crt tft lcd led oled and amoled quotation

"Between 0.0001 and 0.00001 nits" "Sony claims an OLED contrast range of 1,000,000:1. When I asked how the contrast could be so high I was told that the surface is SO black the contrast is almost infinite. If the number representing the dark end of the contrast scale is nearly zero then dividing that number into the brightest value results in a very, very high contrast ratio."

Does not normally occur at 100% brightness level. At levels below 100% flicker often occurs with frequencies between 60 and 255 Hz, since often pulse-width modulation is used to dim OLED screens.

No native resolution. Currently, the only display technology capable of multi-syncing (displaying different resolutions and refresh rates without the need for scaling).Display lag is extremely low due to its nature, which does not have the ability to store image data before output, unlike LCDs, plasma displays and OLED displays.

What are the key differences between leading electronic visual displays available in the market? Such are the times that we live in that today most of us cannot possibly imagine a life without an electronic device. In fact, we have managed to surround ourselves and depend on a growing number of electronic appliances. Several of these devices - as it happens - also have an electronic visual display; be it a mobile phone, a tablet, a desktop monitor or the television set. Without a doubt, these electronic screen devices have revolutionised the way we lead our lives now as all of the four devices have become increasingly commonplace to the point of becoming basic necessities. Which brings to our blog topic: what exactly is an electronic screen and which are the leading screen technologies available today? Read on to know more…

An electronic screen or an electronic visual display, informally called a screen, is basically a device used to display / present images, text, or video transmitted electronically, without creating a permanent record. As mentioned earlier, electronic visual displays include television sets, computer monitors, and digital signage in information appliances. As per the definition, an overhead projector (along with screen onto which the text, images, or video is projected) can also be called an electronic visual display.

1. Cathode Ray Tube (CRT) display:A vacuum tube containing one or more electron guns and a phosphorescent screen, the cathode-ray tube (CRT) is used to display images. It modulates, accelerates, and deflects electron beams onto the screen to make the images. The images could be electrical waveforms (oscilloscope), pictures (television, computer monitor) or radar targets. CRTs have also been used as memory devices, wherein the visible light from the fluorescent material (if any) does not really have any significant meaning to a visual observer, but the visible pattern on the tube face could cryptically represent the stored data. In television sets and computer monitors, the front area of the tube is scanned systematically and repetitively in a pattern called a raster. Thanks to the intensity of each of the three electron beams - one for each additive primary color (red, green, and blue) - being controlled with a video signal as a reference, an image is produced. In modern CRT monitors and TVs, magnetic deflection bends the beams; magnetic deflection is essentially a varying magnetic field generated by coils and driven by electronic circuits around the neck of the tube, although electrostatic deflection is often used in oscilloscopes, a type of electronic test instrument. CRT is one of the older screen/ display technologies.

2. Flat-Panel display: Flat-panel displays are electronic viewing technologies that are used to allow people to see content (still images, moving images, text, or other visual material) in a range of entertainment, consumer electronics, personal computer, and mobile devices, and several kinds of medical, transportation and industrial equipment. They are much lighter and thinner than traditional cathode ray tube (CRT) television sets and video displays and are typically less than 10 centimetres (3.9 in) thick. Flat-panel displays can be classified under two display device categories: volatile and static. Volatile displays need pixels to be periodically electronically refreshed to retain their state (say, liquid-crystal displays). A volatile display only shows an image when it has battery or AC mains power. Static flat-panel displays rely on materials whose color states are bistable (say, e-book reader tablets from Sony), and they retain the text or images on the screen even when the power is off. In recent times, flat-panel displays have almost completely replaced old CRT displays. Most flat-panel displays from the 2010s use LCD and/or LED technologies. Majority of the LCD screens are back-lit as color filters are used to display colors. Being thin and lightweight, flat-panel displays offer better linearity and have higher resolution than the average consumer-grade TV from the earlier decades. The highest resolution for consumer-grade CRT TVs was 1080i, whereas many flat-panels can display 1080p or even 4K resolution.

3. Plasma (P) display: A plasma display panel (PDP) is a type of flat panel display that uses small cells containing plasma; ionized gas that responds to electric fields. Earlier, plasma displays were commonly used in larger televisions (30 inches and larger). But since more than a decade now, they have lost almost all market share due to competition from low-cost LCDs and more expensive but high-contrast OLED flat-panel displays. Companies stopped manufacturing plasma displays for the United States retail market in 2014, and for the Chinese market in 2016.

4. Electroluminescent display (ELD):Electroluminescent Displays (ELDs) are screens that make use of electroluminescence. Electroluminescence (EL) is an optical and electrical phenomenon where a material emits light in response to an electric current passed through it, or to a strong electric field.

So ELD then is a kind of flat panel display produced by sandwiching a layer of electroluminescent material between two layers of conductors. When the current flows, the layer of material emits radiation in the form of visible light. Basically, electroluminescence works by exciting atoms by passing an electric current through them, leading them to emit photons. By varying the material being excited, the color of the light being emitted is changed. The actual ELD is built using flat, opaque electrode strips running parallel to each other, covered by a layer of electroluminescent material, followed by another layer of electrodes, running perpendicular to the bottom layer. This top layer has to be transparent so as to allow light to escape. At each intersection, the material lights, creating a pixel.

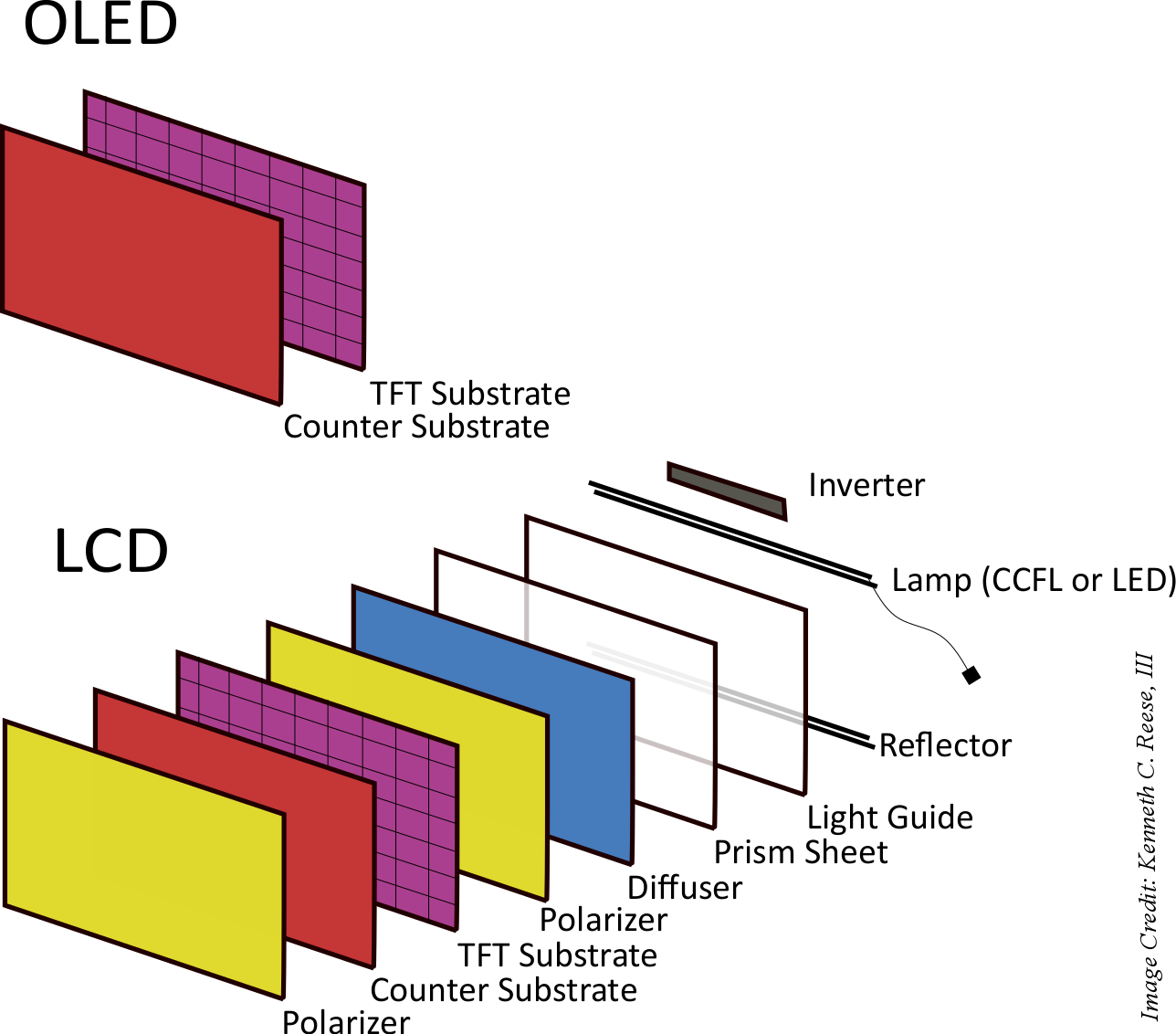

5. Liquid Crystal Display (LCD): A liquid-crystal display (LCD) is a flat-panel display or other electronically modulated optical device that makes use of the light-modulating properties of liquid crystals. Liquid crystals do not give out light directly; they use a backlight or reflector to create images in color or monochrome. LCDs display arbitrary images like in a general-purpose computer display or fixed images with low information content, that can be displayed or hidden, such as preset words, digits, and seven-segment displays, like in a digital clock. They use the same core technology, apart from the fact that arbitrary images are made up of a large number of small pixels, while other displays have larger elements. LCDs could be on (positive) or off (negative), as per the polarizer arrangement. For instance, a character positive LCD with a backlight has black lettering on a background the same color as the backlight, and a character negative LCD has a black background with the letters matching the backlight color. Blue LCDs typically get their characteristic appearance from optical filters being added to white.

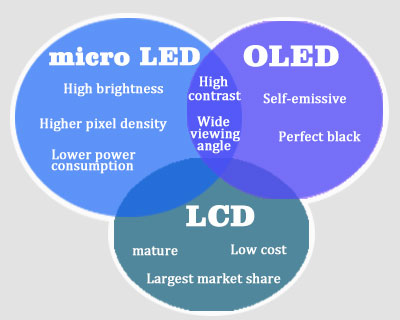

LCD screens are being used in several applications such as LCD televisions, computer monitors, instrument panels, aircraft cockpit displays, and indoor and outdoor signage. Small LCD screens are seen in portable consumer devices such as digital cameras, watches, calculators and mobile telephones, including smartphones. LCDs are also found in consumer electronics products such as DVD players, video game devices and clocks. It is interesting to note that these displays are available in a wide range of screen sizes as compared to CRT and plasma displays. Also, while LCD screens have replaced heavy, bulky cathode ray tube (CRT) displays in almost all applications, they are slowly being replaced by OLEDs, which can be easily made into different shapes, and boast other advantages such as having a lower response time, wider color gamut, virtually infinite color contrast and viewing angles, lower weight for a given display size and a slimmer profile and potentially lower power consumption. OLEDs, however, are more expensive for a given display size and they can suffer from screen burn-in when a static image is displayed on a screen for a long time (for instance, the table frame for an airline flight schedule on an indoor sign), not to mention that there is currently no way to recycle OLED displays. LCD panels, on the other hand, are susceptible to image persistence but they rarely suffer image burn-in as they do not use phosphors, plus they can be recycled, although this technology is not exactly common as yet. Not surprisingly, attempts have been made to increase the lifespan of LCDs in the form of quantum dot displays, which provide performance to that of an OLED display, but the Quantum dot sheet that gives these displays their characteristics can not yet be recycled. LCDs are also more energy-efficient and can be disposed of more safely than a CRT display.

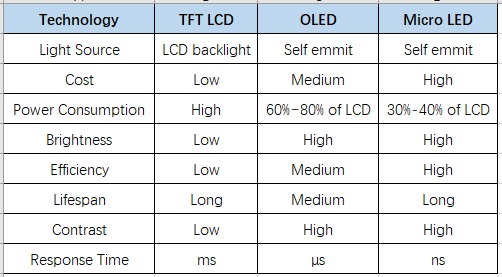

6. Light-Emitting Diode (LED) display:An LED display is a flat panel display that uses an array of light-emitting diodes as pixels for a video display. Their brightness lets them be used outdoors where they are visible in the sun for store signs and billboards. It was in 1962 that LED diodes first came into being; this was when the first practical LED was invented by General Electric’s Nick Holonyak Jr. This was also when they were mainly red in color. While the early models had a monochromatic design, the efficient Blue LED completing the color triad became available in the market only in the late 1980s. Today, large displays use high-brightness diodes to generate a wide spectrum of colors. In fact, recently, LEDs have also become a popular choice among destination signs on public transport vehicles and variable-message signs on highways. LED displays can offer general illumination in addition to visual display, as when used for stage lighting or other decorative (as opposed to informational) purposes. Several big corporations such as Apple, Samsung and LG are currently looking to develop MicroLED displays. These displays are easily scalable, and help with making the production process more streamlined. That said, production costs continue to be quite high and thus remain a limiting factor.

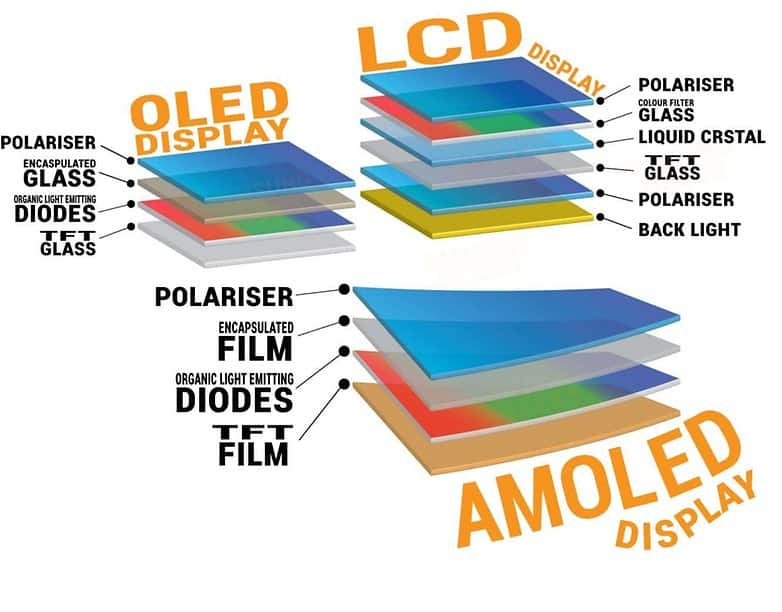

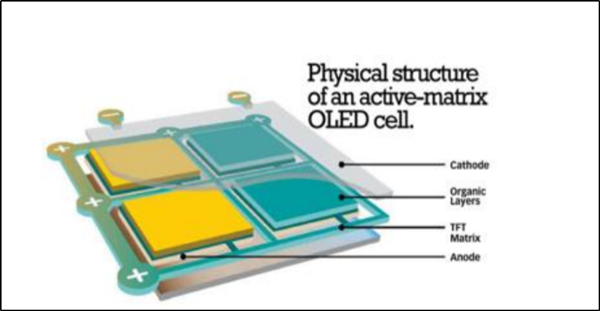

7. Organic Light-Emitting Diode OLED display: An organic light-emitting diode (OLED), also called an organic EL (organic electroluminescent) diode, is a light-emitting diode (LED), where the emissive electroluminescent layer is a film of organic compound that gives out light in response to an electric current. The organic layer is located between two electrodes, at least one of which is transparent. OLEDs are used to build digital displays in devices such as television screens, computer monitors, portable systems such as smartphones, handheld game consoles and digital assistants. Typically, an OLED display works without a backlight because it emits visible light. This means that it can display deep black levels and can be thinner and lighter than a liquid crystal display (LCD). In low ambient light conditions, say in a dark room, an OLED screen can achieve a higher contrast ratio than an LCD, irrespective of whether the LCD uses an LED backlight or cold cathode fluorescent lamps.

Also important to note an OLED display can be driven with a passive-matrix (PMOLED) or active-matrix (AMOLED) control scheme. In the former, each row (and line) in the display is controlled sequentially, one by one, as opposed to in the AMOLED where a thin-film transistor backplane is used to directly control and switch each individual pixel on or off, thus offering higher resolution and larger display sizes.

Lastly, there are two main families of OLED: those based on small molecules and those making use of polymers. A big area of research is the development of white OLED devices for use in solid-state lighting applications.

8. Active-Matrix Organic Light-Emitting Diode (AMOLED) display: AMOLED (Active-Matrix Organic Light-Emitting Diode) is a display device technology being used in smartwatches, mobile devices, laptops, televisions, media players and digital cameras. As mentioned earlier, it is a type of OLED; rather a specific type of thin-film-display technology where organic compounds form the electroluminescent material. What distinguishes it from PMOLED is the active matrix technology behind the addressing of pixels. An AMOLED display basically comprises an active matrix of OLED pixels generating light (luminescence) upon electrical activation that have been positioned or integrated onto a thin-film transistor (TFT) array, which in turn operates as a series of switches to control the current flowing to each individual pixel. AMOLED technology has continued to work towards consuming low power, becoming low-cost and offering scalability (mainly by offering larger sizes.

9. Super AMOLED display: Super AMOLED is essentially an AMOLED display but it is a term coined for marketing purposes by leading device manufacturers. It is used to denote AMOLED displays that come with an integrated digitizer, i.e. the layer that detects touch is integrated into the screen, instead of overlaid on top of it. The display technology however is not an improvement on the AMOLED. For instance, Samsung claims that Super AMOLED displays reflect one-fifth as much sunlight as the first generation AMOLED. In fact, Super AMOLED displays that are part of the Pentile matrix family, are also at times known as SAMOLED. Other variations of this term include Super AMOLED Advanced, Super AMOLED Plus, HD Super AMOLED, HD Super AMOLED Plus and Full HD Super AMOLED.

10. Quantum Dot (QD) display:A quantum dot display is a display device that uses quantum dots (QD), basically semiconductor nanocrystals that can generate pure monochromatic red, green, and blue light. Photo-emissive quantum dot particles are used in a QD layer which converts the backlight to give out pure basic colors that in turn enhance display brightness and color gamut by decreasing light loss and color crosstalk in RGB color filters. This technology is used in LED-backlit LCDs, though it applies to other display technologies as well (such as white or blue/UV OLED).

Among devices employing QD screens, one can find electro-emissive or electroluminescent quantum dot displays, which are currently an experimental type of display based on quantum-dot light-emitting diodes (QD-LED). These displays are similar to active-matrix organic light-emitting diode (AMOLED) and MicroLED displays, as in light is produced directly in each pixel by applying an electric current to inorganic nano-particles. QD-LED displays are supposed to support large, flexible displays and not degrade as readily as OLEDs, making them good bets for flat-panel TV screens, digital cameras, mobile phones and handheld game consoles. As of 2018, all commercial products like LCD TVs that use quantum dots and are called QLED, use photo-emissive particles, whereas electro-emissive QD-LED TVs are only to be found in laboratories today.

Gaspar, D. J. & Polikarpov, E. OLED Fundamentals: Materials, Devices, and Processing of Organic Light-Emitting Diodes. (Taylor & Francis Group, Boca Raton, FL, 2015).

Tull, B. R. et al. High brightness, emissive microdisplay by integration of III-V LEDs with thin film silicon transistors. SID Symp. Digest Tech. Papers46, 375–377 (2015).

Takeda, A. et al. A super-high image quality multi-domain vertical alignment LCD by new rubbing-less technology. SID Symp. Digest Tech. Papers29, 1077–1080 (1998).

Lee, S. H., Lee, S. L. & Kim, H. Y. Electro-optic characteristics and switching principle of a nematic liquid crystal cell controlled by fringe-field switching. Appl. Phys. Lett.73, 2881–2883 (1998).

Kim, H. J. et al. Optical efficiency enhancement in wide color gamut LCD by a patterned quantum dot film and short pass reflector. SID Symp. Digest Tech. Papers47, 827–829 (2016).

Soh, M. Y. et al. Design and characterization of micro-LED matrix display with heterogeneous integration of GaN and BCD technologies. IEEE Trans. Electron Devices66, 4221–4227 (2019).

Ahn, H. A., Hong, S. K. & Kwon, O. K. An active matrix micro-pixelated LED display driver for high luminance uniformity using resistance mismatch compensation method. IEEE Trans. Circuits Syst. II: Express Briefs65, 724–728 (2018).

Chaji, G. R. & Nathan, A. Parallel addressing scheme for voltage-programmed active-matrix OLED displays. IEEE Trans. Electron Devices54, 1095–1100 (2007).

Templier, F. et al. A novel process for fabricating high-resolution and very small pixel-pitch GaN LED microdisplays. SID Symp. Digest Tech. Papers48, 268–271 (2017).

Templier, F. et al. Advanced solutions for high-performance GaN MicroLED displays. Proceedings of SPIE 10918, Gallium Nitride Materials and Devices XIV. (SPIE, San Francisco, 2019).

Takita, Y. et al. Highly efficient deep-blue fluorescent dopant for achieving low-power OLED display satisfying BT.2020 chromaticity. J. Soc. Inf. Disp.26, 55–63 (2018).

Olivier, F. et al. Shockley-Read-Hall and Auger non-radiative recombination in GaN based LEDs: a size effect study. Appl. Phys. Lett.111, 022104 (2017).

Chen, S. M., Sun, X. W. & Kwok, H. S. Hybrid analog-digital driving method for high definition AMOLED. SID Symp. Digest Tech. Papers45, 1514–1517 (2014).

Hosoumi, S. et al. Ultra-wide color gamut OLED display using a deep-red phosphorescent device with high efficiency, long life, thermal stability, and absolute BT.2020 red chromaticity. SID Symp. Digest Tech. Papers48, 13–16 (2017).

Utsumi, Y. et al. Improved contrast ratio in IPS-Pro LCD TV by using quantitative analysis of depolarized light leakage from component materials. SID Symp. Digest Tech. Papers39, 129–132 (2008).

Hoffman, D. M., Stepien, N. N. & Xiong, W. The importance of native panel contrast and local dimming density on perceived image quality of high dynamic range displays. J. Soc. Inf. Disp.24, 216–228 (2016).

Guarnieri, G., Albani, L. & Ramponi, G. Minimum-error splitting algorithm for a dual layer LCD display—part I: background and theory. J. Display Technol.4, 383–390 (2008).

Guarnieri, G., Albani, L. & Ramponi, G. Minimum-error splitting algorithm for a dual layer LCD display—part II: implementation and results. J. Display Technol.4, 391–397 (2008).

Daly, S. et al. Viewer preferences for shadow, diffuse, specular, and emissive luminance limits of high dynamic range displays. SID Symp. Digest Tech. Papers44, 563–566 (2013).

Nishimura, J. et al. Super bright 8K LCD with 10,000 nit realized by excellent light-resistance characteristics of IGZO TFT backplane. SID Symp. Digest Tech. Papers51, paper 3.1 (2020).

Daly, S. & Feng, X. F. Bit-depth extension: overcoming LCD-driver limitations by using models of the equivalent input noise of the visual system. J. Soc. Inf. Display13, 51–66 (2005).

Guo, W. J. et al. The impact of luminous properties of red, green, and blue mini-LEDs on the color gamut. IEEE Trans. Electron Devices66, 2263–2268 (2019).

Kim, H. M. et al. Ten micrometer pixel, quantum dots color conversion layer for high resolution and full color active matrix micro-LED display. J. Soc. Inf. Disp.27, 347–353 (2019).

Chen, H. W. et al. Liquid crystal display and organic light-emitting diode display: present status and future perspectives. Light: Sci. Appl.7, 17168 (2018).

AU Optronics Corp. AUO Showcases Mini LED Backlit LCDs Across Diverse Verticals to Seize Smart Living Market Opportunities. https://www.auo.com/en-global/New_Archive/detail/News_Archive_Technology_190513 (2019).

Handschy, M. A., McNeil, J. R. & Weissman, P. E. Ultrabright head-mounted displays using LED-illuminated LCOS. Proceedings of SPIE 6224, Helmet- and Head-Mounted Displays XI: Technologies and Applications. (SPIE, Florida, 2006).

Zhang, L. et al. Monochromatic active matrix micro-LED micro-displays with >5,000 dpi pixel density fabricated using monolithic hybrid integration process. SID Symp. Digest Tech. Papers49, 333–336 (2018).

Fan, R., Zhang, X. N. & Tu, Z. T. Influence of ambient temperature on OLED lifetime and uniformity based on modified equivalent lifetime detection. J. Soc. Inf. Disp.27, 597–607 (2019).

Display device technology and performance is advancing at a remarkable pace. The design and manufacture of Liquid Crystal and Light Emitting Diode Displays that include touch screen layers is very demanding. These display components and assemblies can be characterized with Bristol Instruments non-contact thickness gauges to sub-micron accuracy.

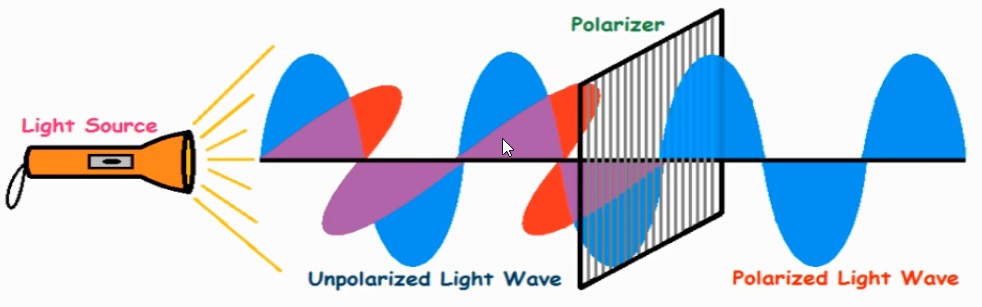

Firstly polarization, in this we will get to another terms which are polarized light and unpolarized light. So a polarized light wave is that light wave in which vibration occur in a single plane and an unpolarized light wave is that light wave in which vibration occur in more than one plane. Now let’s finally understand polarization. Polarization is a process of transforming unpolarized light wave into polarized light wave.

This is older technology which is not used today. In CRT monitors there was a cathode ray tube due to which it is called CRT monitors. It consists of the electron gun which emits electron on the phosphorous screen and with the help of it image is formed on the screen. The signals that is send from the video adapter reaches to the electronic gun through cables. There are three electronic guns for each RGB color Red, Green, and Blue. These three color mixes with each other and form other colors. The electrons beams emitted from the electronic gun can be focussed in different direction using magnetic force. So that it can reach on the whole screen and produce display. The electron beams when hit the phosphorus screen it produces Red, Green, and Blue colours. The CRT monitor was heavy, large and bulky in size. It consumes more energy. The disadvantage of this technology is that it emits radiations which are harmful for human eyes and health. Due to this reason the CRT monitor is now replaced with the LCD monitor.

The flat panel display replaced the CRT. The flat panel display takes small space as compare to the CRT. It is small in size and consumes less power. Now days mostly computer and laptops uses flat panel display. Flat panel display does not emit any harmful radiation. Flat panel display uses three types of technology:

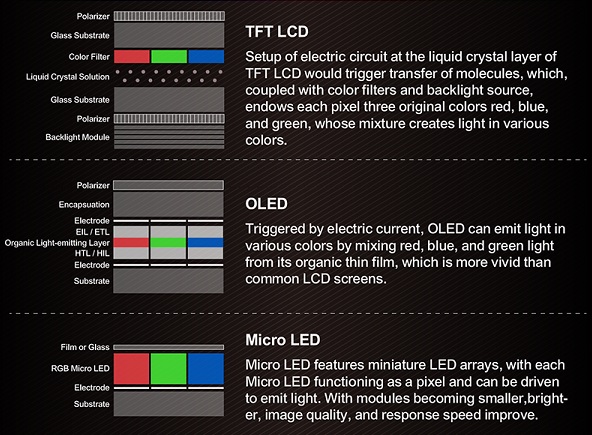

Now the first display panel type we have got is liquid crystal display or LCD it is a type of display panel that uses liquid crystals technologyalong with polarizers and a cold cathode fluorescent lamp as backlight to provide lightning. These liquid crystals do not emit light directly instead of it. They use a backlight or reflector to illuminate screen and produce image in colour or monochrome. The LCD works better in sunlight. The electricity passes through the liquid crystal and produce image.The color accuracy of the LCD is not very good. The LCD works on three things:

When light emits from source then the light wave vibrates in different direction in horizontal, vertical and diagonal. Then the polarization filters which are sheet of plastic which consists of vertical lines which are very near to each other. The important thing about filter is that when it is place in front of light then only vertical waves can pass through this filter. The horizontal waves are blocked by the filter. If we rotate this filter by 90 degree then this filter will block the vertical waves and pass the horizontal waves. Then we have liquid crystals which was discovered by an Australian scientist in 1888 which is state between the solid and liquid. The interesting thing about liquid crystal is that when the current is passes through it. The molecules changes its direction.

This type of LCD used active matrix technology which means that at every pixel transistor and capacitor is separately attached. The TFT contrast is better than LCD. But the disadvantage is that it consume more power due to which the battery timing of the mobile or laptop is minimum and also from the side the display view is not good. TFT technology is not available in the latest mobiles.

IPS LCD is the advanced form of the TFT technology the viewing angle and colour contrast is better than TFT. In IPS technology there are two transistors for each pixel and also the back light is maximum. It consumes less power as compare to TFT due to which it’s battery life is better than TFT.

The next display panel is light emitting diode or simply led. A led display panel also uses liquid crystal technology but instead of cold cathode fluorescent lamps as back lightning led display panel use an area of small light emitting diodes or LEDs as backlighting to illuminate the screen.

LED might seem like a new type of screen but in fact the LED is just an LCD screen but instead of using fluorescent light as the backlight it uses LEDs this gives the LED screen some new advantages for example it’s more energy efficient since LEDs consume less power also LED screens can be made very thinner than LCDs because they don’t have that bulky backlight. LEDs also have slightly more accurate colors than LCDs what’s also nice about LEDs is that black is slightly more black than on an LCD screen.

So the next display panel is organic light emitting diode or simply OLED. OLED display panel is made by putting a series of organic thin films between two conductors and when electric current is applied to this type of structure it emits a bright light unlike LCDS and LEDS.They don’t require backlight so they can be thinner and way lesser.So finally OLED uses an organic substance that glows when electric current is introduced and these displays can be thin and flexible too. Now to show something in OLED display it do not require all the display to turn on and only those pixel work which want to display something and other pixels will remain off. Due to which the black portion of the OLED display looks very good compare to LCD. It also consumes less power due to which the battery life will be good. The contrast ratio of OLED technology is better than LCD because the black pixels remain off. The disadvantage is that in sunlight its light is compromised and we may face problem in watching compare to an LCD display. LCD based phone is relatively cheaper than OLED display phone. The screen of the OLED display is very thinner because it does not need back light. Due to which OLED display phone is very thinner and more flexible than LCD phones. The very important benefit of it is that it is folded display. So we can decrease the phone size by folding the screen.

Now the next display panel is active matrix organic light emitting diode or simply AMOLED in AMOLED display panel. The first two words a and m refers to active and matrix respectively. The active matrix refers to the technology which is used for addressing pixels. AMOLED display panel uses a thin film transistor or TFT which contains a storage capacitor which maintains the line pixel states. So AMOLED display panel is a type of OLED which uses active matrix technology.The AMOLED is called active matrix because it consists of different layers for display formation. The anode layer is integrated with thin film transistor TFT which means it does not depend upon on the external circuit to glow the pixel.

Now the last display type we have got is super active matrix organic light emitting diode or simply assemble it as S-AMOLED is an AMOLED display which has an integrated touch function. So instead of having a layer which recognizes touches on top of screen that layer is embedded directly into screen assembly is a marketing term that is used by Samsung which refers to a display technology. Now you may be thinking what is the difference between S-AMOLED and AMOLED. So the term super make it distinguishable from its older version AMOLED and S-AMOLED are not only similar by name but also similar in function. The difference between them is the integrated touch function technology which S-AMOLED have and AMOLED have not. The super AMOLED is integrated with the touch sensor. As in the AMOLED we were used touch sensor digitizer which was integrated in the S-AMOLED due to which the thickness was decreased and due to removal of the touch sensor digitizer battery consumption is also decreased. In S-AMOLED light reflection is less as compare to the AMOLED. Both shares the same pixel arrangement

Steven Van Slyke and Ching Wan Tang pioneered the organic OLED at Eastman Kodak in 1979. The first OLED product was a display for a car stereo, commercialized by Pioneer in 1997. Kodak’s EasyShare LS633 digital camera, introduced in 2003, was the first consumer electronic product incorporating a full-color OLED display. The first television featuring an OLED display, produced by Sony, entered the market in 2008. Today, Samsung uses OLEDs in all of its smartphones, and LG manufactures large OLED screens for premium TVs. Other companies currently incorporating OLED technology include Apple, Google, Facebook, Motorola, Sony, HP, Panasonic, Konica, Lenovo, Huawei, BOE, Philips and Osram. The OLED display market is expected to grow to $57 billion in 2026.

AMOLED (Active Matrix Organic Light Emitting Diode) is a type of OLED display device technology. OLED is a type of display technology in which organic material compounds form the electroluminescent material, and active matrix is the technology behind the addressing of individual pixels.

An AMOLED display consists of an active matrix of OLED pixels generating light (luminescence) upon electrical activation that have been deposited or integrated onto a thin-film transistor (TFT) array, which functions as a series of switches to control the current flowing to each individual pixel.

Typically, this continuous current flow is controlled by at least two TFTs at each pixel (to trigger the luminescence), with one TFT to start and stop the charging of a storage capacitor and the second to provide a voltage source at the level needed to create a constant current to the pixel, thereby eliminating the need for the very high currents required for PMOLED.

TFT backplane technology is crucial in the fabrication of AMOLED displays. In AMOLEDs, the two primary TFT backplane technologies, polycrystalline silicon (poly-Si) and amorphous silicon (a-Si), are currently used offering the potential for directly fabricating the active-matrix backplanes at low temperatures (below 150 °C) onto flexible plastic substrates for producing flexible AMOLED displays. Brightness of AMOLED is determined by the strength of the electron current. The colors are controlled by the red, green and blue light emitting diodes. It is easier to understand by thinking of each pixel is independently colored, mini-LED.

IPS technology is like an improvement on the traditional TFT LCD display module in the sense that it has the same basic structure, but with more enhanced features and more widespread usability compared with the older generation of TN type TFT screen (normally used for low-cost computer monitors). Actually, it is called super TFT. IPS LCD display consists of the following high-end features. It has much wider viewing angles, more consistent, better color in all viewing directions, it has higher contrast, faster response time. But IPS screens are not perfect as their higher manufacturing cost compared with TN TFT LCD.

Utilizing an electrical charge that causes the liquid crystal material to change their molecular structure allowing various wavelengths of backlight to “pass-through”. The active matrix of the TFT display is in constant flux and changes or refreshes rapidly depending upon the incoming signal from the control device.

The current display technology standard for most PCs and TVs is LCD nowadays. However, LCD technology has significant and well known drawbacks, such as limited viewing angles, poor colours, motion blur and input lag. These problems cause some people to swear by and hold on to the old and now obsolete CRT monitors, as it had none of these problems (it did however, have lots of others). There are various types of LCD technology in mainstream use today which attempt to address these shortcomings, but none fix them all. For example, TN displays are cheap to buy, relatively fast which reduces motion smear and input lag, but at the expense of viewing angle and colour accuracy, making them suitable for fast gaming and animation. Meanwhile, IPS displays have the opposite characteristics, making them suitable for professional photographic work, where accurate colours and vibrant pictures are essential.

Now enter DuPont. They have wanted to bring AMOLED TVs to market for a good five years or so and they believe that they have cracked the problems. They have issued a press release stating that they are partnering with a "leading Asian manufacturer of Active Matrix Organic Light Emitting Diode (AMOLED) display products." but are mentioning no names just yet. Samsung would appear to be a leading candidate here and hopefully there will be products to show at CES 2012, given the timing of this announcement. If successful, AMOLED technology should quickly replace current LCD technology, with all its many compromises, in TVs and monitors.

LAN_deRf_HAIf they make mainstream OLED displays 6-8 bit we"re still going to have shitty colors aren"t we?But why would they? This low bit depth is due to the limitations of TN displays, so they won"t have to do this.

FordGT90ConceptThe big "if" is whether or not it is cost-competitive with TN. It isn"t going to sweep the market if it isn"t. Instead, it would likely replace IPS as "professional grade" (to steal GMC"s slogan).Oh yeah, I"ll bet the first products are going to have a very "premium" price and TN tech will continue. However, if it"s not too expensive to produce, then eventually it will be incorporated into lower and lower end products, as manufacturers try to outdo each other, to the point that LCD technology will be as obsolete the CRT it replaced. It"ll take time though, that"s for sure.

As with all new TV/monitor tech, it"ll be insanely expensive for the first year, then dirt cheap within 5 years. Hopefully it won"t go the same way as LCD did when it got cheap. Meaning, it also got very cheaply made.

did they solve the blue color "pigment" durability issues? i"d really fu*king LOVE an full HD OLED display but if it would become redder and dimmer over the years or simply fade like plasma tv"s...

Damn this is great news! Samsung as really popularized AMOLED recently, so I think that that will help the integration of i\t in the TV market. Hopefully the integration will be as smooth as the LED backlight LCD TVs

NC37As with all new TV/monitor tech, it"ll be insanely expensive for the first year, then dirt cheap within 5 years. Hopefully it won"t go the same way as LCD did when it got cheap. Meaning, it also got very cheaply made.IPS is over 10 years old and it still isn"t cheap.

I swear my old samsung Jet (S8000) uses an AMOLED screenSmall cell phone screens have been around for ages, sure, but this will be the first time there"s ever been an AMOLED television available to consumers.FordGT90ConceptIPS is over 10 years old and it still isn"t cheap.eIPS is starting to get there. You can find the U2211h for $200 and the U2412h for $300. Maybe not quite into TN territory, but entirely reasonable.

qubitcan be hard to view in direct sunlightthat is not true, in fact i have a Samsung Galaxy S Epic 4G which uses Super AMOLED and i also have a Motorola Droid Milestone which uses a TFT display and a Laptop with glossy display

also, the way Super AMOLED is made is it lets more light through so that should save battery because it doesn"t need to have high brightness to be viewable

www.youtube.com/watch?v=E_vPxDDpMWgqubitand it"s serviceable lifetime is relatively short, so it can"t be commercialised easily for large displays such as TVs and monitors. Hence, to this date, AMOLED displays tend to be found in small gadgets, such as smartphones, where these issues are much less of a problem.again, the problem has been fixed by Super AMOLED

raclimjathat is not true, in fact i have a Samsung Galaxy S Epic 4G which uses Super AMOLED and i also have a Motorola Droid Milestone which uses a TFT display and a Laptop with glossy display

also, the way Super AMOLED is made is it lets more light through so that should save battery because it doesn"t need to have high brightness to be viewable

in fact, samsung is constantling improving the AMOLED by introducing Super AMOLED PLUS and Super AMOLED HDThanks for the info, lots to read here. :) I got that statement from the article, so perhaps they weren"t quite correct, lol.IsenstaedtDoes AMOLED requires interpolation like LCDs?It shouldn"t do, but don"t quote me.

The world of mobile display technology is divided between those who prefer AMOLED screens and those who prefer LCD screens. OLED technology, closely related to AMOLED displays, is available on specific mobile devices. Since the two are based on fundamentally different technologies, distinct manufacturers will promote different advantages for their chosen display technology, AMOLED or LCD. AMOLED displays are becoming the standard for smartphones, whereas LCD screens are often kept for budget models.

First, let’s talk about AMOLED, similar to OLED displays but has a few more bells and whistles. One must be familiar with each of its three parts to grasp it fully. LED, short for “Light Emitting Diode,” is the first. The “O” in OLED refers to “organic,” which describes the material used to construct the device.

To put it another way, each LED has two conductors in which organic material is inserted to assist generate light. And the “AM” in AMOLED stands for Active Matrix, which may improve a pixel’s quality. High brightness and sharpness, improved battery life, accurate colour reproduction, etc., are all features shared by the AMOLED and OLED displays. A capacitor connects each LED in an AMOLED display to a thin film transistor (TFT).

TFT is used to control each pixel in an AMOLED screen. There are probably many benefits to this presentation, but because there are also some drawbacks, I’ll mention them.

The benefits of using best AMOLEDscreen include a higher contrast ratio and more vibrant colours, which contribute to a more satisfying video-viewing experience. Individual pixels may be activated or deactivated thanks to the included LEDs. The pixels in the black area of the picture will be disabled, revealing the most accurate black possible.

The use of individual LEDs improves the efficiency of the display. You may notice an increase in battery life as a result of the fact that specific pixels aren’t using any power at all.

LCD stands for “Liquid Crystal Display,” and its colour output differs from that of an AMOLED screen. Instead of employing separate LED lights for every pixel, an LCD screen has its own built-in backlight.

A backlight and colour filter are necessary components of every LCD panel, as we’ve discussed. A polarizer and a matrix of thin-film transistors are required stops for the backlight on its way to the display. This means that the whole screen will be illuminated, yet only a little amount of light will really reach the viewer. This is the main distinction between AMOLED and LCD, the two most common types of electronic displays now available.

Liquid crystal displays (LCDs) have lower production costs than AMOLEDs since they need less expensive light sources. LCD screens are also often seen in low-priced cell phones.

LCDs’ whites are so luminous because the backlight pumps so much illumination into each pixel that text on these screens can be read even in direct sunlight. Aside from that, it displays “Accurate True to Life” colours, which are most faithful to how things seem in the real world.

LCDs also provide the widest field of vision. This may be dependent on the kind of smartphone you use. However, most modern LCD screens have wide viewing angles with little colour shifting or distortion.

There are benefits and drawbacks to each of these presentation methods. Putting those aside, everything comes down to user choice, as different individuals have different tastes in colour schemes and contrast ratios. However, there are a few considerations that may aid you in selecting the one that is most suited to your needs.

Let’s talk about the cost to begin. The cost of a smartphone with an AMOLED screen is often higher than that of a smartphone with an LCD screen. This, is despite the fact that the tide is beginning to turn. Even still,thebest AMOLED screen of sufficient quality are now available on only the most expensive flagship handsets. AMOLED screens also provide very crisp and vivid colours. Additionally, they surpass the visual quality of any LCD screen. Compared to an LCD, an AMOLED screen isn’t nearly as bright. Therefore, an LCD screen performs much better when used in the open air.

Finally, we look at battery life, and no other display technology comes close to AMOLEDs in this regard. All modern smartphones include a “Dark Mode,” where the screen and app icons are black. There is no need for additional lighting while using this dark user interface, which is great for smartphones with AMOLED screens.

AMOLED screens are superior to LCD displays when compared using these criteria. In addition, major display original equipment manufacturers (OEMs) like Samsung and LG emphasise OLED technology for their next endeavours. Therefore, it is prudent to keep an eye out for AMOLED screens. However, if we witness more LCD technology improvements in battery economy and more, there is no need to cancel them at this time.

Alibaba.com offers 1621 amoled display module products. About 52% % of these are oled/e-paper modules, 39%% are lcd modules, and 3%% are mobile phone lcds.

A wide variety of amoled display module options are available to you, such as advertising publish, retail store and display of dishes.You can also choose from video wall, amoled display module,As well as from sdk, {2}, and {3}. And whether amoled display module is datasheet, photo, or {3}.

LCD (Liquid Crystal Display) is a type of flat panel display which uses liquid crystals in its primary form of operation. LEDs have a large and varying set of use cases for consumers and businesses, as they can be commonly found in smartphones, televisions, computer monitors and instrument panels.

LCDs were a big leap in terms of the technology they replaced, which include light-emitting diode (LED) and gas-plasma displays. LCDs allowed displays to be much thinner than cathode ray tube (CRT) technology. LCDs consume much less power than LED and gas-display displays because they work on the principle of blocking light rather than emitting it. Where an LED emits light, the liquid crystals in an LCD produces an image using a backlight.

A display is made up of millions of pixels. The quality of a display commonly refers to the number of pixels; for example, a 4K display is made up of 3840 x2160 or 4096×2160 pixels. A pixel is made up of three subpixels; a red, blue and green—commonly called RGB. When the subpixels in a pixel change color combinations, a different color can be produced. With all the pixels on a display working together, the display can make millions of different colors. When the pixels are rapidly switched on and off, a picture is created.

The way a pixel is controlled is different in each type of display; CRT, LED, LCD and newer types of displays all control pixels differently. In short, LCDs are lit by a backlight, and pixels are switched on and off electronically while using liquid crystals to rotate polarized light. A polarizing glass filter is placed in front and behind all the pixels, the front filter is placed at 90 degrees. In between both filters are the liquid crystals, which can be electronically switched on and off.

LCDs are made with either a passive matrix or an active matrix display grid. The active matrix LCD is also known as a thin film transistor (TFT) display. The passive matrix LCD has a grid of conductors with pixels located at each intersection in the grid. A current is sent across two conductors on the grid to control the light for any pixel. An active matrix has a transistor located at each pixel intersection, requiring less current to control the luminance of a pixel. For this reason, the current in an active matrix display can be switched on and off more frequently, improving the screen refresh time.

Some passive matrix LCD’s have dual scanning, meaning that they scan the grid twice with current in the same time that it took for one scan in the original technology. However, active matrix is still a superior technology out of the two.

Twisted Nematic (TN)- which are inexpensive while having high response times. However, TN displays have low contrast ratios, viewing angles and color contrasts.

LCDs are now being outpaced by other display technologies, but are not completely left in the past. Steadily, LCDs have been being replaced by OLEDs, or organic light-emitting diodes.

OLEDs use a single glass or plastic panels, compared to LCDs which use two. Because an OLED does not need a backlight like an LCD, OLED devices such as televisions are typically much thinner, and have much deeper blacks, as each pixel in an OLED display is individually lit. If the display is mostly black in an LCD screen, but only a small portion needs to be lit, the whole back panel is still lit, leading to light leakage on the front of the display. An OLED screen avoids this, along with having better contrast and viewing angles and less power consumption. With a plastic panel, an OLED display can be bent and folded over itself and still operate. This can be seen in smartphones, such as the controversial Galaxy Fold; or in the iPhone X, which will bend the bottom of the display over itself so the display’s ribbon cable can reach in towards the phone, eliminating the need for a bottom bezel.

QLED stands for quantum light-emitting diode and quantum dot LED. QLED displays were developed by Samsung and can be found in newer televisions. QLEDs work most similarly to LCDs, and can still be considered as a type of LCD. QLEDs add a layer of quantum dot film to an LCD, which increases the color and brightness dramatically compared to other LCDs. The quantum dot film is made up of small crystal semi-conductor particles. The crystal semi-conductor particles can be controlled for their color output.

When deciding between a QLED and an OLED display, QLEDs have much more brightness and aren’t affected by burn-in. However, OLED displays still have a better contrast ratio and deeper blacks than QLEDs.

An LCD or liquid crystal display is a type of flat panel display commonly used in digital devices, for example, digital clocks, appliance displays, and portable computers.

A simple monochrome LCD display has two sheets of polarizing material with a liquid crystal solution sandwiched between them. Electricity is applied to the solution and causes the crystals to align in patterns. Each crystal, therefore, is either opaque or transparent, forming the numbers or text that we can read.

In 1962, RCA researcher Richard Williams generated stripe patterns in a thin layer of liquid crystal material by the application of a voltage. This effect is based on an electrohydrodynamic instability forming what is now called “Williams domains” inside the liquid crystal.

According to the IEEE, “Between 1964 and 1968, at the RCA David Sarnoff Research Center in Princeton, New Jersey, a team of engineers and scientists led by George Heilmeier with Louis Zanoni and Lucian Barton, devised a method for electronic control of light reflected from liquid crystals and demonstrated the first liquid crystal display. Their work launched a global industry that now produces millions of LCDs.”

Heilmeier’s liquid crystal displays used what he called DSM or dynamic scattering method, wherein an electrical charge is applied which rearranges the molecules so that they scatter light.

The DSM design worked poorly and proved to be too power hungry and was replaced by an improved version, which used the twisted nematic field effect of liquid crystals invented by James Fergason in 1969.

Inventor James Fergason holds some of the fundamental patents in liquid crystal displays filed in the early 1970s, including key US patent number 3,731,986 for “Display Devices Utilizing Liquid Crystal Light Modulation”

In 1972, the International Liquid Crystal Company (ILIXCO) owned by James Fergason produced the first modern LCD watch based on James Fergason’s patent.

Liquid crystal refers to the intermediate status of a substance between solid (crystal) and liquid. When crystals with a high level of order in molecular sequence are melted, they generally turn liquid, which has fluidity but no such order at all. However, thin bar-shaped organic molecules, when they are melted, keep their order in a molecular direction although they lose it in molecular positions. In the state in which molecules are in a uniform direction, they also have refractive indices, dielectric constants and other physical characteristics similar to those of crystals, depending on their direction, even though they are liquid. This is why they are called liquid crystal. The diagram below shows the structure of 5CB (4-pentyl-4’-Cyanobiphenyl) as an example of liquid crystal molecules.

A liquid crystal display (LCD) has liquid crystal material sandwiched between two sheets of glass. Without any voltage applied between transparent electrodes, liquid crystal molecules are aligned in parallel with the glass surface. When voltage is applied, they change their direction and they turn vertical to the glass surface. They vary in optical characteristics, depending on their orientation. Therefore, the quantity of light transmission can be controlled by combining the motion of liquid crystal molecules and the direction of polarization of two polarizing plates attached to the both outer sides of the glass sheets. LCDs utilize these characteristics to display images.

An LCD consists of many pixels. A pixel consists of three sub-pixels (Red/Green/Blue, RGB). In the case of Full-HD resolution, which is widely used for smartphones, there are more than six million (1,080 x 1,920 x 3 = 6,220,800) sub-pixels. To activate these millions of sub-pixels a TFT is required in each sub-pixel. TFT is an abbreviation for “Thin Film Transistor”. A TFT is a kind of semiconductor device. It serves as a control valve to provide an appropriate voltage onto liquid crystals for individual sub-pixels. A TFT LCD has a liquid crystal layer between a glass substrate formed with TFTs and transparent pixel electrodes and another glass substrate with a color filter (RGB) and transparent counter electrodes. In addition, polarizers are placed on the outer side of each glass substrate and a backlight source on the back side. A change in voltage applied to liquid crystals changes the transmittance of the panel including the two polarizing plates, and thus changes the quantity of light that passes from the backlight to the front surface of the display. This principle allows the TFT LCD to produce full-color images.

After over 120 years of research in liquid crystals, a large number of liquid crystal phases have been discovered. Liquid crystal phases have a range of different structures, but all have one thing in common: they flow in a similar way to viscous liquids, but show the physical behavior of crystals. Their appearance depends on various criteria, including molecular structure and temperature, as well as their concentration and the solvent.

A crystal can be described using a coordinate system. Each atom of a molecule has its specific position. The structure of a crystal can be reduced to a tiny unit, the primitive cell, which is repeated periodically in all three dimensions. This periodicity describes the long-range order of a crystal. A crystal is a highly ordered system in which the physical properties have different characteristics according to the viewing angle. This is called anisotropy. The properties of a liquid crystal phase are also anisotropic, although the structure can no longer be described in a coordinate system. The periodicity and thus the long-range order are lost. Molecules orient themselves by their neighboring molecules, so that only short-range order can be observed. In contrast, a liquid is a completely disordered system, in which the physical properties are isotropic, i.e. directionally independent. What a liquid crystal phase and a liquid have in common is fluidity.

In LCD technology, the thermotropic nematic phase is by far the most significant phase. It is formed from rod-shaped (calamitic) molecules that arrange themselves approximately parallel to each other. These molecules can also form smectic phases, which exist in multiple manifestations. Smectic phases are more ordered than nematic phases: as well as the parallel alignment of the molecules, they also form layers.

As the temperature rises, the order of a system decreases. The temperature at which a liquid crystal phase is converted to the isotropic liquid is called the clearing point. A substance may form one or more liquid crystal phases if the structural conditions allow this. However, the appearance of liquid crystal phases is not necessarily a consequence of the molecular structure.

Low-temperature polycrystalline silicon (or LTPS) LCD—also called LTPS TFT LCD—is a new-generation technology product derived from polycrystalline silicon materials. Polycrystalline silicon is synthesised at relatively low temperatures (~650°C and lower) as compared to traditional methods (above 900°C).

Standard LCDs found in many consumer electronics, including cellphones, use amorphous silicon as the liquid for the display unit. Recent technology has replaced this with polycrystalline silicon, which has boosted the screen resolution and response time of devices.

Row/column driver electronics are integrated onto the glass substrate. The number of components in an LTPS LCD module can be reduced by 40 per cent, while the connection part can be reduced by 95 per cent. The LTPS display screen is better in terms of energy consumption and durability, too.

LTPS LCDs are increasingly becoming popular these days. These have a high potential for large-scale production of electronic devices such as flat-panel LCD displays or image sensors.

LCD or AMOLED, 1080p vs 2K? There are plenty of contentious topics when it comes to smartphone displays, which all have an impact on the day to day usage of our smartphones. However, one important topic which is often overlooked during analysis and discussion is the type of backplane technology used in the display.

Display makers often throw around terms like A-Si, IGZO, or LTPS. But what do these acronyms actually mean and what’s the impact of backplane technology on user experience? What about future developments?

For clarification, backplane technology describes the materials and assembly designs used for the thin film transistors which drive the main display. In other words, it is the backplane that contains an array of transistors which are responsible for turning the individual pixels on and off, acting therefore as a determining factor when it comes to display resolution, refresh rate, and power consumption.

Examples of backplane technology include amorphous silicon (aSi), low-temperature polycrystalline silicon (LTPS) and indium gallium zinc oxide (IGZO), whilst LCD and OLED are examples of light emitting material types. Some of the different backplane technologies can be used with different display types, so IGZO can be used with either LCD or OLED displays, albeit that some backplanes are more suitable than others.

Amorphous silicon has been the go-to material for backplane technology for many years, and comes in a variety of different manufacturing methods, to improve its energy efficiency, refresh speeds, and the display’s viewing angle. Today, a-Si displays make up somewhere between 20 and 25 percent of the smartphone display market.

For mobile phone displays with a pixel density lower than 300 pixels per inch, this technology remains the preferable backplane of choice, mainly due to its low costs and relatively simple manufacturing process. However, when it comes to higher resolution displays and new technologies such as AMOLED, a-Si is beginning to struggle.

AMOLED puts more electrical stress on the transistors compared with LCD, and therefore favours technologies that can offer more current to each pixel. Also, AMOLED pixel transistors take up more space compared with LCDs, blocking more light emissions for AMOLED displays, making a-Si rather unsuitable. As a result, new technologies and manufacturing processes have been developed to meet the increasing demands made of display panels over recent years.

LTPS currently sits as the high-bar of backplane manufacturing, and can be spotted behind most of the high end LCD and AMOLED displays found in today’s smartphones. It is based on a similar technology to a-Si, but a higher process temperature is used to manufacture LTPS, resulting in a material with improved electrical properties.

LTPS is in fact the only technology that really works for AMOLED right now, due to the higher amount of current required by this type of display technology. LTPS also has higher electron mobility, which, as the name suggests, is an indication of how quickly/easily an electron can move through the transistor, with up to 100 times greater mobility than a-Si.

For starters, this allows for much faster switching display panels. The other big benefit of this high mobility is that the transistor size can be shrunk down, whilst still providing the necessary power for most displays. This reduced size can either be put towards energy efficiencies and reduced power consumption, or can be used to squeeze more transistors in side by side, allow for much greater resolution displays. Both of these aspects are becoming increasingly important as smartphones begin to move beyond 1080p, meaning that LTPS is likely to remain a key technology for the foreseeable future.

The drawback of LTPS TFT comes from its increasingly complicated manufacturing process and material costs, which makes the technology more expensive to produce, especially as resolutions continue to increase. As an example, a 1080p LCD based on this technology panel costs roughly 14 percent more than a-Si TFT LCD. However, LTPS’s enhanced qualities still mean that it remains the preferred technology for higher resolution displays.

Currently, a-Si and LTPS LCD displays make up the largest combined percentage of the smartphone display market. However, IGZO is anticipated as the next technology of choice for mobile displays. Sharp originally began production of its IGZO-TFT LCD panels back in 2012, and has been employing its design in smartphones, tablets and TVs since then. The company has also recent shown off examples of non-rectangular shaped displays based on IGZO. Sharp isn’t the only player in this field — LG and Samsung are both interested in the technology as well.

The area where IGZO, and other technologies, have often struggled is when it comes to implementations with OLED. ASi has proven rather unsuitable to drive OLED displays, with LTPS providing good performance, but at increasing expense as display size and pixel densities increase. The OLED industry is on the hunt for a technology which combines the low cost and scalability of a-Si with the high performance and stability of LTPS, which is where IGZO comes in.

One of IGZO’s other benefits is that it is highly scalable, allowing for much higher resolution displays with greatly increased pixel densities. Sharp has already announced plans for panels with 600 pixels per inch. This can be accomplished more easily than with a-Si TFT types due to the smaller transistor size.

Higher electron mobility also lends itself to improved performance when it comes to refresh rate and switching pixels on and off. Sharp has developed a method of pausing pixels, allowing them to maintain their charge for longer periods of time, which again will improve battery life, as well as help create a constantly high quality image.

Smaller IGZO transistors are also touting superior noise isolation compared to a-Si, which should result in a smoother and more sensitive user experience when used with touchscreens. When it comes to IGZO OLED, the technology is well on the way, as Sharp has just unveiled its new 13.3-inch 8K OLED display at SID-2014.

Essentially, IGZO strives to reach the performance benefits of LTPS, whilst keeping fabrications costs as low as possible. LG and Sharp are both working on improving their manufacturing yields this year, with LG aiming for 70% with its new Gen 8 M2 fab. Combined with energy efficient display technologies like OLED, IGZO should be able to offer an excellent balance of cost, energy efficiency, and display quality for mobile devices.

Innovations in display backplanes aren’t stopping with IGZO, as companies are already investing in the next wave, aiming to further improve energy efficiency and display performance. Two examples worth keeping an eye are on are Amorphyx’ amorphous metal nonlinear resistor (AMNR) and CBRITE.

This developing technology can be manufacturing on a process that leverages a-Si TFT production equipment, which should keep costs down when it comes to switching production, whilst also offering a 40 percent lower cost of production compared w

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey