bistable lcd displays in stock

Bistable LCD Display offers the perfect display in a world of imperfect LCD technology. Think about this; perhaps in a perfect world automobiles would require no gas; air conditioners in Arizona would require no power; and food crops would require no rain or water. We do not live in a perfect world but there is a LCD display technology that can display an image that requires zero power. Is it possible?

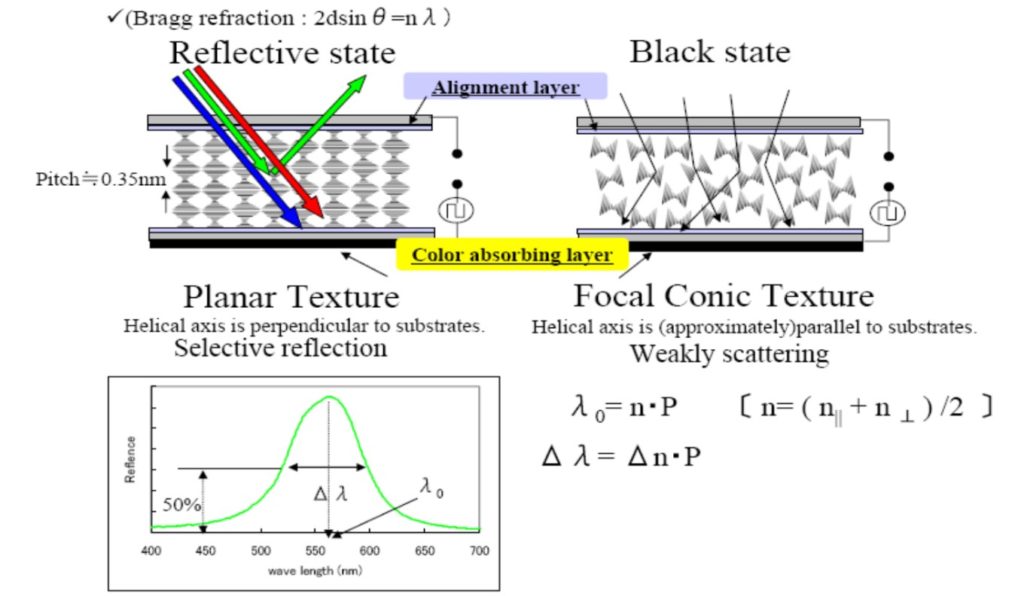

Well, yes and no... the Bistable LCD Display, also called cholesteric liquid crystal (ChLCD), e-paper, and even zero power, do offer a great power savings. They do not require any power to display the image, but there is a need for power to change the image. This unique bi-stable property means that an image placed on the display will remain indefinitely without the need for refreshing as is necessary in an active matrix display such as a TFT LCD Displays or a passive matrix display such as a monochrome character LCDs.

At this time all Bistable LCD displays are custom built to the customer’s specification. This requires a one-time tooling fee and an MOQ (minimum order quantity).

Zero power displays are reflective and do not require a backlight. This can be a disadvantage in areas with dark ambient light, but the plus side is they are very readable in direct sunlight. This is a great advantage over many other display technologies that have to compete with sun light, making the other displays difficult to read.

Some of the bistable LCD display is equipped with on-board RAM memory to store the image. They can be manufactured as a Chip on Glass (COG), Chip on Flex (COF) and Chip on Board (COB).

The largest possible glass size at this time is 18 inches. The product designer can build the custom bistable display to a size that meets their design requirements.

Adding bistability (image memory) to a display has remained an attractive feature for several reasons. In the 80s and 90s, it was seen as a way to allow displays with a large line count to be realized without the need for an active matrix backplane. More recently, bistability is used in many applications where images are updated infrequently and battery life is important.

Many diverse approaches have been investigated to achieve such operation including, bistable LC (nematic, Cholesteric, Smectic A and ferroelectric), electrophoretic, electrowetting, electrochromic and phase change displays. Only a few examples of these have ever “crossed the chasm” and successfully made it into mass production. One example is the ZBD LCD technology – invented in the 1990s and widely deployed in electronic shelf labels.

The ZBD LCD technology uses standard nematic liquid crystal materials within a passive matrix display. However, one surface is no longer a rubbed polyimide layer but instead is a microscopic diffraction grating. This interacts mechanically with the long-range order in the LC material and allows two different optical states to be obtained without any holding voltage.

In summary, a microscopic surface grating of optimum dimensions and chemistry provides two stable pretilt angles (typically 90° and 5°) to a neighboring nematic LC. Of course, this is not enough to create a bistable display since we still need a method to switch between the two states. Once again the grating-induced distortion of the nematic provides the answer.

While standard passive matrix STN displays struggle to address more than 256 lines, the threshold behavior in the ZBD LCD allows addressing of many thousands of lines. Indeed, the practical upper limit of display complexity is constrained by electrode resistivity and driver cost rather than the display technology itself.

The biggest challenge in manufacturing the ZBD LCD has been the realization of a cost-effective method of patterning the high-resolution diffraction grating onto the LCD mother-glass. Direct photolithographic methods proved too slow and too expensive. Therefore a replication process was established in which a high-cost photoresist master grating is copied into nickel (similar to CD/DVD nickel stamper tooling) then the nickel pattern is copied into film (similar to hologram fabrication) which is then cheap enough to be used as a consumable surface for the final UV cured replication step onto the LCD glass surface. The replication process speed matches other processes on an STN production line.

Following the grating replication step, this mother-glass is assembled opposite a standard rubbed polymer surface. This step and all downstream processes use equipment and materials that are common with STN. In the most common ZBD LCD configuration, the grating is placed opposite a rubbed polymer surface such that the low tilt grating state induces a 90° TN arrangement while the high tilt state leads to a HAN (hybrid aligned nematic) arrangement. Usually, front and rear polarizers are arranged so that the TN state is white and the HAN state is black. Unlike a continuously addressed TN display, the bistable TN state in the ZBD LCD has a very low tilt angle throughout the cell and so has much wider optical viewing properties.

Reflective LCDs have traditionally suffered from a ‘metallic-like’ reflection which means that they only show high reflectivity when the display is oriented close to the specular condition with respect to the user and the light source. In recent years, novel light shaping diffusers have become available which have been used in conjunction with the ZBD LCD configuration to deliver a truly paperlike reflectivity similar to electrophoretic displays.

Recent advances in the ZBD LCD technology have also increased the operating temperature range which now extends from -10°C to +90°C. A stored image remains on the display from -40°C to +110°C. Furthermore, these displays can be tested to automotive specifications (e.g. 500 hours at 85°C). These properties together allow a wide variety of portable, outdoor and rugged applications that cannot be served by other technologies.

High contrast and wide viewing angle: The monochromatic bistable LCD’s contrast ratio is as high as 25:1, viewing angle about 80 degree in all directions.

Bistable Liquid Crystal materials require protection from UV light. A UV blocking material with a minimum 98% cut of at 380nm and lower spectral components is required.

The finished product design should incorporate a transparent cover such as acrylic, polycarbonate etc. to protect the viewing area of the display. Place the protective cover as close to the display bistable module as possible. The protective cover should be sufficient thickness to resist bending.

The power used for screen refreshing is pretty high. So, it will not worthwhile for an application if the screen has to be refreshed more than 20 to 50 times depending on the battery used. Bistable display technology has been used for shelf label and E-reader. Bi-stable LCDs requires the use of a voltage booster. Designing into some environments needs to be cautious, examples: explosive gas. Bistable LCDs are limited to one color of character and one color of background.

Bistable LCDs are reflective and do not require a backlight. This can be a disadvantage in areas with dark ambient light. If the lighting has to be used, it can only use front light instead of backlight. It can be expensive and lose its key advantage of low power.

If you want to display items at your shops in the most impressive way, Alibaba.com can help you do that with the sturdy and trendy bistable display collections. These stylish and freestanding bistable display are ideal for displaying all types of products at your space in a fabulous way. The quality of these bistable display is very rigid and made of superior raw materials to ensure long-lasting performance and stability. These products are easy to assemble and can be maneuvered with ease from one place to the other.

The unique and robust bistable display offered on the site are not just tough in terms of quality but are also very appealing aesthetically and spacious enough to display plenty of items in one single place. These bistable display are very easy when it comes to installation and are equipped with compression loads feature that let them withstand any weight you put. You can also customize the shelves as well as hooks of the bistable display as per your needs and are multi-usage.

Alibaba.com offers an exciting range of bistable display according to their sizes, shapes, shelves, designs, and colors to let you choose as per your requirements. These bistable display are made from all types of sturdy materials such as stainless steel, white acrylic and hardware, metal wire, wood, cardboard, and many more. The bistable display come with powder-coated surface treatments and can be completely customized in terms of designs.

Check out the varied bistable display ranges at Alibaba.com and go for the products that meet your finances and requirements. These items are offered as OEM products on bulk orders and you can enjoy brilliant deals at regular intervals. Customized packaging is also available along with free shipping.

This is a 240x160 reflective cholesteric liquid crystal display (ChLCD) from Kent Displays. The most distinguishing feature of a ChLCD is its ability to retain its image even when the LCD is not powered, similar to e-ink technology. This makes the LCD a great fit for portable battery-powered projects. Bistable, sunlight readable, and easy to integrate, the 240x160 (1/8 VGA) is truly a unique LCD display solution.

Integrated into the display is an embedded controller which generates the unique ChLCD drive waveforms and provides automatic temperature compensation. Communication with the controller is achieved through an SPI-compatible interface, which means a minimal number of I/O resources are needed to control the display.

Tanaka T, Sato Y, Inoue A, Momose Y, Notuma H, Iino S (1995) A bistable twisted nematic (BTN) LCD driven by passive-matrix addressing. Asia Disp 26:259–262

Bryan-Brown GP, Towler MJ, Bancroft MS, McDonnell DG (1994) Bistable nematic alignment using bigratings. In: Proceedings of international display research conference (IDRC ’94), pp 209–212

Lasak S, Davidson A, Brown CV, Mottram NJ (2009) Sidewall control of static azimuthal bistable nematic alignment states. J Phys D Appl Phys 42(085114):1–8

Barberi R, Giocondo M, Durand G (1992) Flexoelectrically controlled surface bistable switching in nematic liquid crystals. Appl Phys Lett 60(9):1085–1086

Bradshaw MJ, Brown CV, Haslam SD, Hughes JR, Graham A, Jones JC, Katsuse H, Kawabata Y, Koden M, Miyoshi S, Nonomura K, Numao T, Shigeta M, Sugino M, Tagawa A, Gass PA, Raynes EP, Towler MJ (1997) Key technologies for τVmin FLCDs. In: Proceedings of international display research conference, Toronto, Sept 1997, pp L16–L17

Jones JC, Towler MJ, Hughes JR (1993) Fast, high contrast ferroelectric liquid crystal displays and the role of dielectric biaxiality. Displays 14(2):86–93

Itoh N, Akiyama H, Kawabata Y, Koden M, Miyoshi S, Numao T, Shigeta M, Bradshaw MJ, Brown CV, Graham A, Haslam SD, Hughes JR, Jones JC, Slaney AJ, Bonnett P, Gass PA, Raynes EP, Ulrich DC (1998) 17″ video-rate full colour FLCD. In: Proceedings of the international displays workshop (IDW), Kobe, Dec 1998, PLC 1–2, pp 205–208

Kondoh S, Suguro A, Noguchi K, Iio K, Ueda K, Takahashi N, Fujino M (2005) Low power consumption displays using ferroelectric liquid crystals. In: Proceedings of international display workshop (IDW’05), pp 81–82

Büyüktanir EA, Mitrokhin M, Holter B, Glushchenko A, West J (2006) Flexible bistable smectic-A polymer dispersed liquid crystal display. Jpn J Appl Phys 45:4146–4151

Tang Y, Lei W, Zheng Y, Wang B, Sun G, Xia X (2010) Multi-gray level reflective LCD module design and its tiled application. Proc SID Int Symp Dig Tech Papers 41:1408–1410

Joubert C, Angelé J, Boissier A, Pecout B, Forget SL, Dozov I, Stoenescu D, Lallemand S, Martinot-Lagarde P (2003) Reflective bistable nematic displays (BiNem) fabricated by standard manufacturing equipment. J SID 11(1):217–224

Angelé J, Stoenescu D, Dozov I, Osterman J, Laffitte JD, Compagnon M, Emeraud T, Leblanc F (2007) New developments and applications update of BiNem displays. Proc SID Int Symp Dig Tech Papers 38:1351–1769

Wood EL, Bryan-Brown GP, Brett P, Graham A, Jones JC, Hughes JR (2000) Zenithal bistable device (ZBD) suitable for portable applications. Proc SID Int Symp Dig Tech Papers 31:124–127

Bryan-Brown GP, Wood EL, Jones JC (1998) Optimisation of the Zenithal bistable nematic liquid crystal device. In: Proceedings of 18th international display research conference (IDRC ’98), pp 1051–1053

Uche C, Elston SJ, Parry-Jones LA (2005) Microscopic observation of Zenithal bistable switching in nematic devices with different surface relief structures. J Phys D Appl Phys 38(13):2283–2291

Barron C, Angelé J, Bajic L, Dozov I, Leblanc F, Perny S, Brill J, Specht J (2005) Development of Binem® displays on flexible plastic substrates. J SID 13(3):193–198

Bryan-Brown GP (2000) Zenithal bistable device (ZBD) using plastic substrates. In: Proceedings of 20th international display research conference (IDRC), pp 229–232

Jones JC, Brett P, Bryan-Brown GP, Graham A, Wood EL, Scanlon RJ, Martin H-L (2002) Meeting the display requirements for portable applications using Zenithal bistable devices (ZBD). Proc SID Int Symp Dig Tech Papers 33:90–93

Bobrov Y, Lazarev P, McMurtry D, Remizov S (2001) Incorporation of optiva polarizers in LCD production line. Proc SID Int Symp Dig Tech Papers 32:639–641

Yang D-K, Chien L-C, Doane JW (1991) Cholesteric liquid crystal/polymer gel dispersion bistable at zero field. In: Proceedings of international display research conference, pp 49–52

Yang D-K, West JL, Chien L-C, Doane JW (1994) Control of reflectivity and bistability in displays using cholesteric liquid crystals. J Appl Phys 76:1331–1333

Doane JW, Khan A, Huang X-Y, Miller N (2003) Bistable reflective cholesteric displays. In: Proceedings of international display research conference, Paper 6.1, pp 84–87

Khan A, Shiyanovskaya I, Schneider T, Miller N, Ernst T, Marhefka D, Nicholson F, Green S, Magyar G, Pishnyak O, Doane JW (2005) Reflective cholesteric displays: from rigid to flexible. J SID 13(6):469–474

Nose M, Uehara H, Shingai T (2010) Driving scheme of color e-paper using Ch-LC for high image quality. In Proceedings of the international displays workshops (IDW 10), paper EP6-1

Green A, Montbach E, Miller N, Davis DJ, Khan A, Schneider T, Doane JW (2008) Energy efficient flexible Reflex™ displays. Proc SID Int Symp Dig Tech Papers 39:55–58

The power efficiency offered by bi-stable displays is their primary draw. For example, research conducted by Motorola found that a battery in a PDA can last over 600 times longer on a device that utilises bi-stable technology.

Electronic shelf labels (ESL) using bi-stable technology allow retailers to change product pricing remotely and in real-time. This allows the retailer to be reactive with pricing and promotions, and stay ahead of their competitors. At GTK, our colour bi-stable displays offer the additional benefit of making signage more visually appealing and eye-catching.

In addition to the above benefits, bi-stable displays offer wider viewing angles than most transmissive displays, high contrast ratio and excellent sunlight readability.

Electrically operated display devices have developed from electromechanical systems for display of text, up to all-electronic devices capable of full-motion 3D color graphic displays. Electromagnetic devices, using a solenoid coil to control a visible flag or flap, were the earliest type, and were used for text displays such as stock market prices and arrival/departure display times. The cathode ray tube was the workhorse of text and video display technology for several decades until being displaced by plasma, liquid crystal (LCD), and solid-state devices such as thin-film transistors (TFTs), LEDs and OLEDs. With the advent of metal–oxide–semiconductor field-effect transistors (MOSFETs), integrated circuit (IC) chips, microprocessors, and microelectronic devices, many more individual picture elements ("pixels") could be incorporated into one display device, allowing graphic displays and video.

One of the earliest electronic displays is the cathode ray tube (CRT), which was first demonstrated in 1897 and made commercial in 1922.electron gun that forms images by firing electrons onto a phosphor-coated screen. The earliest CRTs were monochrome and were used primarily in oscilloscopes and black and white televisions. The first commercial colour CRT was produced in 1954. CRTs were the single most popular display technology used in television sets and computer monitors for over half a century; it was not until the 2000s that LCDs began to gradually replace them.

A derivative of CRTs were storage tubes, which had the ability to retain information displayed on them, unlike standard CRTs which need to be refreshed periodically. In 1968, Tektronix introduced the Direct-View Bistable Storage Tube, which went on to be widely used in oscilloscopes and computer terminals.

1968Direct-View Bistable Storage Tube CRT retains static information displayed upon it, written using a steerable electron beam that can be turned off. The DVBST was used in vector displays of early computers and in oscilloscopes.

1984 Super-twisted nematic display (STN LCD) to improve passive-matrix LCDs, allowing for the first time higher resolution panels with 540x270 pixels.

![]()

This is the same technology that is being use on the Amazon Kindle and other e-readers. These zero-power displays are now available to OEM (Original Equipment Manufacturers). Their cost and MOQ’s (Minimum Order Quantities) are decreasing as they become more popular. This makes the new technology more and more attractive for consumer products that require minimal power usage.

Cholesteric liquid crystal displays offer an ultra wide viewing angle; in fact, the display is readable from a full 180 degrees. This exceeds the viewing angle of every other type of LCD display. The reason this is possible is because the technology does not require a polarizer. Without the polarizer—which naturally limits viewing angle—this means you can read the display from extreme high, low, left, or right angles.

The display offers a very sharp contrast between the background and the character segments. The contrast is very close to that of printed type on white paper; that is another quality that speaks to its readability. Bi-stable displays are also versatile in that they are not limited to black letters on a white background. The segments can be other colors and the display can run in negative mode. (Negative mode is when the characters are light in color and the background is darker.)

Bi-stable displays require the use of a booster or charge pump. There are certain conditions or environments wherein this technology is not recommended. Specifically, it can be dangerous in situations where there may be explosive gas.

At this time, while Bi-stable LCD’s can use a wide range of colors for the background and the segments they are limited to one color of character and one color of background. Unlike TFT (thin-film-transistor) and OLED (organic light emitting diode) displays, which allow the user to display 64,000 or more colors.

There is new technology being developed to add colors as an option to these displays. Research by Gamma Displays (http://gammadynamics.net/) in Tempe Arizona has developed a prototype bi-stable display that is able to produce a multitude of colors. Although this is not in production at this time, it could be incorporated in the next generation of tablets or laptops.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey