lcd panel taking advantage of fluorescent lamp brands

The main functionality of the Basic Input/Output System (BIOS) is to perform the initial hardware checks after the computer is powered on and start up the operating system.

Which of the acronyms listed below refers to a series of basic hardware diagnostic tests performed by the startup BIOS after the computer is powered on?

After replacing a modular hardware component inside computer case, the updated information about specific parameters of the new device can be stored in: (Select 2 answers)

After completing the initial diagnostics and assigning system resources, the startup BIOS program checks for information about secondary storage devices that might contain the OS. The list of devices and the order in which they should be checked can be found and arranged in the CMOS setup utility, and this option is commonly referred to as:

After launching Windows Virtual PC application technician receives error message stating that the Hardware-Assisted Virtualization (HAV) feature is not enabled on the computer. Which of the following steps might help in fixing this problem?

LED fluorescent lamp is the newest product line in the fluorescent family and is considered to be the final replacement for traditional fluorescent lamp. It is made up of white LED chip modules. Provided with the advantages of long life-span, radiation-free, energy saving, environmental friendly and stroboflash-free, LED fluorescent lamp is superior to other kinds of lamps.

Besides, the installation of LED fluorescent lamp is quite easy. Just to replace the original fluorescent lamp with the new LED one, and to take out the starter. What’s more, the electricity saving efficiency can reach as high as 50% compared to ordinary fluorescent lamp and the life span is more than 10 times than that of ordinary one, almost totally free of maintenance. LED fluorescent lamp is adaptive to be used in offices, factories, marketplaces, schools and houses and so on indoor spaces.

Traditional fluorescent lamp contains large amount of mercury vapor which will do harm to the environment if the lamp is broken up and the vapor volatilize into the atmosphere. On the contrary, LED fluorescent lamp does not contain mercury or lead, doing no harm to the environment. So, LED products are recognized to be the green lighting lamps in the 21st century.

Compared to traditional lamps which will generate a large amount of heat, LED lamps can directly make electric energy into light energy, causing less heat and no waste of the energy.

LED lamp will not produce any noise, enabling it to be a good choice for illumination application in high precision electrical instrument. It is also fit to be used in occasions like libraries, offices and so on.

Traditional fluorescent lamp uses alternating current, which will generate 100-120 times of stroboflash per second. As to LED fluorescent lamp, it can directly switch the alternating current into direct current, without causing any flickering, helpful to protect the eyes.

Traditional lamps will generate ultraviolet radiation, thus will attract mosquitoes to fly around the lamps. LED lamp doesn’t have this disadvantage, thus the indoor space will become cleaner.

Traditional fluorescent lamp should recur to rectifier to release high voltage to get brighten up. If the voltage fell, the lamp will went out. However, LED lamps can be lighted within a certain voltage range (80V-245V) and its brightness can be adjusted.

The power consumption for LED fluorescent lamp is lower than 1/3 of the traditional lamp’s consumption, and the life span for it is 10 times longer than that of traditional one. So there is no need to change the lamp for a long period of time, reducing the manpower and other costs.

LED lamp body is made by epoxy resin instead of glasses like other traditional lamps. So it is more rigid and safe. Even if falling to the floor, LED lamp will not be broken easily. Users can set their heart at rest when using LED lamps.

The world of LCD backlights can be a confusing one. Determining the right option for your LCD screen can be a challenge as a result. The solution you choose depends on the application, frequency of use, and perhaps your budget. However, different types of backlighting produce different results.

Whether you’re looking to replace your LCD lighting with LED or CCFL lights or just want to know which option is best for you, this brief guide will help you better understand what LCD backlighting is and what options are available.

First, let’s explore what LCD backlighting is. If you’ve made it this far, chances are you already have a general idea, but for those of you who don’t, LCD stands for Liquid Crystal Displays. Because pixels in LCDs are similar to shutters, their contrast relies on the underlying electrical current. To properly illuminate an LCD, a light source must be placed behind the color pixel panel.

It’s important to note that not all LCDs use a backlight. Backlighting simply allows the viewer to see the display more clearly in low light conditions. For commercial purposes, this is important since the consumer must be able to use the screen properly regardless of the external lighting conditions.

LCD displays often run 24/7, which means they lose their brightness over time, often in 3 years or fewer. That’s why replacements are often necessary. There are two primary types of LCD backlighting replacements—CCFL and LED.

CCFL stands for Cold Cathode Fluorescent Lamps. These backlights work very much like the traditional fluorescent lamp and come in a single straight or shaped glass tube. Inside the tube is low-pressure mercury vapor. Once ionized, it emits ultraviolet light. Since humans cannot detect UV light, a coat of phosphorus inside the tube translates it into a white bright light that we can see.

To control where and how light is displayed on your chosen screen, a display panel consisting of two sheets of polarizing material with a liquid crystal solution placed in between is utilized. Again, this is where an electric current comes into play. That current will pass through the liquid. The result is a pattern based on how the crystals align, depending on if the light should or shouldn’t pass through it. Crystals serve as a barrier to create the resulting light display.

Keep in mind that both CFFL and Led can be custom tuned to produce nearly any color and color temperature of light. However, they each have different advantages and disadvantages.

CCFLs are the traditional standard for backlighting. They are the tried-and-true option for backlighting any LCD display. Why? There are several reasons.

On the other hand, LED backlights are getting more traction as of late. They are relatively new and most experts consider them the backlighting preference of the future. Most new displays are only available with LED replacements. However, LEDs do come with one major downside—they cost more than CCFLs, sometimes twice as much. Keep in mind, it is typically best to stick with using the type of backlight that your OEM screen was designed to use, regardless if it is LED or CCFL. One exception is if you have customized your display for LED use.

Yet, some of the advantages of choosing an LED include superior brightness levels, no inverter is required (only a power supply), durability is better, and they can provide longer life (for more cost).

Depending on your application, other types of backlighting might also be available. LCD TVs, for example, use both full-array and direct local backlighting. Direct local dimming is similar to full-array, but there are fewer LEDs spread across a wider area than you’d see with full-array backlighting. For manufacturers, however, there is a difference. LEDs that are spaced farther apart do not have the same consistency or accuracy in lighting that full-array displays do.

If your LCD screen is dimming and not offering the same consistent bright display as it once did, it could be time for repairs. A common repair is CCFL or LED replacement. In fact, companies like Plazmo make exact OEM replacements for the original backlight in the LCD, regardless if it is LED or CCFL.

LCD repair or removing and replacing LCD backlighting is simple but does require some steps. It is far more cost effective than total replacement as well. Your LCD is unique, which means you need to carefully analyze the manufacturer’s information before you go about removing the previous CCFL backlight. You’ll likely need to remove any outer casing you encounter and possibly the screen itself, depending on the application.

You will also have to work around a copper ground or LCD controller board because these often limit access to the backlight. Noting where you removed these items and where they should go back to is important during the removal process.

Next, access the CCFL bulb. Often it has its very own spot. Remove the rubber caps from the previous bulb and add them to your replacement bulb. Run the power cable back into one end of the new bulb—potentially using a soldering tool to do so. If you don’t want to do the rebuilding of your CCFL assembly, check out our mail in repair services here.

After you finish these steps, replace the CCFL and any other components back into your display and test the result. In the vast majority of cases, your screen will be returned to its full brightness potential, just like new.

Did replacing your bulb not do any good? Then you might be dealing with dying capacitors, inverters, or transistors. You’ll need electrical equipment like a voltmeter, to take a measurement of the electrical current flowing into important components.

Whether you aren’t quite sure which backlight your LCD repair needs, or you have not been able to find the CCFL or LED for your screen anywhere, it might be time to contact a professional. Finding the correct backlight can be challenging and getting it wrong can cause you a serious headache.

The good news is, if you opt to choose Plazmo for your replacement parts or LCD repairs, you’re in good hands. We offer affordable replacements that get your screen back to its original brightness without the high costs of buying an entirely new panel.

Give our site a browse to find the right components for your LCD display or contact us at sales@plazmo.com if you’d like to have us do the heavy lifting for your repairs.

LED-vs-LCD? Lately, choosing a TV has become like walking into a candy store. There are so many TV technology options to choose from, and each of them seems just as good.

Then there are the technical terms to deal with, such as LED TV, LCD TV, QLED TV, UHD TV, OLED TV, and more. You might feel like you need to be a tech pro just to watch your favourite TV show in the evening or enjoy a game with your friend.

Here at Dynamo LED, we offer both LED and LCD TVs, and we appreciate the benefits of both TVs. Be sure to check out our buying an LED Display guide for more info.

First, an important thing to understand is that the LED (Light Emitting Diode) monitor is an improvised version of the LCD (Liquid Crystal Display). This is why all LED monitor is LCD in nature, but not all LCDs are LED monitors.

LCD technology revolutionized monitors by using cold cathode fluorescent lamps for backlighting to create the picture displayed on the screen. A cold cathode fluorescent lamp (CCFL) is a tiny fluorescent bulb. In the context of this article, LCDs refer to this traditional type of CCFL LCD TVs.

LED monitors took the old technology a step further by replacing the fluorescent bulbs with LED backlight technology. And OLED (organic light-emitting diode) technology improves it even further by eliminating the need for backlighting.

This turns a single monitor into a modular assortment of countless light-emitting diodes. Additionally, this expands how big the monitor can be without blowing up the cost exponentially.

The quality of direct-view LED screens is measured by pixel pitch. The pixel pitch is the distance between two adjacent LEDs on the display. The smaller the pixel pitch, the better the quality of the image.

Since LEDs replace fluorescent bulbs with light-emitting diodes, LED TVs are more energy-efficient than LCDs. A 32-inch LED TV screen consumes 10 watts less power than the same size LCD screen. The difference in power consumption increases as the size of the display increases.

Light-emitting diodes are considerably smaller than fluorescent lamps used in LCD monitors. Fluorescent lamps have a considerable thickness, but the thickness of diodes is next to none. Moreover, countless diodes are assembled in the same plane, so the thickness of the array isn’t increased no matter how many diodes are present.

Edge-lit LEDs have a slight drawback in viewing angle compared to LCDs, because of the position of the light source. However, direct-view LEDs offer a better angle for viewing than LCDs as the light source is evenly spread on the screen.

This is the time it takes to shift from one colour to another. Response times are generally measured in milliseconds (ms). The shorter the time to respond, the better the quality of the images produced.

Since LED displays use full-array LED backlighting rather than one big backlight, LED TVs offer significantly better contrast than LCDs. LCD backlighting technology only shows white and black, but LED backlighting can emit the entire RGB spectrum, thereby providing a deeper RGB contrast.

If you wonder which display will last longer, this debate is also won by LED displays. LED televisions have a longer lifespan of 100,000 hours on average, compared to 50,000 hours provided by LCD televisions.

An LED display provides the option to dim the backlight, along with other eye comfort features. Not only that, it provides a wider viewing angle without harming image quality. Therefore, an LED display is far better for your eyes than an LCD.

In an LED display, a lot of smaller diodes are used and if a diode is damaged, it can be replaced. In an LCD, you will need to replace the entire bulb in case of damage. Therefore, an LED display is easier and cheaper to maintain than an LCD.

Since LEDs are a better and newer technology, the price of an LED display is higher than an LCD. However, this is only when we are considering the purchase cost.

The picture quality of an LED display is far better than an LCD. Due to modular light-emitting diodes, an LED screen produces better control over the contrast, rendering a clear picture. Also, LED provides RGB contrast, which can show truer blacks and truer whites.

Not to forget, they provide a shorter response time as well. Both of these factors result inLED displays having a better picture quality compared to LCD displays.

Since LED displays are considerably thinner than LCDs, they weigh considerably less. On average, an LED screen weighs about half of an LCD screen of the same size.

As you might have noticed by now, LED wins the battle with LCD without any doubt. This is because LED displays have an advantage in all the factors that matter when considering a purchase, except price.

Even when you consider the price, you will find that while LED technology is costlier, it provides better value for money in the long run. This is because of the longer lifespan and easier maintenance of LED screens.

They are more attractive too. With the increasing shortage of space in new residential complexes, what better solution than an ultra-thin LED display giving a cinematic experience in the comfort of your home.

LED screens are the first choice among the public today, across generations. All are opting to switch to LED from LCD to make their lives more enjoyable and better.

Do you wonder what’s better: fluorescent lights (including compact fluorescent lights, or CFLs) or light emitting diodes (LEDs)? Well here’s a head-to-head comparison of the two followed by an in-depth discussion of each technology in turn.

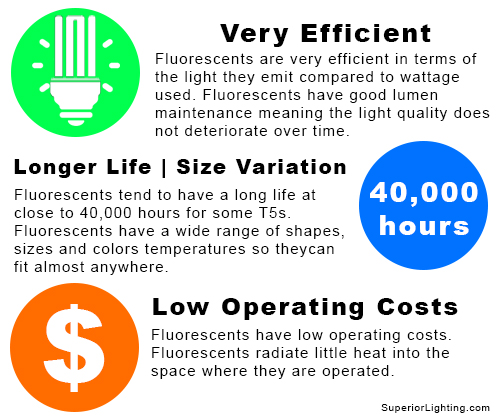

Fluorescent light bulbs are a specific type of gas-discharge light (also known as a high intensity discharge, HID, or arc light). CFL is an acronym that stands for compact fluorescent light. Standard fluorescent lights are available in tubes (generally 48 to 84 inches in length). CFLs are much smaller. They are still tubes but they are, as the name implies, “compact.” CFLs were designed to replace standard applications for incandescent bulbs as they are both more efficient and longer lasting.

Fluorescent bulbs produce light by converting ultraviolet emissions with a fluorescent coating on the inside of the tube. UV radiation is generated in the first place by an electrical charge that is run through the inert mercury glass internal to the bulb. The gas is excited by the electricity andreleases ultraviolet radiation as a consequence. Fluorescent lights require ignition, which is typically provided by a voltage pulse or a third electrode (an additional metal part) internal to the bulb. Starting is relatively simple with small tubes but can require significant voltage with larger lights.

Fluorescent light bulbs previously required a “warm-up” period in order to evaporate the internal gas into plasma, but now there are several near-instantaneous starting technologies for fluorescent light (those include “quick-start,” “instant start,” and “rapid-start”). Additionally, as the light heats up it requires additional voltage to operate. Voltage requirements in fluorescent bulbs are balanced by a ballast (a magnetic device in older bulbs and an electrical one in newer fluorescent technology). As the fluorescent light ages, more and more voltage is required to produce the same amount of light until eventually the voltage exceeds the fixed resistance provided by the ballast and the light goes out (fails). Fluorescent lights become less and less efficient over time because they must use more and more voltage to produce the same lumen output as the light degrades.

Fluorescent technology has been around for more than 100 years and it generally represents a high efficiency way to provide lighting over a vast area. The lights are much more efficient as well as longer lasting than incandescent bulbs, however, they fail in both categories when compared to LED.

Fluorescent lights contain toxic mercury.Mercury, as well as the phosphor inside the bulbs, are hazardous materials that present a waste disposal issue at the end of a light’s life. Broken bulbs release a small amount of toxic mercury as a gas and the rest is contained in the glass itself.

Fluorescent lights age significantly if they are frequently switched on and off.Typical lamp life for a CFL is about 10,000 hours but this can degrade as a consequence of frequent switching (turning on and off). Burning life is extended if lamps remain on continuously for long periods of time. It’s worth thinking about in the event that you are using CFLs in conjunction with motion sensors that frequently activate and time out.

Fluorescent lights are omnidirectional.Omnidirectional lights produce light in 360 degrees. This is a large system inefficiency because at least half of the light needs to be reflected and redirected to the desired area being illuminated. It also means that more accessory parts are required in the light fixture itself in order to reflect or focus the luminous output of the bulb (thus increasing unit costs).

Older fluorescent lights have a brief warm-up period. Once the arc is ignited it melts and evaporates metal salts internal to the device. The light doesn’t arrive at full power until the salts are fully evaporated into plasma. This is corrected in many newer models that utilize “rapid start” or similar technologies.

Fluorescent lighting emits a small amount of UV radiation.Ultraviolet light is known to cause fading of dyed items or paintings exposed to their light.

Fluorescent lights require a ballast to stabilize the light.In the event that there is a minor flaw in the ballastthe light may produce an audible hum or buzz.

Common applications for fluorescent lighting include warehouses and schools or commercial buildings. CFLs are also used as a replacement for incandescent lights in many residential applications.

When current passes through the semiconductor material the device emits visible light.It is very much the opposite of a photovoltaic cell(a device that converts visible light into electrical current).

LEDs have an extremely long lifespanrelative to every other lighting technology (including fluorescent lights). New LEDs can last 50,000 to 100,000 hours or more. The typical lifespan for a fluorescent bulb, by comparison, is 10-25% as long at best (roughly 10,000 hours).

LEDs areextremely energy efficientrelative to every other commercially available lighting technology. There are several reasons for this, including the fact that they waste very little energy in the form of infrared radiation (much different than most conventional lights to include fluorescent lights), and they emit light directionally (over 180 degrees versus 360 degrees, which means there are far fewer losses from the need to redirect or reflect light).

Color:LEDs can be designed to generate the entire spectrum of visible light colors without having to use the traditional color filters required by traditional lighting solutions.

In particular, LED lights are relatively expensive. The up-front costs of an LED lighting project are typically greater than most of the alternatives. This is by far the biggest downside that needs to be considered. That said, the price of LEDs are rapidly decreasing and as they continue to be adopted en masse the price will continue to drop. (If you received a proposal for LED lights that just costs too much, don"t give up hope. Value engineering can help.)

The first practical use of LEDs was in circuit boards for computers. Since then they have gradually expanded their applications to include traffic lights, lighted signs, and more recently, indoor and outdoor lighting. Much like fluorescent lights, modern LED lights are a wonderful solution for gymnasiums, warehouses, schools, and commercial buildings.

They are also adaptable for large public areas (which require powerful, efficient lights over a large area), road lighting (which offer significant color advantages over low and high pressure sodium lights), and parking lots. For an interesting take on the history of street lighting in the United States readhere.

different methods of producing light. Fluorescent bulbs contain inert gas within the glass casing while LEDs are a solid state technology. Fluorescent lights produce UV radiation and then convert it into visible light through the use of a phosphor coating inside the bulb. LEDs emit electromagnetic radiation across a small portion of the visible light spectrum and don’t waste energy by producing waste heat or non-visible electromagnetic radiation (such as UV). There is such a thing as an IRED (infrared emitting diode) which is specifically designed to emit infrared energy.

In the last few yearsLED efficiency has surpassed that of fluorescent lights and its efficiency improvements are progressing at a much more rapid rate. Further, fluorescent lamps require the use of a ballast to stabilize the internal current that produces light. When the ballast has a minor imperfection or is damaged, the light can produce an audible buzzing noise. Other shortcomings include the following:

Fluorescent lights are non-directional, meaning that they emit light for 360 degrees. As you might expect, a large portion of this light is wasted (for example, that portion that is directed at the ceiling).

As good as fluorescent light efficiency has become, LED is better (and continues to improve at a more rapid pace). As long as fluorescent lights last, LED lights last much longer. Further, fluorescentlamps require the use of a ballast to stabilize the internal current that produces light. When the ballast

has a minor imperfection or is damaged, the light can produce an audible buzzing noise. Other shortcomings include waste disposal issues (due to CFL"s reliance on mercury), and non-directional light generation. Non-directional light generation is a bigger deal than you might think. For example, light that is being directed at the ceiling rather than the room is wasted light. Therefore, CFL (as well as the related standard fluorescent bulbs) might have good “source efficiency” (i.e. it looks good on paper), but will fall short of LED when it comes to the more important measure: “system efficiency” (actual efficiency in real world applications).

Fluorescent light is available in a range of CCT values that can be adjusted by changing the amount of phosphor inside the bulb. Typical values range between warm white at 2700K to daylight at 6500K depending on the lighting requirement.

CRI for LED is highly dependent on the particular light in question. That said, a very broad spectrum of CRI values is available ranging generally from 65-95.

Typical CRI values for fluorescent light are between 62 and 80. This is fairly good color rendering but it leaves room for improvement when compared to LED.

LEDs are an ideal light for purposely turning on and off because they respond rather instantaneously (there is no warm up or cool down period). They produce steady light without flicker.

Fluorescent lights exhibit a short delay when turning on. Older fluorescent models actually required a significant warm up period before the tube would light but this has been improved with newer, rapid-start fluorescent lights. Possible failures or delays in the start-up process are typically due to faulty starters, transformers, or ballast. Fluorescent bulbs may also flicker, display swirling or pink light, light at the ends of the tube only, or cycle on and off as the bulb reaches the end of its useful life.

LEDs are very easy to dim and options are available to use anywhere from 100% of the light to 0.5%. LED dimming functions by either lowering the forward current or modulating the pulse duration.

Newer CFL bulbs can be dimmed very effectively (down to about 15% of their normal light) while older fluorescent bulbs are often not suitable for dimming. If looking to dim a fluorescent bulb, make sure that you choose a ballast that is rated for dimming.

LEDs emit light for 180 degrees. This is typically an advantage because light is usually desired over a target area (rather than all 360 degrees around the bulb). You can read more about the impact of directional lighting by learning about a measurement called “useful lumens” or “system efficiency.”

LEDs are very efficient relative to every lighting type on the market. Typical source efficiency ranges 37 and 120 lumens/watt. Where LEDs really shine, however, is in their system efficiency (the amount of light that actually reaches the target area after all losses are accounted for). Most values for LED system efficiency fall above 50 lumens/watt.

Fluorescent and CFL lights are very efficient compared to incandescent lights (50-100 lumens/watt source efficiency). They lose out to LEDs principally because their system efficiency is much lower (<30 lumens/watt) due to all of the losses associated with omnidirectional light output and the need to redirect it to a desired area.

LED efficiency drops as current increases. Heat output also increases with additional current which decreases the lifetime of the device. The overall performance drop is relatively low, however, when compared to fluorescent lights.

Fluorescent lights also experience efficiency losses as the device ages and additional current is required to achieve the same lighting output. Efficiency losses are greater and the degradation time shorter in the case of fluorescent bulbs.

LEDs produce a very narrow spectrum of visible light without the losses to irrelevant radiation types (IR or UV) associated with conventional lighting, meaning that most of the energy consumed by the light source is converted directly to visible light.

Fluorescent lights actually produce primarily UV radiation. They generate visible light because the bulb is coated with a layer of phosphor which glows when it comes into contact with UV radiation. Roughly 15% of the emissions are lost due to energy dissipation and heat.

Fluorescent lights produce primarily UV radiation. They generate visible light because the bulb is coated with a layer of phosphor which glows when it comes into contact with UV radiation. Although most UV radiation stays within the bulb, some does escape into the environment which can potentially be a hazard.

Fluorescent lights can fail in a number of different ways. Generally they exhibit an end-of-life phenomenon known as cycling where the lamp goes on and off without human input prior to eventually failing entirely.

Foot candle is a measure that describes the amount of light reaching a specified surface area as opposed to the total amount of light coming from a source (luminous flux).

LEDs are very efficient relative to every lighting type on the market. Typical source efficiency ranges 37 and 120 lumens/watt. Where LEDs really shine, however, is in their system efficiency (the amount of light that actually reaches the target area after all losses are accounted for). Most values for LED system efficiency fall above 50 lumens/watt.

Fluorescent and CFL lights are very efficient compared to incandescent lights (50-100 lumens/watt source efficiency). They lose out to LEDs principally because their system efficiency is much lower (<30 lumens/watt) due to all of the losses associated with omnidirectional light output and the need to redirect it to a desired area.

Fluorescent lights emit heat that is absorbed by the ballast and/or lost to the environment. Roughly 15% of the emissions are lost due to energy dissipation and heat losses. In some circumstances heat emissions could be beneficial, however, it is generally a bad thing to emit heat as it represents an energy inefficiency. The ultimate purpose of the device is to emit light, not heat.

LEDs last longer than any light source commercially available on the market. Lifespans are variable but typical values range from 25,000 hours to 200,000 hours or more before a lamp or fixture requires replacement.

Fluorescent lights have good lifespan relative to some bulbs but not compared to LED. Typical lifespan values range from 7,000 hours to 15,000 hours before a bulb requires replacement. Note: sometimes fluorescent lights need to be changed out before the end of their useful life to preempt serious degradation effects like flicker or changing light color (turning pink).

Fluorescent lights are relatively cheap to purchase but relatively expensive to maintain. Fluorescent bulbs will likely need to be purchased several times and the associated labor costs will need to be paid in order to attain the equivalent lifespan of a single LED light.

Fluorescent bulbs are particularly fragile - especially T5, T8, and T12 tubes. Perhaps more importantly, broken fluorescent bulbs require special handling and disposal due to hazardous materials like mercury inside the lights.

Compact fluorescent lights (CFLs) are designed to be small (such that they can replace an incandescent household light). Even so, they typically aren’t produced below roughly a centimeter in width. Standard fluorescent tubes are bulky and fragile at the same time. Neither compare to the small size and robust build of a solid state light like LED.

Fluorescent lights with regular magnetic ballasts (such as the T12 tube) are not generally recommended for temperatures below 50-60 Degrees Fahrenheit. For colder weather choose a fluorescent light with an electronic ballast such as a T8 tube.

LEDs produce significantly less heat than conventional gas discharge lights.This is typically a positive, however, for the unique case of application with traffic lights, there is a small potential that snow can accumulate on the bulbs. In reality, however, this is generally not an issue due to the use of visors and/or proper orientation of the light within a fixture that shields it from the elements.

Fluorescent bulbs are not generally recommended for outdoor lighting. CFLs will work but as the temperature drops the light quality suffers significantly. This is noticeable slightly below the freezing level and dramatic below about 5 degrees Fahrenheit.

:max_bytes(150000):strip_icc()/LCD-vs-LED-ac41b4f60a4341bfa3d94f586d47ba74.jpg)

When it comes todisplay technologies such asprojectorsand panels, factors such as resolution and refresh rate are often discussed. But the underlying technology is equally, if not more, important. There are tons of different types of screens, from OLED and LED to TN, VA, and IPS. Learn about the various monitor and television types, from operation to pros and cons!

The most common form of monitor or TV on the market is LCD or Liquid Crystal Display. As the name suggests, LCDs use liquid crystals that alter the light to generate a specific colour. So some form of backlighting is necessary. Often, it’s LED lighting. But there are multiple forms of backlighting.

LCDs have utilized CCFLs or cold cathode fluorescent lamps. An LCD panel lit with CCFL backlighting benefits from extremely uniform illumination for a pretty even level of brightness across the entire screen. However, this comes at the expense of picture quality. Unlike an LED TV, cold cathode fluorescent lamp LCD monitors lack dimming capabilities. Since the brightness level is even throughout the entire array, a darker portion of scenes might look overly lit or washed out. While that might not be as obvious in a room filled with ambient light, under ideal movie-watching conditions, or in a dark room, it’s noticeable. LED TVs have mostly replaced CCFL.

An LCD panel is transmissive rather than emissive. Composition depends on the specific form of LCD being used, but generally, pixels are made up of subpixel layers that comprise the RGB (red-green-blue) colour spectrum and control the light that passes through. A backlight is needed, and it’s usually LED for modern monitors.

Please note that some of the mentioned types may be considered a sub-category of LCD TVs; therefore, some of the names may vary depending on the manufacturer and the market.

1)Film layer that polarizes light entering2)glass substrate that dictates the dark shapes when the LCD screen is on3)Liquid crystal layer4)glass substrate that lines up with the horizontal filter5)Horizontal film filter letting light through or blocking it6)Reflective surface transmitting an image to the viewer

While many newer TVs and monitors are marketed as LED TVs, it’s sort of the same as an LCD TV. Whereas LCD refers to a display type, LED points to the backlighting in liquid crystal display instead. As such, LED TV is a subset of LCD. Rather than CCFLs, LEDs are light-emitting diodes or semiconductor light sources which generate light when a current passes through.

LED TVs boast several different benefits. Physically, LED television tends to be slimmer than CCFL-based LCD panels, and viewing angles are generally better than on non-LED LCD monitors. So if you’re at an angle, the picture remains relatively clear nonetheless. LEDs are alsoextremely long-lasting as well as more energy-efficient. As such, you can expect a lengthy lifespan and low power draw. Chances are you’ll upgrade to a new telly, or an internal part will go out far before any LEDs cease functioning.

Please note that some of the mentioned types may be considered a sub-category of LED TVs; therefore, some of the names may vary depending on the manufacturer and the market.

Further segmenting LED TVs down, you"ll find TN panels. A TN or twisted nematic display is a type of LED TV that offers a low-cost solution with a low response time and low input lag.

These displays are known for their high refresh rates, ranging from 100Hz to 144Hz or higher. As a result, many monitors marketed towards gamers feature TN technology. The fast response time and low input lag make them ideal for fast-paced action and gaming. However, TN panels have some limitations.

They suffer from inferior colour reproduction, meaning that the colours they display may be less accurate and vibrant than other technologies. Additionally, they have poor viewing angles, meaning the picture quality can degrade when viewed from certain angles. This is due to the way the liquid crystal molecules point at the viewer and the orientation of the light polarizers at 90-degree angles.

Overall, while TN panels are an affordable and fast option, they may not be the best choice for those looking for accurate colour reproduction and wide viewing angles.

Like TN, IPS or In-plane Switching displays are a subset of LED panels. IPS monitors tend to boast accurate colour reproduction and great viewing angles. Price is higher than on TN monitors, but in-plane switching TVs generally feature a better picture when compared with twisted nematic sets. Latency and response time can be higher on IPS monitors meaning not all are ideal for gaming.

An IPS display aligns liquid crystals in parallel for lush colours. Polarizing filters have transmission axes aligned in the same direction. Because the electrode alignment differs from TN panels, black levels, viewing angles, and colour accuracy is much better. TN liquid crystals are perpendicular.

A VA or vertical alignment monitor is a type of LED monitor that features excellent contrast ratios, colour reproduction, and viewing angles. This is achieved by using crystals that are perpendicular to the polarizers at right angles, similar to the technology used in TN monitors. VA monitors are known for their deep blacks and vibrant colours, making them popular for media consumption and gaming.

They also have better viewing angles than TN monitors, meaning that the picture quality remains consistent when viewed from different angles. However, the response time of a VA monitor is not as fast as that of a TN monitor, which can be a concern for those looking to use the monitor for fast-paced action or gaming.

The pricing of VA monitors varies, but they are typically more expensive than TN monitors and less costly than IPS or OLED monitors. Overall, VA monitors are an excellent option for those looking for a balance between good picture quality and affordability.

A quantum dot LED TV or QLED is yet another form of LED television. But it’s drastically different from other LED variants. Whereas most LED panels use a white backlight, quantum dot televisions opt for blue lights. In front of these blue LEDs sits a thin layer of quantum dots. These quantum dots in a screen glow at specific wavelengths of colour, either red, green, or blue, therefore comprising the entire RGB (red-green-blue) colour spectrum required to create a colour TV image.

Quantum Dot TV (QD-TV): A type of television that uses quantum dots, also known as semiconductor nanocrystals, to produce more accurate and vibrant colours.

Please note that some of the mentioned types may be considered a sub-category of Quantum Dot TVs; therefore, some of the names may vary depending on the manufacturer and the market. Also, it"s worth mentioning that not all brands use the same technology. Some are using QD films or QD-LEDs, others are using QD-OLEDs, and the list could go on.

An OLED or organic light-emitting diode display isn’t another variation of LED. OLEDs use negatively and positively charged ions for illuminating individual pixels. By contrast, LCD/LED TVs use a backlight that can make an unwanted glow. In OLED display, there are several layers, including a substrate, an anode, a hole injection layer, a hole transport layer, an emissive layer, a blocking layer, an electron transport layer, and a cathode. The emissive layer, comprised of an electroluminescent layer of film, is nestled between an electron-injecting cathode and an electron removal layer, the anode. OLEDs benefit from darker blacks and eschew any unwanted screen glow. Because OLED panels are made up of millions of individual subpixels, the pixels themselves emit light, and it’s, therefore, an emissive display as opposed to a transmissive technology like LCD/LED panels where a backlight is required behind the pixels themselves.

The image quality is top-notch. OLED TVs feature superb local dimming capabilities. The contrast ratio is unrivalled, even by the best of QLEDs, since pixels not used may be turned off. There’s no light bleed, black levels are incredible, excellent screen uniformity, and viewing angles don’t degrade the picture. Unfortunately, this comes at a cost. OLEDs are pricey, and the image isn’t as bright overall when compared to LED panels. For viewing in a darkened room, that’s fine, but ambient lighting isn’t ideal for OLED use.

Please note that OLED technology can be applied to various displays and devices, and the list mentioned above may not be exhaustive. Also, some types may be considered a sub-category of OLED.

As you can see, a wide variety of displays are available on the market today, each with their unique advantages and disadvantages. While many monitors and TVs are referred to by various names, such as LED, IPS, VA, TN, or QLED, many are variations of LCD panels. The specific technology used in a display, such as the colour of backlighting and the alignment of pixels, plays a major role in determining the overall picture quality.

When choosing the right type of monitor or display for your needs, it"s important to consider all the options available and weigh the pros and cons of each one. This can include things like resolution, refresh rate, response time, colour accuracy, and more subjective factors like overall picture quality and viewing angles.

In short, YES! LED lighting technology has come to a point where the efficiency makes it hard to justify keeping your old fluorescent lights or incandescent bulbs in place. Even though the initial replacement costs to choose LED tubes will be higher, you will see energy savings that will pay for those upfront costs within 2 years in most cases. New linear LED tube bulbs are simple plug-and-play and ballast compatible. You will simply need to remove your fluorescent bulb and plug in your LED light replacement.

LED replacement lamps are on average 30% more efficient than their fluorescent light counterparts. That means if you are spending $10,000 on your lighting energy costs per year, your bill will be reduced by $3,000 or more every year that you use the LED bulbs. Standard 4-foot T8 LED bulbs are available at as low as 12 watts of power consumption, while their fluorescent light counterparts will start at 25 watts.

One of the big reasons why LED tubes are more efficient is because it only emits light in one direction. The light emitting diodes (LEDs) are all arranged along the bottom of the lamp and send light downwards. Fluorescent lamps emit light in all directions, including up towards the ceiling where it is not needed.

Have you noticed that many LED fixtures have a lower lumen output than fluorescents? That is okay because LEDs are directional. They only emit light in the desired direction.

Some LED lamps are now rated to last up to 84,000 hours, while the average life of a fluorescent tube lamp is only 30,000 hours. That is over twice as long, so keep that in mind when you are calculating your purchase. The LED lamp is more expensive, but you will need to replace your fluorescent bulbs 2 or 3 times during the lifespan of an LED. Keep in mind the labor costs of replacing those fluorescent bulbs, particularly if you are lighting a large warehouse.

The ability to dim your lights increases their efficiency because you will only be using the wattage necessary for the amount of light that you require. Most fluorescent lights have two settings, ON and OFF. That means that even if you only need a little bit of light, you still need to operate at full power consumption. Some expensive fluorescent bulbs are dimmable with a special ballast, but at that point, your cost is comparable to an LED option.

One of the downfalls of fluorescent lighting is that each bulb contains mercury, which is harmful to the environment and must be disposed of properly. You can purchase special recycling kits to dispose of your fluorescent lamps properly, but add that to the cost of opting for fluorescent lighting over LED lights.

It used to be that LED bulbs were only available in cool color temperatures of 5000K and higher. That is not the case anymore, as LED bulbs are available between very warm(2700K) to extremely cool(5700K). Now you can use LED tube lamps in all sorts of applications from healthcare where you might want a cool color temperature, to your home where you might prefer a low and warm color temperature.

Have you ever picked up a fluorescent lamp that dropped on the ground? If you did it was probably with a broom and dustpan. Fluorescent tube lamps are notoriously fragile, but their LED counterparts are quite strong. They are built with durable, plastic housing that should even be able to withstand a drop from a low height.

Fluorescent lights put off a significant amount of heat. Your air conditioner will be battling that all day to keep your environment at an acceptable temperature. LEDs on the other hand put off virtually no heat. Beyond just the energy consumption of the bulbs, LEDs will help you cut down your air conditioning energy consumption.

A great way to improve efficiency in your warehouse or other space is to install occupancy sensors. This ensures that light will only be produced in areas where someone is present. Unfortunately, this can have a big impact on the life of your fluorescent lights. Each time you turn on a fluorescent bulb, a small amount of mercury vapor is burned off. Once that is diminished, the bulb will no longer work. On the other hand, the life of an LED bulb is not affected by the number of times it is turned on and off.

Many LED tubes are "plug and play", meaning you can just install them like you would a fluorescent bulb. For this to be true, look for bulbs that are "ballast-compatible" meaning that they can use the ballast already installed in your fluorescent fixture to power the LEDs.

The time has come for fluorescent lamps to step aside and make room for LED technology because LED lights are far more efficient and affordable than fluorescent lamps. Simply put, if you want to lower your energy demands while saving time and money on labor, switch your linear light fixtures to LED!

If you don"t have fluorescent fixtures and need to install new lighting, tube LEDs may not be the best choice. It is often more efficient to install a fixture with built-in LEDs that will not require bulbs. You can shop for those on ShineRetrofits.com here.

An LED-backlit LCD is a liquid-crystal display that uses LEDs for backlighting instead of traditional cold cathode fluorescent (CCFL) backlighting.TFT LCD (thin-film-transistor liquid-crystal display) technologies as CCFL-backlit LCDs, but offer a variety of advantages over them.

While not an LED display, a television using such a combination of an LED backlight with an LCD panel is advertised as an LED TV by some manufacturers and suppliers.

The local dimming method of backlighting allows to dynamically control the level of light intensity of specific areas of darkness on the screen, resulting in much higher dynamic-contrast ratios, though at the cost of less detail in small, bright objects on a dark background, such as star fields or shadow details.

A 2016 study by the University of California (Berkeley) suggests that the subjectively perceived visual enhancement with common contrast source material levels off at about 60 LCD local dimming zones.

LED-backlit LCDs are not self-illuminating (unlike pure-LED systems). There are several methods of backlighting an LCD panel using LEDs, including the use of either white or RGB (Red, Green, and Blue) LED arrays behind the panel and edge-LED lighting (which uses white LEDs around the inside frame of the TV and a light-diffusion panel to spread the light evenly behind the LCD panel). Variations in LED backlighting offer different benefits. The first commercial full-array LED-backlit LCD TV was the Sony Qualia 005 (introduced in 2004), which used RGB LED arrays to produce a color gamut about twice that of a conventional CCFL LCD television. This was possible because red, green and blue LEDs have sharp spectral peaks which (combined with the LCD panel filters) result in significantly less bleed-through to adjacent color channels. Unwanted bleed-through channels do not "whiten" the desired color as much, resulting in a larger gamut. RGB LED technology continues to be used on Sony BRAVIA LCD models. LED backlighting using white LEDs produces a broader spectrum source feeding the individual LCD panel filters (similar to CCFL sources), resulting in a more limited display gamut than RGB LEDs at lower cost.

The evolution of energy standards and the increasing public expectations regarding power consumption made it necessary for backlight systems to manage their power. As for other consumer electronics products (e.g., fridges or light bulbs), energy consumption categories are enforced for television sets.

Using PWM (pulse-width modulation), a technology where the intensity of the LEDs are kept constant but the brightness adjustment is achieved by varying a time interval of flashing these constant light intensity light sources,

A first dynamic "local dimming" LED backlight was public demonstrated by BrightSide Technologies in 2003,Sony in September 2008 on the 40-inch (1,000 mm) BRAVIA KLV-40ZX1M (known as the ZX1 in Europe). Edge-LED lighting for LCDs allows thinner housing; the Sony BRAVIA KLV-40ZX1M is 1 cm thick, and others are also extremely thin.

LED-backlit LCDs have longer life and better energy efficiency than plasma and CCFL LCD TVs.mercury, an environmental pollutant, in their manufacture. However, other elements (such as gallium and arsenic) are used in the manufacture of the LED emitters; there is debate over whether they are a better long-term solution to the problem of screen disposal.

Because LEDs can be switched on and off more quickly than CCFLs and can offer a higher light output, it is theoretically possible to offer very high contrast ratios. They can produce deep blacks (LEDs off) and high brightness (LEDs on). However, measurements made from pure-black and pure-white outputs are complicated by edge-LED lighting not allowing these outputs to be reproduced simultaneously on screen.

Quantum dots are photoluminescent; they are useful in displays because they emit light in specific, narrow normal distributions of wavelengths. To generate white light best suited as an LCD backlight, parts of the light of a blue-emitting LED are transformed by quantum dots into small-bandwidth green and red light such that the combined white light allows a nearly ideal color gamut to be generated by the RGB color filters of the LCD panel. The quantum dors may be in a separate layer as a quantum dot enhacement film, or replace pigment-based green and red resists normally used in LCD color filters. In addition, efficiency is improved, as intermediate colors are no longer present and do not have to be filtered out by the color filters of the LCD screen. This can result in a display that more accurately renders colors in the visible spectrum. Companies developing quantum dot solutions for displays include Nanosys, 3M as a licensee of Nanosys, QD Vision of Lexington, Massachusetts, US and Avantama of Switzerland.Consumer Electronics Show 2015.quantum dot displays at CES 2017 and later formed the "QLED Alliance" with Hisense and TCL to market the technology.

Mini LED displays are LED-backlit LCDs with mini-LED–based backlighting supporting over a thousand full array local dimming (FALD) zones, providing deeper blacks and a higher contrast ratio.

LED backlights are often dimmed by applying pulse-width modulation to the supply current, switching the backlight off and on more quickly than the eye can perceive. If the dimming-pulse frequency is too low or the user is sensitive to flicker, this may cause discomfort and eyestrain similar to the flicker of CRT displays at lower refresh rates.

Competing display technologies for the best image performance; A.J.S.M. de Vaan; Journal of the society of information displays, Volume 15, Issue 9 September 2007 Pages 657–666; http://onlinelibrary.wiley.com/doi/10.1889/1.2785199/abstract?

Novitsky, Tom; Abbott, Bill (12 November 2007). "Driving LEDs versus CCFLs for LCD backlighting". EE Times. Archived from the original on 28 November 2010. Retrieved 21 November 2020.

Method of and device for generating an image having a desired brightness; D.A. Stanton; M.V.C. Stroomer; A.J.S.M. de Vaan; US patent USRE42428E; 7 June 2011; https://worldwide.espacenet.com/publicationDetails/biblio?CC=US&NR=RE42428E

"Implementing directive 2005/32/EC of the European Parliament and of the Council with regard to ecodesign requirements for televisions", 2009; http://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:32009R0642

Controlling Power Consumption for Displays With Backlight Dimming; Claire Mantel et al; Journal of Display Technology; Volume: 9, Issue: 12, Dec. 2013; https://ieeexplore.ieee.org/document/6520956

LCD Television Power Draw Trends from 2003 to 2015; B. Urban and K. Roth; Fraunhofer USA Center for Sustainable Energy Systems; Final Report to the Consumer Technology Association; May 2017; http://www.cta.tech/cta/media/policyImages/policyPDFs/Fraunhofer-LCD-TV-Power-Draw-Trends-FINAL.pdf Archived 1 August 2017 at the Wayback Machine

Glass substrate with ITO electrodes. The shapes of these electrodes will determine the shapes that will appear when the LCD is switched ON. Vertical ridges etched on the surface are smooth.

A liquid-crystal display (LCD) is a flat-panel display or other electronically modulated optical device that uses the light-modulating properties of liquid crystals combined with polarizers. Liquid crystals do not emit light directlybacklight or reflector to produce images in color or monochrome.seven-segment displays, as in a digital clock, are all good examples of devices with these displays. They use the same basic technology, except that arbitrary images are made from a matrix of small pixels, while other displays have larger elements. LCDs can either be normally on (positive) or off (negative), depending on the polarizer arrangement. For example, a character positive LCD with a backlight will have black lettering on a background that is the color of the backlight, and a character negative LCD will have a black background with the letters being of the same color as the backlight. Optical filters are added to white on blue LCDs to give them their characteristic appearance.

LCDs are used in a wide range of applications, including LCD televisions, computer monitors, instrument panels, aircraft cockpit displays, and indoor and outdoor signage. Small LCD screens are common in LCD projectors and portable consumer devices such as digital cameras, watches, calculators, and mobile telephones, including smartphones. LCD screens have replaced heavy, bulky and less energy-efficient cathode-ray tube (CRT) displays in nearly all applications. The phosphors used in CRTs make them vulnerable to image burn-in when a static image is displayed on a screen for a long time, e.g., the table frame for an airline flight schedule on an indoor sign. LCDs do not have this weakness, but are still susceptible to image persistence.

Each pixel of an LCD typically consists of a layer of molecules aligned between two transparent electrodes, often made of Indium-Tin oxide (ITO) and two polarizing filters (parallel and perpendicular polarizers), the axes of transmission of which are (in most of the cases) perpendicular to each other. Without the liquid crystal between the polarizing filters, light passing through the first filter would be blocked by the second (crossed) polarizer. Before an electric field is applied, the orientation of the liquid-crystal molecules is determined by the alignment at the surfaces of electrodes. In a twisted nematic (TN) device, the surface alignment directions at the two electrodes are perpendicular to each other, and so the molecules arrange themselves in a helical structure, or twist. This induces the rotation of the polarization of the incident light, and the device appears gray. If the applied voltage is large enough, the liquid crystal molecules in the center of the layer are almost completely untwisted and the polarization of the incident light is not rotated as it passes through the liquid crystal layer. This light will then be mainly polarized perpendicular to the second filter, and thus be blocked and the pixel will appear black. By controlling the voltage applied across the liquid crystal layer in each pixel, light can be allowed to pass through in varying amounts thus constituting different levels of gray.

The chemical formula of the liquid crystals used in LCDs may vary. Formulas may be patented.Sharp Corporation. The patent that covered that specific mixture expired.

Most color LCD systems use the same technique, with color filters used to generate red, green, and blue subpixels. The LCD color filters are made with a photolithography process on large glass sheets that are later glued with other glass sheets containing a TFT array, spacers and liquid crystal, creating several color LCDs that are then cut from one another and laminated with polarizer sheets. Red, green, blue and black photoresists (resists) are used. All resists contain a finely ground powdered pigment, with particles being just 40 nanometers across. The black resist is the first to be applied; this will create a black grid (known in the industry as a black matrix) that will separate red, green and blue subpixels from one another, increasing contrast ratios and preventing light from leaking from one subpixel onto other surrounding subpixels.Super-twisted nematic LCD, where the variable twist between tighter-spaced plates causes a varying double refraction birefringence, thus changing the hue.

LCD in a Texas Instruments calculator with top polarizer removed from device and placed on top, such that the top and bottom polarizers are perpendicular. As a result, the colors are inverted.

The optical effect of a TN device in the voltage-on state is far less dependent on variations in the device thickness than that in the voltage-off state. Because of this, TN displays with low information content and no backlighting are usually operated between crossed polarizers such that they appear bright with no voltage (the eye is much more sensitive to variations in the dark state than the bright state). As most of 2010-era LCDs are used in television sets, monitors and smartphones, they have high-resolution matrix arrays of pixels to display arbitrary images using backlighting with a dark background. When no image is displayed, different arrangements are used. For this purpose, TN LCDs are operated between parallel polarizers, whereas IPS LCDs feature crossed polarizers. In many applications IPS LCDs have replaced TN LCDs, particularly in smartphones. Both the liquid crystal material and the alignment layer material contain ionic compounds. If an electric field of one particular polarity is applied for a long period of time, this ionic material is attracted to the surfaces and degrades the device performance. This is avoided either by applying an alternating current or by reversing the polarity of the electric field as the device is addressed (the response of the liquid crystal layer is identical, regardless of the polarity of the applied field).

Displays for a small number of individual digits or fixed symbols (as in digital watches and pocket calculators) can be implemented with independent electrodes for each segment.alphanumeric or variable graphics displays are usually implemented with pixels arranged as a matrix consisting of electrically connected rows on one side of the LC layer and columns on the other side, which makes it possible to address each pixel at the intersections. The general method of matrix addressing consists of sequentially addressing one side of the matrix, for example by selecting the rows one-by-one and applying the picture information on the other side at the columns row-by-row. For details on the various matrix addressing schemes see passive-matrix and active-matrix addressed LCDs.

LCDs are manufactured in cleanrooms borrowing techniques from semiconductor manufacturing and using large sheets of glass whose size has increased over time. Several displays are manufactured at the same time, and then cut from the sheet of glass, also known as the mother glass or LCD glass substrate. The increase in size allows more displays or larger displays to be made, just like with increasing wafer sizes in semiconductor manufacturing. The glass sizes are as follows:

Until Gen 8, manufacturers would not agree on a single mother glass size and as a result, different manufacturers would use slightly different glass sizes for the same generation. Some manufacturers have adopted Gen 8.6 mother glass sheets which are only slightly larger than Gen 8.5, allowing for more 50 and 58 inch LCDs to be made per mother glass, specially 58 inch LCDs, in which case 6 can be produced on a Gen 8.6 mother glass vs only 3 on a Gen 8.5 mother glass, significantly reducing waste.AGC Inc., Corning Inc., and Nippon Electric Glass.

The origins and the complex history of liquid-crystal displays from the perspective of an insider during the early days were described by Joseph A. Castellano in Liquid Gold: The Story of Liquid Crystal Displays and the Creation of an Industry.IEEE History Center.Peter J. Wild, can be found at the Engineering and Technology History Wiki.

In 1888,Friedrich Reinitzer (1858–1927) discovered the liquid crystalline nature of cholesterol extracted from carrots (that is, two melting points and generation of colors) and published his findings at a meeting of the Vienna Chemical Society on May 3, 1888 (F. Reinitzer: Beiträge zur Kenntniss des Cholesterins, Monatshefte für Chemie (Wien) 9, 421–441 (1888)).Otto Lehmann published his w

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey