data vision lcd module factory

Data Vision is a manufacturer of LCD (Liquid Crystal Display) modules, established in 1990. Currently, we have manufacturing strongholds in Taiwan and China.

We are recognized as one of most progressive companies in our industry. Data Vision offers broad range of LCD modules, including mono LCM, Intelligent and Integrated LCM and TFT. In which, we provide extensive and complete solutions based on customer needs. Hence, Turnkey service is merely a part of our offerings. To make our competence qualified, we have certification of ISO9001:2008.

Our customers vary in size and industry as well as in the services they require. Today, Data Vision offers an array of services to help our customers improve their bottom lines and time to achieve objectives.

The display modules I bought are actually better than Your listing suggests. They have in fact on-board Vee supply, no external negative voltage required! Pin20 is not NC as in the pin-out on the listing, it is Vee out. Connect a pot about 10.22k between 20 and Vss, then moving the contact to pin4.

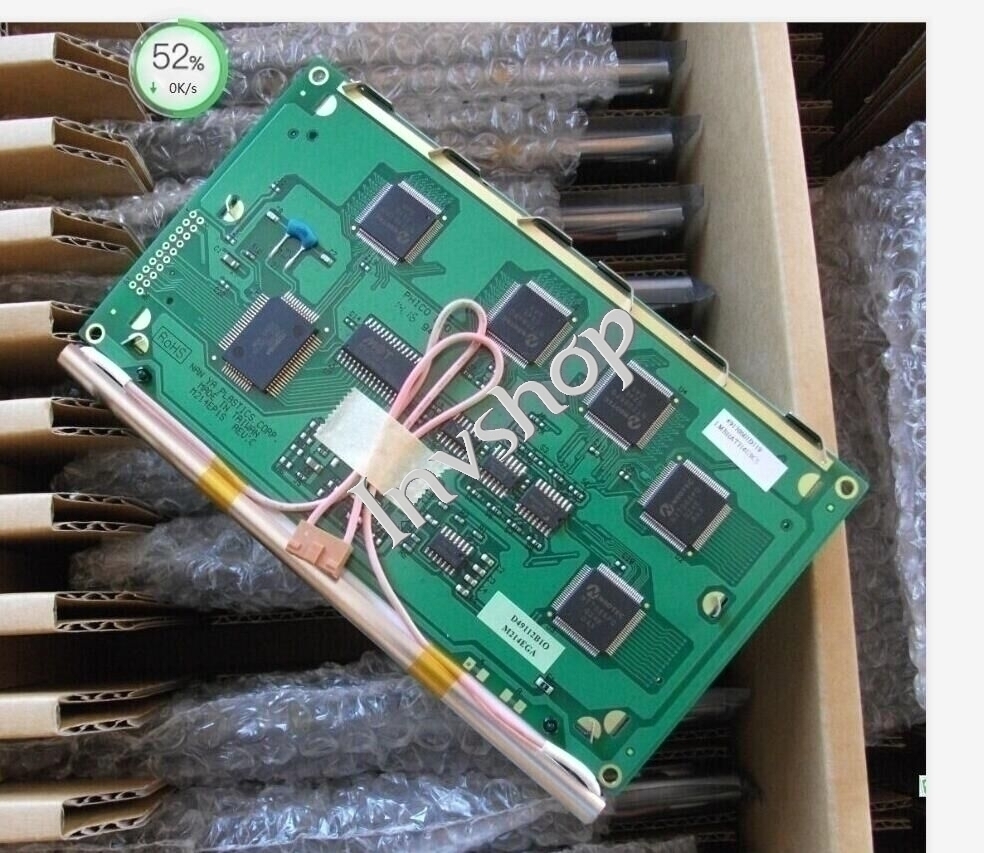

This new open-box LCD screen is new from the manufacturer is out of its original packaging. We have had multiple units in stock and the unit shipped may vary from the unit photographed. Screen might be BLUE or BLACK. Please view our photo set and contact us if you have any questions.

How do you display your metrics? Paper printouts or white boards? LED Scoreboards at each production line? Or perhaps you’ve thought about deploying a manufacturing data display to show your production stats in different areas of your plant. Our Manufacturing Data Display supports your LEAN and paperless manufacturing initiatives with real-time production metrics, KPIs, and inventory figures right on your plant floor.

By communicating directly with your existing database (even data from multiple sources) and displaying it on strategically located screens, our manufacturing data display provides your employees and floor managers with consistent and accurate information when they need it.

Automate — Automated, real-time data provides your employees and floor managers with consistent and accurate information when they need it, from available sources such as SQL, MySQL, Oracle, Excel, HTML, XML and other ODBC compliant applications.

Ignition’s real-time status and control functionality, coupled with advanced analytic capabilities provided by Ignition’s SQL database integration, gives you the power to quickly analyze and easily display the status of your facility.

Included customizable charts, tables and graphs display your real-time and historical data, making at a glance analysis easy. You’ll be able to quickly set up executive dashboards, track key performance indicators (KPIs), and view trends.

Easily integrate data from SQL databases with your SCADA system. Data entered by operators can be written directly to any database. The powerful property binding system makes it easy to display information from databases on any screen.

Clients are configured through the included Ignition Designer. Drag-and-drop configuration makes screen development intuitive; simply drag Tags and drop them onto components to instantly bind data to inputs, displays, tables, charts, and more.

Every client you launch from the Vision Module is secured using SSL protocols. In order to keep your data secure, authentication groups can be used to strictly limit access to certain areas of a project to only the users with appropriate access levels.

With the Ignition Vision Module installed on your server, you can launch as many clients as you want, instantly. No individual client install required!

If the issue persists on the external monitor, it may be an issue with the video card (GPU) or video settings and not the laptop LCD panel. Go to verify display or video issues in Windows Safe Mode. Otherwise, go to the next step.

Performance issues may occur if there is any damage to the LCD screen. The display may stop working, work intermittently, flicker, display horizontal or vertical lines, and so on, if there is damage to the display screen.

Dell laptops have integrated diagnostic tools that can determine if the screen abnormality is an inherent problem with the LCD screen of the Dell laptop or with the video card (GPU) and computer settings.

When you notice screen abnormalities like flickering, distortion, clarity issues, fuzzy or blurry images, horizontal or vertical lines, color fade, running a diagnostic test on the LCD helps identify if the issue is with the LCD panel.

Press and hold the D key and turn on the computer to enter the LCD built-in self-test (BIST) mode. Continue to hold the D key until you see the entire screen change colors.

If you do not detect any screen abnormalities in the integrated self-test mode, the LCD panel of the laptop is functioning properly. Go to the Update the video card (GPU) driver, monitor driver, and BIOS section.

If you notice any abnormalities in the LCD built-in self-test mode, contact Dell Technical Support to learn more about repair options that are available in your region.

Display settings like brightness, refresh rate, resolution, and power management may affect the performance of the LCD screen on your Dell laptop. Changing or adjusting the display settings can help resolve several types of video issues.

If the diagnostic tests on the LCD panel and the video card (GPU) passed, it is most definitely an issue that is related to software that is installed on the computer. If the above troubleshooting steps did not resolve the issue, you may try to restore the computer to factory default settings as a last resort.

WARNING: Restoring or resetting the computer to factory default settings will erase all personal data on the computer. Back up all important data like documents, images, music files, spreadsheets, videos to an external hard drive or a cloud-based backup like Microsoft OneDrive.

Dell computers are built with a small amount of hard disk space that is reserved for reinstalling the operating system. This method is the easiest way to restore the computer to factory condition. The restoration process deletes all user data from the computer, so be sure to back up all your files before starting this process.

This article helps you understand pipelines and activities in Azure Data Factory and Azure Synapse Analytics and use them to construct end-to-end data-driven workflows for your data movement and data processing scenarios.

A Data Factory or Synapse Workspace can have one or more pipelines. A pipeline is a logical grouping of activities that together perform a task. For example, a pipeline could contain a set of activities that ingest and clean log data, and then kick off a mapping data flow to analyze the log data. The pipeline allows you to manage the activities as a set instead of each one individually. You deploy and schedule the pipeline instead of the activities independently.

The activities in a pipeline define actions to perform on your data. For example, you may use a copy activity to copy data from SQL Server to an Azure Blob Storage. Then, use a data flow activity or a Databricks Notebook activity to process and transform data from the blob storage to an Azure Synapse Analytics pool on top of which business intelligence reporting solutions are built.

Azure Data Factory and Azure Synapse Analytics have three groupings of activities: data movement activities, data transformation activities, and control activities. An activity can take zero or more input datasets and produce one or more output datasets. The following diagram shows the relationship between pipeline, activity, and dataset:

An input dataset represents the input for an activity in the pipeline, and an output dataset represents the output for the activity. Datasets identify data within different data stores, such as tables, files, folders, and documents. After you create a dataset, you can use it with activities in a pipeline. For example, a dataset can be an input/output dataset of a Copy Activity or an HDInsightHive Activity. For more information about datasets, see Datasets in Azure Data Factory article.

Copy Activity in Data Factory copies data from a source data store to a sink data store. Data Factory supports the data stores listed in the table in this section. Data from any source can be written to any sink.

Azure Data Factory and Azure Synapse Analytics support the following transformation activities that can be added either individually or chained with another activity.

Web Activity can be used to call a custom REST endpoint from a pipeline. You can pass datasets and linked services to be consumed and accessed by the activity.

To create a new pipeline, navigate to the Author tab in Data Factory Studio (represented by the pencil icon), then click the plus sign and choose Pipeline from the menu, and Pipeline again from the submenu.

The pipeline properties pane, where the pipeline name, optional description, and annotations can be configured. This pane will also show any related items to the pipeline within the data factory.

Type of the activity. See the Data Movement Activities, Data Transformation Activities, and Control Activities sections for different types of activities.

Type of the activity. See the data movement activities, data transformation activities, and control activities sections for different types of activities.

In the following sample pipeline, there is one activity of type Copy in the activities section. In this sample, the copy activity copies data from an Azure Blob storage to a database in Azure SQL Database.

Input for the activity is set to InputDataset and output for the activity is set to OutputDataset. See Datasets article for defining datasets in JSON.

In the typeProperties section, BlobSource is specified as the source type and SqlSink is specified as the sink type. In the data movement activities section, click the data store that you want to use as a source or a sink to learn more about moving data to/from that data store.

In the following sample pipeline, there is one activity of type HDInsightHive in the activities section. In this sample, the HDInsight Hive activity transforms data from an Azure Blob storage by running a Hive script file on an Azure HDInsight Hadoop cluster.

The typeProperties section is different for each transformation activity. To learn about type properties supported for a transformation activity, click the transformation activity in the Data transformation activities.

a line of extreme and ultra-narrow bezel LCD displays that provides a video wall solution for demanding requirements of 24x7 mission-critical applications and high ambient light environments

Manufacturing has traditionally used visual tools to keep employees focused on production. And anyone who has been in the industry remembers the whiteboards, grid boards with tape and string, clipboards used for manual data collection, and other methods derived from or destined for Excel spreadsheet analysis.

These manual visual aids offer no real-time insight, are error-prone, and require a lot of labor to keep reasonably up-to-date. Many manufacturers continue to rely on manual data collection methods. By contrast, the modern connected factory has many data-driven visual tools at its disposal. From Human Machine Interfaces (HMI) to interactive dashboards, today"s smart factory with advanced production monitoring can help operators and managers visualize production status.

Functionality is always tied to a source, such as factory-wide monitoring software that updates production data. The production display board can show real-time data for companies with advanced monitoring systems and IIoT devices.

MachineMetrics provides a robust production monitoring solution for factory automation and IIoT enabled factories and shops. Using real-time data to display key metrics, employees have access to color-coded easy to read, intuitive dashboards out of the box. And manufacturers can customize these dashboards to show the most relevant and critical data in real-time across all display boards.

But production monitoring is just the start! With real-time, accurate production data, manufacturers can begin to enable process optimization and automation. Instead of simply knowing when machines are running or down, you can engage in more advanced analysis of production performance, such as:

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey