taylored lcd tft display factory

Our custom display division provides a wealth of experience in the design and fabrication of custom display products. From LCD and TFT modules to Custom Display Solutions, we provide expert design and manufacturing services. Our high level of detail, technical capabilities, and creative problem-solving enable us to deliver tailored displays that meet the demands across several industries.

At Amulet Technologies, we make standard touchscreen LCD display hardware available worldwide. The standard hardware solutions we offer include smart modules, standard IPS TFT displays, controller boards, and chips. Transform your embedded product with one of our embedded hardware solutions today.

Amulet’s smart displays, known as GEMmodules™ are production ready, fully integrated GUI solutions that significantly reduce time-to-market for embedded product manufacturers. GEMmodules are compatible with our GEMstudio Pro™ software, so your GUI can be created with minimal time and effort. Amulet GEMmodules become the best graphical user interfaces with responsive touch, and can be updated and modified with little-to-no effort.

Our standard LCD product line consists of IPS TFT displays. In-plane-switchingtechnology is an improvement traditional TFT displays with enhanced features and more widespread usability. We also carry chips for color displays and universal LCD controller boards, all designed specifically to help you craft the best user interface for your product. Ultimately, our solutions will save you time and reduce your costs.

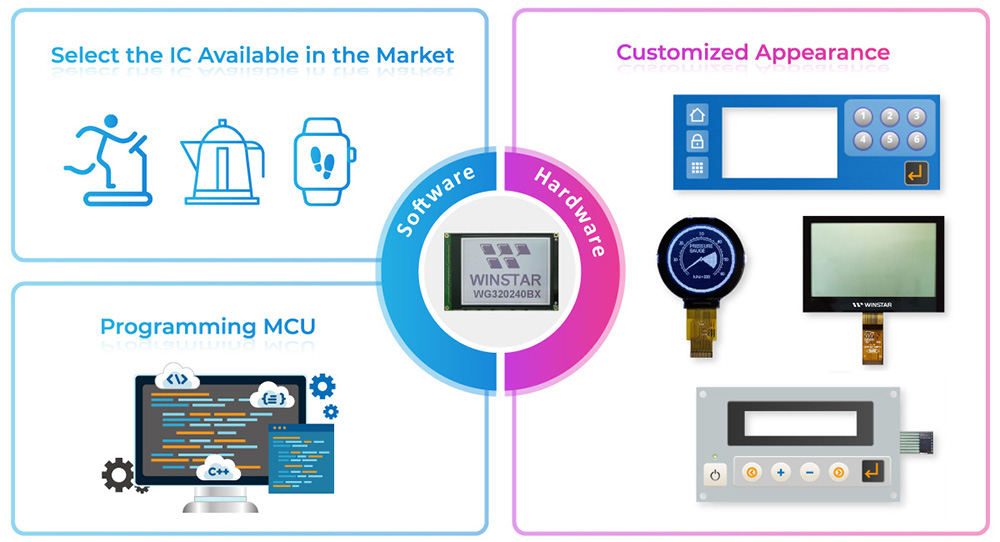

Except the available standard LCD/TFT/OLED display products, Winstar provides tailor made displays. The extensive portfolio makes it possible to create tailor-made solutions for customers to fit their application. We have the advanced display technologies available to use in your design and if there is anything you want to change about one of our existing LCD/TFT/OLED displays, we can make it happen. With more than 23 years experience, our sales and engineering team will be with you through the entire development process and will ensure the semi or fully customization a successful display tailored made to the individual application.

Our LCD/TFT/OLED custom design solutions are available in different options according to customer requirements. Winstar can offer various options on backlight type, pin and connector, cable, resistive touch screen (RTP) and projected capacitive (PCAP) touch screen or anti-reflective or anti-glare coating, or custom cover lens, ZIF PPC or customized PCB board or a fully custom solution for your product application, as well as System Integrated Solution.

One of the things that sets us apart from other touchscreen display manufacturers is the level of customization we offer. Our product portfolio includes a wide range of TFT & Monochrome LCDs, OLED, touch sensor and glass technologies, which we can provide stand-alone or integrated into complete assemblies.

Our custom display, touch and cover lens solutions are used in a variety of end-user applications. For example, our touchscreens are used in many vehicle infotainment systems and dashboard controls. We also provide custom touch displays for popular marine applications such as watercraft navigation screens and fish finders. For consumer electronics, we manufacture custom touchscreen display solutions and smartphone screen protectors. Whether your application will be used in the great outdoors, a construction site, or a hospital operating room, we can build a custom, all-in-one solution for your needs.

Our strength as a custom display company comes from the extensive technical expertise of our engineering team. The approach our engineers take is always based on experience and data-driven decisions that help you find the right solution for your application. In addition, our extensive manufacturing capabilities enable us to deliver quick design cycles, cost-effective solutions, and high-quality products that will meet your specifications even in the harshest conditions. To learn more about what makes us the display manufacturer for your needs, get in touch with us today.

Take your design to the next level with our range of TFT Displays including latest IPS TFT, circular and bar shape as well as large size TFT. With or without touch, these are fully customisable to your system requirements.

TFT-LCD technology is now fairly mature. As a result, manufacturing processes are efficient and production yields are high, leading to very competitive unit prices. Upgrading from a monochrome display to a TFT is now an affordable way to give your product an uplift.

Users of industrial display devices are wanting the same experience they have come to expect from a consumer device with all-round viewing angles. Switching to a superior IPS TFT display has become very cost effective as production increases and unit prices decrease.

Choosing a circular display for your next product design could really set you apart from your competition. Models are available from 1" to 4.2"in TFT, PMOLED and AMOLED, we have something to suit every application.

It is now possible to transform from a monochrome display to a colour display in space constrained systemsby using a letterbox shaped display. These ultra-wide displays are ideal for applications with restricted build height such as rack mount systems or landscape format front panels.

Large TFT display systems are increasingly being used for transportation information, retail signage and vending machines and kiosks. We can supply a large range of TFT solutions up to 65" diameter and in bar-style, square or rectangular configurations.

We are now offering increasing cover lens customisation options and processes to make your TFT LCD user interface truly stand out! Anders’ experienced marketers and engineers work with our manufacturing partners around the world to keep informed of the latest innovations, including mirrored glass,tinted glass, spot-facing, three dimension glass, and many more!

Here at Anders we don"t just strive to design a best in class display solution for your product, but we also want to make sure the display is driven with the right embedded system. We can help achieve a hardware solution that ensures your display works perfectly within your application. Hardware solutions include:

Get started quickly on your new user interface with our HMI development kits. The display, the processor and the OS work together out of the box with optimised QT GUI images. We"ll then optimise the kit to meet exactly your system requirements with our design services.

At Anders we understand that no two customers are the same, which is why we specialise in custom display solutionsand offer unique productstailored to your end application.

See below our range of TFT Displayswith sizes ranging from0.96" to 64.5" and including circular and bar type shape. All our displays can be tailored to suit your application antimicrobial coating technology,

We aim to offer reliable and long-term solutions to our B2B customers. If you are a business and would like to discuss your display and/or embedded system requirements please contact us below

A TFT display is a form of Liquid Crystal Display with thin film transistors for controlling the image formation. The TFT technology works by controlling brightness in red, green and blue sub-pixels through transistors for each pixel on the screen.

There are many display technologies, but do you know which one would be better for your application? Particularly when considering optimum viewing angle and contrast. We discuss 2 of the best options.

Compare IPS vs TFT displays - the TFT display is the display of choice for industrial designs, but it can have its limitations. A newer technology called IPS (in plane switching) offers better viewing angles and colours, but is it really the best choice - we discuss benefits and negatives of both types of TFT display.

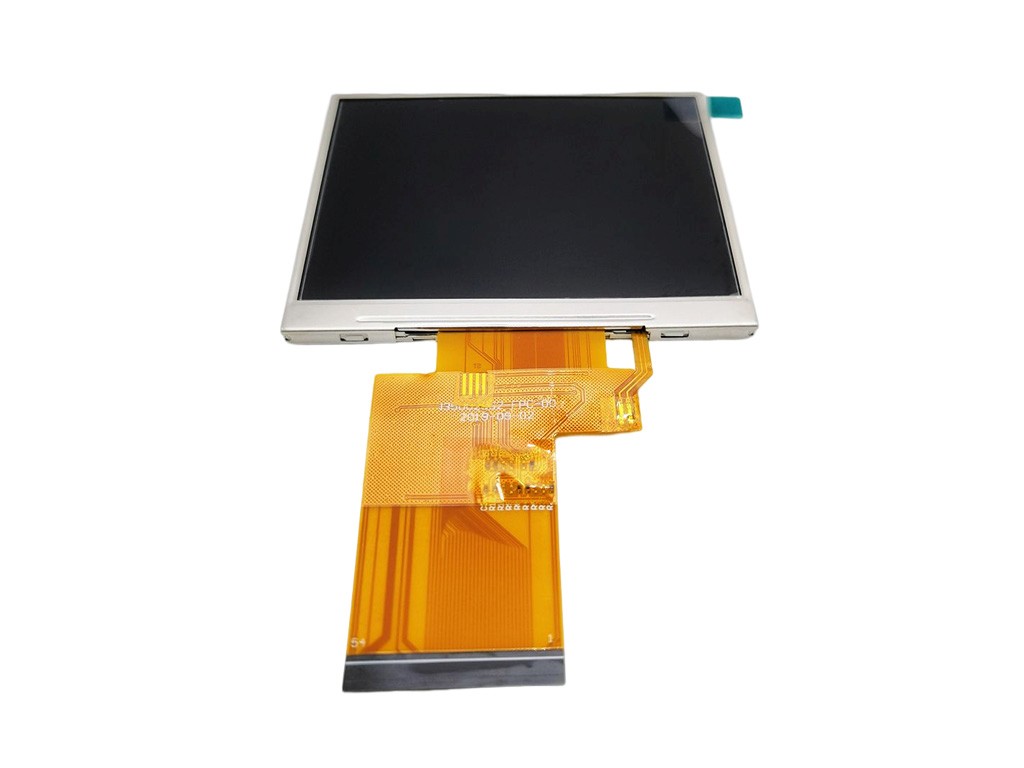

This 320x240 resolution LCD TFT is a standard display with 16-bit parallel interface and a 12:00 optimal view. This Liquid Crystal Display has a built-in SSD1963 controller. It is RoHS compliant and has a 4-wire resistive touchscreen.

Choose from a wide selection of interface options or talk to our experts to select the best one for your project. We can incorporate HDMI, USB, SPI, VGA and more into your display to achieve your design goals.

Equip your display with a custom cut cover glass to improve durability. Choose from a variety of cover glass thicknesses and get optical bonding to protect against moisture and debris.

This premium TFT LCD display has a 1024x600 resolution screen with MVA technology, which delivers higher contrast and improved viewing angles up to 75° from any direction. The 24-bit true color TFT display is RoHS compliant with RGB interface, and does not include a touchscreen.

Discontinued EOL Product: This display has been discontinued and will no longer be available for purchase after stock is gone, however an alternative option is available.

Choose from a wide selection of interface options or talk to our experts to select the best one for your project. We can incorporate HDMI, USB, SPI, VGA and more into your display to achieve your design goals.

Equip your display with a custom cut cover glass to improve durability. Choose from a variety of cover glass thicknesses and get optical bonding to protect against moisture and debris.

In ruling NY N320557 (August 4, 2021), Customs and Border Protection (CBP) discussed the country of origin of five Thin Film Transistor – Liquid Crystal Display (TFT-LCD) modules. All five modules are virtually identical in composition, as they are all composed of a TFT-LCD cell, polarizers, a backlight, a driver and control printed circuit board (PCB), and a flexible PCB for connection. TFT display technology allows for the construction of high-resolution LCD displays, and the modules – once completed – can be incorporated into a variety of consumers display applications.

The manufacturing process for the five modules is also identical. The process begins in Japan where the TFT-LCD cell is manufactured. The TFT is created by depositing transistors onto a substrate through chemical vapor deposition, while the color filter is manufactured by building a color matrix on a glass substrate. The creation process of the cells is then completed when a layer of liquid crystal is deposited between the color filter and TFT as the two part are bonded together, creating a sheet of TFT-LCD cells. As next steps, the sheet of cells is delivered to China to be cut into individual cells. The cut-up cells are then bonded to the printed circuit board assembly (PCBA) – which contains the driver and control circuity – before the polarizers, backlight, and flexible connection PCBA are attached.

CBP also established that “substantial transformation” takes place when a particular product “emerges from a process with a new name, character or use different from that possessed by the article prior to processing.” The agency explained that the completed TFT-LCD cell is what imparts the essential function of the module and that the manufacturing process in Japan is what renders the end-use of the product. Despite the assembly that took place in China, the process did not substantially transform the cell into a new and different article. As such, CBP determined that the country of origin of the five modules is Japan.

According to real LCD manufacturing conditions, the number of normal LCD panels exceeds greatly the number of defective LCD panels. Therefore, the normal PRs greatly outnumber the defective PRs. As a result, the collected data set for training would be imbalanced if a two-class classification approach is adopted, the SVM by Vapnik [4] for example, the class imbalance problem occurs.

In practice, in addition to the class imbalance problem, the LCD defect detection also suffers from another critical problem resulting from the absence of negative information. To facilitate the following problem description, the normal PR class and the defective PR class are defined as the positive class and negative class, respectively.

The main difference between a normal PR and a defective PR is that their appearances are apparently different, as can be observed from Figure 4. The color (or gray level) of a normal PR is nearly uniform, implying that the variation of the gray-level distribution of normal PRs is very small. On the contrary, the surfaces of defective PR not only contain various kinds of textures, but also vary greatly in color, implying that the variation of the true distribution for negative class in the data space is very large. Collecting a set of positive training data that can represent the true distribution of positive class is easy, because: (1) the variation of positive-class distribution is very small; and (2) most of the LCD panels are normal (the number of normal PRs is considerably large). Therefore, the positive class can be well-sampled during the data collection stage in real practice. However, representative defective PRs are difficult to obtain in practice for several reasons. For example, there are numerous types of defects in array process, more than 10 types at least. However, not all the defects would occur frequently. Some of the defects seldom appear, for example the defect caused by abnormal photo-resist coating (APRC). The defect “APRC” seldom occurs, because equipment/process engineers maintain the coating machines periodically. Even so, the coating machines might still break down occasionally. As a result, the number of available images containing the APRC defects is quite limited. But, the APRC defect has a large variation in color and texture. Unfortunately, limited APRC examples cannot stand for all kinds of APRC defects. Therefore, the collected negative training data are most likely under-sampled. Here, the “under-sampled” means that the collected negative training set cannot represent the true negative-class distribution in the data space, which is the problem of absence of negative information. Due to this problem, numerous false positive (i.e., missing defects) will be produced if a two-class classification approach (e.g., a binary SVM) is applied to the LCD defect detection, which has been evidenced by the results reported in [7]. Compared with two-class classification approach, novelty detection approach is a better choice.

Novelty detection is one-class classification [10,35], which is to solve the conventional two-class classification problems where one of the two classes is under-sampled, or only the data of one single class can be available for training [5,6,9–11,35–40]. As analyzed above, for the LCD defect detection application, the normal PRs can be well-sampled, while the defective PRs are in general undersampled. Therefore, the LCD defect detection can be treated as a typical novelty detection problem. Accordingly, one-class classification is a better solution.

To summarize, it can be seen that the LCD defect detection suffers from two problems simultaneously: one is the class imbalance problem, and the other is the problem of the absence of negative information. For the first problem, there have been many sophisticated solutions, including sampling, cost-sensitive learning, SVM-based, and one-class learning approaches. However, the only solution to the second problem is the novelty detection approach (i.e., one-class classification approach). Therefore, one-class classification would be a more appropriate approach to the LCD defect detection application.

There are several approaches for one-class classification, such as density approach (e.g., Gaussian mixture model [5]), boundary approach (e.g., SVDD [9] and one-class SVM [40]), neural network approach [6,36], and reconstruction-based approach (e.g., the kernel principal component analysis for novelty detection [35]). It has been proven in [9] that when a Gaussian kernel is used, the SVDD proposed by Tax and Duin [9] is identical to the one-class SVM proposed by Schölkopf et al. [40]. This paper focuses on the SVDD since it has been applied to the same application in the works of [7] and [10], and has shown to be effective in detecting defective PRs. However, as discussed in Section 1, generalization performance of SVDD is limited. Therefore, the intent of this paper is on proposing a method to improve generalization performance of SVDD, and applying the improved SVDD to the LCD defect detection treated as a novelty detection problem. The improved SVDD is called quasiconformal kernel SVDD (QK-SVDD). Note that the QK-SVDD and SVDD are not two independent classifiers. To obtain QK-SVDD, one has to train an SVDD first, which will be introduced in Section 2.4. In the following part of the paper, we first introduce the defect detection scheme, and then derive the proposed method in details.

TFT or thin-film transistor is combined with LCD to improve colour quality leading to a sharper image, as each pixel on a TFT-LCD is attached to a transistor. Due to the small sizes of each transistor, TFT-LCD display panels consume less power. They are widely used in computers, TVs, laptops, and mobile phones as it gives a more enhanced image than older technologies and prevents the distortion of image.

With the growing applications of TFT-LCD, there has been an increased competition among the manufacturers for the best cutting technology, i.e. ‘generations’, to produce TFT-LCD panels. In 2017, BOE, one of the major TFT-LCD manufacturers globally, put the world’s highest generation line, Generation 10.5 TFT-LCD production line, into production ahead of schedule in Hefei, China. With more Gen 10.5 facilities starting mass production, the market is primed for the production of 65 inches and larger TFT-LCD panels. More than 85.5% of the TFT-LCD display panels consumed in 2018 were large-sized panels sized over 10 inches.

Driven by the demand for TFT-LCD display panels in TV and monitor panels, the global shipment of large TFT-LCD panels grew again in 2018, despite over-supply concerns. The market is also driven by a rising demand for automotive displays. While automotive display systems were earlier reserved for luxury vehicles, cars for the mass-market are increasingly including high resolution display systems in their design due to a decline in prices along with the rising production and demand for automobiles. This growth in automotive displays has been supported by the rising investments in automotive display panels by big display panel manufacturers in Asia. The Asia Pacific countries like China and India are the fastest growing markets in the region due to rapid economic growth and a growing demand for consumer-based electronics. Currently, the global market for TFT-LCD display panel is dominated by North America.

Region-wise, the global market for TFT-LCD display panel can be divided into North America, Europe, the Asia Pacific, Latin America, and the Middle East and Africa.

The report also offers historical (2016-2020) and forecast (2021-2026) market information for the sizes, applications, and major regions of TFT-LCD display panel.

The major players in the global TFT-LCD display panel market are Samsung, LG Electronics Inc., Sharp Electronics Corporation, BOE Technology Group Co., Ltd., and AU Optronics Corp, among others. The comprehensive report by EMR looks into the market share, capacity, and latest developments like mergers and acquisitions, plant turnarounds, and capacity expansions of the major players.

Our TFT line-up is characterized by long production lifetime, extended temperature range, backward compatibility and high flexibility for customization.

With our long experience within display technologies and deep knowledge of the demands in a wide variety of applications and environments you can trust that we will bring you a panel tailored to fit your needs.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey