tft display power consumption factory

For many years, TFT displays have been the dominating technology in visualization. TFT LCDs are all around in our daily lives — in consumer and automotive applications, in our business environments, in healthcare, and within communication devices, home appliances, and factory automation products. While there are many LCD products available today, they’re not all suitable for every application. This is especially the case for industrial LCD monitors. To determine the best LCD display for your application, it’s important to understand your target market and its unique design issues.

The vast majority of LCD displays are designed for consumer devices such as smartphones, cameras, tablet computers, and gaming devices. But they have very different requirements than those for industrial applications. Due to very competitive pricing and quick production cycles, consumer display modules don’t always incorporate the durability, reliability, and advanced features required to survive in an industrial environment. Product life cycles are also typically much shorter in consumer applications. Screens manufactured for these applications are generally only available for one, in best case two years.

In contrast, display modules for industrial applications require Long product life cycles— often up to ten years or more. Plus, when an industrial module is discontinued by the manufacturer, a successor product should be backward-compatible so as to fit into the existing enclosure without requiring a redesign of the entire system.

The ability to withstand temperature variations as well as shock and vibration is also a key consideration when selecting displays for today’s industrial applications. They must be resilient enough to withstand frequent bumps or jiggles by machine operators and surrounding equipment, and also must be able to handle various operating temperatures.

Industrial displays are typically housed in an enclosure as part of a larger piece of equipment. In these situations, the heat generated by the surrounding equipment gets trapped within the enclosure, which can be detrimental to many displays. Therefore, it’s important to keep the real storage and operating temperature requirements in mind when choosing a display. While measures can be taken to dissipate the generated heat — such as using fans within the enclosure — the most efficient way to ensure compliance with the storage and operating temperature requirements is to select a display that is optimized for these types of environments. Fortunately, improvements in liquid-crystal materials have made it possible to extend the operating temperature ranges of LCDs from –30 to 80°C presently.

It’s important that displays used in industrial applications support clear and precise viewing from multiple angles under a variety of ambient light conditions. The brighter the environment, the more difficult it can be to read a standard transmissive LCD display with a typical brightness of 250 to 300 cd/m2. NVD has developed displays that can perform in the 800-cd/m2-and-higher range by implementing high-efficiency LEDs for the backlight unit– if necessary, in combination with special brightness enhancement films.

Increasing the display’s contrast ratio is another effective way that display manufacturers can improve display readability in bright environments. Typical contrast ratios for non-industrial displays are in the range of 200:1 to 300:1, which may not be sufficient when a machine operator is viewing the display from a distance. Displays with contrast ratios around 500:1 or greater are better suited for industrial environments. Another benefit of this method is that it doesn’t increase power consumption.

Transflective LCDs are a good solution for environments with variable lighting. Having both transmissive and reflective characteristics, transflective LCDs have the option of using a backlight in dim lighting (transmissive mode), as well as using reflective properties in bright lighting (reflective mode). This reduces power consumption and heat production in reflective mode since the backlight isn’t used.

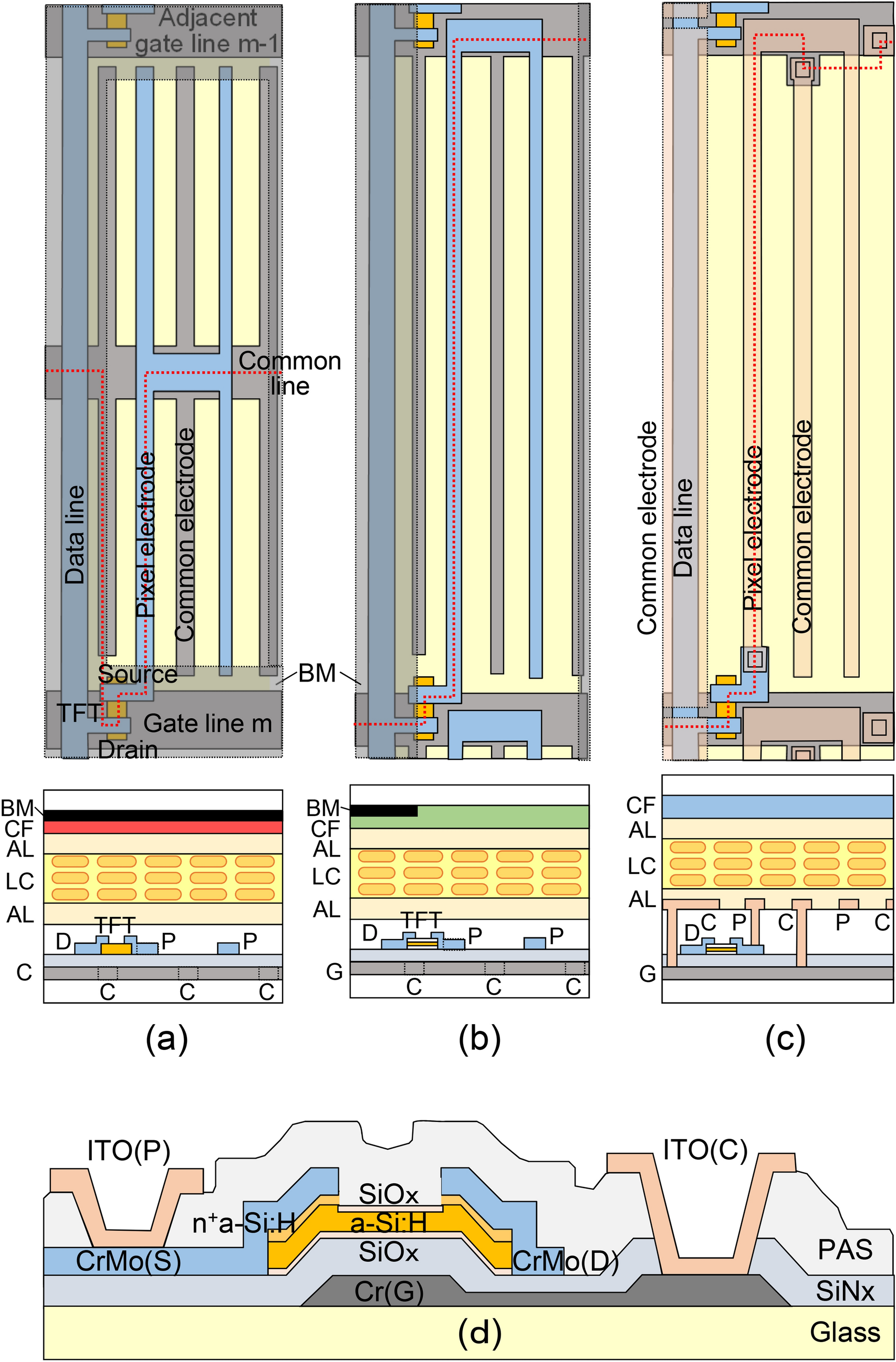

Multi-angle readability is another key selection factor. In a typical industrial environment, a machine operator is more likely to be positioned at an off-angle rather than right in front of the screen. Implementing a display designed for consumer applications typically doesn’t work well in this situation, as there is image distortion and color shifting when viewed at an angle. But, a number of technologies have been employed to improve off-angle viewing in displays, making them suitable for industrial applications. Some film-based technologies yield viewing angles of 160º horizontally and 140º vertically, but in some cases, this is still not sufficient. In-plane switching technology (IPS), multi-domain vertical alignment (MVA), and fringe field switching (FFS)offer alternatives. These proprietary technologies are able to achieve viewing angles of almost 90-degrees into all four directions without any color shift.

Size and resolution also play a role in overall readability. Displays between 2 and 15-inch diagonal sizes are used most often in industrial applications. These sizes provide sufficient area to view figures, waveforms, and other graphical data without taking up too much real estate on a piece of equipment.

From an aspect ratio 4:3 initially, industrial displays are now shifting to wide formats with WVGA to WXGA resolutions. The wide-aspect format enables users to view longer waveforms and more data on a single display. These display modules can also be designed to incorporate touch-key functions, allowing equipment manufacturers to skip physical switches and buttons and design HMIs based more on software than hardware.

New Vision Display’s experts are prepared to assist in defining appropriate solutions for all applications and in helping find the right balance between manufacturing cost and performance.

The display device has a significant contribution to the total power, which is critical for mobile consumer-electronic devices due to a limited battery capacity. We develop a power model of the active-matrix organic light-emitting diode (AMOLED) display and analyze the power contribution of thin-film transistor (TFT), OLED, and VDD line drop. Both theoretical analysis and calculation are derived from TFT mobility, OLED luminous efficiency, pixel aperture ratio, and VDD line drop. The TFT mobility from 0.1 to 10 cm

/(V · s) is a bottleneck of display power. Metal oxide TFT may be more suitable for AMOLED display since relatively high mobility and low fabrication temperature. High luminous efficiency of OLED and top emission structure can decrease power consumption abundantly. The impact of copper wire technology is also discussed in large-size panels.

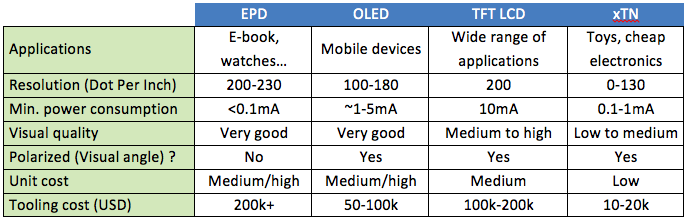

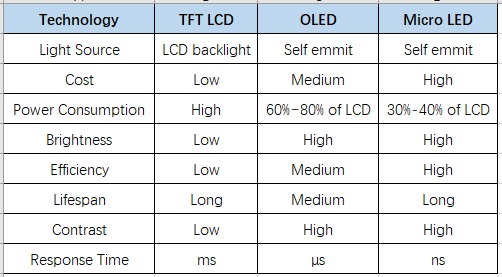

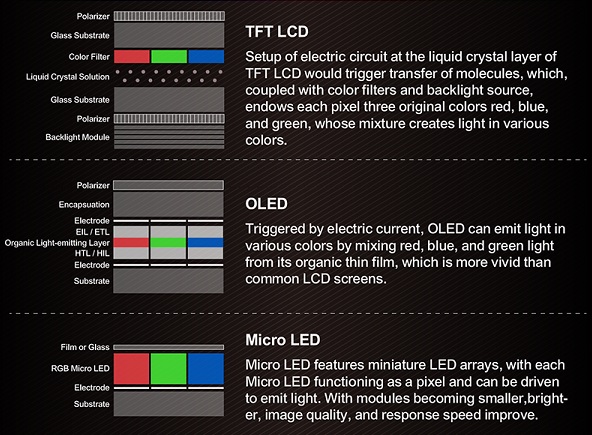

TFT LCD is a mature technology. OLED is a relatively new display technology, being used in more and more applications. As for Micro LED, it is a new generation technology with very promising future. Followings are the pros and cons of each display technology.

TFT Liquid Crystal Display is widely used these days. Since LCD itself doesn"t emit light. TFT LCD relies on white LED backlight to show content. This is an explanation of how TFT LCD works.

Relatively lower contrast:Light needs to pass through LCD glasses, liquid crystal layer, polarizers and color filters. Over 90% is lost. Also, LCD can not display pure black.

Organic Light-Emitting Diode is built from an electro-luminescent layer that contains organic compounds, which emit light in response to an electric current. There are two types of OLED, Passive Matrix OLED (PMOLED) and Active Matrix OLED (AMOLED). These driving methods are similar to LCD"s. PMOLED is controlled sequentially using a matrix addressing scheme, m + n control signals are required to address a m x n display. AMOLED uses a TFT backplane that can switch individual pixels on and off.

Low power consumption and flexible: OLED doesn"t rely on backlight and consumes less power. OLED is essentially created on plastic film. It is bendable and easy to process.

Replacing organic material with inorganic GaN material eliminates the need of polarizing and encapsulation layer, found in OLED. Micro LED is smaller and thinner, consumes less power.

TFT LCD is a mature technology. OLED is a relatively new display technology, being used in more and more applications. As for Micro LED, it is a new generation technology with very promising future. Followings are the pros and cons of each display technology.

TFT Liquid Crystal Display is widely used these days. Since LCD itself doesn"t emit light. TFT LCD relies on white LED backlight to show content. This is an explanation of how TFT LCD works.

Relatively lower contrast:Light needs to pass through LCD glasses, liquid crystal layer, polarizers and color filters. Over 90% is lost. Also, LCD can not display pure black.

Organic Light-Emitting Diode is built from an electro-luminescent layer that contains organic compounds, which emit light in response to an electric current. There are two types of OLED, Passive Matrix OLED (PMOLED) and Active Matrix OLED (AMOLED). These driving methods are similar to LCD"s. PMOLED is controlled sequentially using a matrix addressing scheme, m + n control signals are required to address a m x n display. AMOLED uses a TFT backplane that can switch individual pixels on and off.

Low power consumption and flexible: OLED doesn"t rely on backlight and consumes less power. OLED is essentially created on plastic film. It is bendable and easy to process.

Replacing organic material with inorganic GaN material eliminates the need of polarizing and encapsulation layer, found in OLED. Micro LED is smaller and thinner, consumes less power.

TFT LCD display is characterized by good brightness, high contrast, strong sense of layering, and bright colors, but it also has the disadvantages ofrelatively highpowerconsumptionand high cost. TFT LCD technology has accelerated the development ofmobile phone color screens. Many of the new-generation color screen mobile phones support 65536-color displays, and some even support 160,000-color displays. At this time, the advantages of TFT high contrast and rich colors are very important.

TFT technology was developed in the 1990s. It adopts new materials and new processes for large-scale semiconductor full integrated circuit manufacturing technology. It is aliquidcrystal(LC), inorganic and organic thin film electroluminescence (EL and OEL) flat panel display. basis. TFTs are formed on glass or plastic substrates and other non-single wafers (of course, they can also be on wafers) by sputtering and chemical deposition processes to form various films necessary for manufacturing circuits, and large-scale semiconductor integrated circuits (LSIC) are produced by processing the films . The use of non-single-crystal substrates can greatly reduce costs, which is the extension of traditional large-scale integrated circuits to large areas, multi-functions, and low costs.Manufacturing TFTs thatcontrolthe switching performance of pixels (LC or OLED) on large-area glass or plastic substrates is more difficult than manufacturing large-scale ICs on silicon wafers. The requirements for the production environment (purification degree is 100), the requirements for the purity of raw materials (the purity of electronic special gas is 99.999985%), the requirements for production equipment and production technology exceed the large-scale integration of semiconductors, and are the top of modern large-scale production technology. Its main features are:

(1) Large area: The first generation of large-area glass substrate (300mm×400mm) TFT-LCD production line was put into operation in the early 1990s. By the first half of 2000, the area ofthe glass substrate had been expanded to 680mm×880mm), and 950mm×1200mm The glass substrate will also be put into operation. In principle, there is no area limit.

(2) High integration: The resolution of the 1.3-inch TFT chip used for liquid crystal projection is XGA containing millions of pixels. The 16.1-inch TFT array amorphous silicon with a resolution of SXGA (1280×1024) has a film thickness of only 50 nm, and TABONGLASS and SYSTEMONGLASS technologies. The IC integration, the requirements for equipment and supply technology, and the technical difficulty are more than traditional LSI.

(3) Powerful function: TFT was thefirst matrix addressingcircuitto improve the light valve characteristics of liquid crystal. For high-resolution displays, through the voltage adjustment in the range of 0-6V (its typical value is 0.2 to 4V), the precise control of the object element is realized, thereby making it possible for the LCD to achieve high-quality high-resolution display. TFT-LCD is the first flat panel display in human history that exceeds CRT in display quality. And people began to integrate the driver IC on the glass substrate, the function of the entire TFT will be more powerful, which is unmatched bytraditional large-scalesemiconductorintegrated circuits.

(6) Wide application fields, LCD flat panel displays based on TFT technology are the pillar industries of the information society, and the technology can also be applied to the rapidly growing thin film transistor organic electroluminescence (TFT-OLED) flat panel displays. Growing up.

With the maturity of TFT technology in the early 1990s, color liquid crystal flat panel displays have developed rapidly. In less than 10 years, TFT-LCD has rapidly grown into a mainstream display, which is inseparable from its advantages. The main features are:

(1) Good use characteristics: low-voltage application, low driving voltage, solidified use safety and reliability improvement; flat, light and thin, saving a lot of raw materials and use space; low power consumption, its power consumption is about CRT display One tenth, reflective TFT-LCD is only about 1% of CRT, which saves a lot of energy; TFT-LCD products also have specifications, sizes, series, variety, convenient and flexible use, maintenance, update , Easy upgrade, long service life and many other features. The display range covers the application range of all displays ranging from 1 inch to 40 inches and the large plane of projection. It is afull-size displayterminal; the display quality ranges from the simplest monochrome character graphics to high resolution, high color fidelity, High-brightness, high-contrast and high-response video monitors of various specifications and models; display methods include direct-view type, projection type, perspective type, and reflective type.

(2) Good environmental protection characteristics: no radiation, no flicker, no damage to the user"s health. In particular, the emergence of TFT-LCD electronic books and periodicals will bring human beings into the era of paperless office and paperlessprinting, triggering a revolution in the way humans learn, spread, and document civilization.

(3) Wide application range, can be used normally within the temperature range from -20℃to +50℃, and the low-temperature working temperature of the TFT-LCD after temperature strengthening treatment can reach minus 80℃. It can be used as a mobile terminal display, desktop terminal display, and can also be used as a large-screen projection TV. It is a full-size video display terminal with excellent performance.

(4) The degree of automation of manufacturing technology is high, and the characteristics of large-scale industrial production are good. The technology of the TFT-LCD industry is mature, and the yield rate of large-scale production reaches more than 90%.

(5) TFT-LCD is easy to integrate and update, it is the perfect combination of large-scale semiconductor integrated circuit technology andlightsource technology, and there is great potential for continued development. There are currently amorphous, polycrystalline, and monocrystalline silicon TFT-LCDs, and in the future there will be TFTs of other materials, both glass substrates and plastic substrates.

Super Mobile HR TFT LCDs provide brilliant, vivid images outdoors where it is bright, but their visibility is poor indoors, where ambient light levels are lower.

Thus, though the display panel is transflective, it provides high transmittance and excellent image quality on a par with conventional transmissive TFT-LCDs.

The High Transmission Advanced TFT-LCD is suitable for applications where indoor use is of primary importance but outdoor use is occasionally necessary.

“Blanview” is Toppan’s unique TFT-LCD technology enabling the display to create high contrast and crisp images even in bright circumstances where a sunlight hit to display surface directly.

With leveraging Toppan’s high-quality amorphous silicon (a-Si) technology “HAST” (Hyper Amorphous Silicon TFT), which has been fostered in our 40-years-long display expertise, Toppan succeeded in generating new type TFT-LCD with a good balance between 2 values - “Sunlight Readable” and “Low Power Consumption”

Transmissive-typeis the most common LCD technology that is widely used in many electrical devices. Transmissive can provide clear images in indoor and dark situations, but meanwhile its display readability gets worse in bright outdoor situations. Backlight power increase can improve the display visibility somewhat, but it lead to boost total power consumption; this may be critical impact to battery-driven handheld devices.

Transflective-typeis suitable LCD technology to outdoor applications. Transflective has pixels divided into 2 areas, Transmission and Reflection area; the reflection area (reflective electrode) takes a role to reflect incident light from outside. This can give a clear display readability as well as low power consumption; however, the panel transmittance (backlight efficiency) becomes rather lower due to a 2-divided pixel structure. As a result, Transflective inherently has a drawback of large power consumption in indoor or dark conditions. Complex pixel structure furthermore cause a problem that a color level changes indoors and outdoors; generally white color tends to gain yellowish outdoors.

The above shows how each display technology (Transmissive, Transflective and Blanview) handles the light to create images. Line weight of each arrow indicates its light intensity level.

Transmissive with high light transmittance can utilize backlight efficiently for good display quality; on the other hand, it has little functionality to make use of incident light from outside. Transmissive eventually is not possible to secure good display visibility in outdoor bright situations, unless increasing backlight (= power consumption increase).

Transflective can reflect more incident light with a large size reflection area (reflective electrode), but meanwhile, its backlight use efficiency rather decreases due to a smaller size of transmission area. Transflective requires to consume lots of power in darker environment.

This unique technology enables us to take a “hybrid use” of backlight and incident light from outside. Blanview succeeded in not only ensuring superior display readability in any situations, but also decreasing total power consumption.

This chart shows backlight power consumption required to secure enough display readability with transmissive LCD, transflective LCD and Blanview LCD respectively.

Transmissive requires lots of power in bright circumstances. Transflective is possible to reduce the power greatly in bright circumstances, but meanwhile it requires more power to secure enough readability in dark circumstances.

Blanview can acquire high display visibility along with low power consumption in any circumstances, from dark to bright circumstances. We can say that Blanview is most suitable display technology to a product used in “sometimes outdoor, sometimes indoor” for a long period.

In order to providing more suitable display product for customer’s new product development, Toppan’s Blanview family covers a wide variety of standard (off-the-shelf) products; e.g. Display size, Resolution, Interface, Characteristics, Additional functions.

Blanview TFT-LCD is most appropriate display to electronic equipment, facilities and devices which may be used in “sometimes outdoor, sometimes indoor”. Low-Power-Consumption advantage will extend a battery life of handheld devices.

A thin-film-transistor liquid-crystal display (TFT LCD) is a variant of a liquid-crystal display that uses thin-film-transistor technologyactive matrix LCD, in contrast to passive matrix LCDs or simple, direct-driven (i.e. with segments directly connected to electronics outside the LCD) LCDs with a few segments.

In February 1957, John Wallmark of RCA filed a patent for a thin film MOSFET. Paul K. Weimer, also of RCA implemented Wallmark"s ideas and developed the thin-film transistor (TFT) in 1962, a type of MOSFET distinct from the standard bulk MOSFET. It was made with thin films of cadmium selenide and cadmium sulfide. The idea of a TFT-based liquid-crystal display (LCD) was conceived by Bernard Lechner of RCA Laboratories in 1968. In 1971, Lechner, F. J. Marlowe, E. O. Nester and J. Tults demonstrated a 2-by-18 matrix display driven by a hybrid circuit using the dynamic scattering mode of LCDs.T. Peter Brody, J. A. Asars and G. D. Dixon at Westinghouse Research Laboratories developed a CdSe (cadmium selenide) TFT, which they used to demonstrate the first CdSe thin-film-transistor liquid-crystal display (TFT LCD).active-matrix liquid-crystal display (AM LCD) using CdSe TFTs in 1974, and then Brody coined the term "active matrix" in 1975.high-resolution and high-quality electronic visual display devices use TFT-based active matrix displays.

The liquid crystal displays used in calculators and other devices with similarly simple displays have direct-driven image elements, and therefore a voltage can be easily applied across just one segment of these types of displays without interfering with the other segments. This would be impractical for a large display, because it would have a large number of (color) picture elements (pixels), and thus it would require millions of connections, both top and bottom for each one of the three colors (red, green and blue) of every pixel. To avoid this issue, the pixels are addressed in rows and columns, reducing the connection count from millions down to thousands. The column and row wires attach to transistor switches, one for each pixel. The one-way current passing characteristic of the transistor prevents the charge that is being applied to each pixel from being drained between refreshes to a display"s image. Each pixel is a small capacitor with a layer of insulating liquid crystal sandwiched between transparent conductive ITO layers.

The circuit layout process of a TFT-LCD is very similar to that of semiconductor products. However, rather than fabricating the transistors from silicon, that is formed into a crystalline silicon wafer, they are made from a thin film of amorphous silicon that is deposited on a glass panel. The silicon layer for TFT-LCDs is typically deposited using the PECVD process.

Polycrystalline silicon is sometimes used in displays requiring higher TFT performance. Examples include small high-resolution displays such as those found in projectors or viewfinders. Amorphous silicon-based TFTs are by far the most common, due to their lower production cost, whereas polycrystalline silicon TFTs are more costly and much more difficult to produce.

The twisted nematic display is one of the oldest and frequently cheapest kind of LCD display technologies available. TN displays benefit from fast pixel response times and less smearing than other LCD display technology, but suffer from poor color reproduction and limited viewing angles, especially in the vertical direction. Colors will shift, potentially to the point of completely inverting, when viewed at an angle that is not perpendicular to the display. Modern, high end consumer products have developed methods to overcome the technology"s shortcomings, such as RTC (Response Time Compensation / Overdrive) technologies. Modern TN displays can look significantly better than older TN displays from decades earlier, but overall TN has inferior viewing angles and poor color in comparison to other technology.

Most TN panels can represent colors using only six bits per RGB channel, or 18 bit in total, and are unable to display the 16.7 million color shades (24-bit truecolor) that are available using 24-bit color. Instead, these panels display interpolated 24-bit color using a dithering method that combines adjacent pixels to simulate the desired shade. They can also use a form of temporal dithering called Frame Rate Control (FRC), which cycles between different shades with each new frame to simulate an intermediate shade. Such 18 bit panels with dithering are sometimes advertised as having "16.2 million colors". These color simulation methods are noticeable to many people and highly bothersome to some.gamut (often referred to as a percentage of the NTSC 1953 color gamut) are also due to backlighting technology. It is not uncommon for older displays to range from 10% to 26% of the NTSC color gamut, whereas other kind of displays, utilizing more complicated CCFL or LED phosphor formulations or RGB LED backlights, may extend past 100% of the NTSC color gamut, a difference quite perceivable by the human eye.

In 2004, Hydis Technologies Co., Ltd licensed its AFFS patent to Japan"s Hitachi Displays. Hitachi is using AFFS to manufacture high end panels in their product line. In 2006, Hydis also licensed its AFFS to Sanyo Epson Imaging Devices Corporation.

A technology developed by Samsung is Super PLS, which bears similarities to IPS panels, has wider viewing angles, better image quality, increased brightness, and lower production costs. PLS technology debuted in the PC display market with the release of the Samsung S27A850 and S24A850 monitors in September 2011.

TFT dual-transistor pixel or cell technology is a reflective-display technology for use in very-low-power-consumption applications such as electronic shelf labels (ESL), digital watches, or metering. DTP involves adding a secondary transistor gate in the single TFT cell to maintain the display of a pixel during a period of 1s without loss of image or without degrading the TFT transistors over time. By slowing the refresh rate of the standard frequency from 60 Hz to 1 Hz, DTP claims to increase the power efficiency by multiple orders of magnitude.

Due to the very high cost of building TFT factories, there are few major OEM panel vendors for large display panels. The glass panel suppliers are as follows:

External consumer display devices like a TFT LCD feature one or more analog VGA, DVI, HDMI, or DisplayPort interface, with many featuring a selection of these interfaces. Inside external display devices there is a controller board that will convert the video signal using color mapping and image scaling usually employing the discrete cosine transform (DCT) in order to convert any video source like CVBS, VGA, DVI, HDMI, etc. into digital RGB at the native resolution of the display panel. In a laptop the graphics chip will directly produce a signal suitable for connection to the built-in TFT display. A control mechanism for the backlight is usually included on the same controller board.

The low level interface of STN, DSTN, or TFT display panels use either single ended TTL 5 V signal for older displays or TTL 3.3 V for slightly newer displays that transmits the pixel clock, horizontal sync, vertical sync, digital red, digital green, digital blue in parallel. Some models (for example the AT070TN92) also feature input/display enable, horizontal scan direction and vertical scan direction signals.

New and large (>15") TFT displays often use LVDS signaling that transmits the same contents as the parallel interface (Hsync, Vsync, RGB) but will put control and RGB bits into a number of serial transmission lines synchronized to a clock whose rate is equal to the pixel rate. LVDS transmits seven bits per clock per data line, with six bits being data and one bit used to signal if the other six bits need to be inverted in order to maintain DC balance. Low-cost TFT displays often have three data lines and therefore only directly support 18 bits per pixel. Upscale displays have four or five data lines to support 24 bits per pixel (truecolor) or 30 bits per pixel respectively. Panel manufacturers are slowly replacing LVDS with Internal DisplayPort and Embedded DisplayPort, which allow sixfold reduction of the number of differential pairs.

The bare display panel will only accept a digital video signal at the resolution determined by the panel pixel matrix designed at manufacture. Some screen panels will ignore the LSB bits of the color information to present a consistent interface (8 bit -> 6 bit/color x3).

With analogue signals like VGA, the display controller also needs to perform a high speed analog to digital conversion. With digital input signals like DVI or HDMI some simple reordering of the bits is needed before feeding it to the rescaler if the input resolution doesn"t match the display panel resolution.

Kawamoto, H. (2012). "The Inventors of TFT Active-Matrix LCD Receive the 2011 IEEE Nishizawa Medal". Journal of Display Technology. 8 (1): 3–4. Bibcode:2012JDisT...8....3K. doi:10.1109/JDT.2011.2177740. ISSN 1551-319X.

Brody, T. Peter; Asars, J. A.; Dixon, G. D. (November 1973). "A 6 × 6 inch 20 lines-per-inch liquid-crystal display panel". 20 (11): 995–1001. Bibcode:1973ITED...20..995B. doi:10.1109/T-ED.1973.17780. ISSN 0018-9383.

K. H. Lee; H. Y. Kim; K. H. Park; S. J. Jang; I. C. Park & J. Y. Lee (June 2006). "A Novel Outdoor Readability of Portable TFT-LCD with AFFS Technology". SID Symposium Digest of Technical Papers. AIP. 37 (1): 1079–82. doi:10.1889/1.2433159. S2CID 129569963.

Kim, Sae-Bom; Kim, Woong-Ki; Chounlamany, Vanseng; Seo, Jaehwan; Yoo, Jisu; Jo, Hun-Je; Jung, Jinho (15 August 2012). "Identification of multi-level toxicity of liquid crystal display wastewater toward Daphnia magna and Moina macrocopa". Journal of Hazardous Materials. Seoul, Korea; Laos, Lao. 227–228: 327–333. doi:10.1016/j.jhazmat.2012.05.059. PMID 22677053.

If you want to buy a new monitor, you might wonder what kind of display technologies I should choose. In today’s market, there are two main types of computer monitors: TFT LCD monitors & IPS monitors.

The word TFT means Thin Film Transistor. It is the technology that is used in LCD displays. We have additional resources if you would like to learn more about what is a TFT Display. This type of LCDs is also categorically referred to as an active-matrix LCD.

These LCDs can hold back some pixels while using other pixels so the LCD screen will be using a very minimum amount of energy to function (to modify the liquid crystal molecules between two electrodes). TFT LCDs have capacitors and transistors. These two elements play a key part in ensuring that the TFT display monitor functions by using a very small amount of energy while still generating vibrant, consistent images.

Industry nomenclature: TFT LCD panels or TFT screens can also be referred to as TN (Twisted Nematic) Type TFT displays or TN panels, or TN screen technology.

IPS (in-plane-switching) technology is like an improvement on the traditional TFT LCD display module in the sense that it has the same basic structure, but has more enhanced features and more widespread usability.

Both TFT display and IPS display are active-matrix displays, neither can’t emit light on their own like OLED displays and have to be used with a back-light of white bright light to generate the picture. Newer panels utilize LED backlight (light-emitting diodes) to generate their light hence utilizing less power and requiring less depth by design. Neither TFT display nor IPS display can produce color, there is a layer of RGB (red, green, blue) color filter in each LCD pixels to produce the color consumers see. If you use a magnifier to inspect your monitor, you will see RGB color in each pixel. With an on/off switch and different level of brightness RGB, we can get many colors.

Winner. IPS TFT screens have around 0.3 milliseconds response time while TN TFT screens responds around 10 milliseconds which makes the latter unsuitable for gaming

Winner. the images that IPS displays create are much more pristine and original than that of the TFT screen. IPS displays do this by making the pixels function in a parallel way. Because of such placing, the pixels can reflect light in a better way, and because of that, you get a better image within the display.

As the display screen made with IPS technology is mostly wide-set, it ensures that the aspect ratio of the screen would be wider. This ensures better visibility and a more realistic viewing experience with a stable effect.

Winner. While the TFT LCD has around 15% more power consumption vs IPS LCD, IPS has a lower transmittance which forces IPS displays to consume more power via backlights. TFT LCD helps battery life.

Normally, high-end products, such as Apple Mac computer monitors and Samsung mobile phones, generally use IPS panels. Some high-end TV and mobile phones even use AMOLED (Active Matrix Organic Light Emitting Diodes) displays. This cutting edge technology provides even better color reproduction, clear image quality, better color gamut, less power consumption when compared to LCD technology.

This kind of touch technology was first introduced by Steve Jobs in the first-generation iPhone. Of course, a TFT LCD display can always meet the basic needs at the most efficient price. An IPS display can make your monitor standing out.

Get rich colors, detailed images, and bright graphics from an LCD with a TFT screen. Our standard Displaytech TFT screens start at 1” through 7” in diagonal size and have a variety of display resolutions to select from. Displaytech TFT displays meet the needs for products within industrial, medical, and consumer applications.

TFT displays are LCD modules with thin-film transistor technology. The TFT display technology offers full color RGB showcasing a range of colors and hues. These liquid crystal display panels are available with touchscreen capabilities, wide viewing angles, and bright luminance for high contrast.

Our TFT displays have LVDS, RGB, SPI, and MCU interfaces. All Displaytech TFT LCD modules include an LED backlight, FPC, driver ICs, and the LCD panel.

We offer resistive and capacitive touch screens for our 2.8” and larger TFT modules. Our TFT panels have a wide operating temperature range to suit a variety of environments. All Displaytech LCDs are RoHS compliant.

We also offer semi-customization to our standard TFT screens. This is a cost-optimized solution to make a standard product better suit your application’s needs compared to selecting a fully custom TFT LCD. Customizations can focus on cover glass, mounting / enclosures, and more - contact us to discuss your semi-custom TFT solution.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey