alphanumeric lcd display free sample

STN, Gray background, Yellow/Green LED, Bottom view, Wide temp, Transflective (positive), 5V LCD, 5V LED, Controller=AIP31066, RoHS Compliant. This display has a wide temperature range: -20° Celcius to +70° Celcius which equates to (-4° Fahrenheit to +158° Fahrenheit).

STN (Super-twisted Nematic) provides a sharper image and wider viewing angle than TN (Twisted Nematic). The cost for STN if approximately 5% higher than TN. STN is an ideal fluid for outdoor products that need to be read at various angles. The Transflective polarizer is a mixture of Reflective and Transmissive. It provides the ability to read the LCD with or without the backlight on. It will work for all lighting conditions from dark with backlight to direct sunlight which makes it the most common choice. There is no cost difference between Transflective, Transmissive and Reflective.

Focus LCDs can provide many accessories to go with your display. If you would like to source a connector, cable, test jig or other accessory preassembled to your LCD (or just included in the package), our team will make sure you get the items you need.Get in touch with a team member today to accessorize your display!

Focus Display Solutions (aka: Focus LCDs) offers the original purchaser who has purchased a product from the FocusLCDs.com a limited warranty that the product (including accessories in the product"s package) will be free from defects in material or workmanship.

In this tutorial, we’ll discuss the alphanumeric LCD 16×2 interfacing with STM32 microcontrollers. Starting with an introduction to the LCD 16×2 display, then how to implement a driver for it on STM32 blue pill board. We’ll set up all the configuration parameters and get our first ECUAL layer driver done, so we can make our next applications more portable. This will be detailed by the end of this tutorial and in the next one, so let’s now get started!

We typically add a 16×2 Alphanumeric LCD to small embedded systems & projects to enhance the user experience and UI of the device/project. You can use it to display text messages to the user, number, etc. Other types of LCDs provide different features such as the number of columns and rows (characters) and maybe colored display, and also different interfaces (parallel, spi, i2c, etc).

For this tutorial, we’ll consider the 16×2 LCD with a 16-pin header interface. Assuming it has the standard Hitachi LCD driver HD44780 controller. The Alphanumeric LCD 16×2 Tutorial did highlight everything you need to know. That’s why I highly recommend that you check it out right now. In order to know, the internals of the LCD driver IC, it’s registers, commands, and how it works and gets initialized, etc.

Today’s tutorial is built upon the previous LCD one, and it’s assumed that you’ve got a basic understanding of the topics discussed earlier. We’ll port the LCD driver in 4-Bit mode to make it easily configurable and portable across most STM32 microcontroller devices.

The best way in my opinion for interfacing alphanumeric LCD screens is using an external I2C LCD driver chip. In this way, you save up a lot of valuable GPIO pins for other uses and it only requires 2 wires on the I2C bus. However, it’s going to be a topic for a future tutorial as we didn’t cover the I2C in STM32 MCUs yet.

Therefore, in this tutorial, we’ll be interfacing the LCD 16×2 display in the 4-bit mode which requires 6 GPIO pins. And as you know the STM32 microcontroller is a 3.3v logic device and the LCD is 5v. But it is not a big deal, as the STM32 output (3.3v) pins will be correctly detected by the LCD (5v) input pins. And the only 5v line that is required is the LCD VDD, and you can supply it from the blue pill board 5v pin.

Don’t also forget to connect the contrast control potentiometer as indicated in the diagram shown above. Low contrast may seem to you like a not-working-LCD and hence unnecessarily waste so much time debugging a code that actually works!

After flashing the code to your microcontroller, the LCD may not work from the USB programmer set up. It’s recommended to un-plug the programmer and use external power supply or USB power bank. The LCD may not work at all from the laptop USB or in some cases misbehave, so stay safe with an external power source.

The STM32 microcontroller has to first initialize the LCD display before it can actually send any characters to be displayed correctly. The initialization procedure is step-by-step indicated in the LCD driver datasheet for both modes 4-bit and 8-bit. And it requires a few delay instructions, so I’ll be using the DWT delay which we’ve developed in the previous tutorial.

The available instructions that the LCD driver IC can execute are listed in the datasheet. As well as the execution time for each instruction. Therefore, you should be careful at this time! you can use an extra pin to read the busy flag bit from the LCD to know whether it did execute the last instruction or not. Otherwise, it’s mandatory to use time delays according to the datasheet specs. Here is a list of the LCD instructions.

I’ve received a lot of questions and suggestions from you since the last LCD tutorial that I’ve published. The conclusion that I’ve settled for is that maybe there are various versions of the LCD modules and drivers ICs that can be the direct reason why the signal’s timing differs from a user to another.

Here I’m speaking about the enable pulse that you should send to the LCD driver after each command in order to transfer the 8-bit CMD word (whether at once or at 2 stages in 4bit mode).

The datasheet says it should be no less than 200nSec. However, an old LCD with me didn’t receive any data until this pulse delay was up to 500uSec (which is so long in fact). Another LCD could work just fine with 50uSec pulses but no less than that. Another one with a different color did work absolutely fine with a 1uSec pulse. Which is pretty reasonable amount of delay.

The LCD 16×2 driver is going to be our first ECUAL (ECU Abstraction Layer), driver. This software layer is added to abstract the hardware dependencies from the application layer. All the onboard ECU peripherals, sensors, memory, and so on do depend on the MCU peripherals and their HAL drivers. The procedure followed by calling some HAL drivers and doing some initialization and calculations work will also get abstracted from the application by introducing the ECUAL layer.

The software component (LCD Driver) in the ECUAL layer will call some HAL_GPIO pin manipulation functions, DWT_Delays, and other HAL & utilities. So that the application code can be more portable, and you can easily change the platform (microcontroller) and have your application running with a high level of portability. And you’ll also have configuration files in each driver to add further adjustability to our software.

The first step is to create the source code directory for the ECUAL layer in which we’ll also create the first driver directory called LCD16x2, and finally create the following 4 files.

The purpose of having these files in our driver is to make it easily configurable by the user (the application programmer). We shall put all the important parameters in there in a structure that encapsulates all the config parameters together. I’ve chosen to put in there the LCD GPIO pins, GPIO port, and the enable pulse width time.

This means that my driver in this way of implementation assumes that the user will hook the LCD pins to the sam MCU port whatever the pin numbers are. But you can actually make it even more portable so that the user can use pins from multiple GPIO ports! but the config structure will be a bit larger and it’s not a big deal however, it’s a design decision that I’ve made and preferred to tell you that I did that for simplicity’s sake and can be adjusted by you if it’s really needed.

Note that the configuration parameter structure is externed to the header file so that in the LCD16x2.c source code we can include the configuration header file LCD16x2_cfg.h and see that global config parameter and do our pin manipulations on these defined ones. This type of configuration is called linking configuration, as it gets resolved during the compilation time in the linking stage and the user (the programmer) doesn’t have to compile the whole project in order to change the configurations, only compile the configuration source and link it with your application object files. This topic and other types of configurations will be discussed in the next tutorial as well.

It is a bit long file 150 lines of code, and it’s found in the download link down below as well as the other files. The thing you need to know about this source code file is that it’s an implementation for all the declared functions in the header file above to initialize the LCD, write char, string, and all other stuff. It’s a direct implementation for what is documented in the LCD datasheet and we’ve previously done it in This LCD tutorial. So it should be easily ported to the STM32 ecosystem.

In this LAB, our goal is to build a system that initializes the LCD driver. Which in turn initialized the configuration-defined GPIO pins and therefore send the initialization commands to the LCD as described in its datasheet. After this, we can easily call the LCD driver functions to set the cursor position, print strings, and shift the entire display on the LCD right and left. It’s a very basic and simple LAB.

We come across Liquid Crystal Display (LCD) displays everywhere around us. Computers, calculators, television sets, mobile phones, and digital watches use some kind of display to display the time.

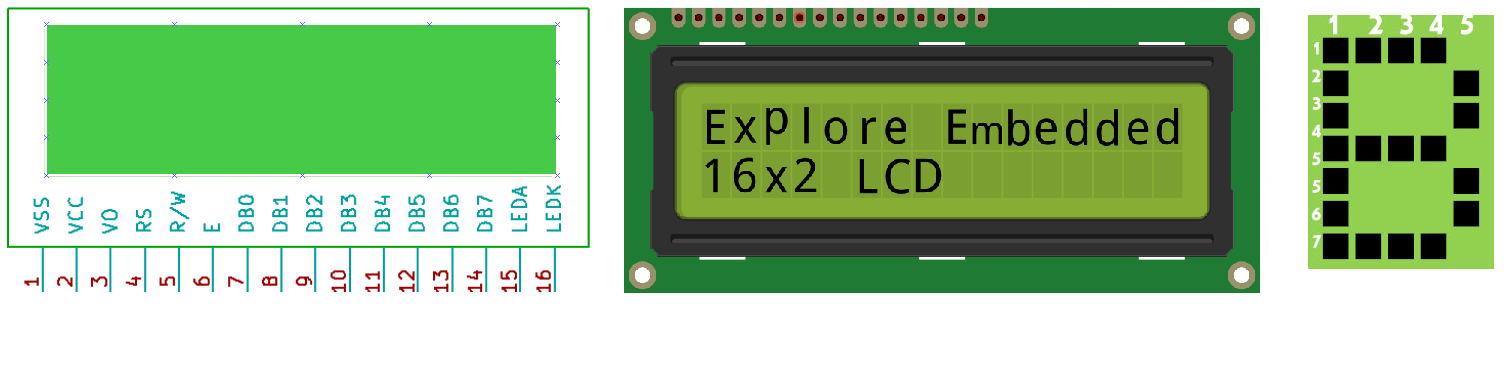

An LCD screen is an electronic display module that uses liquid crystal to produce a visible image. The 16×2 LCD display is a very basic module commonly used in DIYs and circuits. The 16×2 translates a display of 16 characters per line in 2 such lines. In this LCD, each character is displayed in a 5×7 pixel matrix.

Contrast adjustment; the best way is to use a variable resistor such as a potentiometer. The output of the potentiometer is connected to this pin. Rotate the potentiometer knob forward and backward to adjust the LCD contrast.

A 16X2 LCD has two registers, namely, command and data. The register select is used to switch from one register to other. RS=0 for the command register, whereas RS=1 for the data register.

Command Register: The command register stores the command instructions given to the LCD. A command is an instruction given to an LCD to do a predefined task. Examples like:

Data Register: The data register stores the data to be displayed on the LCD. The data is the ASCII value of the character to be displayed on the LCD. When we send data to LCD, it goes to the data register and is processed there. When RS=1, the data register is selected.

Generating custom characters on LCD is not very hard. It requires knowledge about the custom-generated random access memory (CG-RAM) of the LCD and the LCD chip controller. Most LCDs contain a Hitachi HD4478 controller.

CG-RAM address starts from 0x40 (Hexadecimal) or 64 in decimal. We can generate custom characters at these addresses. Once we generate our characters at these addresses, we can print them by just sending commands to the LCD. Character addresses and printing commands are below.

LCD modules are very important in many Arduino-based embedded system designs to improve the user interface of the system. Interfacing with Arduino gives the programmer more freedom to customize the code easily. Any cost-effective Arduino board, a 16X2 character LCD display, jumper wires, and a breadboard are sufficient enough to build the circuit. The interfacing of Arduino to LCD display is below.

The combination of an LCD and Arduino yields several projects, the most simple one being LCD to display the LED brightness. All we need for this circuit is an LCD, Arduino, breadboard, a resistor, potentiometer, LED, and some jumper cables. The circuit connections are below.

LCD connected to this controller will adjust itself to the memory map of this DDRAM controller; each location on the LCD will take 1 DDRAM address on the controller. Because we use 2 × 16 type LCD, the first line of the LCD will take the location of the 00H-0FH addresses and the second line will take the 40H-4FH addresses of the controller DDRAM; so neither the addresses of the 10H-27H on the first line or the addresses of the 50H-67H on the second line on DDRAM is used.

To be able to display a character on the first line of the LCD, we must provide written instructions (80h + DDRAM address where our character is to be displayed on the first line) in the Instruction Register-IR and then followed by writing the ASCII code of the character or address of the character stored on the CGROM or CGRAM on the LCD controller data register, as well as to display characters in the second row we must provide written instructions (C0H + DDRAM address where our character to be displayed on the second line) in the Instructions Register-IR and then followed by writing the ASCII code or address of the character on CGROM or CGRAM on the LCD controller data register.

As mentioned above, to display a character (ASCII) you want to show on the LCD, you need to send the ASCII code to the LCD controller data register-DR. For characters from CGROM and CGRAM we only need to send the address of the character where the character is stored; unlike the character of the ASCII code, we must write the ASCII code of the character we want to display on the LCD controller data register to display it. For special characters stored on CGRAM, one must first save the special character at the CGRAM address (prepared 64 addresses, namely addresses 0–63); A special character with a size of 5 × 8 (5 columns × 8 lines) requires eight consecutive addresses to store it, so the total special characters that can be saved or stored on the CGRAM addresses are only eight (8) characters. To be able to save a special character at the first CGRAM address we must send or write 40H instruction to the Instruction Register-IR followed by writing eight consecutive bytes of the data in the Data Register-DR to save the pattern/image of a special character that you want to display on the LCD [9, 10].

We can easily connect this LCD module (LCD + controller) with MCS51, and we do not need any additional electronic equipment as the interface between MCS51 and it; This is because this LCD works with the TTL logic level voltage—Transistor-Transistor Logic.

The voltage source of this display is +5 V connected to Pin 2 (VCC) and GND power supply connected to Pin 1 (VSS) and Pin 16 (GND); Pin 1 (VSS) and Pin 16 (GND) are combined together and connected to the GND of the power supply.

Pins 7–14 (8 Pins) of the display function as a channel to transmit either data or instruction with a channel width of 1 byte (D0-D7) between the display and MCS51. In Figure 6, it can be seen that each Pin connected to the data bus (D0-D7) of MCS51 in this case P0 (80h); P0.0-P0.7 MCS-51 connected to D0-D7 of the LCD.

Pins 4–6 are used to control the performance of the display. Pin 4 (Register Select-RS) is in charge of selecting one of the 2 display registers. If RS is given logic 0 then the selected register is the Instruction Register-IR, otherwise, if RS is given logic 1 then the selected register is the Data Register-DR. The implication of this selection is the meaning of the signal sent down through the data bus (D0-D7), if RS = 0, then the signal sent from the MCS-51 to the LCD is an instruction; usually used to configure the LCD, otherwise if RS = 1 then the data sent from the MCS-51 to the LCD (D0-D7) is the data (object or character) you want to display on the LCD. From Figure 6 Pin 4 (RS) is connected to Pin 16 (P3.6/W¯) of MCS-51 with the address (B6H).

Pin 5 (R/W¯)) of the LCD does not appear in Figure 6 is used for read/write operations. If Pin 5 is given logic 1, the operation is a read operation; reading the data from the LCD. Data will be copied from the LCD data register to MCS-51 via the data bus (D0-D7), namely Pins 7–14 of the LCD. Conversely, if Pin 5 is given a voltage with logical 0 then the operation is a write operation; the signal will be sent from the MCS51 to LCD through the LCD Pins (Pins 7–14); The signal sent can be in the form of data or instructions depending on the logic level input to the Register Select-RS Pin, as described above before if RS = 0 then the signal sent is an instruction, vice versa if the RS = 1 then the signal sent/written is the data you want to display. Usually, Pin 5 of the LCD is connected with the power supply GND, because we will never read data from the LCD data register, but only send instructions for the LCD work configuration or the data you want to display on the LCD.

Pin 6 of the LCD (EN¯) is a Pin used to enable the LCD. The LCD will be enabled with the entry of changes in the signal level from high (1) to low (0) on Pin 6. If Pin 6 gets the voltage of logic level either 1 or 0 then the LCD will be disabled; it will only be enabled when there is a change of the voltage level in Pin 6 from high logic level to low logic level for more than 1000 microseconds (1 millisecond), and we can send either instruction or data to processed during that enable time of Pin 6.

Pin 3 and Pin 15 are used to regulate the brightness of the BPL (Back Plane Light). As mentioned above before the LCD operates on the principle of continuing or inhibiting the light passing through it; instead of producing light by itself. The light source comes from LED behind this LCD called BPL. Light brightness from BPL can be set by using a potentiometer or a trimpot. From Figure 6 Pin 3 (VEE) is used to regulate the brightness of BPL (by changing the current that enters BPL by using a potentiometers/a trimpot). While Pin 15 (BPL) is a Pin used for the sink of BPL LED.

4RSRegister selector on the LCD, if RS = 0 then the selected register is an instruction register (the operation to be performed is a write operation/LCD configuration if Pin 5 (R/W¯) is given a logic 0), if RS = 1 then the selected register is a data register; if (R/W¯) = 0 then the operation performed is a data write operation to the LCD, otherwise if (R/W¯) = 1 then the operation performed is a read operation (data will be sent from the LCD to μC (microcontroller); it is usually used to read the busy bit/Busy Flag- BF of the LCD (bit 7/D7).

5(R/W¯)Sets the operating mode, logic 1 for reading operations and logic 0 for write operations, the information read from the LCD to μC is data, while information written to the LCD from μC can be data to be displayed or instructions used to configure the LCD. Usually, this Pin is connected to the GND of the power supply because we will never read data from the LCD but only write instructions to configure it or write data to the LCD register to be displayed.

6Enable¯The LCD is not active when Enable Pin is either 1 or 0 logic. The LCD will be active if there is a change from logic 1 to logic 0; information can be read or written at the time the change occurs.

In this case, D500 is the MRR that the OIT has been configured to poll once every 200 milliseconds. When input coil X1 is activated, the controller puts the decimal number 30 into the MRR. The OIT then sees the number 30 in the MRR and Displays Screen #30

Maple Systems OITs can be programmed to send the number representing the screen currently Displayed on the OIT to a register in the controller called the Current Message Register (CMR). The CMR can be used by the controller to determine which screen is currently being Displayed on the OIT, whether Displayed due to MRR, Set Point Limit, Function Key, etc. This might be used to determine which screen an OIT operator sees in a chained sequence.

Clear Alarm is monitored by the OIT to allow the controller to clear the currently Displayed alarm. When the controller sets this coil, the OIT cancels the alarm in progress.

The controller"s discrete and register memory can be monitored, Displayed, and updated by the OIT. This can be done by configuring the OIT"s screens to Display the controller"s discrete and register memory as embedded data fields (register monitors). When the OIT Displays a screen containing a register monitor, the OIT reads the specified memory address in the controller and then Displays the data. If the register monitor has been configured as read/write, when the operator changes the data in the register monitor on the OIT"s Display, the OIT writes the change to the controller"s memory.

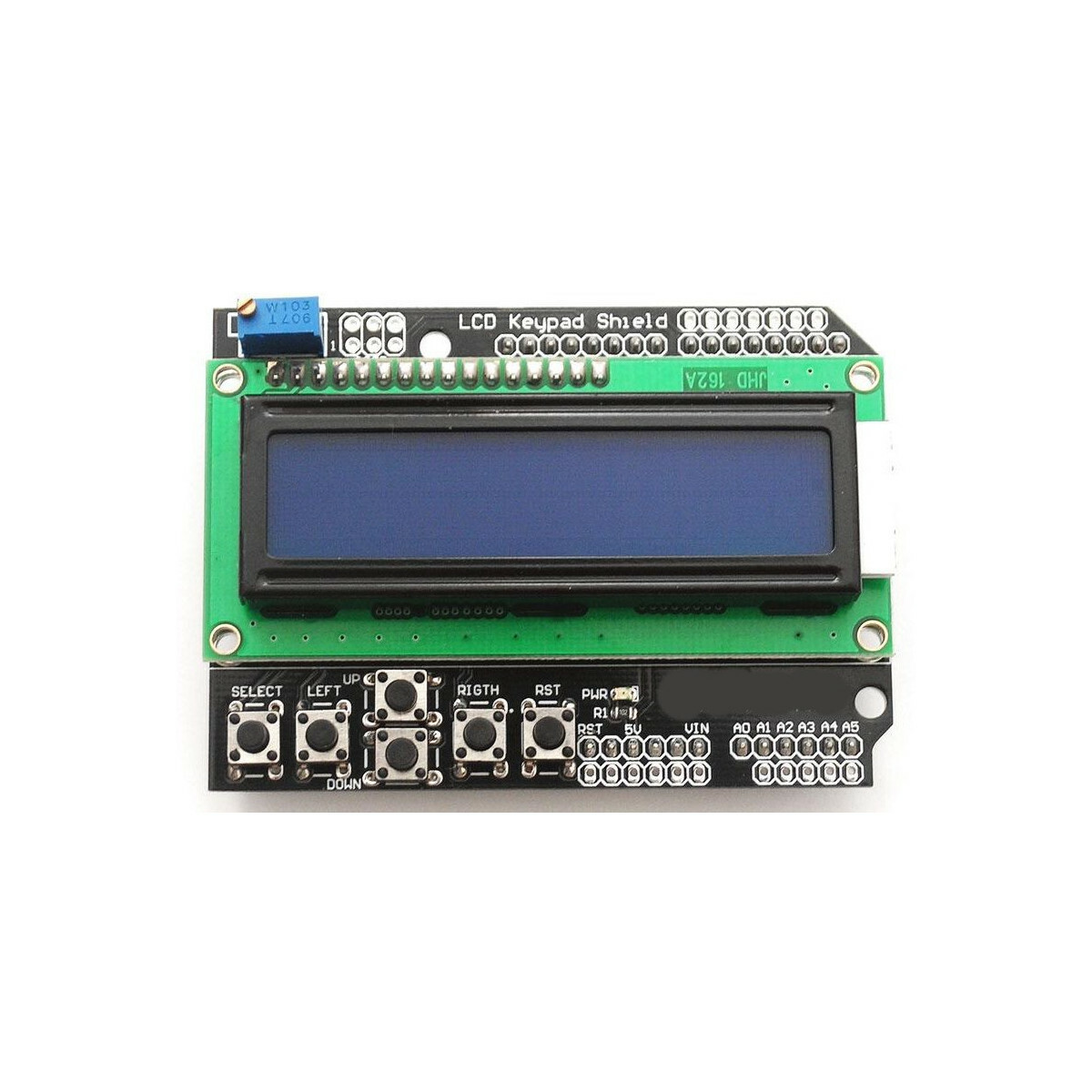

Many Students have issues getting the Display on the 16×2 LCD on the Embedded Learner Board to work. The first thing that we need to ensure is that the connection between the Arduino Uno and the Embedded Learner Board is correct.

As per the name the 2x16 has 2 lines with 16 chars on each line. It supports all the ASCII chars and is basically used for displaying the alphanumeric characters. Here each character is displayed in a matrix of 5x7 pixels.

As it is an 8-bit data bus, we can send the data/cmd to LCD in bytes. It also provides the provision to send the data/cmd in chunks of 4-bit, which is used when there are limited number of GPIO lines on the microcontroller.

Register Select(RS): The LCD has two register namely a Data register and Command register. Any data that needs to be displayed on the LCD has to be written to the data register of LCD. Command can be issued to LCD by writing it to Command register of LCD.

If the RS signal is HIGH then the LCD interprets the 8-bit info as data and copies it to data register. After that the LCD decodes the data for generating the 5x7 pattern and finally displays on the LCD.

After sending the data/cmd, Selecting the data/cmd register, Selecting the Write operation. An HIGH-to-LOW pulse has to be sent on this enable pin which will latch the info into the LCD register and triggers the LCD to act accordingly.

The below configuration is as per the above schematic. You can connect the LCD to any of the PORT pins available on your boards and update this section accordingly

This 16x LCD packs 32 characters into an outline smaller than that of most two-line displays. An LED backlight enables optimal viewing in all lighting conditions. This unit uses the HD44780 interface found on most parallel character displays.

The backlight in this LCD is composed of LEDs in series. The total voltage drop across these LEDs is typically 4.2 V and the recommended current through the LEDs is 120 mA. You should use a current limiting resistor RLIMIT as where:

This expansion module features a 16×2 Alphanumeric LCD Module which can be added to your custom project using a 2×6 pin connector. It is designed to be used with Numato Lab’s FPGA/Microcontroller boards featuring 2×6 pin Expansion connectors. This module can be used with other boards as well by using manual wiring. This product is compatible with most of the Numato Lab’s FPGA boards.

An LCD or liquid crystal display is a combination of two states of material ie, the solid & the liquid. These displays use a liquid crystal to produce a visible image. LCDs are super thin technology display screen that are used in cell phones, TVs, portable video games, laptops, computer screen, portable video games. Compared to CRT (cathode ray tube) technology, this technology permits displays to be much thinner. The LCD is composed of different layers which contain two electrodes and polarized panel filters. This technology is used to display the image in electronic devices. It is made up of active matrix or passive display grid. Most of the gadgets with LCD display uses active matrix display. There are various technologies used to make digital displays. But, we are discussing two different LCDs. The alphanumeric display and customized LCD.

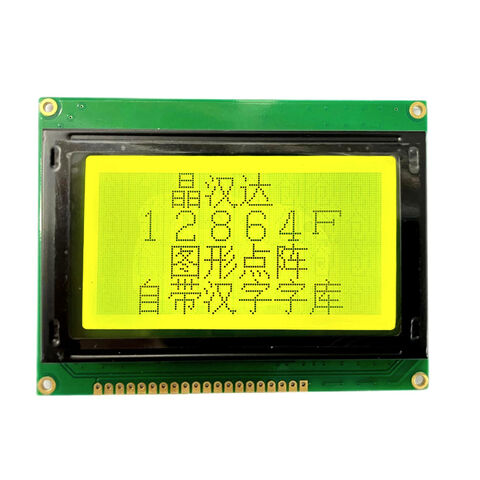

The most common types of monochrome LCDs are called character display or alphanumeric display. Alphanumeric LCD displays are used to display alphabets and numbers. The 16×2 intelligent alphanumeric dot matrix displays are capable of displaying 224 different symbols and characters. Generally, alphanumeric LCDs are used widely in these applications: cellular phones, home appliances, meters, word processors, communication, medical instruments, etc.. These displays are widely used due to the following reasons:

Hardware designers and engineers favor alphanumeric LCD displays for fast developing products. These types of devices contain their own controller driver chip with a character map built into the IC. To integrate the software, the character map makes it easy for the design. When any designer or engineer wants to display or show a letter, all they need to do is to send a command requesting the capital. This is much easier than a graphics LCD module wherein each spot on the letter A needs to be addressed. This is a highly time consuming activity.

The most common structure of alphanumeric display is known as a chip on board (COB) where in the PCB (printed circuit board) is attached to the LCD glass. The name COB means that the controller driver chip is placed on the back of the PCB. This module handles vibration very well. And also the increasing holes placed on the PCB permit an easy and secure method to attach the LCD to the customer’s product.

Alphanumeric LCD displays are designed in standard configurations such as LCD display 16×2, 8×1 and 40×4. The identification of alphanumeric displays is broken down into the number of characters in each row and then the number of rows. The example of this is a 16×2, where there are 16 characters in each row, and there are two rows of these characters. This enables the alphanumeric displays to display 32characters at a time.

A character can be any letter: capital or small, any number,and punctuation mark, such as comma, period and backslash. The character table built into the microcontroller of the LCD display displays 255 different characters.Furthermore, there are many languages, so you can select a character table that displays English, German and French or any other language. Most of the alphanumeric LCD displays cannot display Chinese and Japanese languages without the use of a larger character size. This means that a 16×2 is built to display English characters, but not the Chinese;Chinese will require larger than 16×2 display.

The alphanumeric displays consist of LCD displays or a set of LEDs that are connected in common anode or common cathode mode. 7 segment displays are used for only numbers in decimal and hexadecimal format.For both alphabets and numbers, the 18 segment display consisting of the 5 by 7 dot matrix is used.

Alphanumeric LCD Displays are most commonly used in test and measurement equipment, process control equipment, handheld devices, PLC’s, data loggers, PCO displays energy meters, and a host of other applications. Displaying Scrolling Messages on Alpha Numeric Displays using a PC is one of the most frequently used application of alphanumeric display.

The above block diagram can be used to display scrolling message on alphanumeric LCDs by using PC. The information can be sent through a PC that is interfaced with an 8051 microcontroller through MAX232. An external memory is connected to the microcontroller which stores the information. The endless scrolling can be displayed using alphanumeric LCD display, which is connected to a microcontroller.

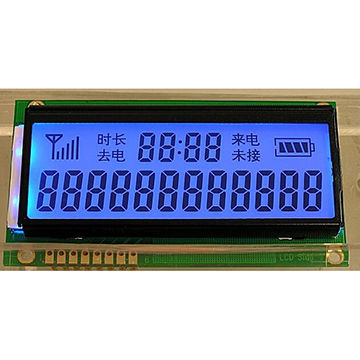

In present days, different types of LCDs are used in a wide range of applications from calculators, watches, games to medical and industrial applications. One of the main advantages of LCDs over other display technologies is the display content can be modified to satisfy the exact requirements of an application. In this way, the customized LCD panels can present particular user interface information that enhances the product value and performance.

Customized LCD displays are used to display a combination of numeric, alphanumeric digits, on/off indicators,messages, graphic icons, symbols, pie charts, bar graphs, etc. The content of this panel is limited only by the imagination of the product designer. There are manyfactors that should be considered in the design of a customized LCD panel. In order to design a quotation for a customized LCD panel, the following information is necessary:LCD panel, display modes, polarisers, viewing mode, backlight requirement, operating environment, drive method, connection method, and a keypad is required if applicable.

This is all about Alphanumeric and Customized LCD displays with Applications. We all know that these LCD displays play an essential role in many applications like measurement equipment, process control equipment, handheld devices, PLC’s, Measuring device, Marine equipment, Medical equipment, Automotive display etc. This article deserves readers’ feedback, suggestions and comments. Furthermore, any doubts regarding electronics projectsreaders can post their comments in the comment section below.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey