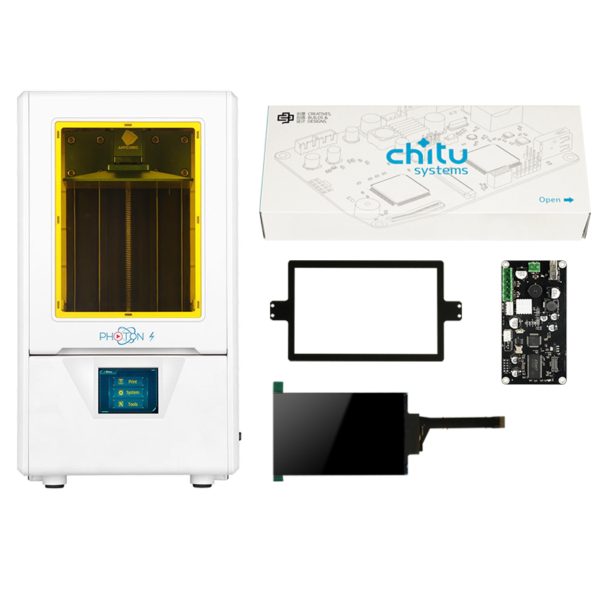

photon s lcd screen replacement free sample

Patrick Prints was founded on the idea to help startup businesses. No minimum order quantities on any product we can supply made it easier for customers to make their dreams come true. Our services are quite a few: Bureau Printing (business cards, flyers, menus, invites & more), DTS printing (branding of hardware like pens, keychains, lighters, electronics gadgets and more), Garment Printing (Printing on t-shirts, Uniforms, Bags, Polo shirts, combat trousers), Embroidery Service, Computer Cut Stickers, Sublimation (Mugs and Promo items).

We collect user journey data to show you relevant sponsored content about our products. For example, we use information from your previous purchases and interactions with the site. We may share this information and a customer identifier, such as device data, with third parties such as Facebook and Google. We use the following services on this site:

Chitu systems, with over 7 years 3d printing experience, is the most reliable 3d printing systems provider. We offer you high-quality mono screens and other 3d printing accessories like nFEP film and tempered glass,we also design many upgrade kits for older printers.

We also cooperate with JamgHe to develope Conjure series resin for engineerings like printing demand, which can help you with functional gadgets and highly-detail display pieces.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Without any prior announcements, Anycubic quietly started to ship these machines to unsuspecting buyers. These new printers look exactly like the original Photons (with steel bodies and yellow windows) but are not. The motherboard has been changed, making them an entirely different printer that only looks like the original.

These look-alike Photons (commonly called Faux Photons or Fauxtons) share the same mainboards (PTB2BK) with the Photon-S and could then only print new *.pws files as they had Photon-S mainboards, making them incompatible with the original Photons.

Due to community outcry, in early November 2019 Anycubic were finally forced to admit that they were indeed shipping these Fauxtons. In an official announcement on their Facebook page, they apologised for the "confusion" their ambiguity caused and clarified that they were still shipping the original Photons side by side with the lookalike Fauxtons and that buyers would have to specify their preferred versions. Since then, the new Fauxtons (and the Photon-S) received firmware updates allowing them to print original Photon files.

As of mid-November 2019, all Photon printers shipping from China are the new Fauxtons. Last remaining stocks of the original Photon were still being shipped only from NA and European warehouses.

Unfortunately, since the Fauxton look physically the same as the original Photon, the only way to tell is to check the firmware version or check the motherboard inside. Look-alike Fauxtons ship with firmware version v3.x.x or v5.x.x).

All newer original Photons and new Fauxtons look-alikes come with Yellow windows. Older original Photons (prior to August, 2018) had Blue windows. Blue doesn"t block UV well and they were changed to yellow later, with newer firmware, slight revisions to uncap the top end of the Z lead screw and include a better PSU.

Originally, the file formats were incompatible. Since the November 2019 firmware update for the Fauxton (and the Photon-S), original Photon files can now be printed on the new Fauxton. This post on the Photon Owners Group provides details the confusing state of the various different file formats (before the Fauxton firmware update).

The Photon-S was released in February 2019, supposedly as an interim upgrade to the original Photon. However, it turned out to be a sidegrade, rather than a true upgrade. Due to the different motherboard, it"s actually a completely different printer altogether.

When first released, the fundamental difference was that the S model was not file compatible with the original Photon, and thus could not use any of the original print files sliced for the original Photon. With the November 2019 firmware update, it can now print original Photon files although initial user reports say compatibility is buggy.

Do note that many of the essential community software and tools that have been developed for the original Photon are not compatible and do not work with the S model (or new Fauxton).

Contrary to many misleading online reports, when first released, the S model did NOT have anti-aliasing (AA) while the original Photon had this important feature via an unofficial firmware and an official AA firmware update in May 2019.

In August 2019, Anycubic finally released a new firmware for the S model which included the AA feature, but with the update the file format was changed from *.photons to *.pws and made it incompatible. It also broke Chitubox slicer support for the previous file format. At that point, no other slicer (except for paid ones) supported the new *.pws format. Since the November 2019 firmware update, compatibility has been restored.

Two column guide sliders on the same central Z lead screw instead of a single column slide. (Note that these are just simple sliders on guide rods, not recirculating bearing linear rails.)

You will also need a known good branded USB stick (beware of fakes), formatted FAT32. The included usb stick is known to be problematic and prone to eventual failure. Transfer all the files from it to your known good USB stick and use that instead.

No, it"s not necessary, and not recommended at all. Set your printer up and do the test print first. Make sure that your Photon is functioning as it should before considering doing any firmware updates.

Do not update if your Photon is working well. If you"re running older firmware and need AA functionality, do not update to version v4.2.19 as that version is buggy, it is recommended to use v4.2.18 instead.

Incorrect build plate tramming (levelling) is the number one reason for print failures. It is a statistical fact, most of the issues posted on the Anycubic Photon Printer Owners Group invariably traces back to imperfect build plate leveling as the root cause.

Once your build plate is leveled correctly and locked down tight, you do not have to relevel it anymore unless you make other adjustments that affect the build plate.

Press Home to bring the build plate down before starting to make build plate leveling adjustments. If you do not Home first, it will not set Z=0 correctly.

After setting Z=0 verify that it is set correctly by removing the vat and starting a print (aka dry run), put a piece of paper on the screen and check that the build plate starts the first layer at the correct Z=0 position that you have set.

If you are using the recommended paper method, the paper should be tight enough to pull out with even resistance but not able to push back in. Remember that the build plate must grip the paper evenly.

Remember that as you tighten the setting (grub) screw it will move the plate down a tiny fraction more. You will find that you cannot pull the paper anymore, so you should raise / backoff the build plate level by 0.1mm (100um) until the plate is gripping the paper with even resistance, and that you can pull but not push it back. Then only set Z=0.

Just regular photocopy paper, they"re generally around 80gsm, but any paper 70 ~ 120gsm (average thickness ranging from 0.05 to 0.10mm) should work too. Just ensure that the paper is clean and not creased or folded.

Using your fingers, push the opposite side of the plate when tightening the grub screw. Alternatively, if you"re using the paper method, you can slip another strip of paper to the side which is too tight and then tighten the screw. You may need to try this a few times to get perfect level.

If no matter how much you tightened the grub screw to lock the build plate down and the plate still moves, remove the grub screw and check if there"s another one already in the hole. Remove the extra screw and retighten.

Home is not Z=0! Home is fixed, it is the hardware Z endstop, unless you change it physically, it will always be the same position. Z=0 is the offset distance between Home and your screen, you define it when you level the build plate, that"s why you have to Home first then move the platfrom, then set Z=0.

When a new Z=0 is specified, pressing Home will NOT move the platform to the position you specified, it will be the start position when a real print actually starts. You can check it by removing the vat and starting a print. (Thanks to Philippe Maegerman for the original explanation.)

No, it is absolutely not necessary. If you have correctly leveled and then tightened and securely screwed and locked down the build plate tight, it will remain in place and correctly leveled for a very long time.

Make sure you have really tightened the setting (grub) screw to lock the build plate. You only need to relevel your build plate if it has slipped or been knocked or you made changes that affect the Z=0 position.

If not, then it is absolutely NOT NECESSARY at all. Contrary to all the claims and misinformation being repeated that sanding away the blue anodized colour solves adhesion problems, it does not.

When you have correctly leveled, the blue anodized aluminium surface of the stock build plate provides plenty of texture to ensure good adhesion. Adhesion is so good that some owners have difficulty removing prints.

Speciality castable resins such as Bluecast are monomer-free formulations. In this situation, the anodized surface of the build plate inhibits adhesion of the oligomers used.

Bluecast recommends the use of a primer coat as a solution. In the Bluecast Users Group on Facebook, a post by Bluecast recommends to sand the build plate as well. Do note that raw aluminium will self anodise in time, so periodic sanding may be necessary.

That"s not true at all. Once again, it is not about the texture (there"s already plenty on the stock blue build plate), it"s about build plate flatness and the resin formulation. If your build plate is leveled correctly and its surface is flat, and you"re not using speciality monomer-free resin such as Bluecast, you will have good print adhesion. Resin will adhere even to glass as you can see in this video by Photocentric.

Did you just switch resins? Did you use an unsuitable resin formulated for SLA Laser or DLP printers? Are you using speciality castable resins? Did you mix the resin properly before use? Is the resin expired? Is it too cold? There are many factors that may affect print adhesion. Keep testing to find the root causes for your plate adhesion issues.

Some resins such as Anycubic Maroon or Monocure Rapid are known to be notoriously difficult to obtain adhesion. This is due to their formulation. Try other resins, or increase bottom exposures by 10 second increments and keep testing.

Castable and other speciality resins such as Bluecast (monomer-free) generally need longer bottom exposures and the help of a primer coat. Primers are basically just uv glue and can be found online cheaply. You can also try LOCA (Liquid Optically Clear Adhesive),

For the vast majority of regular modelling resins, ensuring a leveled build plate and increasing bottom exposures should enable plate adhesion. Do not pay for uv glues marketed as miracle cure adhesion bonding concoctions.

If you"re positively sure it"s not the resin or other factors mentioned above, and you"ve got your build plate leveled perfectly, and it"s not warped or defective, and you still can"t get a print or some parts didn"t stick to the plate, try following these steps very, very carefully.

You may have a warped or defective build plate, the plate surface may not be true and flat. Check for flatness by placing a steel rule across the build plate, against a light source, check if there are any uneven gaps showing.

It would be more accurate to check by making an imprint. Lightly coat the build plate surface with engineer"s blue dye or evenly roll a thin layer of printmaking ink. Place a sheet of paper on a known flat surface such as plate glass or polished granite /marble, then press the build plate on the paper and check the imprint for blank spots.

If you"ve verified that the build plate surface is not flat, you can try to achieve a true flat surface by a process termed lapping. Unfortunately, most people will not have the tools or skills to achieve this. Try bringing your build plate to a machine shop nearby, they"ll know what to do.

If you want to try this at home, do not simply go rubbing the build plate with sandpaper, you"ll probably make things worse. Proceed only if you have the necessary tools and know-how to achieve a true flat surface.

When you receive your new Photon, it will come with an aluminium vat frame with a FEP film already installed. Check that the film is tight by lightly tapping with your finger. If it is tensioned correctly it should sound just like a snare drum.

Sometimes the screws may seem loose, but it may be tensioned correctly from the factory. Do not simply tighten the screws or you may then over tension the FEP.

If it sounds like a snare drum when you lightly tap with a finger, it should be good enough. But since hearing is subjective, to be precise, you should use an audio analyser to check, factory tensioned FEP film (about 127 to 150 microns thick) is around 350Hz, but anything between 250Hz to 375Hz is fine.

Some owners have obtained good prints with tensions as low as 150Hz, but there are also reports of leaking vats at those low tensions, For that reason, we advise 250Hz to 350Hz. Be careful when adjusting, over tensioning above 375Hz may tear your FEP film, or may cause bad prints. (FB post)

When your print peels from the FEP film, there are a lot of suction forces involved. Unlike more expensive machines, the Photon does not have a tilt peel mechanism, it therefore relies on the flexibility of the FEP film to provide a clean and successful peel.

If the film is too tightly tensioned, your prints won"t peel off properly and may stick to the build plate, too loosely tensioned and it"ll have layer lines or other unwanted artifacts.

A correctly tensioned FEP therefore will give the best print results and avoid print failures or delamination problems. For an example of print problems which was only resolved by proper FEP tensioning, check this FB post.

No, FEP (fluorinated ethylene propylene, invented by DuPont, sold under the brandname Teflon FEP), is already one of the most slippery materials known to science. Coating your FEP film with a hydrophobic substance like Rain-X may in fact cause bad quality prints.

When new, the film is clear. But it is easily scratched by handling or cleaning. Use soft tissue to soak resin when cleaning up the vat, do not aggressively wipe the film as even tissue will scratch it. These micro scratches cause the film to go cloudy. Buffing the film with microfibre cloth will restore some clarity. It is important that the film is kept clear to ensure sharp and detailed prints.

If you take care of it, it will not need to be replaced for months. FEP film needs to be replaced only when it becomes too scratched up or cloudy from use. If it is not replaced your print quality will deteriorate. Replace immediately if it is punctured or torn. If you notice cured resin on your LCD glass, it means the film may have a micro tear.

Watch the video by Anycubic for a detailed step by step. It is important to note one very important omission in that video: some replacement FEP film may come sandwiched between two layers of protective plastic. These have to be peeled off before the FEP film can be used.

It"s difficult to see if there"s protective plastic film on your FEP. An easy way to test is by dripping a few drops of resin on your FEP film, then hold the film vertical. If the resin slides downward easily without sticking and leaves the FEP clear, it"s good. If the resin sticks where you dripped it and moves slowly or smears, then you have protective plastic which needs to be removed.

Not advisable. There"s a reason why FEP (Fluorinated Ethylene Propylene) is used. Besides low friction, non-reactivity, flexibility, high heat resistance, high transparency, uv resistance, etc., it is also one of the most slippery substance known to science.

The bottle cap, 30mm diameter x 13mm height, will allow some slack to the film, so that when you tighten the frame down you will get approximate tension. If you don"t do that, you will over tension the film and it may tear. If it didn"t tear, later on you"ll be wondering why all your prints fail.

None. The test file that came on the included USB stick has been pre-sliced and settings configured for the 250ml bottle of translucent green sample resin. All you need to do is select the file and print. If you didn"t receive this sample resin with your printer, or received a different colour sample, only then will you need to change the exposure settings. You will then need to either do an exposure test for your resin, or consult the quick settings chart (see below).

You first need to convert those 3D models by generating sliced layers into a format that your Photon understands and can print. This is done in what"s known as a slicer program. A free slicer program comes included in the usb stick provided with your printer.

If you"re new to resin printing, the included slicer is best to start with. Once you"ve familiarised yourself with the basics, there are other slicers with more features you can try. Here is a list of slicers that work with the Photon.

Every resin behaves differently, there are no best settings that will work for every resin and every machine. For a quick start, you can refer to the community resin exposure settings. Those settings should enable you to quickly get a print going but you will need to test and adjust from there to find the best settings applicable for your machine.

It used to be only possible via a messy and time consuming trial and error method involving multiple bracketed prints. But thankfully we now have the Photon Resin Calibration Test aka the Photon XP Finder. This test enables you to find the optimum settings for your resin, matched to your machine, all in one simple and quick print.

For Anycubic branded resin, first check if the date is printed in black ink. If it is, then that is the production date. For other resin brands, unless it is clearly stated, double check with the manufacturer first whether the date codes are production or best-by dates.

Generally, most resin manufacturers advice that resin be used within one year. The dates are basically "use by" dates, not expiry per se. In practice, when kept properly in a cool dry location and unexposed to light, resin can be stored and used without issues.

This is assuming you"re using the Anycubic Photon slicer program (rebadged Chitu slicer v.1.3.6) that is included on the USB stick. Other slicers may use different terminology but they"re functionally the same. If you"re just starting out, it"s highly recommended you use the Anycubic slicer. It"s basic, won"t overwhelm you with bells and whistles, and just works.

This is how long the UV light will turn on to set the layer of resin that is on your build plate for the first few layers (it"s extra long to give the resin the best chance to stick to your plate and form a super hard base to help keep your part from wobbling and rocking about.) For the sample green resin at 0.05mm layers, the exposure for bottom layers is 60 seconds.

After your base layers have finished this is the time the UV will be on to cure all the rest of the layers of your print and will always be lower than your base/bottom layers setting, For the sample green resin at 0.05mm layers, the exposure for normal layers is 10 seconds.

Light off delay. This is the amount of time that the UV light is turned off between the end of one exposure cycle and the beginning of the next. After an exposure, the UV light turns off, the build plate lifts and peels, then descends ready for the next cycle and will wait at the bottom (resting at the set layer height over the FEP sheet, at the bottom of your vat) before the UV light comes on again for the next exposure cycle.

Longer offtimes leave more time for the resin to settle out and form a new layer with fresh resin. This is especially useful for more viscous resins to mitigate issues of poor definition of surfaces facing the build plate

If unsure, leave the value at 1, your printer will then default to the firmware settings, usually 6.5 secs for older printers or firmware, 4.5 secs for newer printers or firmware. Any value below your printer"s defaults will be ignored. The fastest prints are at default settings.

Vent holes are often improperly called "drain" holes, they are not for draining resin. Imagine a glass full of water upside down in a bucket of water. When you pull the glass up out of the bucket, it stays full until the lip of the glass breaks the surface of the water in the bucket.

In the vat, the lowest point of the print, the new layer does not (generally) rise above the level of the liquid resin in the vat. Therefore, the liquid resin inside the "bowl" or "cup" cannot evacuate, unless you add a vent hole. This is a significant cause of failures. You have to reduce the work that the stepper motor has to do to lift the platform.

Initially, In the printer vat, the inside volume of resin will be pulled up. Eventually, depending on the volume of the inside space and the volume of resin in the vat, the new layer will rise above the fluid level because the surface of the fluid will be moving down at ever increasing rates with each layer. That is, the level of the fluid inside the space and in the vat are actually moving in opposite directions. When that happens, all of the fluid inside will be released, but now you have a trapped volume of air, so you will alternate between struggling with lifting up and struggling with pushing down.

Without vent holes, it"s really a recipe for bad prints. The result is that you can get multiple failures at various heights, depending on where these extremes occur. Formlabs has a good article on model orientation,v enting and suction cups.

It depends on the software. Two popular free programs that make it easy to hollow your models are Chitubox and Meshmixer. Here is a link on how to hollow with Meshmixer.

This is due to your offtime (or light off) settings in the slicer. The program will calculate the print time based on the offtime value that you set, it is an estimate, it does not reflect the actual print time. To get an accurate estimate that matches your actual print time, time your actual offtime and use that value in your slicer program.

No. For simple models, auto supports should generally work but as with anything automatic it will never be perfect. For a start, you can use auto supports and supplement with manual supports on parts that the software missed. But it will be best to learn to place your supports manually and precisely, you will find that you will need less supports and produce better prints in the long run.

There isn"t one best angle for printing everything. It really depends on your layer height, and the type of model you"re printing. Don"t forget that model orientation also plays a big part to determine the best angles. You could actually be losing details printing at the wrong angle for the layer height.

This image by Michael Van Kesteren from the post on the Facebook group shows the approximate best angle for each layer height to maximize details and minimize layer stepping (pixelation / aliasing) lines.

It is highly recommended that you print it. The test file has been presliced for the included sample green resin, all you have to do is select the file and print.

A successful test print will confirm that your Photon works as it should, and that you have properly leveled your build plate and your FEP tension is correct. It will also confirm that your machine will reliably work as the test takes over five hours.

If it did not print successfully, then troubleshooting will be easier as you can rule out various other problems such as with resin, settings or slicing.

Do not exceed the line, if there is too much resin, it will rise from displacement and cause a spill. Or get into the screws and ball joint of your build plate. There have been reports that resin in the ball joint may cause the build plate to slip and shift during a print, making it out of level. Besides, once resin cures in there, it"s also difficult to clean.

Yes , no problem. You do not have to pause the print, just slowly and gently pour resin into the vat. Make sure to not bump or touch the build plate while pouring. Be mindful of displacement when adding resin.

Make sure to mix the fresh resin well before adding. Try to ensure the resin temperature is the same, if the difference is more than 5~10 degrees Celsius, it may cause a layer line.

Yes, you can pause at anytime during your print. Resume as quickly as you can to ensure that your print will continue safely. However it is generally not recommended as it will most likely leave a line at the layer where you paused.

It"s completely normal. It"s a good sign that your print is sticking to the build plate and that the layers are releasing from the FEP film. It will be more audible during the first few bottomlayers of the print, don"t worry if you can"t hear it later on as it depends on the layer section being printed.

One easy way to tell is by listening for the sound that"s made as the layer peels off the FEP. You can hear it clearly especially for the first few bottom layers. Don"t worry if you can"t hear it anymore later, it varies depending on the size of the layer being printed.

This is normal for the test print. The test cube is supported only by three prongs on the base, as the plate rises the print is releasing from the FEP film in a side to side flex action, hence the wobble. If your build plate is leveled correctly, the test cube will finish printing successfully.

First, ensure that your exposure settings are optimal for the resin used. Underexposure causes thinner parts, while overexposure will swell. Many of the basic resins swell when printed. There could also be slight shrinkage. It all depends on your settings and the brand of resin and formulations that manufacturers use. It usually isn"t noticeable on organic prints.

After testing your resin performance, you can make the adjustments for the model itself in software. This method is not advisable as it will differ if you share the model, or use a different resin as the compensation will then be off.

Some commercial slicing software have a "horizontal size compensation" feature that can make precise adjustments. Chitubox has also announced this feature for a future "Pro" version.

There are many resins available and are formulated for various usage. Most are general printing resins suitable for models, figures, decorative and non functional prints. When deciding on resins that need to be strong, the resin must be formulated with a high degree of hardness, which also makes it brittle. Therefore, to be both strong and functional, a certain degree of flexibility needs to be blended in. For a start, check the Shore D (Shore Durometer) rating of the resin, then check the flexibility or tensile rating. A high Shore D rating over 80 combined with a high flexibility rating indicates a strong resin.

Build plate is too high or low, this is caused by incorrectly seated ball joint screws. Disassemble, clean and retighten the build assembly. See disassembly guide below.

The FEP film may be too tight or too loose. New vats sometimes comes with loosened screws, but they could be correctly tensioned. Adjust to the correct tension, or replace. (FB post) (how to tighten) and (how to replace)

You may be using resin formulated for SLA laser or DLP printers. Try using a known resin like the sample green. Note that some resins like maroon or yellow are very difficult to work with.

If your prints have good bottom adhesion but fail at the supports, this is generally due to incorrect exposure setting for your normal layers. As a first step, try increasing exposure.

The best layer slices for a good balance of speed and quality is 50um (0.05mm) thickness, but (depending on resin) some owners have sucessfully printed at 100um (0.1mm} layer thickness. Use the Resin Exposure Finder from the community projects to test if your resin can print at that layer height.

During the printing process, resin components form covalent bonds, but layer to layer, the part remains in a semi-reacted or semi-cured state. While in this semi-reacted state, the resin retains polymerizable groups that can still form bonds across layers. Polymerization only stops when resin is fully cured via post-processing in a UV station or sunlight.

Simply put, during printing, the layers of the model facing the FEP film are always sharply defined as the layer is exposed perfectly against it. Whereas the layers facing the build plate, previously exposed, still receive uv light from diffusion/defraction/scattering from the current exposed layer and thus will still cure slightly. This is akin to overexposure and thus details will be lost. Coupled with this, some resin always remains around the bottom parts (facing the build plate), and will also bond and cure to the details as well.

When you switch on your printer, you may have noticed that the little fan in the print compartment automatically turns on, and stays on. That is the number one cause of resin smells from your printer. What this fan claims to do is to draw smells into a charcoal filter below it, but in reality all it does is to circulate and distribute smells out of the print compartment and into your room.

The simplest solution to reduce smells, without requiring complicated and time consuming additions such as in-line fans, ducting and drilling, is to simply disconnect that little fan. Here are several ways to do this:

Unscrew the two screws that hold the fan onto the red base plate, lift the fan, cut the red and black wires, tape and insulate the wires, and remount the now deactivated fan.

Finally, there"s also a gcode to switch the fan off, but it will be reset when firmware is updated. Search the Facebook group for fan_off.gcode if you"d like to try this.

Check the LCD settings in your slicer program. There should be a tab where you can select between LCD_mirror, DLP_normal or Normal. The correct setting should be LCD_mirror. Here is a screenshot of the selection tab for the Chitubox slicer, it should be similar in the Anycubic slicer and others.

The recommended method is the two tub system. Fill both containers with 91% Isopropyl Alcohol (IPA) or other solvents such as 95% Ethanol. Although not necessary, heating the first tub to around 45°C helps dissolve the resin faster.

Drop the print into the first tub and swirl for several seconds. Use a soft brush on hard to reach parts, crevices, etc. Then dunk the part in the second tub of solvent and rinse clean. Do not leave your prints soaking too long in the tubs. Remove then dry thoroughly (blow drying with compressed air works best) before uv curing.

Resin manufacturers universally recommend 91% Isopropyl Alcohol (IPA) or 95% Ethanol. Other solvents may be used but generally not recommended. Do not pay for overpriced cleaning solutions marketed for 3D resin printers. Here is a solvents compatibility chart published by Formlabs for their resins which can be used as a general guide for most resins.

For as little time as possible to get your prints cleaned of uncured resin. Do not leave your prints to soak. Some manufacturers advise no longer than 30 seconds. In a post, Formlabs mentioned that prolonged exposure to solvents may make some resins swell from absorbtion. In a related article, Ameralabs tested prolonged soaking of parts in IPA and found consequent shrinkage and cracking.

Use soft tissues and a small spray of IPA to remove any dust and stains. If there is dried resin on the glass, you can carefully scrape it off with a razor. Finally, buff the glass with microfibre cloth.

Damp a piece of cloth or tissue with IPA then lay it on the cured resin. Wait a few minutes, then with a fingernail gently try to prise the layer of cured resin off the LCD glass. If you can"t easily prise it off, use a razor or glass scraper, but be careful with that.

Once you have drained the vat of resin, spray down with IPA and gently wipe off with paper towel or soft tissue. Spray again and use soft tissue to soak off the remaining residue from the FEP. You may need to repeat this several times. Finally buff the FEP with microfiber lens cloth. Be careful of dried resin on the cloth that could scratch or puncture the FEP.

Manufacturers universally advice the use of a solvent like 91% IPA (Isopropyl Alcohol) or 95% Ethanol, Proprietary cleaning solutions or other solvents may also be used such as Mineral spirits (aka White spirits, Turpentine), etc.

Anything containing uncured resin if no curing is possible should be disposed in a hazards facility near you. Uncured resin is considered extremely hazardous to the envoirenment and must be cured before disposal.

Resin saturated water (for the water washable resins) and Saturated solvents should be cured in the sun and evaporated, resulting solids can be disposed in the solids trash.

Yes, if you regularly cure the washing solvents along with your printed parts and filter out the solids your solvents will last longer. For methods to filter, see this FB post. about it

It depends on environmental factors and type/brand of resin, typically if the resin is kept out of light and moisture/dirt it may sit in the vat for a few weeks. Clear resins tend to sit better, opaque resins will need more stirring before use to mix the pigments back.

Cover the vat, you can cut a piece of cardboard that fits over the vat, or print one out on an FDM printer. Here is a good vat cover found on Thingiverse.

Do not leave the build plate hanging with uncured resin, take it out and clean with IPA, leave it out until you are ready to print, this will lessen the weight on the single lead screw thus prevent deformation and potential Z wobble.

Water washable resin works because it uses water soluble monomers. Water isn"t an acrylate. Water can not cure. When you dilute resin into anything that"s not capable of curing, it won"t be inert again.

Even after you expose the mixture to UV, the photoinitiators in the diluted resin water will still cleave and generate free radicals. If some acrylate molecules are nearby there will be a tiny bit of chain growth taking place. The spent photoinitiators, pigments, and the portion of the resin that actually cures will settle out, but the rest will still remain diluted in the water.

What this means is that resin cannot cure to completion in solution (water). It cannot cure due to change in concentration of reactants and there will be contaminates in the wash that are not safe down the drain.

The only proper way to dispose of the wash is to reduce solution by evaporation, and then collect and UV cure the resin residuals and dispose of them properly.

Congratulations on having a well leveled plate. Sometimes prints adhere so well that removal is difficult. Try the following methods to remove recalcitrant prints, in order of recommendation:

The best way to find out if your print has cured enough with sunlight or a UV light set up is to find an area where you don"t mind a mark and try to dent it with your fingernail, If you can then it"s not ready yet, and as soon as you can"t dent it it"s ready. Do not overcure as resin may become overly brittle, and white or clear resin will turn yellow.

It depends. While it is easier to remove before uv curing (it"s softer and you can just pull or rub them off), you may want to remove them after, especially thin parts that may warp during the curing process.

It depends on the resin used. Unlike PLA or ABS, regular hobby grade resin prints are quite brittle and can easily break when dropped. There are specially formulated resins for prototyping or even functional usage which have different properties such as flexibility, hardness and uv resistance. Once you have familiarised yourself with your printer using the sample green resin, you might want to experiment further with different resins.

The white residue appears if there"s moisture or water on your prints when you UV cure. One way to avoid this is not to wash your prints in water after cleaning in solvents. Always make sure your prints are completely dry before final UV curing.

Make absolutely sure that you have tightened the grub screw that secures the build plate fully. This can also happen if there"s another grub screw already in the hole preventing tightening fully. Also check that the screws in the carriage arm of your build plate (there are three of them in there) are not loose. Or, if you had overfilled the vat and resin has gotten inside, it makes the grip of the ball joint slip. You"ll need to disassemble the build plate assembly and clean thoroughly with IPA then.

First remove the 4 bolts you can see just either side of the carriage arm (with the red platen knob on it) put them some place safe then take the build plate off, you will see three more screws, unscrew these and then you can take the mechanism of the ball joint apart, be sure to note where it all goes so you can easily put it back together again.

Now you have it all apart, clean everything with IPA and remove any cured or uncured resin you find, Then just put it all back together nice and tight and relevel the build plate.

My Photon doesn"t work anymore, the touchscreen is fine but the Z motor stopped working, the fans are off, and the LCD doesn"t show anything. Is my printer dead?

If you had accidently switched the printer off in the middle of an operation, or if there was a power disruption, it may cause a corruption to the EEPROM. The printer can be easily revived by resetting the EEPROM by reflashing the.gcode file. Download the factory defaults, extract the .gcode file, put it on your usb stick and "print" the file.

Nothing much really. Keep everything clean by wiping down with a microfibre cloth slightly dampened with IPA. Wipe resin drops and spills off immediately with IPA and tissue. Keep your vat and FEP clean. Keep the LCD screen perfectly clean. Dust off and keep the printing compartment clean. And every three months or earlier, depending on usage frequency, clean and replace the grease for the lead screw. If it squeaks, do this immediately.

Wipe all the old dirty grey grease off with a cloth rag, or kitchen towels. Then really get it clean by wiping again with solvent and use a toothbrush to get between the threads. IPA works great. Make sure solvent doesn"t drip down into the stepper motor beneath. When it"s clean and dry, regrease with good quality grease, apply by dabbing onto the entire length of the screw, then switch on the printer and run the slide block up and down.

Although not strictly necessary, most owners apply tape as an added safety measure in case of resin leaks or the LCD being pulled off together with the vat.

According to the warranty terms stated on Anycubic"s website, the standard warranty period is three months for the LCD mask panel and UV LED unit. All other components (except tools and FEP film) are warranted for twelve months.

Most of the information, insights, tips and tricks were gleaned from posts by the helpful members of the Anycubic Photon Printer Owners Group, tested, verified and curated by the Photonsters team. Special thanks goes out to Flint Read for his invaluable "Photon Guide & Tips" from which formed the initial core of this FAQ.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Once you have found the correct part number, see HP Consumer Notebook PCs - Ordering HP certified replacement parts. Use the instructions in this document to order a replacement part.

HP recommends that you only order parts from an authorized HP repair parts dealer. Parts ordered from third-party companies might not perform as expected and might cause additional

Have you ever left your TV or monitor on for days, stuck on the same image? You return to your screen, only to find an image burned into the display. No matter what you do, it won"t go away. It is a permanent image burn.

Why do monitors and TVs get image burn? Why can"t manufacturers prevent LCDs and plasma screens from a burnt image imprint? Moreover, what can you do to fix an image burn?

In some cases, you can minimize the image burn effect. In others, you can remove the image burn completely, so long as it hasn"t been burning too long.

Before flat-screens and crystal displays, most TVs and monitors featured CRT (Cathode Ray Tube) technology. In CRTs, individual pixels comprise a red, blue, and green phosphor component. Depending on the intensity of each phosphor component, the pixel appears to the human eye as a unique color.

When a particular still image remains for too long, the intensity of each phosphor component diminishes at an uneven rate. The result is a ghost image on the screen, which is known as image burning.

Plasma displays use plasma, a gaseous substance containing free-flowing ions. When the plasma is not in use, the particles in the plasma are uncharged and display nothing. With the introduction of an electric current, the ions become charged and begin colliding, releasing photons of light.

This is a very simplified version of how a plasma screen works. However, the main thing to understand is that plasma screens use phosphor material (like CRTs) to turn those photons into images.

LCD and LED do not work in the same way as CRTs, either. LCD and LED screens use backlit liquid crystals to display colors. Although manufacturers market screens using LED and LCD, an LED screen is still a type of LCD. The white backlight filters through the liquid crystals, which extract particular colors per pixel.

LCD and LED displays don"t suffer from the same type of image burn as CRTs and plasma screens. They"re not completely clear, though. LCD and LED screens suffer from image persistence. Read on to find out more about image persistence.

Before you can fix screen burn-in, take a second to understand why these images burn in the first place. LCDs and LEDs don"t suffer from burn-in as seriously as plasma screens. But static images can leave an imprint on both display types if left alone for too long. So, why does image burn happen?

First, let"s tackle plasma screen burn-in. Remember why CRTs experience image burn? When a still image remains on the screen for too long, the phosphor components in each pixel wear out at different rates. The uneven burn rates leave behind a ghost image, forever etched into the screen.

Plasma screens also suffer from phosphor deterioration. Plasma burning occurs when pixels on the screen are damaged through long exposure. The phosphor loses its intensity and only shows the light it was fed repeatedly. In this case, the still image, which causes the burn.

LCD and LED screens can also experience image burn, though the image burn process can take longer to develop into a permanent issue. In addition, LCD and LED screens suffer from another issue, known as image retention (also known as image persistence or an LCD shadow).

Image retention is a temporary issue that you are more likely to notice before it becomes a permanent issue. However, proper image burn can still affect LCD, LED, and OLED screens.

Image retention is a different issue from image burn (although it is a precursor to image burn). For example, you"re using an image of a steam train as a reference point for a drawing. You have the steam train image on your screen for a few hours before you decide to play a video game instead.

When you load up the video game on the screen, you can still see the faint outline of the steam train on the screen. The steam train image will remain for a short while, but the movement and color changes of the video game (or film, TV show, or other media type) should erase the retained image.

The other thing to consider is that LED and OLED image burn-in, when it happens, is irreversible. That"s because of how LED and OLED screens work. Individual pixels within an LED display decay when they emit light.

Under normal use, an LED, OLED, or QLED screen won"t suffer image burn. However, if you leave your screen on a single channel for hours every day, then burn-in can become an issue, as it would with almost any screen.

Issues arise when a screen shows a single news channel 24 hours a day, every day, causing channel logos to burn-in, along with the outline of the scrolling news ticker and so on. News channels are a well-known source of television burn-in, no matter the screen type.

Image burn-in fixes exist for LCD and plasma screens. How effective an image burn-in fix is depends on the screen damage. Depending on the length and severity of the image burn, some displays may have permanent damage.

The best fix for screen burn is to prevent it in the first place. Okay, that isn"t super useful if your screen is already experiencing image burn. However, you should always try not to leave your screen on a still image for too long. The time it takes for an image to burn-in varies from screen to screen, between manufacturers, sizes, and panel type.

My personal rule of thumb is to turn off the display if I plan on being away for more than 15 minutes. That way, it is difficult to get caught out, plus you save yourself money on electricity costs and monitor or TV wear and tear.

Another prevention method is to reduce screen contrast as much as you can. Unfortunately, most screens aren"t calibrated correctly, often pushing the contrast and brightness settings too high.

Lower contrast means the lighting across your screen is more even. This means less strain on specific areas of the screen, which helps protect against image burning.

If your plasma or LCD screen already has image burn-in, you can try turning on white static for 12 to 24 hours. The constant moving of white-and-black across your screen in random patterns can help remove the ghost image from your screen.

Unfortunately, this won"t work for extreme cases. Some TVs will have a built-in pattern swiping option that basically accomplishes the same thing (filling your screen with random patterns).

Pixel-shift constantly slightly adjusts the image on your screen, which varies the pixel usage to counteract image burn. You might have to enable a pixel or screen shift option in your screen settings. Pixel-shift is a handy feature for LED and OLED screens that cannot recover from image burn and should help counteract an LCD shadow.

Other modern screens feature built-in screen refresh functions that the manufacturer will advise using to remove image retention and image burn issues.

The best tool for fixing ghost images is JScreenFix. The original program helps fix monitors with dead pixels, but the same company also released an "advanced" version of the tool, known as JScreenFix Deluxe.

While the Deluxe version uses advanced algorithms to repair burned screens and prolong plasma and LCD longevity, the official site is no longer up and running, and there is no way to download the full version officially.

You can find the free version of the Deluxe app online, but it is limited to 20 minutes running at a time. Furthermore, we"re not going to link out to the versions you can find online as we cannot verify the security of these installations. If you do use the Deluxe version, you do so at your own risk.

Another option is to set a completely white desktop background and leaving to run for a few hours. The solid color might reset the image burn. A solid color background is more likely to help with image persistence than image burn, but it is still worth trying.

If you have television burn-in, you can attach a laptop to your TV using an HDMI cable, extend your desktop to the television, and share the white screensaver. Hopefully, that will shift your television burn-in.

The team over at ScreenBurnFixer offers a few different ways you can attempt to fix screen burn on your TV or monitor. As with any other screen burn-in fixes, their chance of working depends on the scale of the issue.

You can head to the ScreenBurnFixer Video page and find a video that matches your screen type, then let the video play for as long as possible (we"re talking multiple hours, not a quick half an hour blast). Alternatively, head to the Chart page and find your device or a device that matches your specifications.

There are several ways you can attempt to fix screen burn-in. The results will vary between the screen type and the level of burn-in. A screen with extensive image burn may not clear entirely, although you might see an improvement.

Some screen degradation over time is understandable. However, if you follow the steps in this guide, you"ll protect your screen from image burn before it becomes a permanent issue.

1. The screen will go through a strict exposure calibration test before leaving the factory. Most of the new screen damage is related to transportation After receiving the screen, first check whether the screen is normal. If there are cracks, or breakage please contact us within three days. We will give you a new screen or a refund.

2. Feedback after installation and use, it will not have a warranty. The screen is consumable. Most of the environment, such as resin selection, printing techniques, etc, will affect the screen.

As 3D printing continues to become cheaper and more accessible, resin 3D printers have become a popular choice for anyone interested in making highly-detailed models that wouldn’t be feasible using a filament-fed, FDM 3D printer. These MSLA (Masked Stereolithography) resin 3D printers typically have a single axis of motion, and this simple mechanical system means these machines can regularly be found for less than $300. With so many models on the market, we’ve made this list to help you find the best resin 3D printer for you.

The best resin 3D printers are capable of making high-resolution models by curing a liquid resin using a UV light source. This MSLA process uses a masking LCD to selectively block the UV light on a pixel-by-pixel basis, allowing these printers to create models that have a resolution of down to .035mm on the XY axes.

This high resolution comes at a price, as parts made on a resin 3D printer require post-processing after printing, and UV resin requires caution when handling. Because resin requires gloves and a mask to handle, we recommend beginners or anyone with young kids consider one of the FDM (fusion deposit modeling) printers on our overall best 3D printers page.

Why you can trust Tom"s HardwareOur expert reviewers spend hours testing and comparing products and services so you can choose the best for you. Find out more about how we test.Mono or RGB LCD? The type of masking LCD on your resin 3D printer can have the single largest impact on your overall print speed. Because they are commonly used in other electronics, RGB masking LCDs are cheaper, but slower because they don’t allow UV light to pass through efficiently and need more exposure time per layer. For example, the RGB LCD on the Creality LD-002R requires 9 seconds per layer, while the Mono LCD on the Elegoo Mars 2 Pro requires only 2.2 seconds per layer.

How much build volume do you need?Most resin 3D printers have smaller build volumes than FDM 3D printers, so you may find yourself limited by this relatively small build volume. If you are interested in printing large parts, you’ll want to look at a large format resin 3D printer such as the Elegoo Saturn or theAnycubic Photon Mono X.

2K, 4K, or Beyond?A resin 3D printer that uses a 6.08-inch 2K screen like the Elegoo Mars 2 Pro is capable of an XY resolution of .05mm as well as a layer height of .05mm. For context, this means even a relatively low-resolution resin 3D printer is still capable of making extremely fine details that simply wouldn’t be possible on an FDM printer. If you need even more resolution, a 4K screen is capable of making finer features, but is typically more expensive.

Post Processing Equipment? Resin 3D printers create parts that require post-processing before they are completely finished. Typically, this workflow involves rinsing the parts in a solvent to dissolve any excess resin on the surface of the part, followed by a cure cycle that uses UV light to fully polymerize the part. This process can be done manually by submerging the part in a solvent and using an inexpensive UV light for curing, but some manufacturers have created post-processing equipment like the Elegoo Mercury X that automate the process and reduce the mess.

The Anycubic Photon M3 is the best all around resin 3D printer we’ve reviewed. It produces crisp details with 4K+ quality that rivals more expensive machines and has a wide build plate allowing it to make larger models than competitors in its class.

A sample print of a unicorn was extremely detailed, with the ridges on its horn and its mane appearing really sharp and free from layer lines. It was also a full 180mm tall and printed in 10 hours.

The etched build plate works really well at holding models tight during printing, but also allows for easy removal when they’re done. The metal vat has a convenient pour spout, and Anycubic includes a screen protector for the LED light source to prevent accidental drips from ruining your printer.

If you’re ready to throw some serious cash down for a decent-sized resin 3D printer with quality that will knock your socks off, the Phrozen Sonic Mighty 8K is here for you. Its roomy 218 x 123 mm build plate can accommodate an army of gaming miniatures or a gift-worthy superhero statue. Priced at around $600 at press time, this printer isn"t cheap. But in return for the premium, you get crispy details, prints that practically slide off the build plate, a built-in webcam and a machine that’s WiFi ready.

We enjoyed navigating through the Mighty 8K’s menus, thanks to its large and easy-to-use touch screen display. There’s little need to consult the manual – the printer walks you through an onboard tutorial to handle leveling and your first test print. Want to rerun a test file at a different exposure? No problem – the Sonic Mighty 8k will let you change exposure settings and more right inside the printer. I found this extremely helpful while dialing in a new resin.

The Phrozen Sonic Mighty 8K size is closer to what we see in FDM printers, without being so large that it dominates your workshop. The quality and extra wiggle room would be a worthwhile investment for someone running an Esty shop or an artist wanting to showcase their work. We were able to print 12 very-detailed gaming figures at once and the process only took 4 hours and 2 minutes.

The Creality Halot-One Plus is the flagship of the Halot line of MSLA resin 3D printers, offering an impressive set of features while still coming in at a prosumer-friendly price of $399. Unlike other printers in this price range, the Halot-One Plus includes Wi-Fi connectivity and a slicer app which allows users to quickly process models and prepare them for printing almost effortlessly.

The large 7.9-inch Mono LCD provides 4K resolution (4320 x 2560), fast per-layer cure times (3 seconds per layer), and a solid dual linear rail Z axis to allow for fast and accurate printing. The Halot-One Plus also includes an integrated air filtration system which reduces the amount of odor when printing, a surprising addition not typically seen at this price point. Finally, the 5-inch LCD interface allows users to adjust settings mid-print (including exposure time), and also provides an accurate estimate of remaining time during a print.

It’s only available for pre-order right now, but when it’s available, Elegoo’s Jupiter printer will offer a combination of great quality and a huge build volume. And, despite its $1,300 price, the Jupiter is actually a great deal for its size, given that competitors cost closer to $1,000.

Where the $499 Saturn provides a 192mm x 120mm x 200mm volume, the Jupiter provides a ton more, going all the way to 277.8mm x 156.3mm x 300mm. And the print quality is pretty good as we found when outputting a detailed model of the Notre Dame Cathedral.

The Anycubic Photon M3 Premium set an impressive standard. Offering both high resolution and large build volume in a single machine, it effectively does the work of two separate printers and still comes in cheaper than buying them individually.

The 10-inch 8K masking LCD provides an ultra-high 0.0285mm XY resolution which allows even the finest details to resolve on printed models. We were particularly impressed when we printed a model that had a tiny, open book on a pedestal; the words on the pages were sharp and legible (though one might need a magnifying glass to see them).

The 219mm x 123mm x 250mm build volume allows users to print large models with high resolution, or simply pack the oversized build platform with multiple small parts to produce many in parallel. Featuring integrated dual air filters, a laser-etched build platform, and a razor-thin NFEP vat film, the Photon M3 Premium is easily capable of handling anything you can throw at it.

If you’re looking for a reliable 3D printer to start your journey with resin printing, the Elegoo Mars 3 is a great place to start. The printer has outstanding 4K resolution for beautifully detailed models and a simple leveling system to get that first layer to stick perfectly.

Beginners should factor the high price of resin when considering their first printer, and the Elegoo Mars 3 only needs 350ml to fill its vat. The build volume is average for its class, with plenty of room for gaming miniatures and models.

If you’re looking to create small models for table-top gaming, or just display, the Elegoo Mars 3 Pro is a great choice, thanks to its great build quality and high resolution. The Mars 3 Pro has an XY resolution of 35 microns (0.035mm) which allows you to show intricate details in even small objects.

When we printed mz4250"s Red Dragon model, fine ridges on the tail and bones in the wing were sharp, without any visible splotching or errors. Even the spines and beard on the head were crystal clear. Its LCD screen provides a 4098 x 2560 resolution for prints, which is higher than the 4K resolutions of competitors like the Phrozen Sonic Mini 4K and AnyCubic Photon Mono 4K.

Unlike the Phrozen Sonic Mini 4K, which is very competitive in this area, the Mars 3 Pro doesn’t suffer from any build quality issues.It’s easy to level and even has a built-in air purifier that, in our tests, mitigated but did not completely remove the resin odor that all MSLA printers emit. With a price in the $300 - $350 range, this isn’t the cheapest resin printer on the market, but it offers great quality output and strong usability for the money.Round up of today"s best deals

Too many people have already ruined the screen that comes with their Anycubic Photon Mono-X. Once you get resin cured on the screen there are two options.

The FEP ends up getting pulled up too far and it tears just a enough for resin to leak through. The resin is then spread all over the bottom of the FEP by the vacuum created during the printing of the next layers. Then the next layers cured cure the resin on the screen and not the resin in the vat. At that point you are pretty much out of luck.

You can try and soak IPA in a rag and place it on the cured resin and depending on the resin you may be able to get it off without damage, but this doesn’t work for most people. You have to be very careful to make sure you don’t scratch the glass underneath the polarizing plastic (more on that in a minute)

What you will probably find is a layer of plastic comes up with the resin. This is a layer of polarizing film on top of the screen. This film helps direct the light so it is focused is all directed straight up to the pixels you want to be cured. From here you have two options for what to do next.

Replacement film is available kind of hard to get right now. But it has been confirmed that this film can work for some people. We know the Mono-X ships with two different screen and the polarizing film seems to be different on the two of them. These instructions work for one of them but not the other and at this time we don’t have a good way to know if it will work for a specific unit or not. This will be updated as more details are figured out.

The tricky part is that you can’t just cut and install it on the screen. It has to be tilted at about a 15 degree angle. This can be tricky, but I have tried to make it really easy for you. Here is a PDF you can download and print that will show you exactly how to cut your film so it will be the right size and angle.

This is what the print out will look like after you print it. From here line up one of the corners of your film with the upper left hand corner and then trace the rectangle and cut it out. This will give you a square the right size to install on your screen (with the tape removed), and will be at the correct angle.

There are several ways you can cut it. It really don’t have to be extremely exact. I recommend taping the film to the paper then using a straight edge and a sharpie to outline the square where you need to cut. You can cut it with scissors, but I feel like you get a better cut with a X-Acto Knife.

Install the film just like a screen protector on a cell phone. Make sure the screen is SUPER SUPER clean

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey