lcd screen size chart made in china

One of today’s modern technological wonders is the flat-panel liquid crystal display (LCD) screen, which is the key component we find inside televisions, computer monitors, smartphones, and an ever-proliferating range of gadgets that display information electronically.What most people don’t realize is how complex and sophisticated the manufacturing process is. The entire world’s supply is made within two time zones in East Asia. Unless, of course, the factory proposed by Foxconn for Wisconsin actually gets built.

Liquid crystal display (LCD) screens are manufactured by assembling a sandwich of two thin sheets of glass.On one of the sheets are transistor “cells” formed by first depositing a layer of indium tin oxide (ITO), an unusual metal alloy that you can actually see through.That’s how you can get electrical signals to the middle of a screen.Then you deposit a layer of silicon, followed by a process that builds millions of precisely shaped transistor parts.This patterning step is repeated to build up tiny little cells, one for each dot (known as a pixel) on the screen.Each step has to be precisely aligned to the previous one within a few microns.Remember, the average human hair is 40 microns in diameter.

For the sake of efficiency, you would like to make as many panels on a sheet as possible, within the practical limitations of how big a sheet you can handle at a time.The first modern LCD Fabs built in the early 1990s made sheets the size of a single notebook computer screen, and the size grew over time. A Gen 5 sheet, from around 2003, is 1100 x 1300 mm, while a Gen 10.5 sheet is 2940 x 3370 mm (9.6 x 11 ft).The sheets of glass are only 0.5 - 0.7 mm thick or sometimes even thinner, so as you can imagine they are extremely fragile and can really only be handled by robots.The Hefei Gen 10.5 fab is designed to produce the panels for either eight 65 inch or six 75 inch TVs on a single mother glass.If you wanted to make 110 inch TVs, you could make two of them at a time.

The fab is enormous, 1.3 km from one end to the other, divided into three large buildings connected by bridges.LCD fabs are multi-story affairs.The main equipment floor is sandwiched between a ground floor that is filled with chemical pipelines, power distribution, and air handling equipment, and a third floor that also has a lot of air handling and other mechanical equipment.The main equipment floor has to provide a very stable environment with no vibrations, so an LCD fab typically uses far more structural steel in its construction than a typical skyscraper.I visited a Gen 5 fab in Taiwan in 2003, and the plant manager there told me they used three times as much structural steel as Taipei 101, which was the world’s tallest building from 2004- 2010.Since the equipment floor is usually one or two stories up, there are large loading docks on the outside of the building.When they bring the manufacturing equipment in, they load it onto a platform and hoist it with a crane on the outside of the building.That’s one way to recognize an LCD fab from the outside – loading docks on high floors that just open to the outdoors.

LCD fabs have to maintain strict standards of cleanliness inside.Any dust particles in the air could cause defects in the finished displays – tiny dark spots or uneven intensities on your screen.That means the air is passed through elaborate filtration systems and pushed downwards from the ceiling constantly.Workers have to wear special clean room protective clothing and scrub before entering to minimize dust particles or other contamination.People are the largest source of particles, from shedding dead skin cells, dust from cosmetic powders, or smoke particles exhaled from the lungs of workers who smoke.Clean rooms are rated by the number of particles per cubic meter of air.A class 100 cleanroom has less than 100 particles less than 0.3 microns in diameter per cubic meter of air, Class 10 has less than 10 particles, and so on. Fab 9 has hundeds of thousands of square meters of Class 100 cleanroom, and many critical areas like photolithography are Class 10.In comparison, the air in Harvard Square in Cambridge, MA is roughly Class 8,000,000, and probably gets substantially worse when an MBTA bus passes through.

The Hefei Gen 10.5 is one of the most sophisticated manufacturing plants in the world.On opening day for the fab, BOE shipped panels to Sony, Samsung Electronics, LG Electronics, Vizio, and Haier.So if you have a new 65 or 75-inch TV, there is some chance the LCD panel came from here.

Over the years, with the wider and wider application of LCD screens, more and more brand products have been favored by the people. Together, more and more LCD manufacturers have emerged. Of course, the most popular brands in China are BOE, INNOLUX, CHIMEI, AUO, CSOT, etc. So, Which is the best brand of

It is better to say who is more professional than good or bad. In fact, the above mentioned LCD screen manufacturers are very professional, and the quality is guaranteed. But the most popular must be BOE and INNOLUX, these two panel manufacturers are also obvious to all. They all have multiple distributors, but not every distributor has the best size and price.

SZ XIANHENG TECHNOLOGY CO., LTD. is the agent of AUO, BOE, INNOLUX, SHARP, IVO and Mitsubishi, and other domestic and foreign well-known brands of small and medium-sized LCD display; specializing in customized production of touch screen display, LCD and industrial touch display and other high-tech products. According to the needs of customers, we can provide various LCD products: high-brightness LCD screen, LCD driver board, touch screen, booster board, all kinds of LCD special wires, etc. to produce industrial displays.

What brand of LCD screen is good? If you choose BOE, INNOLUX, CHIMEI, AUO or CSOT, you can buy them from us. 18.5 inch LCD screen, 21.5 inch LCD screen and other small and medium size, our price is the lowest in the industry.

China is the leader in producing LCD display panels, with a forecast capacity share of 56 percent in 2020. China"s share is expected to increase in the coming years, stabilizing at 69 percent from 2023 onwards.Read moreLCD panel production capacity share from 2016 to 2025, by countryCharacteristicChinaJapanSouth KoreaTaiwan-----

DSCC. (June 8, 2020). LCD panel production capacity share from 2016 to 2025, by country [Graph]. In Statista. Retrieved February 16, 2023, from https://www.statista.com/statistics/1056470/lcd-panel-production-capacity-country/

DSCC. "LCD panel production capacity share from 2016 to 2025, by country." Chart. June 8, 2020. Statista. Accessed February 16, 2023. https://www.statista.com/statistics/1056470/lcd-panel-production-capacity-country/

DSCC. (2020). LCD panel production capacity share from 2016 to 2025, by country. Statista. Statista Inc.. Accessed: February 16, 2023. https://www.statista.com/statistics/1056470/lcd-panel-production-capacity-country/

DSCC. "Lcd Panel Production Capacity Share from 2016 to 2025, by Country." Statista, Statista Inc., 8 Jun 2020, https://www.statista.com/statistics/1056470/lcd-panel-production-capacity-country/

DSCC, LCD panel production capacity share from 2016 to 2025, by country Statista, https://www.statista.com/statistics/1056470/lcd-panel-production-capacity-country/ (last visited February 16, 2023)

LCD panel production capacity share from 2016 to 2025, by country [Graph], DSCC, June 8, 2020. [Online]. Available: https://www.statista.com/statistics/1056470/lcd-panel-production-capacity-country/

Introduction: Global LCD industry shift and automotive intelligence together to promote the rapid development of China’s LCD panel industry, which will bring a continuous increase in demand for backlight modules, China’s backlight module industry has greater potential for development.

LCD panel backlight module consists of a backlight light source, light guide, optical film, and a plastic frame, which is an important component of LCD display panel. As the backlight module has technology-intensive and labor-intensive attributes, with abundant high-skilled labor advantage China is attracting the global LCD panel industry to the domestic rapid transfer.

From LCD application to the present, the global LCD panel industry capacity transfer has gone through three periods, 2000 Japan dominated the global LCD industry; 2000 – 2010, Japan’s production capacity to South Korea and Taiwan; 2010 to the present, Japanese manufacturers gradually withdraw from the LCD panel industry, production capacity began to transfer to mainland China, so far, mainland China LCD production capacity has occupied the global half of the world.

In recent years, South Korea’s Samsung and LG display will shift their business focus to OLED, and will gradually shut down their LCD production lines and withdraw from the LCD panel industry; at the time of South Korean manufacturers’ withdrawal, domestic enterprises are stepping up new construction to expand LCD production capacity.

BOE, Huaxing photoelectric, Huike, CEC in 2020 – 2021, a total of eight 7 generation LCD production lines completed and put into operation, and domestic panel manufacturers have further expansion plans, the next few years domestic LCD production capacity will continue to increase.

LCD panel manufacturers tend to choose the nearby supporting module suppliers for the safety of the key component supply chain and cost reduction considerations. LCD panel production capacity transfer to China will bring opportunities to domestic backlight module manufacturers and drive the development of the domestic backlight module industry.

The future of the car will pay more attention to the human driving experience, to the intelligent development, which will bring the increasing demand for car display. On the one hand, the number of car displays gradually increased, for example, the instrument panel, rearview mirror, central control platform more to display the way, the passenger and rear position with entertainment display. On the other hand, the car display is constantly to a large screen, multi-screen development, especially in high-end models, the large display has become standard, for example, Tesla Model S screen size of 17 inches, Mercedes-Benz A-class car configuration of two 10.5-inch display.

According to the terminal application size, backlight module can be divided into large, medium, and small size, of which small size backlight module is mainly used in smartphones, wearable devices, and other terminals, the medium size used in notebook computers, tablet PCs, car screens and other terminals, the large size is mainly used in LCD TV.

From the market competition pattern, the domestic backlight module enterprises are deeply plowed in their respective competitive advantage in the field of segmentation, including Baoming technology, Longli technology mainly layout small size cell phone display field, Hanbo high-tech, Weishi electronics mainly layout in the size of car display and notebook computer field, Rui Yi photoelectric and photoelectric in each field have layout.

From the industry development trend, smartphone display is transitioning to OLED, LCD TV market is gradually saturated, the future of large size and small size backlight module market potential is relatively small; and the future of the car display market potential is huge, by the backlight module manufacturers are unanimously optimistic, are currently accelerating the layout ( see Table 2 ). Focusing on the traditional medium-sized backlight module field, Hanbo Hi-Tech and Weishi Electronics have significant advantages in core technology patents, downstream customer resources, process experience accumulation, production costs, etc., and have more development advantages in the future.

The current global LCD display panel industry is rapidly moving to China, which brings development opportunities to China’s backlight module industry. In addition, automotive intelligence will also bring a continuous increase in demand for medium-sized car displays, the first to enter the field of medium-sized backlight module manufacturers with its customer resources, core technology, scale efficiency, and other advantages will be more beneficial.

The iPhone XR display has rounded corners that follow a beautiful curved design, and these corners are within a standard rectangle. When measured as a standard rectangular shape, the screen is 6.06 inches diagonally (actual viewable area is less).

It is such a waste to only use the LCD for desktop computers. Connecting it up with a laptop PC has many merits for the user and can also bring out the latent power of the laptop.

Most laptops have a handy "external display output" port. It can be used in the home to transmit videos played on the laptop to a large screen TV or, in the office, to connect up with a projector for presentations. In fact, there must be many users who already use it like this. However, people tend to use just the laptop in their daily routine and there are probably not so many cases where they use the external display output.

A laptop can be put to more effective use if it is connected to an external LCD. The photograph shows an EIZO 23-inch wide-screen LCD connected by HDMI to a Sony VAIO C laptop (VPCCW28FJ/R).

This time we would like to suggest a style that can be used in both the home and the office, where a laptop and stand-alone LCD remain connected. A laptop already has an LCD, but using it with an additional stand-alone LCD offers various merits. Not only does it make the laptop environment more pleasant and convenient, it also expands the potential of the computer itself, for example by making it possible to use it for new purposes.

Even if the LCD is already connected to a desktop computer and being used for something other than the laptop, most monitors nowadays have two or more video inputs and they tend not to use this capability to the full. It is such a waste to let the laptop"s external display output function and the monitor"s video input function remain dormant, so we would like them to be put to effective use. Of course, we would also recommend the introduction of a new LCD to connect to your laptop.

The biggest merit of connecting a laptop with a stand-alone LCD is that it gives you a large screen and high resolution dual display environment. Standard laptop models usually come with a built-in 13-inch to 15-inch wide-screen LCD with a 1280 × 800 dot or 1366 × 768 dot resolution.

This level of resolution is good enough for basic Windows operations, but it goes without saying that a large, high-resolution computer screen is much more user-friendly. Combining a laptop with one of the latest wide-screen monitors enables you to easily construct a large-screen, high-resolution dual display environment. It is a real boon to dramatically boost the screen size and resolution while continuing to use your familiar laptop.

Another plus is that you can create the luxury of a "watching while" environment where you run the web browser, for instance, on the laptop"s built-in LCD and watch the video content on the large screen of the external monitor. This can be really useful for hobbies too. For example, while playing a game on the large external LCD screen you can check out strategies on websites, post information on a BBS or communicate with other users.

You can smoothly use multiple applications at the same time in the large workspace provided by a dual display. The photograph shows an EIZO 24.1-inch wide-screen LCD, the FlexScan SX2462W connected to a VAIO C. By supplementing the laptop"s built-in 1366 × 768 dot 14-inch wide-screen LCD with a 1920 × 1200 dot 24.1-inch wide-screen, it is possible to show more data at a time, a huge boost to work efficiency.

With two screens it"s easy to have full-screen display of the video content on one screen while you operate the computer on the other. The photograph shows an EIZO 23-inch wide-screen LCD monitor connected to a VAIO C. The VAIO C has HDMI output and the LCD monitor has HDMI input so visuals and sound can be transmitted by a single HDMI cable. The LCD monitor has full HD screen resolution (1920 × 1080 dot), making it the perfect match for HD video content.

At the office, it is very helpful for presentations to use "clone view" for the laptop"s built-in LCD and the external LCD screen. Clone view means showing exactly the same content on two display screens. It is normally set by a graphics driver function.

When holding small meetings it is certainly very convenient to be able to offer simple explanations of the presentation materials displayed on the external LCD, rather than having to ready a projector. Being able to explain about what is displayed on the screen means fewer documents to distribute, helping your office to "go paperless", which can only be a good thing.

We would like to point out here that you should check in advance the maximum resolution that the laptop"s external display output can handle. This can be found in documents such as the laptop"s specifications chart and support information. This is because, although most laptops can handle output up to 1920 × 1080 dots or 1920 × 1200 dots, some slightly older computers have an upper limit of 1680 × 1050 dots or 1600 × 1200 dots.

Even if the upper limit is 1680 × 1050 dots, the LCD can still display the data if its own resolution is 1680 × 1050 dots or higher. In such cases, it is better to use a monitor that offers dot-by-dot display, which displays the input resolution as it is, or enlarged display, which maintains the screen"s aspect ratio as it is. You do not need to worry because EIZO wide-screen LCDs can handle such display methods (although in some cases they do not function properly depending on the laptop computer or input resolution).

This is an example of a low-resolution display on the 1920 × 1200 dot display SX2462W. Since dot-by-dot display outputs the physical "1 dot" of the LCD and the input resolution "1 dot" without enlargement or reduction, it is shown small in the center of the screen (photo on the left). The display is a little blurred if it is enlarged while maintaining the aspect ratio, but this method is suitable for displaying images as they are shown large with low resolution to make the most of the screen size (photo on the right). Many monitors that cannot handle such display methods enlarge the display to full screen regardless of the input resolution. In such cases you have to be careful as the aspect ratio of the image is altered (for example, people appear to be thinner or fatter).

It is easy to set up a dual display in Windows 7. A menu is displayed when you right-click on the desktop. From "Screen resolution" it is possible to detect and align the external LCD, and set details such as resolution, display method and which will be the main display screen.

The "Screen resolution" menu. If the external LCD is not automatically recognized, click on "Detect". After the monitor has been recognized, you can select the display mode from the "Multiple displays" drop-down menu. Select "Extend display screen" to make the laptop screen and the external LCD into a single display screen (dual display).

Select "Duplicate display screen" from the "Multiple displays" drop-down menu to display the same content on the laptop screen and the external LCD screen (clone view). With this drop-down menu you can also set it to display video on one of the LCDs.

It is also worth noting that Windows 7 has added functions so that dual display can be used more effectively. An active window can be moved to the screen of another LCD by simultaneously pushing "Windows" + "Shift" + "→" (or "←"). It is also possible to maximize the window by pressing "Windows" + "↑", minimize it by pressing "Windows" + "↓", and shift it to the left or right of each screen by pressing "Windows" + "→" (or "←"). Making good use of these shortcuts should enable the efficient placing of windows in the two screens.

In Windows 7, pressing "Windows" + "Shift" + "→" instantly moves the active window from the left-hand screen (photo on the left) to the right-hand screen (photo on the right). Conversely, you can move the active window from the right-hand screen to the left-hand one by pressing "Windows" + "Shift" + "←".

We would recommend a wide-screen model with a screen resolution of 1920 × 1080 dots (Full HD) or 1920 × 1200 dots (WUXGA) as the LCD to connect to a laptop, so that you can make full use of the advantages of dual display. EIZO has an extensive line up of wide-screen LCDs which can offer many benefits, in addition to the merits of a large screen and high resolution, when used with a laptop for dual display.

One such feature is the flexible stand adjustment. For example, the tilt, swivel and height can be adjusted for the FlexScan SX2462W, a 24.1-inch WUXGA model, and the FlexScan EV2333, a 23-inch full HD model. This enables users to adjust the screen position for easy viewing according to their own posture, which not only boosts work efficiency but also reduces physical strain.

The SX2462W stand. The simultaneous adjustment of its tilt, swivel and height enables the optimum screen position to be aligned for its operating environment.

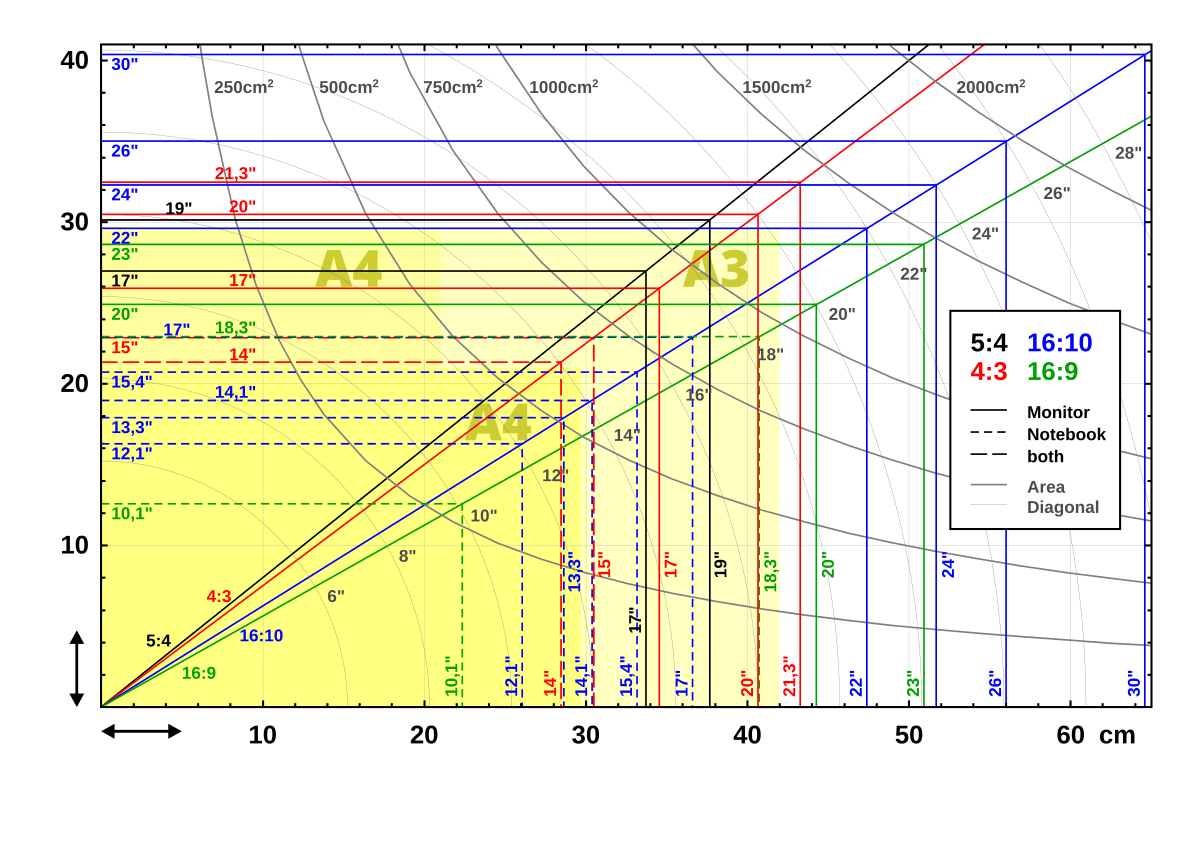

The SX2462W is also equipped with vertical display function, turning the screen through 90 degrees. Vertical display is really handy when viewing elongated documents, graphics or web pages. In addition, when used as a standard horizontal screen, a 24.1 wide-screen, with its 518.4 × 324.0 mm display area, can display two A4 sheets, in other words one A3 (420 × 297 mm) in actual size. As well as being very useful in areas such as graphics or desk top publishing, this is also bound to come in handy when checking large business or accounting documents.

With a 24.1 inch wide-screen like the SX2462W, an A3 sheet (two A4 sheets side by side) can be viewed in actual size, particularly effective for paper-based creative work ITmedia LCD Course II, Lesson 3: Which is better, 16:10 or 16:9 ? – "Screen size / resolution / aspect ratio"

We must not forget that EIZO"s wide-screen LCDs have non-glare screens (processed to reduce ambient light reflection). Nowadays the trend is for laptops to have an LCD with glare (glossy) surface treatment. While these can display images in bright color, reflected ambient light can sometimes be distracting.

A laptop screen is not so large and adjusting its angle can avoid the reflection of lights and so on, however it is not so easy with the large screen of an external LCD. When it comes to the large screen of an LCD in habitual use, a non-glare type that is not reflective is probably easier to see, as well as being kinder on the eyes. A large screen, high resolution and non-glare ensure that you can comfortably continue viewing over a prolonged period of time.

The surface treatment of an LCD makes a difference to the background reflection. Glare panels do not diffuse background light, making it easier to achieve high color purity, but easily reflect the user or lights (photo on the left). If the lights are similarly trained on a non-glare panel they do not have much effect, only appearing as a fuzzy brightness (photo on the right).

Another distinctive feature of EIZO wide-screen LCDs is a commitment to energy saving. They incorporate various power saving features that support "EcoView". A pivotal feature is the "EcoView Sense" adopted in the FlexScan EV series, such as the EV2333W.

This is the motion sensor on the front of the LCD. It constantly monitors the user"s movements to automatically take finely-tuned power saving measures. To be more precise, if the user"s presence is not detected for a specified period of time, for example if he leaves his seat, the monitor automatically switches to power save mode, and then automatically switches back when the user"s presence is detected again.

Other features include "Auto EcoView", which automatically optimizes the brightness of the LCD based on ambient lighting, and "EcoView Index", which displays a meter on the screen showing how much power is being saved. All these features can be expected to have a strong energy saving effect and to boost the user"s awareness of power saving, making them particularly useful in the office.

A standard laptop computer switches to sleep mode if the built-in LCD is closed while it is running but, if this function is turned off, a laptop can be treated as a "small desktop computer."

It can be set to use only the connected external LCD and not to react when the laptop"s built-in LCD is closed. The transformation into a small desktop PC is complete if you add a keyboard and mouse connected to the laptop via USB ports, for example. The OS is still running even though the laptop"s built-in LCD is closed, so you can carry out normal operations using the external keyboard and mouse, and also use the laptop"s built-in optical drives.

The idea is to use a large screen, high resolution external LCD at home or in the office, and to use the laptop"s built-in LCD as usual for mobile purposes. This helps to boost the longevity of the laptop"s built-in LCD and many people do use their laptop in this way. If you feel reluctant to use a dual display environment, where the screen is split in two, why not give this a try?

Select "Only show the desktop on 2" from the "Multiple displays" list in the "Screen resolution" menu. The laptop"s built-in LCD will be switched off and the external LCD will become the main display.

By making this simple setting your laptop can be used as a space saving desktop computer. Another plus is that the laptop"s built-in LCD will last longer.

Recently some high-end laptop computers, such as the Sony VAIO F, are insisting on good display quality for their LCDs. However, a typical laptop"s built-in LCD does not have as good image quality as a stand-alone LCD. This is only natural since the costs allowed for display quality are completely different for an LCD incorporated into the PC as one of its parts and a specialized LCD.

However, by using an EIZO wide-screen LCD a laptop user can still fully enjoy such benefits of a stand-alone high-quality LCD as excellent color reproduction, a wide viewing angle, more even display and a wealth of items that can be adjusted to improve image quality. This is a crucial point for people who use their computer for photographs and videos in particular.

EIZO"s wide-screen LCDs emphasize color reproduction, and the coloration in sRGB mode has a high degree of accuracy. The standard color gamut used in PC environments and Internet content is sRGB, so you need have no worries about viewing or editing videos and photographs. They can also display images on web pages, such as products in online shops or goods for sale in online auctions, in colors that are very close to the real thing. (This is also influenced by how the seller took the photographs and processed the images, so we cannot say that the colors will always be accurate.)

Adobe RGB is the de facto standard in the publishing field and, closer to home, is used in digital SLR cameras and high grade compact digital cameras. The FlexScan SX series can reproduce the colors of photos taken in Adobe RGB mode with almost perfect accuracy on the screen. Retouching photographs proceeds more efficiently since subtle differences in color can be checked on the screen.

In this case, if the image is edited on the external LCD with its high color reproducibility and the many tool palettes in the application are grouped in the laptop"s built-in LCD, there is less need to display or hide the tool palettes or to switch back and forth, and the image data to be edited can be displayed in a large form, making for more efficient work.

In this case, if the image is edited on the external LCD with its high color reproducibility and the many tool palettes in the application are grouped in the laptop"s built-in LCD, there is less need to display or hide the tool palettes or to switch back and forth, and the image data to be edited can be displayed in a large form, making for more efficient work.

When doing things like photo retouching, using software where there is a lot of switching between tool palettes it is very handy to display the image data to be edited on the external LCD with its high color reproducibility, and to gather the palette tools to be used on the laptop"s built-in LCD.

Going back to the subject of laptop computers, it is not going too far to say that applications and functions are being spoiled in laptops whose built-in LCD"s image quality is not too good. Connecting a laptop to a monitor with high image quality dispels any concerns about work that deals with colors and also helps to bring out the laptop"s potential.

Combining an EIZO wide-screen LCD with a laptop computer makes viewing videos and images even more fun. Just being able to see them on a large screen is a pleasure, but what makes it even better is that our LCDs are equipped with Fine Contrast, the optimum image quality mode for video and visuals. You can also use the Custom mode to create the image quality you prefer.

We expect that you now understand how displaying screens from a laptop computer on a stand-alone LCD can create a very pleasant environment. It feels as if your everyday laptop has been transformed into a completely different desktop machine. Even if you only use laptop computers, it is definitely worthwhile to add a stand-alone LCD.

When choosing the type of LCD the most important consideration is to choose one with overall high quality. When it comes to that, we can recommend EIZO wide-screen LCDs to a broad range of laptop users. In addition to their high image quality, EIZO wide-screen LCD are built with careful attention to detail, including non-glare screens, versatile stand features, dot-by-dot capability, abundant image quality modes, and our proprietary eco-functions. We want you to make full use of your beloved laptop computer along with an EIZO wide-screen LCD.

This time we have spoken about how an external LCD can be connected to a laptop computer, but if your main machine is a desktop computer then you probably already have a LCD.

In which case, why not consider adding a full HD (1920 × 1080 dot) or WUXGA (1920 × 1200 dot) wide-screen LCD and creating a more advanced dual display environment to further enhance your computer"s usability.

The dual display environment of a desktop PC has a wider range of options than a laptop computer, which is already installed with an LCD. Depending on the combination of products used you can seek for a larger screen, higher resolution and better image quality.

You can get a super high resolution of 3840 × 1200 dots in total by putting two 24.1-inch 1920 × 1200 dot wide-screen LCDs side by side. The advantage in this is that a larger screen and higher resolution are achieved at a lower cost than buying a single 30-inch high resolution model

Not too long ago, we’ve just got some samples of the new China Made iPhone 6 LCD Display. No doubt that this will be another option for all who are suffering from the high price of the iPhone screens. Let’s take a deep look of these screens.

At the moment, there are two companies producing the iPhone 6 LCD screens, one is LT, the other one is JDF (no iPhone 6 screens made by TM are available now). Below are some detailed comparisons after our tests.

When taking a closer look at both of the LT and JDF iPhone 6 screens under direct light, you’ll see the digitizer textures. While for the original screen, the textures had been hidden by a special painted layer.

The glass lens of LT made iPhone 6 screen is far too thin compared with the original one, which can’t secure the display well. At the same time, thinner glass lens will make the home button stick up above the screen. While for the JDF made the screen, a plastic layer has been added to make it thicker.

It’s hard to be realized through eyes, but it’s easily to be touched. When you grab the iPhone 6 with LT made screen, it’s hard to ignore that annoying uncomfortable feeling. At this point, the JDF made screen is much better.

High and low temperature tests have been applied to both the LT and JDF iPhone 6 screens. Both of them have survived and worked well after been putted in a 55 centi degrees room for 2 hours and -5 centi degrees room for 2 hours.

Through our tests, the first version of both the LT and JDF displays are not good choices for the repair industry. The obvious color differences, thickness differences still need to be improved. If you have any questions regarding the LT/JDF iPhone 6 screens, please leave your comment below, we’ll try our best to answer it.

That’s what we found in our analysis of more than three years of Consumer Reports’ TV ratings. Our crack team of statisticians looked at prices and CR’s test results from March 1, 2019, through March 1, 2022, for a number of leading TV brands sold in the U.S. The results are shown in the charts below, broken out by screen size, which is the first factor people usually consider when shopping for a television.

As you can see, TVs from LG, Samsung, and Sony earned top scores in our testing across just about every size range. And generally, sets from these companies cost more than their competitors’ TVs.

Prices and average brand scores tend to drop off in step with each other, according to our analysis. One major change this year is that some secondary brands, including Element, Philips, and Westinghouse, no longer appearin our list. Sharp is no longer in our listing; it stopped selling TVs in the U.S. for several years but began selling them again in 2022. RCA is represented in just two screen sizes, where it has the lowest Overall Score, and in one instance the lowest price by a large margin.

Although we’ve tested a few TVs from Onn, Walmart’s house brand, we didn’t test enough sets in any one screen size for it to appear. We hope to include it in next year’s evaluation.

This information should be useful if you choose a TV largely based on brand. However, it’s smart to use this analysis as just one factor when you’re shopping. The charts below are average prices and scores. Performance can vary by series and even by model within a single brand. That means that some brands with a lower average Overall Score might have a model or two that did very well in our tests. If they’re priced lower than comparable sets from bigger brands, they might be worth considering.

Last, you don’t always need to settle for poor performance just because you’re on a budget. In some size categories, there aren’t big price differences between the highest- and lowest-performing brands.

The average price figures we show are a bit higher than the average for all big TVs on the market. That’s both because the largest sets carry a premium and because CR tends to purchase a lot of expensive, high-end sets. That allows us to test the latest features, such as Mini LED backlights in LCD/LED TVs, which can help boost contrast and reduce halos, and high dynamic range (HDR), which can produce brighter, more vibrant images.

We test these flagship models from all the brands, but with major brands there is a much greater difference in pricing between the least and most expensive sets they offer. For example, for TCL there’s a $600 difference between the cheapest ($700) and priciest ($1,300) 75-inch TVs in our current ratings. With Samsung, that difference is dramatic: $1,900. (See the best big-screen TV bargains for sets 70 inches and larger.)

TCL, Vizio, and Hisense are additional brands to consider, especially if you’re on a budget. With TCL and Hisense, higher-end sets (the 6- and 8-series TVs from TCL, and 8-series sets from Hisense) have done very well in our tests, offering a lot of bang for the buck in terms of both picture quality and high dynamic range (HDR) experience. TCL’s higher average price is due to its top-tier sets having newer technologies (Mini LED, 8K resolution), plus a push into very large screen sizes. The company also offers many low-priced sets that haven’t done as well, lowering the brand’s Overall Score. Vizio sets have done well for overall picture quality across the board, though they generally fall behind a bit when it comes to HDR.

This has become a popular screen size for people looking for a large TV. And you’ll see that LG, Samsung, and Sony top the list in average Overall Score and average price here, as well. One reason for the fine showing by both LG and Sony is they offer OLED TVs that have consistently been at the top of our ratings. Samsung’s top QLED (and Neo QLED) TVs have also done very well in our ratings, and the best of those sets now rival OLED TVs in performance. All these sets tend to be pricy.

In this size category, we again see much greater differences in pricing between the least and most expensive sets from major brands than from smaller players. For example, there’s a $600 difference between the cheapest ($400) and priciest ($1,000) 65-inch Hisense TVs in our current ratings. With Samsung and Sony, that difference is a whopping $2,400. One reason for Samsung’s large spread is the debut of itsfirst QD OLED TV ($3,000), which is now in our ratings (though it arrived too late this year for our statistical analysis). Sony TVs tend to be expensive in part because the company offers several OLED TVs, which tend to cost more, and because it stopped making lower-end LED/LCD sets. (See the best 65-inch TVs under $1,000.)

As in the 70-inch size category, Hisense, TCL, and Vizio appear to be good options for those on tighter budgets. Their better-performing sets tend to be pricier but still less expensive than comparable TVs from LG, Samsung, and Sony. Hisense has the best balance of price and performance of the group. But given the wide differences in performance and price between the best- and worst-performing models within these brands, you should look at specific models to determine the best value.

If you’re shopping for a 55- to 60-inch set, you’ll see a particularly wide range of prices and brands. That’s because some TVs this size are relatively bare-bones when it comes to features, while others come loaded with lots of features. These can include 120Hz refresh rates, full-array LED backlights with local dimming, more effective HDR performance, and special gaming features, such as low-latency modes and variable refresh rates.

Average prices go from a low of $342 (for Toshiba, which makes Fire TV Edition sets sold at Amazon and Best Buy) to a high of $1,034 (Sony’s average). As we note above, Sony focuses on higher-priced sets, and both Sony and LG’s average prices are pulled up by their OLED sets—these TVs can look great, but they tend to cost more than all but the very best LED/LCD models.

Two years ago, Vizio began offering OLED TVs, but that hasn’t yet had a big impact on its average price, because the majority of its sales are still less expensive LED/LCD TVs.

For those shopping for a TV in this size range, CR’s analysis shows that Samsung, Sony, and LG again tend to have the highest-performing TVs—along with the most expensive ones.

In fact, the price range is fairly narrow in this size category once you get past those top three brands. Hisense and TCL emerge as good possible options for those on the tightest TV budgets because their average price is actually lower than a few brands’, such as Vizio and Toshiba, that have lower average scores.

There’s also a pretty big spread in both price and performance in this screen size, with prices ranging from $226 (Hisense) to more than $568 (Sony). One reason is that in this size category, you’ll find a mix of both 4K and more basic HD sets.

You may notice that Samsung is missing from this size category; there weren’t enough tested models in our analysis this year for it to be included. It’s the only brand in our current ratings that offers 32-inch 4K TVs with HDR, but those sets are more expensive, and consumers don’t seem to want to pay for the higher resolution in sets this small. Samsung does offer a number of less expensive HD sets, which are in our ratings. Shoppers seem to buying based on price rather than brand.

As you can see in the chart, with Samsung absent, along with Sony, LG becomes the clear top brand based on performance, and its average price isn’t all that much higher than prices on other brands.

With both price and performance averages so closely packed among the brands, smart shoppers are likely to look to other criteria in our TV ratings, such as screen resolution, sound quality, or reliability, or features such as built-in access to streaming content, to help make a buying decision.

Glass substrate with ITO electrodes. The shapes of these electrodes will determine the shapes that will appear when the LCD is switched ON. Vertical ridges etched on the surface are smooth.

A liquid-crystal display (LCD) is a flat-panel display or other electronically modulated optical device that uses the light-modulating properties of liquid crystals combined with polarizers. Liquid crystals do not emit light directlybacklight or reflector to produce images in color or monochrome.seven-segment displays, as in a digital clock, are all good examples of devices with these displays. They use the same basic technology, except that arbitrary images are made from a matrix of small pixels, while other displays have larger elements. LCDs can either be normally on (positive) or off (negative), depending on the polarizer arrangement. For example, a character positive LCD with a backlight will have black lettering on a background that is the color of the backlight, and a character negative LCD will have a black background with the letters being of the same color as the backlight. Optical filters are added to white on blue LCDs to give them their characteristic appearance.

LCDs are used in a wide range of applications, including LCD televisions, computer monitors, instrument panels, aircraft cockpit displays, and indoor and outdoor signage. Small LCD screens are common in LCD projectors and portable consumer devices such as digital cameras, watches, calculators, and mobile telephones, including smartphones. LCD screens have replaced heavy, bulky and less energy-efficient cathode-ray tube (CRT) displays in nearly all applications. The phosphors used in CRTs make them vulnerable to image burn-in when a static image is displayed on a screen for a long time, e.g., the table frame for an airline flight schedule on an indoor sign. LCDs do not have this weakness, but are still susceptible to image persistence.

Each pixel of an LCD typically consists of a layer of molecules aligned between two transparent electrodes, often made of Indium-Tin oxide (ITO) and two polarizing filters (parallel and perpendicular polarizers), the axes of transmission of which are (in most of the cases) perpendicular to each other. Without the liquid crystal between the polarizing filters, light passing through the first filter would be blocked by the second (crossed) polarizer. Before an electric field is applied, the orientation of the liquid-crystal molecules is determined by the alignment at the surfaces of electrodes. In a twisted nematic (TN) device, the surface alignment directions at the two electrodes are perpendicular to each other, and so the molecules arrange themselves in a helical structure, or twist. This induces the rotation of the polarization of the incident light, and the device appears gray. If the applied voltage is large enough, the liquid crystal molecules in the center of the layer are almost completely untwisted and the polarization of the incident light is not rotated as it passes through the liquid crystal layer. This light will then be mainly polarized perpendicular to the second filter, and thus be blocked and the pixel will appear black. By controlling the voltage applied across the liquid crystal layer in each pixel, light can be allowed to pass through in varying amounts thus constituting different levels of gray.

The chemical formula of the liquid crystals used in LCDs may vary. Formulas may be patented.Sharp Corporation. The patent that covered that specific mixture expired.

Most color LCD systems use the same technique, with color filters used to generate red, green, and blue subpixels. The LCD color filters are made with a photolithography process on large glass sheets that are later glued with other glass sheets containing a TFT array, spacers and liquid crystal, creating several color LCDs that are then cut from one another and laminated with polarizer sheets. Red, green, blue and black photoresists (resists) are used. All resists contain a finely ground powdered pigment, with particles being just 40 nanometers across. The black resist is the first to be applied; this will create a black grid (known in the industry as a black matrix) that will separate red, green and blue subpixels from one another, increasing contrast ratios and preventing light from leaking from one subpixel onto other surrounding subpixels.Super-twisted nematic LCD, where the variable twist between tighter-spaced plates causes a varying double refraction birefringence, thus changing the hue.

LCD in a Texas Instruments calculator with top polarizer removed from device and placed on top, such that the top and bottom polarizers are perpendicular. As a result, the colors are inverted.

The optical effect of a TN device in the voltage-on state is far less dependent on variations in the device thickness than that in the voltage-off state. Because of this, TN displays with low information content and no backlighting are usually operated between crossed polarizers such that they appear bright with no voltage (the eye is much more sensitive to variations in the dark state than the bright state). As most of 2010-era LCDs are used in television sets, monitors and smartphones, they have high-resolution matrix arrays of pixels to display arbitrary images using backlighting with a dark background. When no image is displayed, different arrangements are used. For this purpose, TN LCDs are operated between parallel polarizers, whereas IPS LCDs feature crossed polarizers. In many applications IPS LCDs have replaced TN LCDs, particularly in smartphones. Both the liquid crystal material and the alignment layer material contain ionic compounds. If an electric field of one particular polarity is applied for a long period of time, this ionic material is attracted to the surfaces and degrades the device performance. This is avoided either by applying an alternating current or by reversing the polarity of the electric field as the device is addressed (the response of the liquid crystal layer is identical, regardless of the polarity of the applied field).

Displays for a small number of individual digits or fixed symbols (as in digital watches and pocket calculators) can be implemented with independent electrodes for each segment.alphanumeric or variable graphics displays are usually implemented with pixels arranged as a matrix consisting of electrically connected rows on one side of the LC layer and columns on the other side, which makes it possible to address each pixel at the intersections. The general method of matrix addressing consists of sequentially addressing one side of the matrix, for example by selecting the rows one-by-one and applying the picture information on the other side at the columns row-by-row. For details on the various matrix addressing schemes see passive-matrix and active-matrix addressed LCDs.

LCDs are manufactured in cleanrooms borrowing techniques from semiconductor manufacturing and using large sheets of glass whose size has increased over time. Several displays are manufactured at the same time, and then cut from the sheet of glass, also known as the mother glass or LCD glass substrate. The increase in size allows more displays or larger displays to be made, just like with increasing wafer sizes in semiconductor manufacturing. The glass sizes are as follows:

Until Gen 8, manufacturers would not agree on a single mother glass size and as a result, different manufacturers would use slightly different glass sizes for the same generation. Some manufacturers have adopted Gen 8.6 mother glass sheets which are only slightly larger than Gen 8.5, allowing for more 50 and 58 inch LCDs to be made per mother glass, specially 58 inch LCDs, in which case 6 can be produced on a Gen 8.6 mother glass vs only 3 on a Gen 8.5 mother glass, significantly reducing waste.AGC Inc., Corning Inc., and Nippon Electric Glass.

In 1922, Georges Friedel described the structure and properties of liquid crystals and classified them in three types (nematics, smectics and cholesterics). In 1927, Vsevolod Frederiks devised the electrically switched light valve, called the Fréedericksz transition, the essential effect of all LCD technology. In 1936, the Marconi Wireless Telegraph company patented the first practical application of the technology, "The Liquid Crystal Light Valve". In 1962, the first major English language publication Molecular Structure and Properties of Liquid Crystals was published by Dr. George W. Gray.RCA found that liquid crystals had some interesting electro-optic characteristics and he realized an electro-optical effect by generating stripe-patterns in a thin layer of liquid crystal material by the application of a voltage. This effect is based on an electro-hydrodynamic instability forming what are now called "Williams domains" inside the liquid crystal.

In the late 1960s, pioneering work on liquid crystals was undertaken by the UK"s Royal Radar Establishment at Malvern, England. The team at RRE supported ongoing work by George William Gray and his team at the University of Hull who ultimately discovered the cyanobiphenyl liquid crystals, which had correct stability and temperature properties for application in LCDs.

The idea of a TFT-based liquid-crystal display (LCD) was conceived by Bernard Lechner of RCA Laboratories in 1968.dynamic scattering mode (DSM) LCD that used standard discrete MOSFETs.

On December 4, 1970, the twisted nematic field effect (TN) in liquid crystals was filed for patent by Hoffmann-LaRoche in Switzerland, (Swiss patent No. 532 261) with Wolfgang Helfrich and Martin Schadt (then working for the Central Research Laboratories) listed as inventors.Brown, Boveri & Cie, its joint venture partner at that time, which produced TN displays for wristwatches and other applications during the 1970s for the international markets including the Japanese electronics industry, which soon produced the first digital quartz wristwatches with TN-LCDs and numerous other products. James Fergason, while working with Sardari Arora and Alfred Saupe at Kent State University Liquid Crystal Institute, filed an identical patent in the United States on April 22, 1971.ILIXCO (now LXD Incorporated), produced LCDs based on the TN-effect, which soon superseded the poor-quality DSM types due to improvements of lower operating voltages and lower power consumption. Tetsuro Hama and Izuhiko Nishimura of Seiko received a US patent dated February 1971, for an electronic wristwatch incorporating a TN-LCD.

In 1972, the concept of the active-matrix thin-film transistor (TFT) liquid-crystal display panel was prototyped in the United States by T. Peter Brody"s team at Westinghouse, in Pittsburgh, Pennsylvania.Westinghouse Research Laboratories demonstrated the first thin-film-transistor liquid-crystal display (TFT LCD).high-resolution and high-quality electronic visual display devices use TFT-based active matrix displays.active-matrix liquid-crystal display (AM LCD) in 1974, and then Brody coined the term "active matrix" in 1975.

In 1972 North American Rockwell Microelectronics Corp introduced the use of DSM LCDs for calculators for marketing by Lloyds Electronics Inc, though these required an internal light source for illumination.Sharp Corporation followed with DSM LCDs for pocket-sized calculators in 1973Seiko and its first 6-digit TN-LCD quartz wristwatch, and Casio"s "Casiotron". Color LCDs based on Guest-Host interaction were invented by a team at RCA in 1968.TFT LCDs similar to the prototypes developed by a Westinghouse team in 1972 were patented in 1976 by a team at Sharp consisting of Fumiaki Funada, Masataka Matsuura, and Tomio Wada,

In 1983, researchers at Brown, Boveri & Cie (BBC) Research Center, Switzerland, invented the passive matrix-addressed LCDs. H. Amstutz et al. were listed as inventors in the corresponding patent applications filed in Switzerland on July 7, 1983, and October 28, 1983. Patents were granted in Switzerland CH 665491, Europe EP 0131216,

The first color LCD televisions were developed as handheld televisions in Japan. In 1980, Hattori Seiko"s R&D group began development on color LCD pocket televisions.Seiko Epson released the first LCD television, the Epson TV Watch, a wristwatch equipped with a small active-matrix LCD television.dot matrix TN-LCD in 1983.Citizen Watch,TFT LCD.computer monitors and LCD televisions.3LCD projection technology in the 1980s, and licensed it for use in projectors in 1988.compact, full-color LCD projector.

In 1990, under different titles, inventors conceived electro optical effects as alternatives to twisted nematic field effect LCDs (TN- and STN- LCDs). One approach was to use interdigital electrodes on one glass substrate only to produce an electric field essentially parallel to the glass substrates.Germany by Guenter Baur et al. and patented in various countries.Hitachi work out various practical details of the IPS technology to interconnect the thin-film transistor array as a matrix and to avoid undesirable stray fields in between pixels.

Hitachi also improved the viewing angle dependence further by optimizing the shape of the electrodes (Super IPS). NEC and Hitachi become early manufacturers of active-matrix addressed LCDs based on the IPS technology. This is a milestone for implementing large-screen LCDs having acceptable visual performance for flat-panel computer monitors and television screens. In 1996, Samsung developed the optical patterning technique that enables multi-domain LCD. Multi-domain and In Plane Switching subsequently remain the dominant LCD designs through 2006.South Korea and Taiwan,

In 2007 the image quality of LCD televisions surpassed the image quality of cathode-ray-tube-based (CRT) TVs.LCD TVs were projected to account 50% of the 200 million TVs to be shipped globally in 2006, according to Displaybank.Toshiba announced 2560 × 1600 pixels on a 6.1-inch (155 mm) LCD panel, suitable for use in a tablet computer,

In 2016, Panasonic developed IPS LCDs with a contrast ratio of 1,000,000:1, rivaling OLEDs. This technology was later put into mass production as dual layer, dual panel or LMCL (Light Modulating Cell Layer) LCDs. The technology uses 2 liquid crystal layers instead of one, and may be used along with a mini-LED backlight and quantum dot sheets.

Since LCDs produce no light of their own, they require external light to produce a visible image.backlight. Active-matrix LCDs are almost always backlit.Transflective LCDs combine the features of a backlit transmissive display and a reflective display.

CCFL: The LCD panel is lit either by two cold cathode fluorescent lamps placed at opposite edges of the display or an array of parallel CCFLs behind larger displays. A diffuser (made of PMMA acrylic plastic, also known as a wave or light guide/guiding plateinverter to convert whatever DC voltage the device uses (usually 5 or 12 V) to ≈1000 V needed to light a CCFL.

EL-WLED: The LCD panel is lit by a row of white LEDs placed at one or more edges of the screen. A light diffuser (light guide plate, LGP) is then used to spread the light evenly across the whole display, similarly to edge-lit CCFL LCD backlights. The diffuser is made out of either PMMA plastic or special glass, PMMA is used in most cases because it is rugged, while special glass is used when the thickness of the LCD is of primary concern, because it doesn"t expand as much when heated or exposed to moisture, which allows LCDs to be just 5mm thick. Quantum dots may be placed on top of the diffuser as a quantum dot enhancement film (QDEF, in which case they need a layer to be protected from heat and humidity) or on the color filter of the LCD, replacing the resists that are normally used.

WLED array: The LCD panel is lit by a full array of white LEDs placed behind a diffuser behind the panel. LCDs that use this implementation will usually have the ability to dim or completely turn off the LEDs in the dark areas of the image being displayed, effectively increasing the contrast ratio of the display. The precision with which this can be done will depend on the number of dimming zones of the display. The more dimming zones, the more precise the dimming, with less obvious blooming artifacts which are visible as dark grey patches surrounded by the unlit areas of the LCD. As of 2012, this design gets most of its use from upscale, larger-screen LCD televisions.

RGB-LED array: Similar to the WLED array, except the panel is lit by a full array of RGB LEDs. While displays lit with white LEDs usually have a poorer color gamut than CCFL lit displays, panels lit with RGB LEDs have very wide color gamuts. This implementation is most popular on professional graphics editing LCDs. As of 2012, LCDs in this category usually cost more than $1000. As of 2016 the cost of this category has drastically reduced and such LCD televisions obtained same price levels as the former 28" (71 cm) CRT based categories.

Monochrome LEDs: such as red, green, yellow or blue LEDs are used in the small passive monochrome LCDs typically used in clocks, watches and small appliances.

Today, most LCD screens are being designed with an LED backlight instead of the traditional CCFL backlight, while that backlight is dynamically controlled with the video information (dynamic backlight control). The combination with the dynamic backlight control, invented by Philips researchers Douglas Stanton, Martinus Stroomer and Adrianus de Vaan, simultaneously increases the dynamic range of the display system (also marketed as HDR, high dynamic range television or FLAD, full-area local area dimming).

The LCD backlight systems are made highly efficient by applying optical films such as prismatic structure (prism sheet) to gain the light into the desired viewer directions and reflective polarizing films that recycle the polarized light that was formerly absorbed by the first polarizer of the LCD (invented by Philips researchers Adrianus de Vaan and Paulus Schaareman),

A pink elastomeric connector mating an LCD panel to circuit board traces, shown next to a centimeter-scale ruler. The conductive and insulating layers in the black stripe are very small.

A standard television receiver screen, a modern LCD panel, has over six million pixels, and they are all individually powered by a wire network embedded in the screen. The fine wires, or pathways, form a grid with vertical wires across the whole screen on one side of the screen and horizontal wires across the whole screen on the other side of the screen. To this grid each pixel has a positive connection on one side and a negative connection on the other side. So the total amount of wires needed for a 1080p display is 3 x 1920 going vertically and 1080 going horizontally for a total of 6840 wires horizontally and vertically. That"s three for red, green and blue and 1920 columns of pixels for each color for a total of 5760 wires going vertically and 1080 rows of wires going horizontally. For a panel that is 28.8 inches (73 centimeters) wide, that means a wire density of 200 wires per inch along the horizontal edge.

The LCD panel is powered by LCD drivers that are carefully matched up with the edge of the LCD panel at the factory level. The drivers may be installed using several methods, the most common of which are COG (Chip-On-Glass) and TAB (Tape-automated bonding) These same principles apply also for smartphone screens that are much smaller than TV screens.anisotropic conductive film or, for lower densities, elastomeric connectors.

Monochrome and later color passive-matrix LCDs were standard in most early laptops (although a few used plasma displaysGame Boyactive-matrix became standard on all laptops. The commercially unsuccessful Macintosh Portable (released in 1989) was one of the first to use an active-matrix display (though still monochrome). Passive-matrix LCDs are still used in the 2010s for applications less demanding than laptop computers and TVs, such as inexpensive calculators. In particular, these are used on portable devices where less information content needs to be displayed, lowest power consumption (no backlight) and low cost are desired or readability in direct sunlight is needed.

A comparison between a blank passive-matrix display (top) and a blank active-matrix display (bottom). A passive-matrix display can be identified when the blank background is more grey in appearance than the crisper active-matrix display, fog appears on all edges of the screen, and while pictures appear to be fading on the screen.

STN LCDs have to be continuously refreshed by alternating pulsed voltages of one polarity during one frame and pulses of opposite polarity during the next frame. Individual pixels are addressed by the corresponding row and column circuits. This type of display is called response times and poor contrast are typical of passive-matrix addressed LCDs with too many pixels and driven according to the "Alt & Pleshko" drive scheme. Welzen and de Vaan also invented a non RMS drive scheme enabling to drive STN displays with video rates and enabling to show smooth moving video images on an STN display.

Bistable LCDs do not require continuous refreshing. Rewriting is only required for picture information changes. In 1984 HA van Sprang and AJSM de Vaan invented an STN type display that could be operated in a bistable mode, enabling extremely high resolution images up to 4000 lines or more using only low voltages.

High-resolution color displays, such as modern LCD computer monitors and televisions, use an active-matrix structure. A matrix of thin-film transistors (TFTs) is added to the electrodes in contact with the LC layer. Each pixel has its own dedicated transistor, allowing each column line to access one pixel. When a row line is selected, all of the column lines are connected to a row of pixels and voltages corresponding to the picture information are driven onto all of the column lines. The row line is then deactivated and the next row line is selected. All of the row lines are selected in sequence during a refresh operation. A

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey