lcd panel connectors dropped in stock

I would suggest you let someone else handle this as they will have test parts etc to eliminate the possibility of a bad cable or a bad LCD. Knowledge rules but without proper tools knowledge is almost useless.

deggie wrote:You have this experience where? Most Apple Stores do not do any piecemeal repairs, they replace the screen or the entire device which is why so many people complain about the cost here. The alignment of the cable would not cause this problem, the cable losing connection might but this type of symptom is almost always the screen.Since this iPhone has been dropped repeated times it is well out of warranty and Apple would charge to do anything with it.Please define "lots" and what Apple Store is this?

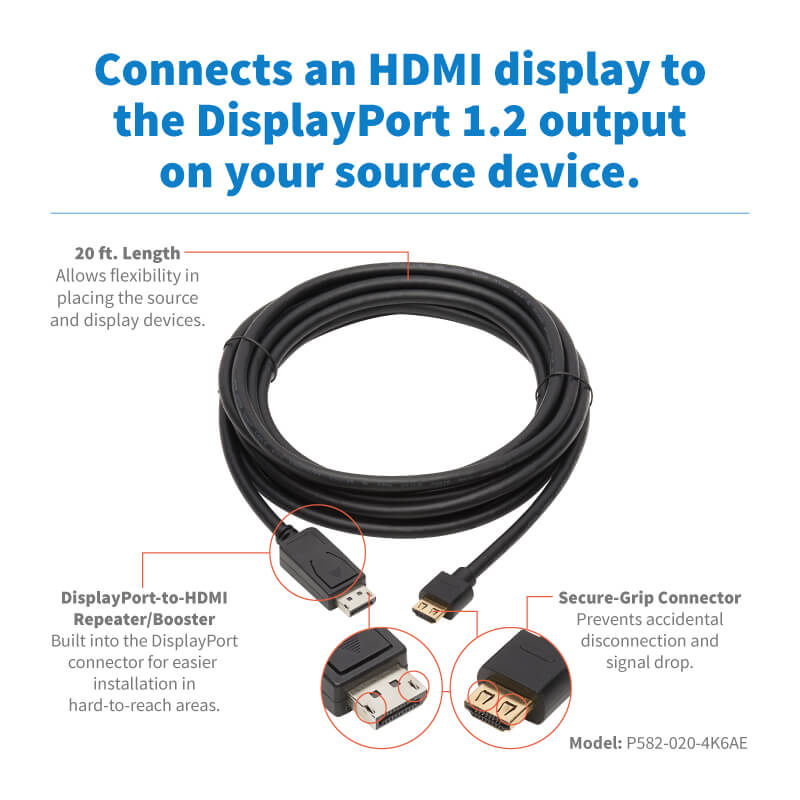

There are two cable options for connecting the PanelDue, both options are included with the PanelDue V3 kit. Option 1 is the included 4-wire cable with Molex KK connector ends. Option 2 is the included 10-wire ribbon cable. For some boards, both cables need to be plugged in to enable both TFT panel and SD card socket.

The length of the 4-way cable is not critical, however the resistance per conductor should not exceed 0.1 ohm. The SD card socket on the TFT panel will not be functional. The cables supplied by Escher3D and Duet3D are about 800mm long. There have been reports of cables up to 1500mm long being successfully used. Take care to route the cable away from motor and endstop cables. Twisting the cables may help prevent cross talk interference.

A PanelDue can be connected to connector IO_0 using a 4-core cable wired like the one shown in the images below. The 4-wire cable supplied with the PanelDue has a 4-way Molex KK connecter on each end, but is supplied with a 5-way Molex KK connector for use with Duet 3. You will need to rewire one end. The 4-wire cable does not allow access to the SD card socket on the PanelDue.

Older versions of the Duet 2 WiFi/Ethernet need both the 4-wire and ribbon cable to be plugged in to use the TFT Panel and the SD card socket, when connecting PanelDue v2.0 or v3.0.

Use a 4-core cable terminated in a Molex KK or compatible connector at the PanelDue end and a 2x4 Dupont-style connector at the Duet end. This plugs into the end of the expansion connector. See https://miscsolutions.wordpress.com/pane....

In order to use the SD card slot on the PanelDue, you must use the ribbon cable option. If you do not wish to use the SD card slot, it"s recommended to use the 4-wire cable option described in Option 1.

The Duet 3 MB6HC has no PanelDue_SD socket. To use the external SD card, it requires RRF 3.4 or later, and a special wiring scheme; see "Duet 3 MB6HC using ribbon cable" section below.

Connect a 10-way ribbon cable between socket X5 on the PanelDue and socket CONN_SD (Duet 2) or PanelDue_SD (Duet 3). The connector is a standard 10 pin 2 row 2.54mm pitch box connector that accepts IDC connectors for 1.27mm ribbon cable.

Caution: if you are using a thermocouple and/or PT100 daughter board, the use of long ribbon cables between the Duet and PanelDue may affect communication between the Duet and the daughter boards, because the ribbon cable connection to the SD card on PanelDue uses the same SPI bus as the daughter boards.

Although the Duet 3 MB6HC does not have a connector for the PanelDue ribbon cable, if access to the SD card on PanelDue is required then this is possible using a special wiring arrangement. You must use RepRapFirmware 3.4 or later, and you must enable the external SD card using this command:

where cs_pin is the pin that the SD card CS line is connected to and cd_pin is the pin that the SD card detect pin (if available) is connected to. For these pins, if you are not using a temperature daughter board then we suggest that you use CS0 and CS2 respectively on the SPI daughter board connector to simplify the wiring; otherwise use the output pin and the input pin on one of the IO connectors. So the M950 line would look like this:

Note: if you are using an older version of either PanelDue 7i or PanelDue 5i, or a non-integrated version of PanelDue, then those do not support the CD signal. In that case you should omit the second port, for example:

The card detect signal (CD) is used to tell the Duet whether a card is inserted or not. Non-integrated versions of PanelDue (V2, V3) and older versions of PanelDue 5i and 7i (v1.0 of the 5i and v2.0 of the 7i) do not provide a card detect signal.

Duet 2 boards do not support the card detect signal on the external SD card, so can never tell whether a card is inserted or not except by trying to read it, and can"t detect a card being removed. No modifications are required connected older or newer PanelDue, or other external SD card adapters, to Duet 2 boards.

Duet 3 boards do support the card detect signal. Newer versions of the PanelDue 5i and 7i (v1.01 and later of the 5i and v2.01 and later of the 7i) provide this signal.

However, if you use a non-integrated versions of PanelDue or older versions of PanelDue 5i and 7i with Duet 3, it is necessary to ground the card detect signal, or the firmware will permanently think no card is inserted. There are a number of ways to achieve this.

This mod will enable the card detect signal. See the pictures below showing how to modify a PanelDue 5i v1.0. Connect a wire (thin enamelled copper in this instance) from the SD card socket Card Detect pin to the appropriate pin on the ribbon cable connector.

Generally it is best to run the latest version of the PanelDue firmware that is supported by the RepRapFirmware version on your Duet mainboard. See: Installing and Updating PanelDue Firmware

From RRF v3.2, PanelDue firmware releases are co-ordinated with the RRF release, and share the same version number. Use the PanelDue firmware version that matches your Duet mainboard"s firmware version.

PanelDue will display the bed heater H0 first (even if it is disabled), then iterate the defined tools. It then iterates the defined heaters below this. It expects a 1:1 relationship between tools and heaters. This means:if you have a machine that uses one heater for more than one tool (eg a 2-into-1, filament-swapping hot end), it will display more tools than heaters. Tools may not line up with their respective heaters.

The PanelDue also iterates the heaters from the first defined heater to the last, including all heaters in between, whether defined or not. This means if you have a heater defined on H0 (bed) and one on H5 (Duex output), it will show all the ones in between, eg H0, H1, H2, H3, H4 and H5. For an example, see |https://forum.duet3d.com/post/136207|this forum post|. Ideally, configure heaters on consecutive heater connections.

Due to constraints on display resolution, PanelDue can only display 7 heaters in total on 5" and 7" panels, and 5 on 4.3" panels. If there are more heaters and/or tools than this, some columns will overlap.

These restrictions are largely removed in later versions of the PanelDue firmware. However, they will require you to update RepRapFirmware on your Duet mainboard.

You can use the external SD card socket on the LCD panel if you have used a ribbon cable as described above. Please note, the SPI interface provided by this SD card socket is much slower than the on-board SD card socket built into the Duet. Therefore we recommend that you do not upload files to this card over the network. Use the external SD card socket only if you want to write files to the SD card on a PC and then move the SD card to your printer.

Caution! Do not use an SD extender cable from the SD socket on the Panel Due. Some types of SD card extender cable have been found to damage the SD card socket. Damage to the SD card socket from using an extender cable is not covered by the warranty.

You will need to make a custom 5-way cable using this table of connections. For the PanelDue 1.1, the X5 connector pins are numbered from the bottom end of the connector (the end close to the X5 legend). On the Duet 0.6 and 0.8.5 you need RepRapFirmware 1.17d or later to get support for the second SD card.

SD signal namePanelDue 1.1 X5 pin #PanelDue 2.0 X5 pin #Duet 2 signal nameDuet 2 CONN_SD pin #Duet 0.6/0.8.5 signal nameDuet 0.6/0.8.5 Expansion pinDueX4 Expansion1 pin

These displays are typically clones of the RepRapDiscount Full Graphic Smart Controller and look like this. The better ones include a contrast adjustment potentiometer. Unfortunately some manufacturers of other displays using the same controller chip reverse the pinouts on the two ribbon cable connectors. The ST7920 controller chip is invariably powered from 5V, which means that the display need 5V input signal levels.

An example of this is the Fysetc Mini 12864 Panel. The controller chip is run from 3.3V, so these displays normally include level shifters which tolerate a wide range of input voltages.

Duet 3 Mini provides two 2x5 ribbon cable headers for connecting a Fysetc 12864 Mini Panel version 1.2 or 2.1 (not 2.0) or compatible ST7567-based controller. When using a version 2.1 controller, the colours of the three Neopixel LEDs built into the display can be set using the M150 command with LED type parameter X2.

Use the pins +5V, GND, IO_0_OUT and IO_0_IN on the IO_0 header (Duet 3), or +5V, GND, TX and RX on the PanelDue header (Duet 2). These should be connected to +5V, GND, TX and RX on the TFT, making sure that TX and RX are swapped.

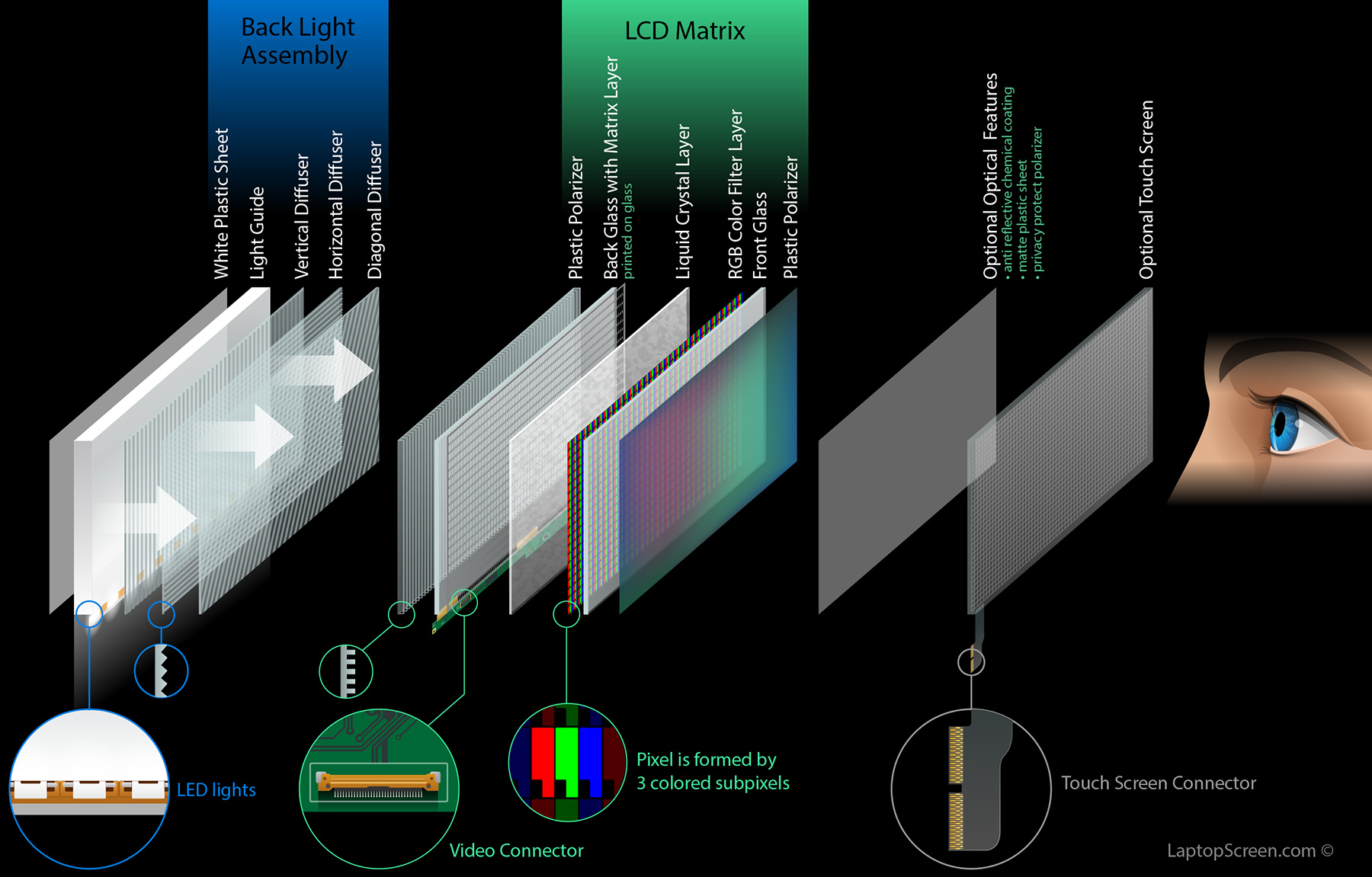

A while back I was sitting around and wondering what to do with my dead laptop. I knew the mother board was fried but everything else was still in working condition. As a result, I decided to make an external monitor from my dead laptop and proceeded to do the research to find out if this was possible. Below is what I discovered. Unfortunately, there was no way to use the motherboard"s VGA connector. The VGA connector on a laptop is used to connect to an external monitor. In any case the VGA connector is output only and wouldn"t work for an external screen. As a result, I found that I needed to buy a controller board for the LCD screen, to make it work as an external monitor. This was the main cost but was still less than half the cost of buying an external monitor.

Step Two. To Remove the LCD screen from the laptop, you will need to remove the screws. There are rubber pads on the front of the LCD screen to protect it when the laptop lid is closed. Behind the rubber pads are the screws. Find and remove all the screws holding the front plastic frame on the laptop lid. Keep track of the pads and screws as you will need them to reassemble everything.

Step Three. Remove the plastic frame from the LCD screen. Here is where you need to be careful. The screws are not the only thing holding the plastic frame on the LCD screen! The plastic frame is snapped into place. Carefully pry loose the frame from the LCD screen. Pry it loose gently. Try to keep it as close as possible to the LCD panel while you are prying it loose because you may also find that you need to slide it to the left or right to completely remove it from the laptop. There is a small protrusion of the plastic frame where the hinge is. Because of this protrusion you need to slide the frame, in this case, to the right, to detach it from the laptop.

Step Four. Locate and remove the screws holding the LCD panel to the laptop. These are located on the bottom. The screws are attached to a small metal hinge. this is the component that is attached to the keyboard frame.

Next you will need to remove the LCD screen. Note that there is a cable attached. This is the LVDS cable. It is best to take apart the rest of the laptop and unplug it from the keyboard. However, the cable can be cut at the bottom. Take care not to cut the two wires going into the inverter (that"s the slim circuit board at the bottom.

Once the LCD panel is removed, you can remove the LVDS cable and unplug the inverter at the bottom. Unplug the inverter from both ends. Do not cut it. The LVDS cable is taped to the back of the LCD screen at the top. It is the flat cable running up the back. Remove the tape and slid the cable down. Since you need to buy an LCD controller board, you will no longer need the LVDS cable the laptop came with or the inverter. At this point you should just have an LCD screen with a pair of wires coming out of it.

Keep track of the plastic front frame and the plastic backing. You will need them to resemble the LCD screen. On the other hand, you have different fingers, just kidding. On the other hand, you can buy a picture frame and put the LCD screen in the picture frame.

Here is a picture of the LVDS cable and the inverter detached from the LCD screen. Since we will be buying an LCD control board these cables will not be needed again.

Next, once you have removed the LCD panel. Flip it over and look for a model number on the back. You will need this model number to order the correct LCD controller board. I went to E-Bay and found one for $42.00. I bought the LCD controller board and then received an email from the seller requesting the model number of the LCD screen and manufacturer. This is because each controller board is flashed, (programed to run a specific LCD) I gave him my model number, LP171WX2 A4K1 and told him it was made by LG Phillips. Since the board was coming from China, I received my order about 2 weeks later. Due note to buy one with a power cord! The LCD controller board has the VGA input connection which allows you to connect it to another computer and use it as a second monitor or as a back up in the event the one on your working computer goes out.

The LCD controller board is real easy to connect. It comes with all the required cables, except a VGA cable which you will need, in order to connect your LCD to another computer. You can buy a VGA cable from Best Buy or a computer parts store.

The LCD control Bard comes with all the cables except the VGA cable which you will have to buy. Once you have received your kit, proceed to connect it to the LCD screen. Plug the LVDS cable into the LCD panel where you removed the original from. The two wires at the bottom of the LCD screen that were connected to the inverter need to be unplugged from the old inverter and plugged into the new inverter below. Then, plug the power in. Make sure that the LCD control board is not sitting on anything conductive, like metal or it will short and fry. Next connect the VGA cable to the LCD control board and plug the other end of the VGA cable to another computer. Make sure the computer is on before you plug in the VGA cable. At this point you should have the same image that is on the computer you plugged the VGA cable into, on the LCD panel.

Next, I attached a 4 inch section of two by four on the outside back of the laptop lid. I needed this in order to attach my stand to the LCD screen. I used 5 screws and screwed them in place from the inside. I did splice and extend the cables going from the LCD controller to the inverter it came with just to have a little more room.

Originally, I built a nice wooden stand for my LCD panel but was not satisfied with it. So, I took a broken florescent desk lamp and dremeled off the section holding the florescent tubes, leaving enough metal to screw on to the two by four on the laptop lid. Before attaching the stand, I drilled four holes in the metal to make it easier to screw it on the two by four.

Next you will need to attach the LCD controller to the laptop lid. To do this, screw in a few sections of wood from the inside of the lid. Then on the outside of the lid attach the LCD control board. Place the wood in an area where the control board can reach.

Next you will need to find all those screws you have been saving and reassemble the LCD screen. I also added some surgical tubing to the top springs for added strength.

By the way a store bought swing arm half the size of this one, I found, cost around $400.00. If you choose to use a swing arm like this one, go with the one that has a magnifier on it and dremel off the magnifier leaving enough metal to attach to your LCD lid. You need one of this caliber to hold the LCD screen. Swing arms with the light attached are not strong enough.

Since I was asked about the web cam, I though Should add it to the instructable. There is a nice instructable here at this site showing how to convert a web cam from an LCD screen: http://rntmns.com/2011/02/rebirth-of-a-webcam/

Actually, you can do One better. You can salvage the RAM, the Wireless card, the Batteries, the charger, the hard drive, the DVD disk player and sell them to people that need them on E-bay and Still keep the LCD screen for yourself.

I checked ebay for the LCD control Board and all I did was punch in " LCD control Board for a LP154W01(A3)" , That"s my model number. You, of course, use your"s. ebay came up with the correct one for $25.00 and it has all the imputs you could want. This is good today, 2/11/19. Have fun folks!

i have a similar lcd panel to yours. infact 3 of them! they"re so easy to work with and doesn"t need a backlight controller LP154WH4 TLA1 except the lvds cable sold separately. I"ve build one and runs on

Nicely done and very informative!! However unfortunately, by the time you add the cost of the LCD Controller card, various parts and time you could have bought a new inexpensive monitor.

it really depends on what kind of display your laptop came with. I recently had a laptop that featured a 4k OLED screen and If I add the price up of the controller kit and materials (depending how you are going to make the stand) it would actually in my case be cheaper to make that an external monitor because, quite frankly 4k is pretty expensive and I don"t want to degrade to a lower resolution. in said laptop the motherboard died so I just scavenged everything including the LCD which I have just lying on my desk. so I might even consider trying this.0

The Keycap of Keyboard dropped off and the customer preserves the keycap when sending in for RMA. If customer does not preserve keycap, keyboard repair considered out of warranty.

You can exclude specific inventories from the item counting mechanism. This could be useful if you don"t want the autocrafting to see certain items in docked ships for example. Also, the inventory panels won"t show the items of that inventory either.

To start off, you need to build an LCD and name it "LCD Autocrafting". The script will put a list of components, that are autocraftable on the LCD. To set a new wanted amount, you simply have to edit the text on the LCD and change the number to your likings.

Autocrafting LCDA LCD with the keyword "Autocrafting" is required where you can set the wanted amount! This has multi LCD support. Just append numbers after the keyword, like: "LCD Autocrafting 1", "LCD Autocrafting 2", ..

If you want autocrafting to manage the amount of an item but you don"t want it to be shown on the autocrafting LCD, you can use the "H" modifier. The item with its current wanted amount will be moved to the custom data of your (first) autocrafting LCD and hidden from the LCD itself. The amount can be changed afterwards by editing it in the custom data. If you want to show it on the LCD again, just remove the line in the custom data.

If you want you want to hide an item from the autocrafting LCD and don"t want autocrafting to manage it, use the "I" modifier (this was done with a negative item amount before v2.8.0). The item will be moved to the custom data of your (first) autocrafting LCD and hidden from the LCD itself. If you want to show it on the LCD again, just remove the line in the custom data.

Modifiers are also combineable. "AP" for example will assemble only and prioritize. "AD" will basically just show the item on the LCD but neither assemble nor disassemble it.

If you set up your autocrafting LCD already and set all your wanted amounts, you can enable automatic disassembling in your config section (heading Autocrafting). This feature will disassemble all your excess materials automatically using all available assemblers.

Please be sure to set your wanted amounts BEFORE your enable this feature as this will disassemble all your goods imediately and turn them back into ingots. Also, manual crafting is kind of limited after enabling this because the script always tries to keep the set amount of items on the autocrafting LCD at all times.

The following topic explains, how to use LCD panels (regular and block LCDs) of my script. Whenever you add one of the following keywords to a LCD name, the keyword gets transformed to the universal [IsyLCD] keyword. In the custom data, you can then set different options about the LCD as well as the screen, the information should be shown (on blocks like cockpits, programmable blocks and so on). The custom data will look like this:

It is also possible to display informations of different scripts in one block by using this syntax (MMaster"s Automatic LCDs 2 uses the same syntax and all of my other scripts).

You can display all the main script informations like type container fill levels, managed blocks and last script actions on the main LCD. Just add the following keyword to a LCD name:

You can show the current amounts of your stored items on LCD panels. To display them, build a LCD panel, add the keyword "IIM-inventory" to its name and follow the on screen instructions:

If an inventory panel line has 0 as the max value, a single line only containing the item name and current amount is shown (no bars, percentages or max values).

Multi-panel inventory screensYou can display your inventory items over multiple screens by giving all screens the same group tag (this has to be set in the custom data of a screen after giving it the IIM-inventory tag in the name). The syntax is the following:

Note: Every panel"s name still has to contain the [IsyLCD] keyword in order to be recognized by the script (gets automatically set after giving the LCD the "IIM-inventory" tag).

Nearly every feature of the script can be temporarily enabled or disabled without the need to edit the script. These commands are sent to the script by writing them in the programmable block"s argument field and pressing run or by pulling the programmable block to any hotbar (cockpits, button panels and so on), selecting run and typing in the arguments in the popup window.

If you have one of Holley"s 3.5-inch Touch-Screen LCD displays you have already encoutered the Mizu P25 waterproof connector. This connector was designed specifically for low-voltage signals in the automotive, industrial, and consumer appliance industries. It allows for the connection of as many as 4 wires but was not specifically designed for applications that might require the frequent disconnection of the two sides.

The preferred technique requires a sturdy thumbnail. If you are one to chew your nails to the quick, best to move on to the next suggestion. Otherwise, the idea is to drive your thumbnail into the crack between the locking lever and the body of the female connector. Press the lever down as you use your fingers and the leverage of your thumbnail in the opening to separate the connectors. The good news is that depressing the locking lever itself is generally very easy. It is actually demating the connectors that can be the challenge. If you use steady force and a bit of side-to-side action as you separate it is generally doable. Important note: Do not succomb to the temptation to grasp the harness along with the connectors. These are extremely fine wires and they will not survive that for long.

To be honest, even with good thumbnails these connectors can sometimes be a challenge to separate. If you aren"t getting anywhere that way then you might try a small, thin-bladed screw-driver. But this must be done carefully.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey