lcd panel proyektor brands

HTPS is an abbreviation of High Temperature Poly-Silicon, an active matrix transmissive LCD. It"s superior in that it is smaller, has higher resolution and higher contrast, and can embed drivers. The main function of HTPS is as a light valve for projectors.

Of the three technologies, LCD, DLP and LCoS, no one is in all ways better than the others. Each has distinct advantages. LCD projectors produce highly saturated colors. In home theater space many LCD projectors add a special color filter to get the best overall color tracking. This creates an interesting difference between the LCD projectors and the other technologies. A typical home theater projector using LCD technology, like Epson’s popular, mid $2500s Home Cinema 5020UB, can produce a good two thousand lumens at its brightest – unusually bright for home theater. When you get into its best modes Cinema or THX, though, the filter slides into place, and color goes from very good to great, but down go the lumens to about 670 lumens calibrated. The thing is, few projectors calibrated offer much more than 700 lumens. And most of the competition, ($1500 to $5000) except for the Panasonic PT-AE8000 (another LCD projector) produce less than 1200 lumens maximum and many less than 1000 lumens maximum. In home theater space, only lower end DLP projectors that are not true “home theater” quality can match that brightness.

OK, LCD projectors designed for business and education are also particularly known for great color compared to single-chip DLP projectors. Consider though, LCoS projectors also have great color, they are usually significantly more expensive than their kin, the LCD projectors. Furthermore, LCD projectors are perhaps the greenest of the technologies, they get noticeably more brightness out of lamps of similar wattage, than their LCoS and DLP competition.

In the home projector market, LCD projectors tend to dominate sales in all but the most entry-level price point, which consists of all DLP projectors. LCD based projectors sold in the US start at just over $1000 for 2D models and from about $1600 for 3D capable projectors. LCD doesn’t really place in the high end space, with no popular models over $3500, yet they give many more expensive projectors some serious comptition.

In the business, education, and government segments, (excluding pico projectors), LCD projectors outsell the other technologies, except when it comes to the very smallest and most portable projectors – under 3 pounds – that, so far seems to be primarily DLP. On the very high end, LCD projectors offer more bang for the buck than the drastically more expensive 3-chip DLP projectors which are generally the best projectors, but you might buy a loaded 8000 lumen LCD projector for $8000, and an 8000 lumen DLP, for $25,000 or more. One “limitation” of LCD projectors on the high end. They top out around 10,000 lumens. Those 3 chip DLP’s which can hit 25,000 lumens or more are reserved for really high end installations. You know. for lighting up screens 100 feet wide, or more. Sorry, the brightest LCD projectors are merely bright enough for a sports arena, or major auditorium.

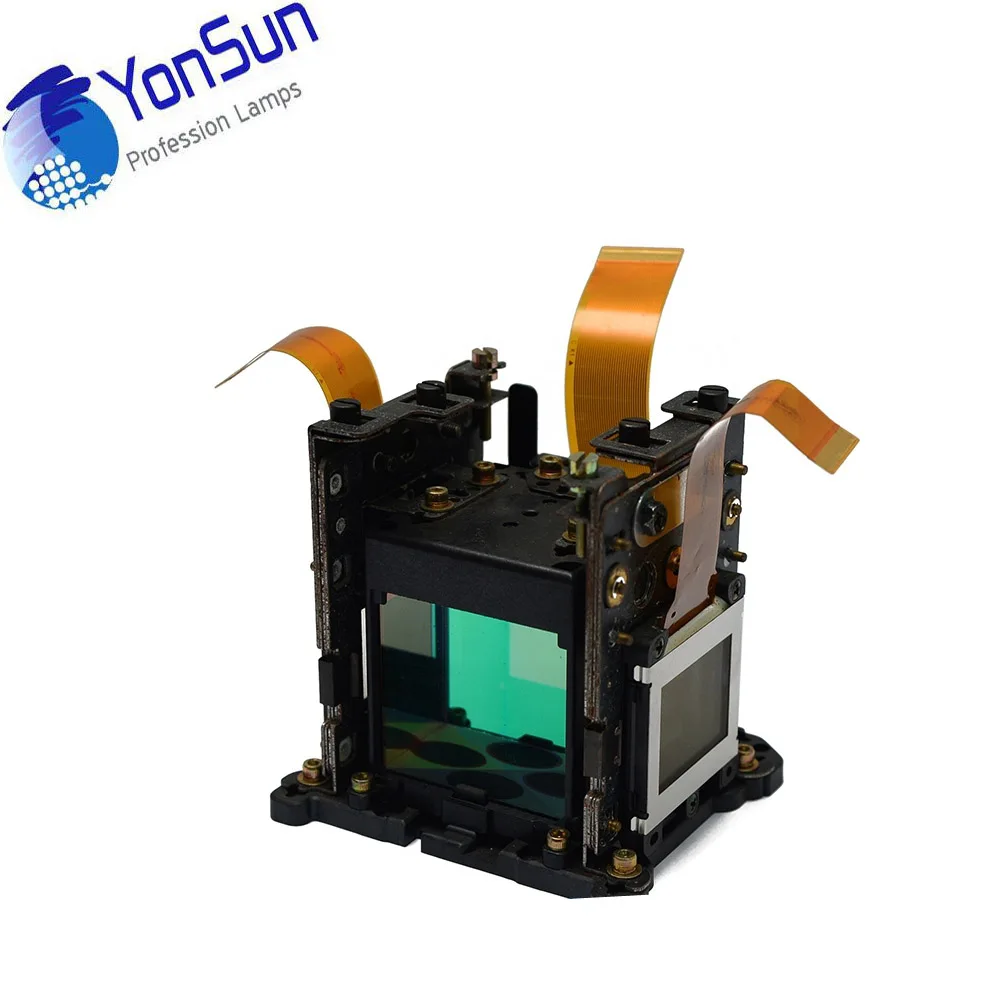

An LCD projector is a type of video projector for displaying video, images or computer data on a screen or other flat surface. It is a modern equivalent of the slide projector or overhead projector. To display images, LCD (liquid-crystal display) projectors typically send light from a metal-halide lamp through a prism or series of dichroic filters that separates light to three polysilicon panels – one each for the red, green and blue components of the video signal. As polarized light passes through the panels (combination of polarizer, LCD panel and analyzer), individual pixels can be opened to allow light to pass or closed to block the light. The combination of open and closed pixels can produce a wide range of colors and shades in the projected image.

Because they use small lamps and the ability to project an image on any flat surface, LCD projectors tend to be smaller and more portable than some other types of projection systems. Even so, the best image quality is found using a blank white, grey, or blackprojection screens are often used.

Early experiments with liquid crystals to generate a video image were done by John A. van Raalte at the RCA-Laboratories in 1968.CRT with a modified faceplate to generate a charge pattern on its surface. No practical application of this concept for projection purposes is known. However, a similar concept was used for print heads without an LCD.

The first experiments with a direct-driven, transmissive matrix-addressed LCD using a converted slide projector by Peter J. Wild working at Brown Boveri Research in Switzerland were conducted in 1971. A projector was shown in operation at the SID Conference 1972 in San Francisco.thin-film transistors) at the matrix intersections) were not capable of displaying images with sufficient resolution for video pictures, a combination of a fixed image together with an LCD matrix for the variable elements was proposed as an LC projector for certain control room applications,

A lot of effort went into optimizing thin-film transistors (TFT) suitable for active matrix-addressed (AM) LCDs. The concept was invented and early trials were conducted by teams at RCA and Westinghouse Electric. T Peter Brody left Westinghouse and founded Panelvision in 1981 to manufacture AM LCDs. Breakthroughs occurred elsewhere in new materials and thin-film structures, with Hitachi of Japan as a pioneering company. Such AM LCDs became commercially available in the early 1980s.

Gene Dolgoff had the idea of using LCDs as light valves in projectors. However, he had to wait until 1984 to get a digitally-addressable LCD matrix device with sufficient resolution and contrast, which is when he completed building his LCD video projector. After building it, he saw many problems that had to be corrected including major light losses and very noticeable pixels (sometimes referred to as the "screen-door effect"). He then invented new optical methods to create efficient and bright projectors and invented depixelization to reduce the screen-door effect.

At about the same time, the German company "Bonner Ingenieurbüro für Optoelektronik CrystalVision" started experimenting with LCD projection devices from 1985 onwards. Although traditional slide projectors already used infrared filters to reduce heating of the photographic slides, LCDs are much more sensitive to overheating. When the temperature in the nematic liquid crystal layer reaches the "clearing point" (i.e. enters the isotropic phase), the LC light valve does not work anymore until the temperature drops below again. Bernt Haastert, an engineer working at CrystalVision, found out, that placing the required polarizing filters at a certain distance on both sides of the LC cell allowed for efficient air cooling of the arrangement.

With patents filed worldwide (filing his first LCD video projector patent application in 1987), Dolgoff started Projectavision, Inc. in 1988, as one of the world"s first dedicated LCD-projector companies, which he took public on Nasdaq in 1990. He licensed the technology to other companies including Panasonic and Samsung. Early pioneers of LCD projection in Japan were Epson and Sharp,

Since 2005,Epson and Sony. Epson owns the technology and has branded it as "3LCD". To market 3LCD projector technology, Epson also set up a consortium called the "3LCD Group" in 2005 with other projector manufacturer licensees of 3LCD technology that use it in their projector models.

Early LCD systems were used with existing overhead projectors. The LCD system did not have a light source of its own: it was built on a large "plate" that sat on top of the projector in place of transparencies. This provided a stop-gap solution in the era when the computer was not yet a universal display medium, creating a market for LCD projectors before their current main use became popular.

This technology was employed in some sizes of rear-projection television consoles when there was a cost advantages in mid-size sets (40- to 50-inch diagonal). In 2014, 60-inch 1080p flat panel televisions were less costly than a projector with 1080p native resolution. Projection systems were typically marketed as offering a diagonal image size of 100 to 300 inches.

In 2004 and 2005, LCD front projection began a comeback with the introduction of the dynamic iris and other modifications that have improved perceived contrast to levels similar to DLP.

The basic design of an LCD projector is frequently used by hobbyists who build their own DIY (do-it-yourself) projection systems. The basic technique is to combine a high color-rendering index (CRI) high-intensity discharge lamp (HID lamp) and ballast with a condenser and collector Fresnel lens, an LCD removed from a common computer display and a triplet lens.

Fischetti, Mark (November 2007). "Two Technologies Shine". Two technologies – micromirrors and liquid-crystal displays (LCDs) – have been vying for these markets, but they are doing equally well in today"s home and business areas....

Today, film has been almost completely replaced by digital-video projectors that are based on one of three imaging technologies: LCD, LCoS, and DLP. All of these technologies offer many advantages over film and CRT projectors—smaller size, lower weight, less heat generation, and more efficient energy usage—and each one has its own strengths and weaknesses for different applications.

The first digital-projection technology was LCD (liquid crystal display). It was conceived by Gene Dolgoff in 1968, but LCD technology was not sufficiently developed to be practical in a projector at the time; that would have to wait until the mid-1980s.

Fig. 1: In many LCD projectors, white light from a lamp is split into its red, green, and blue components using dichroic mirrors. The three colored beams are directed to pass through three LCD panels that form the images associated with each color. Then, the light from the three panels is combined into a full-color image that is projected onto the screen. (Source: Epson)

In some LCD projectors, the light source is a blue laser. With most laser projectors, some of the blue light from the laser hits a spinning wheel coated with phosphor that emits yellow light, which is then split into its red and green components using dichroic mirrors (Fig. 2). The rest of the blue laser light is directed to the blue imager.

Fig. 2: Some LCD projectors use an array of blue lasers as the light source. Some of the blue light is directed to a spinning wheel coated with a phosphor that emits yellow light, which is split into its red and green components. The red, green, and remaining blue-laser light beams are then directed to the LCD imagers. (Source: Epson)

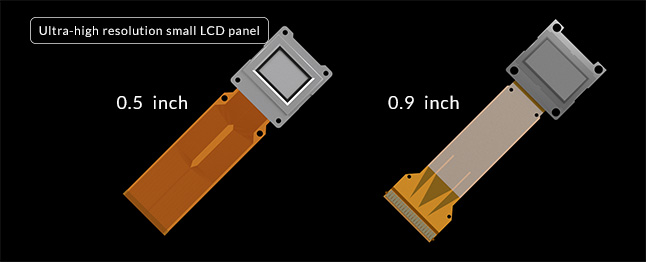

Either way, each beam of red, green, and blue light is directed toward its own LCD imager, which typically measures 0.55-inch to about 1-inch diagonally (Fig. 3) and consists of an array of tiny, transparent cells. These cells are individually and dynamically controlled by electrical signals to allow more or less light to pass through them at any given moment. Each cell can be made transparent, opaque, or translucent in varying degrees based on the signal. As the cells change the amount of light they pass, they form a digital image for each frame in the video signal.

The imager for each color forms a portion of the final image associated with that color, and the image is generally held for each entire frame in the video signal; this process is called sample and hold. Modern LCD imagers can be switched at faster rates—up to 480 times per second—which allows projector designers to implement features such as 3D, frame interpolation, and pixel-shifted UHD (more on that in a moment) instead of holding one image for the entire frame.

The individual cells in an LCD imager measure about 6 to 12 microns across and are surrounded by opaque lines that carry the electrical signals to control each cell"s transparency. These lines occupy a certain percentage of the total area of the imager that can"t be used as part of the image. The percentage of the total area that can be used as part of the image—in other words, the area occupied by the cells themselves—is called the fill factor, which is roughly 80% to 90% for LCD imagers. As a result, it"s possible to see the boundaries around the pixels as you get close to the screen, which is known as the screen-door effect. Some longtime enthusiasts may recall the prominence of screen-door effect in earlier, lower-resolution LCD projectors, though today"s 1080p imagers have greatly reduced its visibility on a typical-size home-theater screen.

Another important characteristic of all digital projection imagers is their inherent or native contrast ratio—that is, the ratio of the most to least light they can pass without enhancements such as a dynamic iris or modulated light source. Epson won"t reveal the native contrast ratio of its LCD imagers, but the company"s UB (Ultra Black) enhancement technology—which incorporates a dynamic iris and light polarization to reduce light scatter in the engine—is known to achieve impressive contrast ratios and black levels when viewed in appropriately dark conditions.

Most modern LCD imagers have resolutions up to 1920x1200 (WUXGA); home-theater models typically use 1920x1080 (1080p) imagers. Higher resolutions are possible but uncommon—I know of only one commercially available projector today that uses LCD imagers with native 3840x2160 (UHD) resolution: the recently introduced Epson Pro L12000QNL, which is designed for large venues such as stadiums and convention halls.

Some home-theater LCD projectors with 1080p imagers simulate UHD resolution with a pixel-shifting technique. The pixel-shifting in Epson"s models is part of a technology suite Epson calls 4K PRO-UHD. In this process, an optical refracting plate oscillates back and forth, shifting the final image diagonally by half a pixel once per frame (Fig. 4). Because the LCD cells can be switched to different levels of transparency much faster than any current frame rate, each set of shifted pixels is independently controllable, doubling the effective number of pixels on the screen. In addition, the pixels overlap, so the pixel grid is more dense, further reducing the screen-door effect.

LCD imagers for projectors are made by Epson and Sony. Epson is the only major manufacturer of consumer-oriented LCD projectors, though it also makes models for business and educational applications as well as large venues. Sony makes a variety of LCD projectors for the business and education markets, and Panasonic offers models for large-venue and commercial installations. Other companies that make LCD projectors for various applications include Christie, Maxell, NEC, Ricoh, and Sharp.

LCoS (liquid crystal on silicon) is a variation of LCD technology. General Electric first demonstrated a low-resolution LCoS projector in the 1970s, but it wasn"t until 1998 that JVC introduced its first SXGA+ (1400x1050) projector using its implementation of LCoS technology, which the company calls D-ILA (Direct Drive Image Light Amplifier). In 2005, Sony introduced its first 1080p home-theater model, the VPL-VW100 (aka "Ruby"), using its own implementation of LCoS—called SXRD (Silicon X-tal Reflective Display)—which was followed by JVC"s DLA-RS1 in 2007.

Like LCD projectors, LCoS projectors separate light into its red, green, and blue components that are directed to three separate LCD-based imagers. But instead of light simply passing through the LCD cells, it is reflected off a shiny surface directly behind the cell array and passes back through the cells again (Fig. 5).

Fig. 5: An LCoS imager includes a layer of LCD material that lets more or less light through each pixel according to the signal it receives. The light passes through the LCD layer and reflects off a mirror before passing back through the LCD layer a second time. (Source: JVC)

The light source in LCoS projectors is often a white lamp, but some use a blue laser and yellow phosphor wheel as the light source, a technology that JVC calls Blu-Escent and Sony calls Z-Phosphor. Either way, as with LCD projectors, the red, green, and blue light beams are directed to their respective imagers. The reflected light from the three imagers is then combined and projected onto a screen through the main lens (Fig. 6).

LCoS imagers today measure 0.7 to 1.3 inches diagonally (Fig. 7). As with LCD, each imager forms its image and generally holds it for each frame. Modern LCoS imagers can switch at rates up to 120 Hz, which allows things like 3D, frame interpolation, and pixel-shifted UHD. At 120 Hz, however, they can"t do pixel-shifted UHD and 3D at the same time.

Fig. 8: JVC claims to have developed a way to control the LCD molecules in the gaps between cells, greatly reducing the screen-door effect. (Source: JVC)

In any case, red, green, and blue light is directed to DLP imagers, which currently measure from 0.2 inches for small, portable devices to 1.38 inches for digital-cinema projectors; home-theater models today typically use imagers that measure 0.47-inch or 0.66-inch diagonally. However, they work quite differently from LCD or LCoS imagers. Instead of tiny LCD cells, a DLP imager is covered with an array of microscopic mirrors that correspond to the individual pixels (Fig. 10). This type of imager is called a Digital Micromirror Device (DMD).

As in all LCD and LCoS projectors, some DLP projectors use three DMDs, one each for red, green, and blue. However, these so-called 3-chip models are very expensive. Fortunately for consumers, there"s a less-expensive alternative that uses only one DMD.

By comparison, color brightness (aka color light output or CLO) is calculated by adding the maximum brightness of red, green, and blue. Ideally, white and color brightness should be identical, and for all 3-chip projectors—LCD, LCoS, and 3-chip DLP—they are, since white is simply a combination of red, green, and blue. A standard method for measuring color brightness was introduced by SID (Society for Information Display) in 2012.

Why is this important? If a projector"s color brightness is much less than its white brightness, images with saturated colors can appear noticeably dimmer and duller than they would from a projector with equal white and color brightness. You might think this means it is always preferable to have a 3-chip projector that delivers equal white and color brightness, and since all LCD and LCoS projectors are 3-chip designs, you should automatically select one of those. However, depending on the projector, its brightness rating, and the content, ProjectorCentral"s tests suggest there can be trade-offs in perceived contrast or color accuracy that may come into play with 3-chip LCD projectors. ProjectorCentral"s investigation "ANSI Lumens vs Color Light Output: The Debate between LCD and DLP" takes a close look at this subject. There are also many other factors to consider when selecting a projector, such as the quality of signal processing and optics, and the overall cost just to name a few.

LCD can exhibit excellent blacks and contrast with enhancement techniques such as a dynamic iris and/or dynamic lamp or laser modulation. In particular, Epson"s UB (Ultra Black) technology is effective at improving the level of deep black and boosting contrast by using polarized filters to reduce the amount of stray light inside the light engine that would otherwise make its way to the screen.

By comparison, many of the 1-chip DLP projectors I"ve reviewed over the years have had black levels and contrast that lagged well behind the best LCoS and LCD projectors. Of course, this doesn"t mean that DLP projectors always have worse or poor contrast. A projector"s overall brightness rating also has an effect on contrast (brighter projectors typically have higher black levels), and as with LCD and LCoS, enhancements like a dynamic iris and/or dynamic light modulation can help a lot. Still, ProjectorCentral"s comparison reviews, which directly face-off similar, calibrated home-theater projectors in the same environment, often report better contrast in dark images with LCD and LCoS models compared to single-chip DLP projectors.

Along with inherently better contrast, another advantage of LCoS among the three technologies is the availability and relative affordability of native-4K resolution. JVC and Sony both offer LCoS projectors with native 4K (4096x2160) resolution for as little as $5,000 to $6,000. DLP with native-4K resolution is available only in digital-cinema and other super-high-end projectors, which run well into six figures, and LCD projectors are not available with native 4K or UHD resolution at all as of this writing (except for the one large-venue model from Epson mentioned earlier).

Some Epson LCD and JVC LCoS models offer two-phase pixel shifting with native 1080p (1920x1080) imagers, which puts 4.15 million pixels on the screen. This is not true UHD, which would require 8.3 million pixels to be delivered to the screen for each frame. However, many respected reviewers have reported that the image from these projectors is subjectively sharper than true 1080p, and that the difference between double-pixel-shifted 1080p and true UHD is minimal. Of course, here again, other factors, including the quality of the image processing and the lens optics, also come into play in these comparisons.

Many LCD, LCoS, and 3-chip DLP projectors offer a pixel-alignment function that lets users shift the red, green, and/or blue pixels by tiny amounts to correct an imperfect factory alignment. In some cases, you can even shift different zones within the image by different amounts.

Whether you"re shopping for a budget model for a dedicated home theater or an expensive state-of-the-art projector for a large-venue installation, cost is almost always a factor. The most expensive projectors today tend to be ultra-high-brightness LCD or 3-chip DLP, while LCD and 1-chip DLP tend to be the least-expensive options among digital projectors, with prices today starting as low as $250. However, the resolution of these models is typically less than 1080p, or they feature low-light LED engines, making them unsuitable for serious home theater.

Today, decent 1080p home-theater projectors typically start around $450 and go up from there. If you search by resolution and price in ProjectorCentral"s Find a Projector Database (which lists more than 11,000 current and past projectors), home-theater projectors in the $450 to $1,000 range are almost entirely dominated by 1-chip DLP models from several major brands, including BenQ, Optoma, ViewSonic, Acer, Vivitek, and others. Epson—the only major brand selling LCD projectors for home theater, is represented by a trio of Home Cinema series models in this price range starting at $649.

The lowest-cost UHD models are found in the $1,000 to $2,000 range and include both 1-chip DLP projectors with full UHD resolution (achieved with pixel-shifting) and 3-chip LCD projectors (the latter only from Epson) that have native 1080p imagers but are UHD-compliant and apply pixel-shifting to enhance apparent resolution. Here again, the vast majority are single-chip DLP models. Of course, there are much more expensive—and higher performance—1-chip DLP projectors in the marketplace that utilize the same pixel-shifting XPR technology found in the budget DLP models, though brighter projectors often feature the larger 0.66-inch DMD with native 2716x1528 resolution, which uses only two-phase TRP pixel-shifting instead of the four-phase XPR quadrupling required for the 0.47-inch, native-1080p DMD.

LCoS is generally more expensive than consumer-oriented LCD and 1-chip DLP, and as noted earlier, the home-theater market for this technology is dominated by just two manufacturers, JVC and Sony. The lowest-cost LCoS projector in the ProjectorCentral database is a Sony model with 1080p resolution that costs $1,999. JVC"s current LCoS models start with the $3,999 DLA-X790/RS540 model mentioned earlier (until it is phased out), which uses a 1080p imager with e-Shift dual pixel-shifting. Beyond these are native-4K models from both manufacturers, starting at $4,999 for Sony and $5,999 for JVC. Wolf Cinema also offers its own LCoS projectors based on JVC chassis, including native 4K models, starting at $15,000.

@Rob Sabin My pricing example was indeed a bit off. I think the €3000 to €6000 price range is becoming more important for consumers who are upgrading from the €1500 to €3000 price range. Although Epson did showcase their first 1.64 inch (HTPS) TFT 4096 x 2169 panel back in 2009, this market segment hasn’t really changed for true native 4K projector’s since the release of the Sony VPL285ES back in 2017. And it’s successor is also still priced at €4999. With the upcoming release of Epson’s new EB-L12000Q it is highly unlikely that the UB series are getting this kind of 4K panel or a scaled down version of it. I am waiting to see the next generation of Epson’s UB series with a higher resolution or sharpness, to fill the gap between the LCD forefront and the LCOS forefront currently dominated by JVC and Sony (for the consumer market).

There has been a lot of email asking for comments on a test recently published by Texas Instruments that examined the reliability of the DLP and LCD technologies. In essence, the test results seemed to indicate that DLP-based projectors deliver stable picture quality over their expected usable life, whereas LCD projectors may be expected to degrade over time. This has prompted two obvious questions: Was TI"s test valid? And should the results of the test be taken into consideration by consumers who are about to purchase a projector? This article will attempt to address these questions for readers who are concerned about it.

Last year Texas Instruments commissioned a lab test to compare the relative stability and longevity of the DLP and LCD technologies. The test commenced in May, 2002. Two DLP projectors and five LCD projectors were run 24 hours a day, 7 days a week for five months, with breaks only to change lamps as needed. During this time each projector was periodically measured for lumen output, contrast, uniformity, and color chromaticity for white, red, green, and blue.

Texas Instruments released the results of the test to the public in March, 2003. In summary, the test results indicated that the two DLP projectors used in the evaluation delivered stable contrast and color balance that remained relatively unchanged for over 4,000 hours of continuous operation. Meanwhile, the five LCD projector test units tended to shift color balance and lose contrast over time. Based on the judgment of TI personnel overseeing the test, the image quality of the LCD projectors eroded fairly rapidly, eventually degrading to the point of becoming subjectively "unacceptable." TI defined this unacceptable condition as the point at which TI believed the picture quality was sufficiently degraded that an average user would not be satisfied with it. The first LCD projector was judged to reach this unacceptable condition in just 1368 hours of operation. The remaining four units were said to have degraded to an unacceptable state in 2160, 2352, 3456, and 3456 hours respectively.

Other than to say that the five LCD models selected for the test were popular products in the marketplace at the time the test commenced in May, 2002, TI has not disclosed either the models or manufacturers of the LCD units. They did release some limited spec information as noted below. However some of the salient technical specifications that might reasonably be suspected to have a bearing on the outcome including specific size and weight of the units, and lamp type and wattage, was not disclosed.

Texas Instruments claims that the results of this test are evidence that DLP technology is superior to LCD when it comes to "picture reliability" over the projector"s anticipated lifetime. Picture reliability is defined by TI as the ability to maintain consistent image quality throughout the life of the projector.

The test was conducted at the facilities of the Munsell Color Science Laboratory in Rochester, NY. It was carried out in a dedicated 10 x 18 foot room. Eight projectors were operated essentially 24 hours per day, 7 days per week. These included the two DLP projectors and five LCD projectors already noted, plus an LCOS-based projector. The technical performance data pertaining to the LCOS machine was not included in the final report issued by TI since a sample of one is not sufficient to support any conclusions about the technology.

The two DLP and five LCD machines were portable-class machines. Six of the seven units (both DLPs and all but one of the LCDs) were XGA resolution. The fifth LCD unit was 16:9 format of unspecified resolution. The five LCD projectors consisted of three with 0.9" panels and two with 0.7" panels. The DLP units represented one each of 0.9" and 0.7" chips. Both DLP projectors were rated at 2000 ANSI lumens. The five LCDs had brightness ratings of 800, 1000, 1100, 2000, and 2000 ANSI lumens.

3. Color chromaticity remained stable on the DLPs, but significant changes were seen in the LCDs. There was a visible yellowing of the image on all the units, and some later developed a "blue blemish" as well.

4. The pattern of degradation was the same on all five LCD products tested. The degradation occurred first in the blue channel. TI"s theory is that the organic compounds in the polarizer and LCD panel were breaking down under exposure to high frequency blue and UV light. Eventually there are signs of breakdown in the red and green channels as well.

5. The first of the LCD projectors to fail was judged by TI personnel to have reached an unacceptable condition in 1368 hours of operation. Subsequent failure of the other four units occurred at 2160, 2352, 3456, and 3456 hours.

Based on these test results, TI suggests that a fundamental flaw exists in LCD technology that causes the picture quality it delivers to deteriorate well before the end of life of the projector itself might be expected. Because DLP technology is allegedly immune to degradation, it is purported to offer a lower cost-of-ownership since DLP projectors do not need to be replaced as often as LCD-based products.

While the test conducted by TI clearly highlights a failure mode in LCD panels and polarizers, the public must take care not to jump to the conclusion that the failure rates produced in the lab are in any way indicative of expected failure rates in the field. To the contrary, the statistical results in this test do not match up well with general marketplace experience.

To illustrate, let"s assume a typical three-hour per day usage on a portable projector. If it fails in just 1368 hours as one of the units did in this test, that translates to a usable lifespan of about 15 months. Taking it one step further, TI"s test results indicate that three of the five units (60% of the test population) failed in 2352 hours or less. If we were to use this data to predict the lifespan of LCD projectors in general, we would conclude that with a typical 3-hour per day usage, 60% of all LCD projectors sold would degrade into a condition unacceptable to the user in just a bit over two years.

This extrapolation is not credible. LCD is by far the most popular projector technology in the marketplace, outselling DLP worldwide by a factor of about three-to-one in the last 18 months. Major brand manufacturers including Epson, Panasonic, Sharp, and Sony have projector product lines either exclusively based upon LCD technology or heavily oriented toward it. These companies have outstanding reputations for quality and are not known for marketing products that routinely degrade to failure within a year or two.

Furthermore, the major LCD manufacturers do not have truckloads of bad units coming back from users and dealers. If they did, they would quickly discontinue those LCD product lines since the cost of warranty repair claims would be unbearable. Dealers would stop carrying them to avoid customer complaints, the cost of handling returned items, and the damage to their own reputations for having recommended faulty merchandise. None of this is happening. So there is no evidence that the failure rates documented in the test correspond in any realistic way to typical LCD performance in the field.

There is no doubt that a common failure mode appeared in all five LCD products in the test. We are confident that the measurements taken by Munsell Color Lab are reliable. We are also confident in TI"s representation that image quality on the LCD units in question degraded significantly in unusually short periods of time. The question is what could have caused this to occur? We believe some factor or combination of factors not present under typical usage was acting upon the units in the lab test, and that these factors accelerated failure rates to an alarming degree. We need to examine what those influences might have been. Possibilities include the following:

1. 24x7 operation. Clearly an obvious difference between the test environment and typical usage was 24x7 operation. The vast majority of LCD projectors sold are not deployed in 24x7 duty cycles. Constant round the clock operation is a high stress factor that contributes to a breakdown of compounds in the polarizers and panels if they are not properly cooled. Because of this projector manufacturers who build products intended for 24x7 operation typically use larger LCD panels, include comprehensive UV protection, and build them into larger form factors with substantial cooling systems that move large volumes of air. Units with this type of design were not included in the test.

2. Exclusive use of portables. When it comes to making any generalizations about LCD technology"s reliability, the test is inconclusive since it used portable units exclusively. Portable projectors by their nature are restricted in their ability to keep panels cool. They simply cannot move volumes of air without making a lot of noise which nobody wants. Thus internal operating temperatures in portables tend to be higher than those in larger LCD projectors. As designed they are not really intended to be deployed in round the clock operation. Yet the test was conducted using portables exclusively under 24x7 operation.

3. Higher than normal ambient temperatures. With heat management already known to be an issue in portable projectors, we believe the test would have been more indicative of real world results had ambient temperatures been maintained at 72 degrees rather than 77 degrees with periodic swings into the mid-80s. The ambient temperature has a direct impact on the efficiency of a projector"s cooling system. The hotter the panels and polarizers are, the more susceptible they will be to damage from high intensity light. By selecting products that already have limited cooling capacity, running them 24x7, and then adding a warmer than normal environment into the equation, it is possible that this combination of factors could account for rapid degradation not typically experienced in normal usage.

Manufacturers recognize that the organic compounds in LCD panels and polarizers are susceptible to high heat and light energy stress, and will eventually break down if deployed in high stress environments-in particular 24x7 operation with higher than normal ambient temperatures. Compact portable LCD projectors are in general not recommended for 24x7 duty cycles because of this.

On the other hand, DLP technology does not use organic compounds. Thus the elements which can be expected to degrade over time under high stress in an LCD projector do not exist in a DLP projector. Therefore when these two technologies are placed side-by-side in an unusually high stress environment as they were in this test, the DLP-based products should be more resistant to image shift over time. TI"s test demonstrated this in no uncertain terms.

Thus the generalized inference that many observers have drawn from the test data, which is that LCD technology itself may be expected to routinely break down under normal usage before the expected lifespan of the projector, is difficult to sustain based upon the limited sample size and the abnormal conditions we believe may have existed in the lab.

The test at Munsell Color Science Lab clearly draws attention to the fact that LCD technology has a failure mode that does not exist with DLP, and that this failure mode becomes readily apparent in an unusually high stress environment. What the test does not tell us is how much of a problem this really is in real life. In addition to the test results there is ancedotal evidence of LCDs eventually breaking down in extended use applications. When this occurs the problem is usually fixed by replacing the LCD panel and polarizer in the blue channel. But for the most part typical users of LCD projectors do not seem to experience either the severity of degradation or the rapidity with which it occurred in this particular lab test.

To explore this further a more comprehensive set of lab tests must be run. In order to generate test results that would more reliably predict the long term reliability of LCD and DLP technologies in the field, we would need to incorporate the following elements:

1. A wider array of both LCD and DLP products needs to be included in the sample. LCD machines featuring 1.3" and 1.8" glass must be included along with the smaller formats. SVGA and widescreen resolutions in both WSVGA and WXGA should be included. Furthermore a sample of two DLP units is not adequate to reveal potential long term failure modes that might exist with that technology as well.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey