oled screen vs lcd screen factory

If you’re designing a display application or deciding what type of TV to get, you’ll probably have to choose between an OLED or LCD as your display type.

LCDs utilize liquid crystals that produce an image when light is passed through the display. OLED displays generate images by applying electricity to organic materials inside the display.OLED and LCD Main Difference:

graphics and images visible. This is the reason you’re still able to see light coming through on images that are meant to be dark on an LCD monitor, display, or television.

OLEDs by comparison, deliver a drastically higher contrast by dynamically managing their individual pixels. When an image on an OLED display uses the color black, the pixel shuts off completely and renders a much higher contrast than that of LCDs.OLED vs LCD - Who is better at contrast?

Having a high brightness level is important if your display is going to be used in direct sunlight or somewhere with high ambient brightness. The display"s brightness level isn"t as important if it’s going to be used indoors or in a low light setting.OLED vs LCD - Who is better at Brightness?

Have you ever looked at a screen from an angle and noticed that the images became washed out or shadowy? The further away you get from the “front and center” view, the worse the image appears to be. This is an example of viewing angles in action – the wider the viewing angle, the better the images on screen will appear as you view them from different vantage points.

This means the display is much thinner than LCD displays and their pixels are much closer to the surface of the display, giving them an inherently wider viewing angle.

You’ll often notice images becoming distorted or losing their colors when tilting an LCD or when you view it from different angles. However, many LCDs now include technology to compensate for this – specifically In-Plane Switching (IPS).

LCDs with IPS are significantly brighter than standard LCDs and offer viewing angles that are on-par with OLEDs.OLED vs LCD - Who is better at Viewing Angles?

LCDs have been on the market much longer than OLEDs, so there is more data to support their longevity. On average LCDs have proven to perform for around 60,000 hours (2,500) days of operation.

With most LCDs you can expect about 7 years of consistent performance. Some dimming of the backlight has been observed but it is not significant to the quality of the display.

OLEDs are a newer technology in the display market, which makes them harder to fully review. Not only does OLED technology continue to improve at a rapid pace, but there also hasn’t been enough time to thoroughly observe their performance.

You must also consider OLED’s vulnerability to image burn-in. The organic material in these displays can leave a permanent afterimage on the display if a static image is displayed for too long.

So depending on how your OLED is used, this can greatly affect its lifespan. An OLED being used to show static images for long periods of time will not have the same longevity as one displaying dynamic, constantly moving images.OLED vs LCD - Which one last longer?

There is not yet a clear winner when it comes to lifespans between LCD and OLED displays. Each have their advantages depending on their use-cases. It’s a tie!

For a display application requiring the best colors, contrast, and viewing angles – especially for small and lightweight wearable devices – we would suggest an OLED display.

Tech observers and investors revel in lively discussions about the latest, greatest gadget and whose bottom line will get the greatest bounce. They enjoy debating the intricacies and details of materials that contribute to these devices, and the related trends and developments. For us at Corning, materials innovators for 165 years, it’s been great to see a recent uptick in discussions about OLED versus LCD display panel technology - a genuine #GlassAge debate.

Corning.com staff sat down with Mike Kunigonis, business director for Corning’s High Performance Displays Group, to understand key differences between OLED and LCD display technology.

Corning.com: Thanks for your time today, Mike. Let’s start with a key question: In the context of display panels, how does OLED technology work and what are the main differences between it and LCD technology?

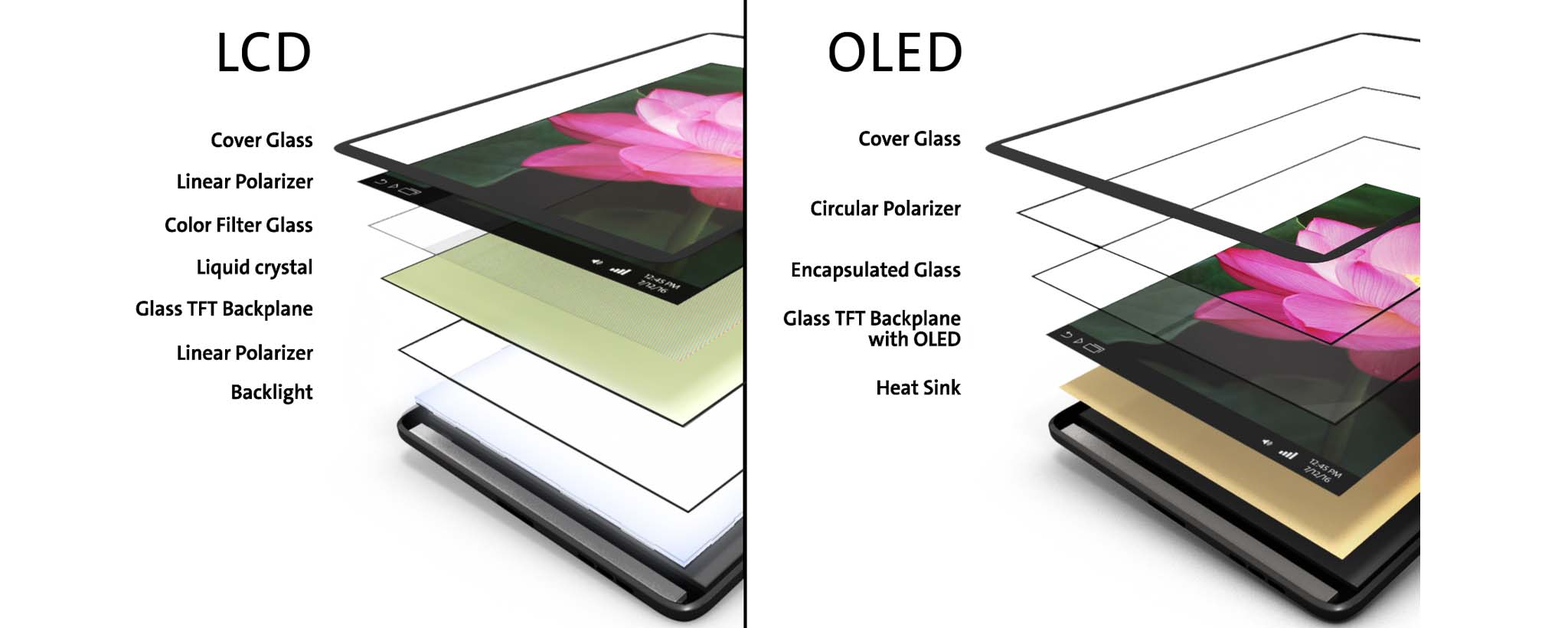

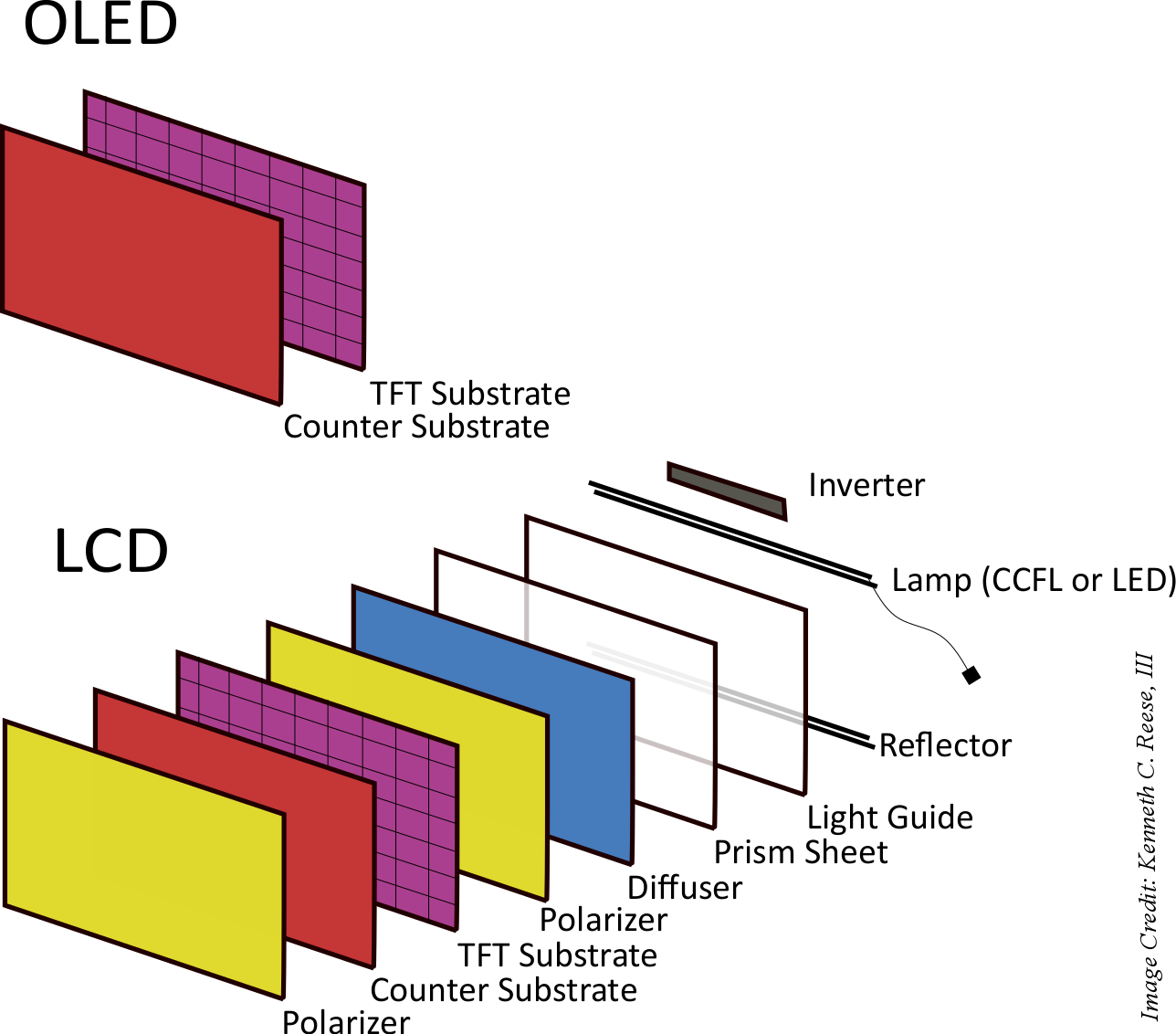

MK: OLED stands for Organic Light-Emitting Diode, or Organic LED. It’s an alternative to LCDs for consumer electronic devices that range in size from wearable to TVs. Like LCD, OLED is a type of panel that enables the displays on device screens. An OLED display picture is generated by turning on and off millions of tiny individual LEDs, each forming the individual pixels of a display. Compare this to LCD, where an always-on backlight projects light through a liquid crystal, sandwiched between two pieces of glass. When the liquid crystal is excited by an electrical current, it lets the light of an individual pixel pass through like a shutter. LCD and OLED display panels both excel at delivering vibrant consumer displays, each in its own unique way.

Corning.com: We’ve heard industry analysts with varying opinions on the benefits an OLED device offers. So why would a consumer prefer a device with an OLED display over an LCD display?

MK: Adoption of OLED displays on smaller, mobile devices is the driver behind most of today’s OLED industry growth, so let me focus on that. A handheld OLED display is attractive to consumers because of the industrial design and display attributes that this technology can support. For example, OLED displays can be curved, or be thinner, or have narrower bezels – or no bezels at all – or flex and bend. Plus, an OLED display will be a great solution for virtual reality applications because it can provide high resolution and superior response time and latency.

OLED displays have higher contrast ratios (1 million : 1 static compared with 1,000 : 1 for LCD screens), deeper blacks and lower power consumption compared with LCD displays. They also have greater color accuracy. However, they are more expensive, and blue OLEDs have a shorter lifetime.

OLED displays offer a much better viewing angle. In contrast, viewing angle is limited with LCD displays. And even inside the supported viewing angle, the quality of the picture on an LCD screen is not consistent; it varies in brightness, contrast, saturation and hue by variations in posture of the viewer.

There are no geographical constraints with OLED screens. LCD screens, on the other hand, lose contrast in high temperature environments, and lose brightness and speed in low temperature environments.

Blue OLEDs degrade more rapidly than the materials that produce other colors. Because of this, the manufacturers of these displays often compensate by calibrating the colors in a way that oversaturates the them and adds a bluish tint to the screen.

With current technology, OLED displays use more energy than backlit LCDs when displaying light colors. While OLED displays have deeper blacks compared with backlit LCD displays, they have dimmer whites.

LCDs use liquid crystals that twist and untwist in response to an electric charge and are lit by a backlight. When a current runs through them, they untwist to let through a specific amount of light. They are then paired with color filters to create the display.

AMOLED (Active-Matrix Organic Light-Emitting Diode) is a different form of OLED used in some mobile phones, media players and digital cameras. It offers higher refresh rates with OLEDs and consume a lot less power, making them good for portable electronics. However, they are difficult to view in direct sunlight. Products with AMOLED screens include Galaxy Nexus, Galaxy S II, HTC Legend and PlayStation Vita.

Liquid Crystal Displays or LCD is a fairly old technology that has seen a recent burst in advancement. From calculator screens, LCDs are now fairly common in mobile phones, PDAs, computers, and a lot more applications. OLEDs (Organic Light Emitting Diode) are an improved version of LEDs that utilizes organic compounds to produce light. OLEDs have been eyed by many manufacturers as a good replacement for LCDs in many applications due to multiple advantages.

From the phrase ‘light emitting’ we can deduce that OLEDs produce their own light unlike LCDs which require a backlight that means fewer parts. Another advantage that this presents is the lower power consumption; a great amount of the power consumed by LCDs goes to the backlight, thus the big power difference. The lack of a backlight also means that an OLED display can be significantly slimmer than an LCD display. OLEDs have also been observed to show warmer images with better contrast making their image quality far superior than what LCDs currently achieve.

Manufacturing OLEDs could also be a lot cheaper than manufacturing LCDs. LCD screens are made out of transistors that are expensive to manufacture. OLEDs on the other hand can be applied to a substrate that has been treated to accept organic compounds via printing methods just like ink. Any inkjet printer can do this, making it easier and more economical to mass produce OLED displays. The printing method of production could also make it viable to have OLED displays on different mediums like cloth and paper which are unthinkable places for LCD displays.

The current problem that most OLED displays face nowadays is the very short lifetime. OLEDs are currently rated to last for up to 14,000 hours of operation before elements in the display begin to fail. This means that it won’t last four years if used for 10 hours every day. LCDs are known to last for over 4 times longer at 60,000 hours. This limitation is currently being looked into to make OLED displays more viable and a good candidate as an LCD replacement.

Competition and innovation are hallmarks of the consumer electronics market which has experienced practically uninterrupted growth for decades. Many consumers own a range of electronic devices (laptop, smartphone, tablet, TV, etc.), each of which is available in a plethora of options: brands; grades, formats; technologies. This technological array is further complicated by marketing terms that try to differentiate between competing products. Acronyms like OLED and LCD are rife in the electronics sector, but what is the actual difference between the two?

The inordinate popularity of smart consumer devices continues to drive growth in the global display market, currently valued in the region of $135 billion. Screens based on LEDs (light-emitting diodes) used to be the industry-standard, but trends towards device miniaturization, portability, improved efficiency, and greater picture quality gradually fuelled OLED (organic light-emitting diode) panels. Over the next few years, the OLED market is expected to expand by a CAGR (compound annual growth rate) of 14.27%.

Currently, OLED televisions outperform traditional LED products on several fronts. They come in a versatile range of formats: panels as large as 88-inches satisfy the demands of premium TV displays; while smaller AMOLED (active-matrix OLED) screens set the benchmark of picture quality in the smartphone industry. Foldable OLED devices have finally begun to enter the consumer electronics market too, fulfilling a long-standing promise from proponents of the technology.

Traditional LED TVs are based on liquid crystal display (LCD) screen technology; a tried-and-tested panel structure. On an LCD screen, images are produced by a thin layer of liquid crystal solution overlaid on a transistor grid which uses small electrical charges to set the individual crystals to an open/closed state. This produces a pattern of light and dark pixels, but the light itself is produced by a bank of LEDs arranged at the edges of the screen or in a backlit array.

The best possible picture on LCD screens is produced using a full-array LED backlight with local-dimming which yields the widest possible contrast. However, LCDs comprise multiple sequential layers within the panel (color filters, polarizers, etc.) which are necessary for producing fully-saturated images but may inhibit picture uniformity and viewing angles. This also makes LED TVs thicker and heavier, rendering them undesirable for applications where reduction of thickness or weight is important.

OLEDs circumvent each of these issues by eschewing a backlight in favor of a self-emissive panel of organic carbon-based material. This allows each subpixel onscreen to be controlled independently. Alongside greater dynamic ranges and energy efficiency, the unique characteristics of OLED panels allow for significantly fewer layers in the screen matrix. Consequently, OLED TVs are typically thinner and lighter in weight than conventional LCDs, but cost significantly more to produce than LCD displays.

Avantama is one of the industry-leading formulators for consumer electronics applications, generating solutions for today’s cutting-edge displays and devices. If you would like more information about our full portfolio of nanoparticle inks and dispersions for OLED manufacturing, simply contact a member of the Avantama team today.

If you need to repair your phone screen you may have been looking into different types of screen replacements. You’ve probably heard of the acronyms LCD and OLED in TVs before, but what are the differences between LCD and OLED screens and what will be best for your phone?

LCD or Liquid Crystal Display has been the standard for computer, tablet, and phone screens for the past decade. These screens offer great brightness, high definition, and are becoming relatively inexpensive. We tend to see LCD screens on the less expensive cell phone models, today. LCD screens can have great HD quality and have good performance in direct sunlight but tend to be more inefficient when it comes to power consumption compared to an OLED screen.

Over the past few years, many companies have been switching to newer screen technology: OLED displays. OLED, which stands for organic light-emitting diode, is being used on all of the latest flagship devices. They tout amazing contrast of color, they’re lighter and flexible and tend to be more efficient than LCDs. OLED technology is being used for curved edge phones like theGalaxy S10+and theGalaxy S20, S20+, and S20 Ultra 5G. OLEDs have also been used in folding smartphone displays like theSamsung Galaxy Fold, the newMotorola razrsmart flip phone, and theSamsung Galaxy Z Flip.

OLED displays are being used by Apple in their iPhone 11 Pro Max, 11 Pro, XS Max, XS, and X. iPhone X flagship series and newer will come with OLED. Both flagship Samsung Galaxy S and Note Series have OLED displays as the standard on all recent devices including the Samsung Galaxy S10 and Note 10 series, S9+, S9, Note 9, S8, S8+, Note 8, and so on. These phones also all have OLED displays: LG V40, LG V30, Huawei P30 Pro, Huawei Mate 20 Pro, OnePlus 6T, and the Motorola Moto Z2 Force Edition.

The iPhone 11 and the XR still use LCD displays as well as all other iPhones that came before the X series including the iPhone 8, iPhone 8 Plus, iPhone 7, iPhone 7 Plus, iPhone 6s, and so on. Basically, any iPhone with a Home Button will have a LCD screen on it. The LG G7 ThinQ, LG G6, Moto E5, and Moto E6 all have LCD displays as well.

When getting your device repaired, it is a good idea to use the display type that was originally installed on your phone. For example, if you have the iPhone X, which comes with an OLED display, ideally, you will want to get an OLED replacement. This will keep your phone running as efficiently as possible. If you need a more economical solution it is sometimes possible to get an LCD replacement, but keep in mind that they can drain your battery faster and may not have the same color contrast and may not be optimized for your phone.

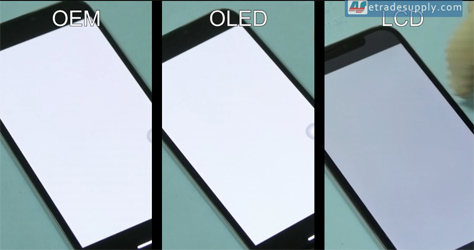

One of the easiest ways to determine which display type you have is to go to a true black screen – you can search for this on Google Images. If your display type is LCD your pixels will still be displaying a dark gray light. If you have an OLED display the screen will be totally black. It is easier to tell when this experiment is performed in a dark room. You can also searchGSMArenafor your phone and then view its display type.

In most cases, yes, you can trade-in a repaired iPhone with a non OEM display on it. However, depending on the company you choose to trade your iPhone in with the trade-in price may decrease due to a non OEM display. For example, at SmartphonesPLUS you can trade in a phone that has a replacement screen on it or with other replacement parts as well.

The LCD is currently the display of choice in small devices and is also popular in large-screen TVs. Regular LEDs often form the digits on digital clocks and other electronic devices. OLEDs offer many advantages over both LCDs and LEDs:

Because the light-emitting layers of an OLED are lighter, the substrate of an OLED can be flexible instead of rigid. OLED substrates can be plastic rather than the glass used for LEDs and LCDs.

OLEDs are brighter than LEDs. Because the organic layers of an OLED are much thinner than the corresponding inorganic crystal layers of an LED, the conductive and emissive layers of an OLED can be multi-layered. Also, LEDs and LCDs require glass for support, and glass absorbs some light. OLEDs do not require glass.

OLEDs do not require backlighting like LCDs (see How LCDs Work). LCDs work by selectively blocking areas of the backlight to make the images that you see, while OLEDs generate light themselves. Because OLEDs do not require backlighting, they consume much less power than LCDs (most of the LCD power goes to the backlighting). This is especially important for battery-operated devices such as cell phones.

OLEDs are easier to produce and can be made to larger sizes. Because OLEDs are essentially plastics, they can be made into large, thin sheets. It is much more difficult to grow and lay down so many liquid crystals.

OLEDs have large fields of view, about 170 degrees. Because LCDs work by blocking light, they have an inherent viewing obstacle from certain angles. OLEDs produce their own light, so they have a much wider viewing range.

Lifetime - While red and green OLED films have longer lifetimes (46,000 to 230,000 hours), blue organics currently have much shorter lifetimes (up to around 14,000 hours[source: OLED-Info.com]).

limited at first. Will be benefits of the new screen make it worth the wait? Here’s a quick rundown on OLED (organic light emitting diode) technology and how it differs from today’s LCD (liquid crystal display) screens.

iPhone 8 and 8 Plus are built on a backlight—a panel as large as the screen itself that produces a constant white light anytime the screen is on. A series of polarizers and filters are layered in front of the backlight to control the light and produce the image you see on screen. It’s been the dominant technology used in flat-panel displays for almost two decades, but keeping that backlight on draws a lot of power—and that’s a big disadvantage in a portable device.

An OLED does away with the backlight completely. Each individual pixel has a tiny amount of organic material that fluoresces when current flows, so the pixels produce light directly. It’s also possible to control brightness at a per-pixel level.

It’s not the only reason to applaud OLED. Getting rid of the backlight allows for the entire display module to be thinner, which is an important consideration in a smartphone. Apple could use the extra space to make the phone thinner or add a little more battery capacity.

Just as important is the image. OLEDs display more vibrant colors, have deeper blacks and brighter whites and a greater contrast ratio so most people find them superior to LCD.

No. OLED screens began appearing in smartphones several years ago and are used today in phones from Samsung, LG, and other competitors. Several companies also offer OLED monitors and TV screens and flexible OLEDs are increasingly used in smartwatches, fitness bands, and automobile dashboards. Apple is already using an OLED in the Apple Watch.

In part it’s a problem of production. As the iPhone is the world’s best-selling smartphone, Apple needs to be able to ensure a reliable stream of OLED panels from its display partners, but OLED has proved a difficult technology to master.

To date, most of the world’s smartphone OLEDs are produced by Samsung Display, which leaves Apple at the mercy of a single supplier for a key component—typically a position the company has tried to avoid.

While Apple doesn’t comment on its supply chain, the availability of OLED panels is already expected to impact availability of the high-end iPhone with limited supplies being available at launch and back orders being the norm. It will also contribute to the expected record-setting price of the new handset.

Whilst I’ll endeavour to keep this post as short as possible it’s a minefield of a subject which is definity worth knowing if you own an OLED based device.

OLED technology has been used in Samsung devices for quite some time and has recently been incorporated into various Apple devices. At the time of writing this article the iPhone X, XS, XS Max and 11pro and 11 pro Max all came out of the factory with a soft OLED resulting in the heavier price tag.

First off, it’s easier to let the differences between hard and soft OLED speak for themselves than it is to declare one objectively better than the other.Soft OLEDs are pricier, better match the iPhone X’s and 11 range and display size compare favorably to OEM performance.

Soft OLEDs are made of a flexible plastic substrate, which is why they last longer than Hard OLEDs. They are much more resistant to impact. Soft OLEDs also fit better into the frame of an iPhone X than Hard OLEDs.

At half the price of the Soft OLED, Hard OLED screens are built using a hard glass substrate instead of the flexible substrate found on the iPhone X’s original screen. These come at the expense of display size and durability. The hard glass substrate can’t flex to accommodate the original curve of the display, so the screen has an enlarged bezel that fractionally, but noticeably, reduces the size of the 5.8” display.

LCD is a proven technology and has been used since the inception of the iPhone. To this date Apple still uses it themselves on their budget range (if there was such a thing) on the iPhone XR and iPhone 11. Whilst to the eye you wouldn’t really notice the difference between an LCD and OLED you will notice 15% more battery drain. The advantage is the cost, as they offered to the market at a fraction of the cost of the more expensive Soft OLED are are far stronger than the Hard OLED.

Here at Mobile Screen Fix we believe whatever you choose you shouldn’t be paying twice and longevity is the backbone of what we do. It is for this reason we don’t offer a hard OLED option, in our testing they have proved far too fragile and will only see our customers coming back. After all if they were that viable why would Apple not use them and halve their production costs.

Third, the color displayed by OLED is closer to the real world, especially in black scenes. When it displays a black scene, it just turns off the pixels and does not glow. It is really pure black. But LCD can not do this, almost all LCD TVs will leak light when showing black scenes.

The color gamut coverage value of OLED is relatively high, and NTSC is generally around 95%, which can provide nearly perfect natural color. Its visual angle can reach 178 ° and the picture is not distorted. No matter which angle you look at, you can enjoy outstanding pictures. It can directly control the light and dark changes of pixel points without the need to deflect the liquid crystal molecules like LCD. It performs well on high-speed dynamic pictures.

In the field of television, OLED screen has many advantages, but it is subject to the rate of good products. It can be successfully mass produced in the size of 55-65 inches, and the price is high. Due to the relatively mature technology development, LCD TV can produce larger size TV, and the price is not expensive. We can see that LCD TVs on the market have a wide range of sizes, ranging from 32 inches to 120 inches, and even larger sizes, but OLED TVs are mostly 55 inches.

Mobile phone products have become the fastest updating consumer electronics products. On mobile phones, buy LCD or OLED phones? You may be able to find the answer through the screen quality, service life and power consumption issues that consumers care about.

First of all, OLED displays better in contrast and black. Contrast refers to the ratio of white to black. The higher the contrast, the thicker the color of the picture. Because the LCD has a backlight layer, the display of black is not pure black. OLED black does not emit light. It can directly turn off some pixels in the black area, so the black display effect is more pure.

Secondly, LCD has more advantages in the service life that consumers care about. Why do you say that? Look at the problem of screen burning and flashing, and you will understand. Perhaps you would say that it is 2021 now, and OLED mobile phones will not have this situation, right? But in fact, according to the news exposed by the domestic and foreign media, the phenomenon of mobile phone screen burning still exists, but the technology is improving, and the probability of screen burning has also decreased significantly.

For example, changing the pixel arrangement of the screen can effectively increase the service life of the OLED screen, but the problem is that the display effect of the screen will decline. In contrast, LCD screen phones have no such problems at all. They not only have a long life, but also are more eye friendly.

LCD has the advantage of changing the power by changing the current/voltage to change the brightness of the mobile phone screen. This adjustment method is DC dimming. OLED uses PWM dimming. Compared with DC dimming, PWM dimming is in the form of alternating current, which is constantly powered on and off to adjust the brightness of the screen. Because the strobe is too fast, the human eye cannot capture the process of the screen lighting, but it can be seen intuitively by using mobile phone video.

Third, in terms of power consumption, OLED is more power-saving than LCD because its pixels work independently. When the LCD is turned on, the whole backlight layer is turned on. It is either turned on or off. Each pixel of OLED is independent, and some pixels can be lit separately, which can achieve screen display and greatly reduce the number of times the screen is lit.

In the field of mobile phones, OLED screens are widely used. OLED screens are used in screen fingerprints, off-screen cameras and folding mobile phones, but there are many mobile phone brands using LCD screens, which have their own positioning and development plans.

At present, LCD screen is still the mainstream of the market. OLED screen has limited the penetration of OLED TV, OLED mobile phone and other products due to high cost, fast aging, low yield and other reasons.

LCD has its own advantages over OLED screen. In fact, it is not difficult to make a decision on the choice of hardware. If you are sensitive to light and have low requirements for pure black color, the budget is limited, and the LCD screen hardware is more suitable for you. It is better to start with OLED technology when it is more mature. If you are not sensitive to light, pursue the fashion and artistic sense of products, have no economic pressure, and want to try new high-tech, then OLED screen hardware can meet your needs.

An organic light-emitting diode (OLED or organic LED), also known as organic electroluminescent (organic EL) diode,light-emitting diode (LED) in which the emissive electroluminescent layer is a film of organic compound that emits light in response to an electric current. This organic layer is situated between two electrodes; typically, at least one of these electrodes is transparent. OLEDs are used to create digital displays in devices such as television screens, computer monitors, and portable systems such as smartphones and handheld game consoles. A major area of research is the development of white OLED devices for use in solid-state lighting applications.

There are two main families of OLED: those based on small molecules and those employing polymers. Adding mobile ions to an OLED creates a light-emitting electrochemical cell (LEC) which has a slightly different mode of operation. An OLED display can be driven with a passive-matrix (PMOLED) or active-matrix (AMOLED) control scheme. In the PMOLED scheme, each row and line in the display is controlled sequentially, one by one,thin-film transistor (TFT) backplane to directly access and switch each individual pixel on or off, allowing for higher resolution and larger display sizes.

OLED is fundamentally different from LED which is based on a p-n diode structure. In LEDs doping is used to create p- and n- regions by changing the conductivity of the host semiconductor. OLEDs do not employ a p-n structure. Doping of OLEDs is used to increase radiative efficiency by direct modification of the quantum-mechanical optical recombination rate. Doping is additionally used to determine the wavelength of photon emission.

An OLED display works without a backlight because it emits its own visible light. Thus, it can display deep black levels and can be thinner and lighter than a liquid crystal display (LCD). In low ambient light conditions (such as a dark room), an OLED screen can achieve a higher contrast ratio than an LCD, regardless of whether the LCD uses cold cathode fluorescent lamps or an LED backlight. OLED displays are made in the same way as LCDs, but after TFT (for active matrix displays), addressable grid (for passive matrix displays) or indium-tin oxide (ITO) segment (for segment displays) formation, the display is coated with hole injection, transport and blocking layers, as well with electroluminescent material after the first 2 layers, after which ITO or metal may be applied again as a cathode and later the entire stack of materials is encapsulated. The TFT layer, addressable grid or ITO segments serve as or are connected to the anode, which may be made of ITO or metal.transparent displays being used in smartphones with optical fingerprint scanners and flexible displays being used in foldable smartphones.

In 1960, Martin Pope and some of his co-workers at New York University developed ohmic dark-injecting electrode contacts to organic crystals.work functions) for hole and electron injecting electrode contacts. These contacts are the basis of charge injection in all modern OLED devices. Pope"s group also first observed direct current (DC) electroluminescence under vacuum on a single pure crystal of anthracene and on anthracene crystals doped with tetracene in 1963volts. The proposed mechanism was field-accelerated electron excitation of molecular fluorescence.

Research into polymer electroluminescence culminated in 1990, with J. H. Burroughes et al. at the Cavendish Laboratory at Cambridge University, UK, reporting a high-efficiency green light-emitting polymer-based device using 100nm thick films of poly(p-phenylene vinylene).plastic electronics and OLED research and device production grew rapidly.et al. at Yamagata University, Japan in 1995, achieved the commercialization of OLED-backlit displays and lighting.

In 1999, Kodak and Sanyo had entered into a partnership to jointly research, develop, and produce OLED displays. They announced the world"s first 2.4-inch active-matrix, full-color OLED display in September the same year.

Manufacturing of small molecule OLEDs was started in 1997 by Pioneer Corporation, followed by TDK in 2001 and Samsung-NEC Mobile Display (SNMD), which later became one of the world"s largest OLED display manufacturers - Samsung Display, in 2002.

The Sony XEL-1, released in 2007, was the first OLED television.Universal Display Corporation, one of the OLED materials companies, holds a number of patents concerning the commercialization of OLEDs that are used by major OLED manufacturers around the world.

On 5 December 2017, JOLED, the successor of Sony and Panasonic"s printable OLED business units, began the world"s first commercial shipment of inkjet-printed OLED panels.

A typical OLED is composed of a layer of organic materials situated between two electrodes, the anode and cathode, all deposited on a substrate. The organic molecules are electrically conductive as a result of delocalization of pi electrons caused by conjugation over part or all of the molecule. These materials have conductivity levels ranging from insulators to conductors, and are therefore considered organic semiconductors. The highest occupied and lowest unoccupied molecular orbitals (HOMO and LUMO) of organic semiconductors are analogous to the valence and conduction bands of inorganic semiconductors.

Originally, the most basic polymer OLEDs consisted of a single organic layer. One example was the first light-emitting device synthesised by J. H. Burroughes et al., which involved a single layer of poly(p-phenylene vinylene). However multilayer OLEDs can be fabricated with two or more layers in order to improve device efficiency. As well as conductive properties, different materials may be chosen to aid charge injection at electrodes by providing a more gradual electronic profile,quantum efficiency (up to 19%) by using a graded heterojunction.

During operation, a voltage is applied across the OLED such that the anode is positive with respect to the cathode. Anodes are picked based upon the quality of their optical transparency, electrical conductivity, and chemical stability.electrons flows through the device from cathode to anode, as electrons are injected into the LUMO of the organic layer at the cathode and withdrawn from the HOMO at the anode. This latter process may also be described as the injection of electron holes into the HOMO. Electrostatic forces bring the electrons and the holes towards each other and they recombine forming an exciton, a bound state of the electron and hole. This happens closer to the electron-transport layer part of the emissive layer, because in organic semiconductors holes are generally more mobile than electrons. The decay of this excited state results in a relaxation of the energy levels of the electron, accompanied by emission of radiation whose frequency is in the visible region. The frequency of this radiation depends on the band gap of the material, in this case the difference in energy between the HOMO and LUMO.

Experimental research has proven that the properties of the anode, specifically the anode/hole transport layer (HTL) interface topography plays a major role in the efficiency, performance, and lifetime of organic light-emitting diodes. Imperfections in the surface of the anode decrease anode-organic film interface adhesion, increase electrical resistance, and allow for more frequent formation of non-emissive dark spots in the OLED material adversely affecting lifetime. Mechanisms to decrease anode roughness for ITO/glass substrates include the use of thin films and self-assembled monolayers. Also, alternative substrates and anode materials are being considered to increase OLED performance and lifetime. Possible examples include single crystal sapphire substrates treated with gold (Au) film anodes yielding lower work functions, operating voltages, electrical resistance values, and increasing lifetime of OLEDs.

Balanced charge injection and transfer are required to get high internal efficiency, pure emission of luminance layer without contaminated emission from charge transporting layers, and high stability. A common way to balance charge is optimizing the thickness of the charge transporting layers but is hard to control. Another way is using the exciplex. Exciplex formed between hole-transporting (p-type) and electron-transporting (n-type) side chains to localize electron-hole pairs. Energy is then transferred to luminophore and provide high efficiency. An example of using exciplex is grafting Oxadiazole and carbazole side units in red diketopyrrolopyrrole-doped Copolymer main chain shows improved external quantum efficiency and color purity in no optimized OLED.

Organic small-molecule electroluminescent materials have the advantages of a wide variety, easy to purify, and strong chemical modifications. In order to make the luminescent materials to emit light as required, some chromophores or unsaturated groups such as alkene bonds and benzene rings will usually be introduced in the molecular structure design to change the size of the conjugation range of the material, so that the photophysical properties of the material changes. In general, the larger the range of π-electron conjugation system, the longer the wavelength of light emitted by the material. For instance, with the increase of the number of benzene rings, the fluorescence emission peak of benzene, naphthalene, anthracene,anthracenes, biphenyl acetylene aryl derivatives, coumarin derivatives,Ching W. Tang et al.Eastman Kodak. The term OLED traditionally refers specifically to this type of device, though the term SM-OLED is also in use.

Molecules commonly used in OLEDs include organometallic chelates (for example Alq3, used in the organic light-emitting device reported by Tang et al.), fluorescent and phosphorescent dyes and conjugated dendrimers. A number of materials are used for their charge transport properties, for example triphenylamine and derivatives are commonly used as materials for hole transport layers.perylene, rubrene and quinacridone derivatives are often used.3 has been used as a green emitter, electron transport material and as a host for yellow and red emitting dyes.

Because of the structural flexibility of small-molecule electroluminescent materials, thin films can be prepared by vacuum vapor deposition, which is more expensive and of limited use for large-area devices. The vacuum coating system, however, can make the entire process from film growth to OLED device preparation in a controlled and complete operating environment, helping to obtain uniform and stable films, thus ensuring the final fabrication of high-performance OLED devices.However, small molecule organic dyes are prone to fluorescence quenching

Polymer light-emitting diodes (PLED, P-OLED), also light-emitting polymers (LEP), involve an electroluminescent conductive polymer that emits light when connected to an external voltage. They are used as a thin film for full-spectrum colour displays. Polymer OLEDs are quite efficient and require a relatively small amount of power for the amount of light produced.

Vacuum deposition is not a suitable method for forming thin films of polymers. If the polymeric OLED films are made by vacuum vapor deposition, the chain elements will be cut off and the original photophysical properties will be compromised. However, polymers can be processed in solution, and spin coating is a common method of depositing thin polymer films. This method is more suited to forming large-area films than thermal evaporation. No vacuum is required, and the emissive materials can also be applied on the substrate by a technique derived from commercial inkjet printing.Langmuir-Blodgett film.

Phosphorescent organic light-emitting diodes use the principle of electrophosphorescence to convert electrical energy in an OLED into light in a highly efficient manner,

The heavy metal atom at the centre of these complexes exhibits strong spin-orbit coupling, facilitating intersystem crossing between singlet and triplet states. By using these phosphorescent materials, both singlet and triplet excitons will be able to decay radiatively, hence improving the internal quantum efficiency of the device compared to a standard OLED where only the singlet states will contribute to emission of light.

Applications of OLEDs in solid state lighting require the achievement of high brightness with good CIE coordinates (for white emission). The use of macromolecular species like polyhedral oligomeric silsesquioxanes (POSS) in conjunction with the use of phosphorescent species such as Ir for printed OLEDs have exhibited brightnesses as high as 10,000cd/m2.

a) Bottom-emitting and b) top-emitting OLED structures; c,d) Schematic diagrams based on bottom-emitting and top-emitting OLEDs with low and high contrast ratio, respectively.

The bottom-emission organic light-emitting diode (BE-OLED) is the architecture that was used in the early-stage AMOLED displays. It had a transparent anode fabricated on a glass substrate, and a shiny reflective cathode. Light is emitted from the transparent anode direction. To reflect all the light towards the anode direction, a relatively thick metal cathode such as aluminum is used. For the anode, high-transparency indium tin oxide (ITO) was a typical choice to emit as much light as possible.thin film transistor (TFT) substrate, and the area from which light can be extracted is limited and the light emission efficiency is reduced.

An alternative configuration is to switch the mode of emission. A reflective anode, and a transparent (or more often semi-transparent) cathode are used so that the light emits from the cathode side, and this configuration is called top-emission OLED (TE-OLED). Unlike BEOLEDs where the anode is made of transparent conductive ITO, this time the cathode needs to be transparent, and the ITO material is not an ideal choice for the cathode because of a damage issue due to the sputtering process.transmittance and high conductivity.

Since both electrodes are reflective in TEOLED, light reflections can happen within the diode, and they cause more complex interferences than those in BEOLEDs. In addition to the two-beam interference, there exists a multi-resonance interference between two electrodes. Because the structure of TEOLEDs is similar to that of the Fabry-Perot resonator or laser resonator, which contains two parallel mirrors comparable to the two reflective electrodes),

In the case of OLED, that means the cavity in a TEOLED could be especially designed to enhance the light output intensity and color purity with a narrow band of wavelengths, without consuming more power. In TEOLEDs, the microcavity effect commonly occurs, and when and how to restrain or make use of this effect is indispensable for device design. To match the conditions of constructive interference, different layer thicknesses are applied according to the resonance wavelength of that specific color. The thickness conditions are carefully designed and engineered according to the peak resonance emitting wavelengths of the blue (460 nm), green (530 nm), and red (610 nm) color LEDs. This technology greatly improves the light-emission efficiency of OLEDs, and are able to achieve a wider color gamut due to high color purity.

In "white + color filter method," red, green, and blue emissions are obtained from the same white-light LEDs using different color filters.uneven degradation rate of blue pixels vs. red and green pixels. Disadvantages of this method are low color purity and contrast. Also, the filters absorb most of the light waves emitted, requiring the background white light to be relatively strong to compensate for the drop in brightness, and thus the power consumption for such displays can be higher.

Color filters can also be implemented into bottom- and top-emission OLEDs. By adding the corresponding RGB color filters after the semi-transparent cathode, even purer wavelengths of light can be obtained. The use of a microcavity in top-emission OLEDs with color filters also contributes to an increase in the contrast ratio by reducing the reflection of incident ambient light.

Transparent OLEDs use transparent or semi-transparent contacts on both sides of the device to create displays that can be made to be both top and bottom emitting (transparent). TOLEDs can greatly improve contrast, making it much easier to view displays in bright sunlight.Head-up displays, smart windows or augmented reality applications.

Stacked OLEDs use a pixel architecture that stacks the red, green, and blue subpixels on top of one another instead of next to one another, leading to substantial increase in gamut and color depth,

In contrast to a conventional OLED, in which the anode is placed on the substrate, an Inverted OLED uses a bottom cathode that can be connected to the drain end of an n-channel TFT especially for the low cost amorphous silicon TFT backplane useful in the manufacturing of AMOLED displays.

Although the shadow-mask patterning method is a mature technology used from the first OLED manufacturing, it causes many issues like dark spot formation due to mask-substrate contact or misalignment of the pattern due to the deformation of shadow mask. Such defect formation can be regarded as trivial when the display size is small, however it causes serious issues when a large display is manufactured, which brings significant production yield loss. To circumvent such issues, white emission devices with 4-sub-pixel color filters (white, red, green and blue) have been used for large televisions. In spite of the light absorption by the color filter, state-of-the-art OLED televisions can reproduce color very well, such as 100% NTSC, and consume little power at the same time. This is done by using an emission spectrum with high human-eye sensitivity, special color filters with a low spectrum overlap, and performance tuning with color statistics into consideration.

Like ink jet material deposition, inkjet etching (IJE) deposits precise amounts of solvent onto a substrate designed to selectively dissolve the substrate material and induce a structure or pattern. Inkjet etching of polymer layers in OLED"s can be used to increase the overall out-coupling efficiency. In OLEDs, light produced from the emissive layers of the OLED is partially transmitted out of the device and partially trapped inside the device by total internal reflection (TIR). This trapped light is wave-guided along the interior of the device until it reaches an edge where it is dissipated by either absorption or emission. Inkjet etching can be used to selectively alter the polymeric layers of OLED structures to decrease overall TIR and increase out-coupling efficiency of the OLED. Compared to a non-etched polymer layer, the structured polymer layer in the OLED structure from the IJE process helps to decrease the TIR of the OLED device. IJE solvents are commonly organic instead of water-based due to their non-acidic nature and ability to effectively dissolve materials at temperatures under the boiling point of water.

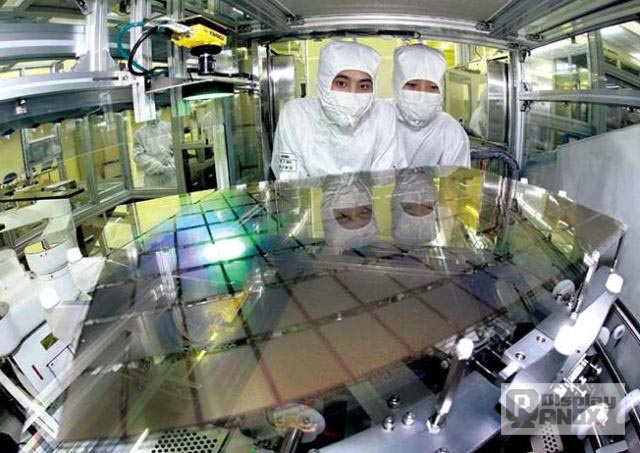

Transfer-printing is an emerging technology to assemble large numbers of parallel OLED and AMOLED devices efficiently. It takes advantage of standard metal deposition, photolithography, and etching to create alignment marks commonly on glass or other device substrates. Thin polymer adhesive layers are applied to enhance resistance to particles and surface defects. Microscale ICs are transfer-printed onto the adhesive surface and then baked to fully cure adhesive layers. An additional photosensitive polymer layer is applied to the substrate to account for the topography caused by the printed ICs, reintroducing a flat surface. Photolithography and etching removes some polymer layers to uncover conductive pads on the ICs. Afterwards, the anode layer is applied to the device backplane to form the bottom electrode. OLED layers are applied to the anode layer with conventional vapor deposition, and covered with a conductive metal electrode layer. As of 2011mm × 400mm. This size limit needs to expand for transfer-printing to become a common process for the fabrication of large OLED/AMOLED displays.

Experimental OLED displays using conventional photolithography techniques instead of FMMs have been demonstrated, allowing for large substrate sizes (as it eliminates the need for a mask that needs to be as large as the substrate) and good yield control.

For a high resolution display like a TV, a thin-film transistor (TFT) backplane is necessary to drive the pixels correctly. As of 2019, low-temperature polycrystalline silicon (LTPS)– TFT is widely used for commercial AMOLED displays. LTPS-TFT has variation of the performance in a display, so various compensation circuits have been reported.excimer laser used for LTPS, the AMOLED size was limited. To cope with the hurdle related to the panel size, amorphous-silicon/microcrystalline-silicon backplanes have been reported with large display prototype demonstrations.indium gallium zinc oxide (IGZO) backplane can also be used.

OLEDs can be printed onto any suitable substrate by an inkjet printer or even by screen printing,plasma displays. However, fabrication of the OLED substrate as of 2018 is costlier than that for TFT LCDs.registration — lining up the different printed layers to the required degree of accuracy.

OLED displays can be fabricated on flexible plastic substrates, leading to the possible fabrication of flexible organic light-emitting diodes for other new applications, such as roll-up displays embedded in fabrics or clothing. If a substrate like polyethylene terephthalate (PET)

OLEDs enable a greater contrast ratio and wider viewing angle compared to LCDs, because OLED pixels emit light directly. This also provides a deeper black level, since a black OLED display emits no light. Furthermore, OLED pixel colors appear correct and unshifted, even as the viewing angle approaches 90° from the normal.

LCDs filter the light emitted from a backlight, allowing a small fraction of light through. Thus, they cannot show true black. However, an inactive OLED element does not produce light or consume power, allowing true blacks.nm. The refractive value and the matching of the optical IMLs property, including the device structure parameters, also enhance the emission intensity at these thicknesses.

OLEDs also have a much faster response time than an LCD. Using response time compensation technologies, the fastest modern LCDs can reach response times as low as 1ms for their fastest color transition, and are capable of refresh frequencies as high as 240Hz. According to LG, OLED response times are up to 1,000 times faster than LCD,μs (0.01ms), which could theoretically accommodate refresh frequencies approaching 100kHz (100,000Hz). Due to their extremely fast response time, OLED displays can also be easily designed to be strobed, creating an effect similar to CRT flicker in order to avoid the sample-and-hold behavior seen on both LCDs and some OLED displays, which creates the perception of motion blur.

The biggest technical problem for OLEDs is the limited lifetime of the organic materials. One 2008 technical report on an OLED TV panel found that after 1,000hours, the blue luminance degraded by 12%, the red by 7% and the green by 8%.hours to half original brightness (five years at eight hours per day) when used for flat-panel displays. This is lower than the typical lifetime of LCD, LED or PDP technology; each rated for about 25,000–40,000hours to half brightness, depending on manufacturer and model. One major challenge for OLED displays is the formation of dark spots due to the ingress of oxygen and moisture, which degrades the organic material over time whether or not the display is powered.

However, some manufacturers" displays aim to increase the lifespan of OLED displays, pushing their expected life past that of LCD displays by improving light outcoupling, thus achieving the same brightness at a lower drive current.cd/m2 of luminance for over 198,000hours for green OLEDs and 62,000hours for blue OLEDs.hours for red, 1,450,000hours for yellow and 400,000hours for green at an initial luminance of 1,000cd/m2.

Degradation occurs three orders of magnitude faster when exposed to moisture than when exposed to oxygen. Encapsulation can be performed by applying an epoxy adhesive with dessicant,Atomic Layer Deposition (ALD). The encapsulation process is carried out under a nitrogen environment, using UV-curable LOCA glue and the electroluminescent and electrode material deposition processes are carried out under a high vacuum. The encapsulation and material deposition processes are carried out by a single machine, after the Thin-film transistors have been applied. The transistors are applied in a process that is the same for LCDs. The electroluminescent materials can also be applied using inkjet printing.

The OLED material used to produce blue light degrades much more rapidly than the materials used to produce other colors; in other words, blue light output will decrease relative to the other colors of light. This variation in the differential color output will change the color balance of the display, and is much more noticeable than a uniform decrease in overall luminance.

Improvements to the efficiency and lifetime of blue OLEDs is vital to the success of OLEDs as replacements for LCD technology. Considerable research has been invested in developing blue OLEDs with high external quantum efficiency, as well as a deeper blue color.

Blue TADF emitters are expected to market by 2020WOLED displays with phosphorescent color filters, as well as blue OLED displays with ink-printed QD color filters.

As an emissive display technology, OLEDs rely completely upon converting electricity to light, unlike most LCDs which are to some extent reflective. E-paper leads the way in efficiency with ~ 33% ambient light reflectivity, enabling the display to be used without any internal light source. The metallic cathode in an OLED acts as a mirror, with reflectance approaching 80%, leading to poor readability in bright ambient light such as outdoors. However, with the proper application of a circular polarizer and antireflective coatings, the diffuse reflectance can be reduced to less than 0.1%. With 10,000 fc incident illumination (typical test condition for simulating outdoor illumination), that yields an approximate photopic contrast of 5:1. Advances in OLED technologies, however, enable OLEDs to become actually better than LCDs in bright sunlight. The AMOLED display in the Galaxy S5, for example, was found to outperform all LCD displays on the market in terms of power usage, brightness and reflectance.

While an OLED will consume around 40% of the power of an LCD displaying an image that is primarily black, for the majority of images it will consume 60–80% of the power of an LCD. However, an OLED can use more than 300% power to display an image with a white background, such as a document or web site.

OLEDs use pulse width modulation to show colour/brightness gradations, so even if the display is at 100% brightness, any pixel that"s, for example, 50% grey will be off for 50% of the time, making for a subtle strobe effect. The alternative way to decrease brightness would be to decrease the constant power to the OLEDs, which would result in no screen flicker, but a noticeable change in colour balance, getting worse as brightness decreases.

Almost all OLED manufacturers rely on material deposition equipment that is only made by a handful of companies,Canon Tokki, a unit of Canon Inc. Canon Tokki is reported to have a near-monopoly of the giant OLED-manufacturing vacuum machines, notable for their 100-metre (330 ft) size.Apple has relied solely on Canon Tokki in its bid to introduce its own OLED displays for the iPhones released in 2017.

OLED technology is used in commercial applications such as displays for mobile phones and portable digital media players, car radios and digital cameras among others, as well as lighting.Philips Lighting has made OLED lighting samples under the brand name "Lumiblade" available onlineNovaled AG based in Dresden, Germany, introduced a line of OLED desk lamps called "Victory" in September, 2011.

Nokia introduced OLED mobile phones including the N85 and the N86 8MP, both of which feature an AMOLED display. OLEDs have also been used in most Motorola and Samsung color cell phones, as well as some HTC, LG and Sony Ericsson models.ZEN V, the iriver clix, the Zune HD and the Sony Walkman X Series.

The Google and HTC Nexus One smartphone includes an AMOLED screen, as does HTC"s own Desire and Legend phones. However, due to supply shortages of the Samsung-produced displays, certain HTC models will use Sony"s SLCD displays in the future,Nexus S smartphone will use "Super Clear LCD" instead in some countries.

OLED displays were used in watches made by Fossil (JR-9465) and Diesel (DZ-7086). Other manufacturers of OLED panels include Anwell Technologies Limited (Hong Kong),AU Optronics (Taiwan),Chimei Innolux Corporation (Taiwan),LG (Korea),

DuPont stated in a press release in May 2010, that they can produce a 50-inch OLED TV in two minutes with a new printing technology. If this can be scaled up in terms of manufacturing, then the total cost of OLED TVs would be greatly reduced. DuPont also states that OLED TVs made with this less expensive technology can last up to 15 years if left on for a normal eight-hour day.

The use of OLEDs may be subject to patents held by Universal Display Corporation, Eastman Kodak, DuPont, General Electric, Royal Philips Electronics, numerous universities and others.

Flexible OLED displays have been used by manufacturers to create curved displays such as the Galaxy S7 Edge but they were not in devices that can be flexed by the users.

On 31 October 2018, Royole, a Chinese electronics company, unveiled the world"s first foldable screen phone featuring a flexible OLED display.Samsung announced the Samsung Galaxy Fold with a foldable OLED display from Samsung Display, its majority-owned subsidiary.MWC 2019 on 25 February 2019, Huawei announced the Huawei Mate X featuring a foldable OLED display from BOE.

Textiles incorporating OLEDs are an innovation in the fashion world and pose for a way to integrate lighting to bring inert objects to a whole new level of fashion. The hope is to combine the comfort and low cost properties of textile with the OLEDs properties of illumination and low energy consumption. Although this scenario of illuminated clothing is highly plausible, challenges are still a road block. Some issues include: the lifetime of the OLED, rigidness of flexible foil substrates, and the lack of research in making more fabric like photonic textiles.

The number of automakers using OLEDs is still rare and limited to the high-end of the market. For example, the 2010 Lexus RX features an OLED display instead of a thin film transistor (TFT-LCD) display.

A Japanese manufacturer Pioneer Electronic Corporation produced the first car stereos with a monochrome OLED display, which was also the world"s first OLED product.Yazaki,Hyundai Sonata and Kia Soul EV use a 3.5-inch white PMOLED display.

By 2004, Samsung Display, a subsidiary of South Korea"s largest conglomerate and a former Samsung-NEC joint venture, was the world"s largest OLED manufacturer, producing 40% of the OLED displays made in the world,AMOLED market.million out of the total $475million revenues in the global OLED market in 2006.

Samsung SDI announced in 2005, the world"s largest OLED TV at the time, at 21 inches (53 cm).million pixels. In addition, the company adopted active matrix-based technology for its low power consumption and high-resolution qualities. This was exceeded in January 2008, when Samsung showcased the world"s largest and thinnest OLED TV at the time, at 31inches (78cm) and 4.3mm.

In October 2008, Samsung showcased the world"s thinnest OLED display, also the first to be "flappable" and bendable.mm (thinner than paper), yet a Samsung staff member said that it is "technically possible to make the panel thinner".cd/m2. The colour reproduction range is 100% of the NTSC standard.

At the Consumer Electronics Show (CES) in January 2010, Samsung demonstrated a laptop computer with a large, transparent OLED display featuring up to 40% transparency

Samsung"s 2010 AMOLED smartphones used their Super AMOLED trademark, with the Samsung Wave S8500 and Samsung i9000 Galaxy S being launched in June 2010. In January 2011, Samsung announced their Super AMOLED Plus displays, which offer several advances over the older Super AMOLED displays: real stripe matrix (50% more sub pixels), thinner form factor, brighter image and an 18% reduction in energy consumption.

On 8 January 2013, at CES Samsung unveiled a unique curved 4K Ultra S9 OLED television, which they state provides an "IMAX-like experience" for viewers.

Samsung introduced the Galaxy Round smartphone in the Korean market in October 2013. The device features a 1080p screen, measuring 5.7 inches (14 cm), that curves on the vertical axis in a rounded case. The corporation has promoted the following advantages: A new feature called "Round Interaction" that allows users to look at information by tilting the handset on a flat surface with the screen off, and the feel of one continuous transition when the user switches between home screens.

At the 2007, Las Vegas Consumer Electronics Show (CES), Sony showcased a 11-inch (28 cm), (resolution 960×540) and 27-inch (69 cm), full HD resolution at 1920 × 1080 OLED TV models.contrast ratios and total thicknesses (including bezels) of 5mm. In April 2007, Sony announced it would manufacture 1000 11-inch (28 cm) OLED TVs per month for market testing purposes.XEL-1, was the first commercial OLED TV

In May 2007, Sony publicly unveiled a video of a 2.5-inch (6.4 cm) flexible OLED screen which is only 0.3 millimeters thick.mm thick 3.5 inches (8.9 cm) display with a resolution of 320×200 pixels and a 0.3mm thick 11-inch (28 cm) display with 960×540 pixels resolution, one-tenth the thickness of the XEL-1.

In July 2008, a Japanese government body said it would fund a joint project of leading firms, which is to develop a key technology to produce large, energy-saving organic displays. The project involves one laboratory and 10 companies including Sony Corp. NEDO said the project was aimed at developing a core technology to mass-produce 40inch or larger OLED displays in the late 2010s.

In October 2008, Sony published results of research it carried out with the Max Planck Institute over the possibility of mass-market bending displays, which could replace rigid LCDs and plasma screens. Eventually, bendable, see-through displays could be stacked to produce 3D

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey