The flexibility of an FPC cable is ideal for compact devices. The cable is made of a flat, bendable material that insulates the conductive wire connected to the LCD. The conductive leads to the display are heat sealed between durable insulative strips.

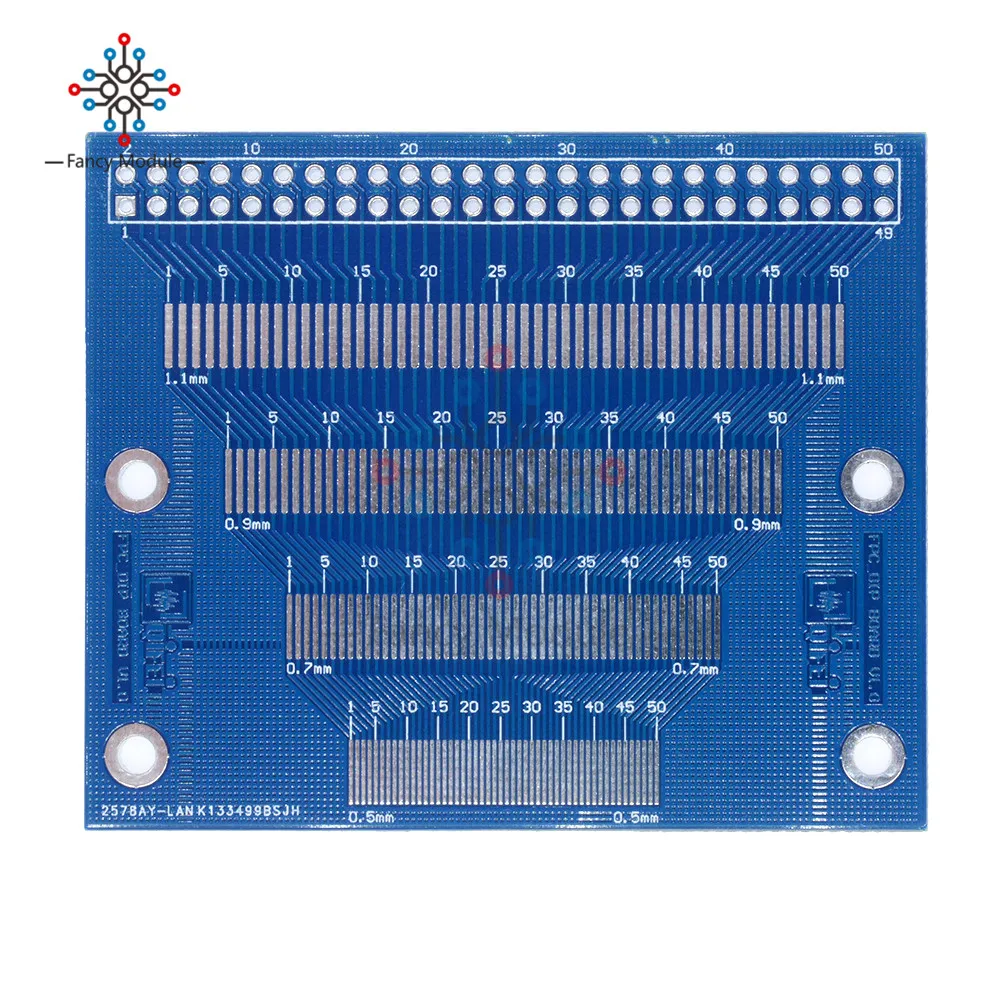

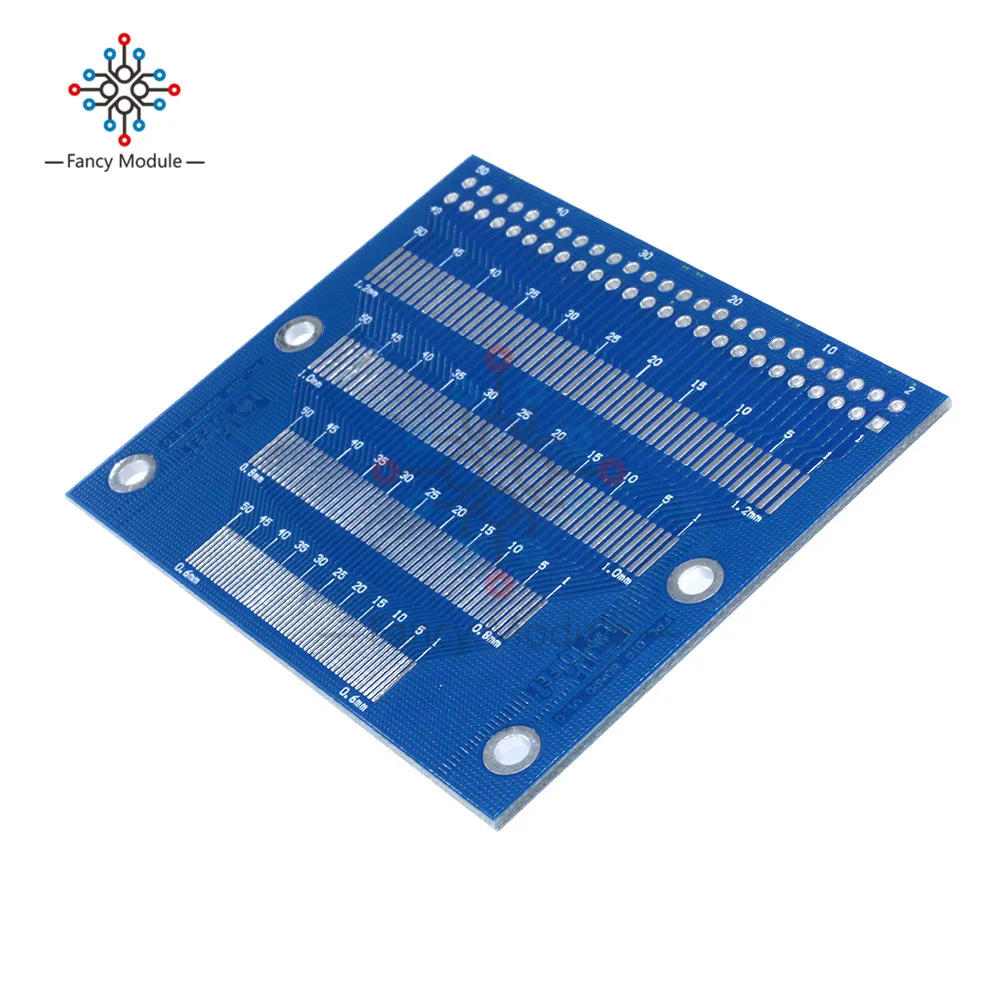

The spacing between each metal contact on the ribbon cable is called the pin pitch. The pin pitch for a display’s FPC cable can vary and is specified by each display. A common pin pitch for a display is 0.5 mm, but can range from 0.3 mm to 1.0 mm.

Throughholesarea standard connection type for many displays that offer a connection through small holes on the PCB. This connection type is most common for LCDs that have an external PCB controller circuit mounted to the display, such as most character and segment LCDs. Typically, the PCB will include the required liquid crystal driver, a voltage converting circuit, and backlight control.

Through holes have conductive metal holes on PCB that can be connected to using solder or a bezel. A through hole connection gives many options for connecting and interfacing the display. Connecting the display via through holes is a good option for prototyping because the standard pitch between holes and wide range of options for connecting.

Through holes are not a good connection type for compact enclosures. They have a standard spacing that requires a hardwire solder connection or a bezel to hold the interface pins to the holes. However, this standard spacing is advantageous for hardware to plug into breadboard or peripheral devices.

Metal pins are a connection type for LCDs that have metal pins already mounted and connected to the display. Metal pins can be connected to the internal display controller or to the COM and Segment lines of an LCD. Typically, this connection type is used for character and segment LCDs.

Metal pins are a reliable, sturdy connection type that can be mounted into similarly spaced devices. They are accessed by plugging the display into a socket or by soldering the display into conductive holes on a PCB. Similar to the through hole connection type, metal pins are spaced to be compatible with breadboards for prototyping.

Metal pins are good for applications that have standard pin mappings so that the display can be plugged into the controlling device. This connection type is less versatile than the previous LCD connection types as the pins are hardwired into place and cannot be moved unless unsoldered. The standard distance between pins is 2.54 mm.

Heat seal connections for LCDs are a reliable connection type utilizing a flexible cable connector that is heated and sealed to a displays’ interface ports. This connection uses a special heat seal paper that is then adhered to the display using a conductive glue and sealed by applying heat.

Heat seal connections are intended for hinged applications where the display is mounted at a different angle than the port and can be found in calculators and military grade devices.

Similar to FPCs, a heat seal cable is flexible and can be used for finely pitched pins. Therefore, they are another great option for compact display connections. However, heat seal cables have the added advantage of superior durability.

While FPC cables will degrade or become damaged with continuous bending, a heat seal connector will maintain the performance with continuous bending and will not become damaged.

Heat seal connections are similar in cost to the other connection types but are less expensive than the comparable FPC connection type. The heat seal connection is not changeable once adhered to the display. Once the cable is glued and sealed to the display it cannot be removed, replaced, or reused.

Buyers and others who are developing systems that incorporate FocusLCDs products (collectively, “Designers”) understand and agree that Designers remain responsible for using their independent analysis, evaluation and judgment in designing their applications and that Designers have full and exclusive responsibility to assure the safety of Designers" applications and compliance of their applications (and of all FocusLCDs products used in or for Designers’ applications) with all applicable regulations, laws and other applicable requirements.

Designer agrees that prior to using or distributing any applications that include FocusLCDs products, Designer will thoroughly test such applications and the functionality of such FocusLCDs products as used in such applications.

This TFT kit comprises one of our smallest TFT displays and an adapter board that breaks the tail connections out to a simple 2x5 10-position header. The adapter board includes a backlight driver, so only a single 3.3v power input is required to bring up the display.

The adapter board is specifically designed for use with this display, so it fits directly behind the display with no PCB overlap. The display is a 1.3", full color, IPS display that looks incredibly sharp.

Let’s face it, full-colour TFT displays are cool and adding one to your project is going to instantly endow your project with coolness. The problem for the hobbyist is that they come with flexible flat connectors known as FPC or FFC connectors. These are designed to be soldered to a PCB using a ‘hot-bar’ device that is pressed across all the terminals at once, instantly soldering them to the board. Nice if you’ve got one.

Help is at hand. There are many suppliers on ebay that will sell you a small TFT already mated to a PCB with the FPC connector broken out into a 2.54mm DIP header. If these satisfy your needs then buy them, you’ll be saving yourself a whole lot of work.

But what if the panel you want only comes ‘naked’, or perhaps you want to drive the signals directly as you’ll have to do if you want to stream video to it. If you fall into these categories then you are going to have to tackle the FPC connector yourself, and I’m going to show you how.

The breakout board is suitable for many different FPC pin pitches. By holding the FPC connector up against the board I can see that mine has a 0.8mm pitch and 37 terminals. As a bonus I can see that each terminal has a very small hole punched in it. This hole is designed to allow solder to flow up from underneath, making a better connection.

We are going to use a reflow technique to solder this connector. The idea is that we lay down solder on to the board pads and then reflow it to create the connection. I was surprised how easy this was.

Now is a great time to solder the DIP header into place because you’re not going to be able to get to it easily after the FPC connector has been soldered down.

Before starting on the FPC connector make sure you paste a thin layer of flux over the tinned board connectors. This will help the solder to reflow smoothly over the FPC terminals.

Working under the microscope or magnifier, carefully align the FPC connector with the tinned pads ensuring that it’s straight and that each terminal is completely overlapping the pad. Don’t overlap the pad more than the terminal length because there may be some traces further back on the connector that could cause a short circuit. Hold it down like that with one of your hands.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey