is an lcd panel with a broken ribbon cable unfixable supplier

So, the main board and power board and cables are good (replaced them all), screen gets power and lights up full with no issues, however it goes into a boot loop when everything is connected. WHEN I disconnect only the ribbon cable (which is new) the TV boots full, the sound lets me know it is in the operating menu and clicking around dings and selects things properly. Obviously because the ribbon is disconnected the screen (which is on and backlit fine) just has no picture. So the only thing left is this long thin (about 1 in) strip of computer board that runs along the entire bottom of the back that the ribbon cable is plugged into and has connectors that wrap to the front LEDs (I also replaced the metal Y connectors that go to this long stripy board thingy). I cant find this long thin stripy board part anywhere. Please let me know if this is fixable, and how to find this part if that is the answer. Thanks so much, mahalo. - Mike

This instructable came about from a broken LCD control module out of a modern VW Camper Van. The LCD module is part of a control unit which was virtually unreadable and a replacement for a new unit was £400+. It really was a no lose option, either have a go at fixing it or end up buying a new unit.

The fault of the LCD was that it only displayed a couple lines of output on the LCD. The symptoms are caused by poor location of the LCD ribbon in manufacture and also the poor position of the whole module in the vehicle which exposes it to heat and is subject to vibration within the vehicle. This causes the ribbon to fail eventually and is a known common fault.

The ribbon in this display actually controls the Rows of the LCD matrix and the Columns were handled by a rubber standoff connection on the longest side of the LCD. There were no problems with the rubberized connection.

Some re-work on the LCD ribbon had already been tried with a little improvement but the poor registration of the ribbon pushed me to try a new attachment.

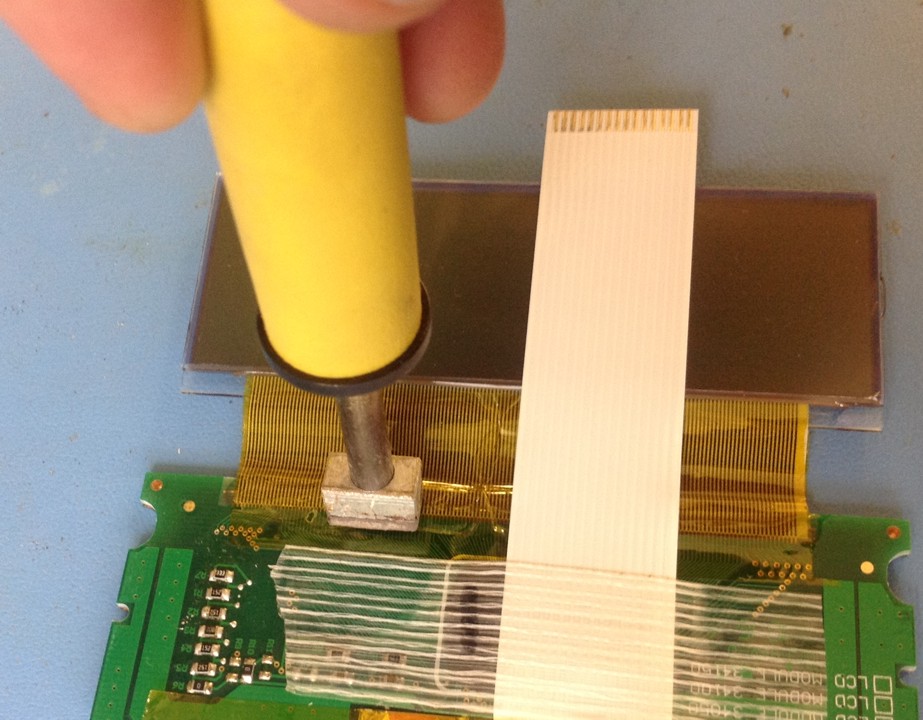

From the photos below you can see the LCD control unit and the state of the LCD ribbon before repair. You can just make out the offset placement and poor registration of the ribbon before repair.

Do not under estimate the patience required for this repair as some delicate and nimble work is required and i cannot stress how important it is to take your time and not rush. You may only get one chance with this sort of repair.

The registrations of the LCD ribbon in this repair was difficult. It took me and my friend 20 minutes just to line up the ribbon for re-attachment. The ribbon in this case is sub 1mm pitch OR less than 25.4 thousands of an inch. You may want to try a simpler ribbon repair on an old LCD clock for example before jumping in head first with fine pitch.

Also the removal of the LCD ribbon is a delicate process as you do not want to tear what is a good ribbon or damage the carbon printed lines. Also the PCB must be respected to avoid introducing other faults and the the re-attachment may need an extra pair of hands.

You may also want to review the last step for results and lessons learned from this instructable before jumping in head first but i believe this will give a you a good insight to some important factors of LCD ribbons and possible success.

Other favorites of reworking the LCD connection that i have read here are the tinfoil on a heat gun. This has good temperature management but not so good in tight spaces. The solder iron with flat blade and tin foil is more precise but a 25 Watt iron can be too brutal on the ribbon.

1. Do you have enough spare ribbon to detach and re-attach? The more ribbon you have the more goes you may get but watch out for the mechanical caveat below.

2. Will you be mechanically constrained if you cut the ribbon. This is a tough one as some shortening of the ribbon may make it impossible to re-assemble the device!!

3. Is the Ribbon continuity visibly good, by that i mean the carbon connection lines are continuous and unbroken - Do check otherwise you may be wasting your time.

In the photos below you can see the available ribbon length was generous enough but do watch for mechanical constraints. In some cases you could find yourself not being able to lay down the LCD back down as it is too tight a radius to sit down.

The ribbon removal needs careful thought depending on your device. It would be difficult to write a complete panacea solution for every device so please use some careful judgement on your device.

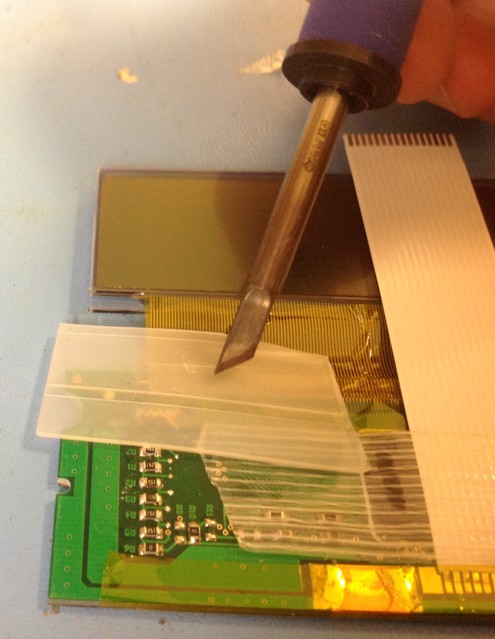

You do not want to pull at the ribbon as you will most likely damage what you already have. In my instance it was best to cut the ribbon free as close to the PCB pads as possible.I used a scalpel to slice parallel to the PCB board to remove the ribbon. Do make a good job of this as you may need to preserve as much extra ribbon to re-attach the LCD module.

The LCD assembly was lifted off and put in safe place to avoid damage. The ribbon was then gently lifted and peeled back with tweezers to remove the bulk. You must not use force to remove the remainder ribbon especially if your PCB is off a cheap quality OR single sided cardboard type variety. The PCB pads can come off with the ribbon! If you have a double sided PCB of FR4

If you have a half decent PCB the connecting pads may be gold flashed (actually called Electroless Plated gold). This gold flashing is good as it provides a very good flatness to the PCB pads but they are not as mechanically strong as gold edge connectors (like you see on old PC adapter cards) which is a hard gold . The gold plate here is soft and also micrometer thin on the surface.

For either connection style you need to remove any old glue from the ribbon and remaining carbon debris from the pads. I used isopropanol on a cotton wool bud. Do not flood the PCB with cleaning fluidas you may effect electro-mechanical elements in close proximity such as switches and other items on the PCB which are not sealed against cleaning!

The PCB pads must be thoroughly cleaned and no debris must exist. Use you X10 OR x20 eyepiece here to check how clean the pads are. The PCB pads need to be pristine and nothing less.

From the photos you can see the PCB pads before cleaning through the eyepiece and the final photo shows the clean PCB pads with leftover cotton wool buds.

From the photos you can see that ribbon was trimmed with a rounded scalpel blade. The ribbon also had extra green tape which adhered to the original heel of the PCB pad connection. This gave extra mechanical stability for the ribbon but has to be peeled off to allow for re-connection. Later in this instructable i will mention about putting back extra mechanical stability for ribbon support.

If you have a fine pitch ribbon like i had this will cause you the most trouble. I needed an extra steady pair of hands to help and some patience before i got the the ribbon aligned. It took twenty minutes of nudging the PCB and ribbon to get a precise alignment. Our alignment was actually better than the original which was slightly skewed to one side.

If you do not have an extra pair of hands then i did think of using a large ball of Blu-tak to hold things in place but a second pair of hands is much better!

The trick to get good alignment is to allow some the gold pad fingers toes of the PCB to be visible just beyond the carbon lines of the ribbon. You then get the pads toes to line up with the carbon lines of the LCD ribbon.

Do not continue until you have excellent alignment of the black carbon lines of the ribbon to the PCB pads. The finer the pitch of the ribbon the better registration is required.

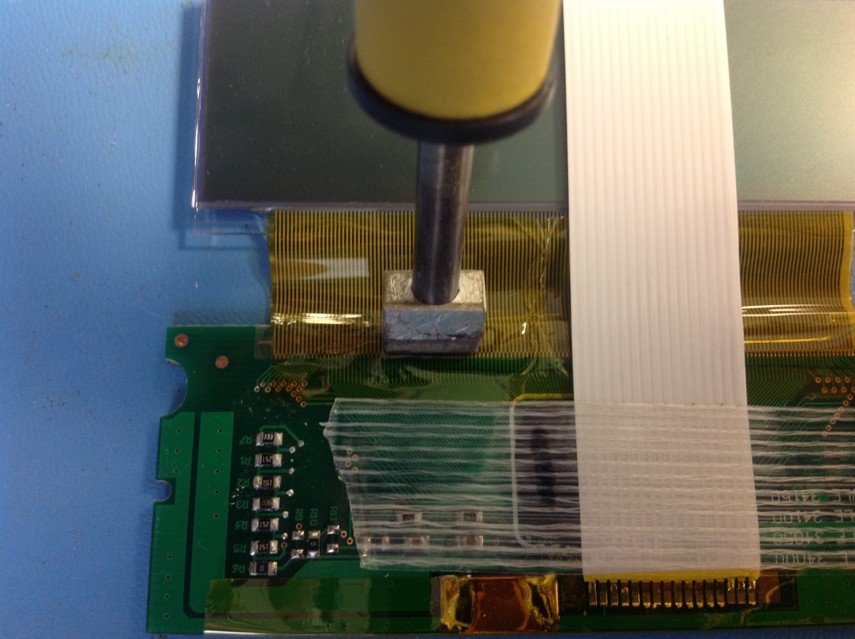

The photos below show how i handled the PCB and LCD and clamped the ribbon in place. The LCD display is being held by a plastic clamp above the PCB assembly. The PCB below which has components both sides is laying on some foam (try polystyrene). This allowed me to nudge the PCB under the ribbon into position. The plastic ruler acts as a LCD ribbon clamp. When you have got the registration get a steady handed friend to hold the ruler as a ribbon clamp in place so you can then apply the heat to stick the ribbon back down.

Check out the third photo and you can see what fine pitch means. There are two carbons tracks with a gap in every 1mm (25.4 thou). Now you see why it took twenty minutes to align!

You may want to skip forward to the next step to see the re-attached picture of the ribbon and to see how the alignment was achieved. You should see the gold PCB pad finger toes in line with the carbon of the ribbon

1. Do not apply so much heat you obliterate the ribbon. Yes it sounds stupid but i over cooked one side of my ribbon and got away with it. You may want to test on the bit you trimmed off elsewhere to get correct amount of heat.

2. Only tack the ribbon down my pressing the heated tip down vertically and stroking from the heel to the toe. That is to say in the same line that the carbon lines flows.

Tools for apply heating are up to you but i used a 25W Soldering iron with a wide flat tip covered in tin foil. Warning, the solder iron is too hot with tin foil so i cool it a little by dipping it into a wet sponge just before applying the heat. I used the solder iron tip method because i have more fine control but it did not have a regulated heat. If you have a good soldering iron with temperature control start low and work up to get the right heat.

Again Do not apply heat to the ribbon in one broad stroke. Work from the heel of the ribbon to the toe Or work by dabbing. By dabbing I mean hitting one spot on the ribbon with the heated tip and then lifted vertically again cooling the tip with the wet sponge before each dab.

The second photo in this step is the actual ribbon re-attached. You can see that the left hand side of the ribbon has not worked out as well as the right. I had too much heat in the solder iron. This is how i ended up cooling the solder iron with the wet sponge before applying heat.

In our case the LCD ribbon was not only glued to the PCB pads but there was some additional tape at the heel of the ribbon to hold the ribbon in place. By holding at the heel the ribbon you get some good extra mechanical support.

I did not go further with more re-work as the VW LCD module was considered a good enough result and some other time pressures intervened. It was concluded that we could read the display well enough and operate items from the controller. It was also considered as one of those quit while your ahead things!

For some people this may not be good enough but i hope that some of the steps i have listed will get people going in the correct direction when considering this. I do believe with a little more time a 100% is achievable. I took two hours to dismantle and remove the ribbon, Most of this was thinking things through... and another two hours to re-register and re-attach ribbon.

The technique for LCD ribbon removal and re-attachment are achievable certainly on simpler ribbons and fine pitch ribbons with careful preparation and thought. I hope this instructable is comprehensive enough for people to get some good results.

The ribbon is know as a "Heat Seal Connection" OR "HSC". In the industry heat and pressure are used to make this type of connection. The material comes from a family of "Anisotropic Conductive Films" OR "ACF".

The material bonds at 180 DegreeC. Direct Ribbon connection is used for economy (i.e. no fancy connectors) and for the number of connections its offers in a small footprint which would not be possible through traditional connectors.

The other end of the ribbon that joins to the LCD is terminated on the glass on Indium tin oxide (ITO) which is one of the most widely used transparent conducting oxides.

If you want more information there are many different types of LCM assemby (LCD Display plus it driving chips) to look at but these are the main ones (increasing in density):

In manufacture of these modules a machine is used for assembly which would compress HSC to the LCD Or the PCB and then apply the correct amount of heat.

very nice and complicated work but...my question is, where can I find a ribbon cable like this? I have a keyboard Technics KN2000 with a display not working because the cable was disconnected from both the glass display and the circuit board. Thank You!

I am attempting to fix a TV with vertical lines in it. Actually it was showing a black screen. I cleaned the ribbon connections and now I get an image with some multicolored vertical lines. ( good progress) . When I looked at the ends of the cable some of them were "missing" the last 1 - 2 mm of gold plating? do you think the method you used of slicing the ribbon to even the pads up is a good method? Or is there a way of replating/tinning the missing portions?

These graphite ribbon cables appear to have a layer of clear tape on either side of the graphite paths. To expose a new area of graphite paths for reconnection should the original path be damaged, the tape on one side needs to be peeled back. In my case, when I attempted to peel back the tape some of the paths fragmented and went with the peeled back tape. I suspect that in the case at hand, the peel back was not necessary and heat was used to reattach the previously exposed paths.0

My flat ribbon seems to have a plastic covering on both sides but looks just like your pictures. Must I remove the plastic covering on the attachment side before applying heat to make the connection or does the plastic stay in place and somehow act as a glue when hot?0

Attached is a picture of a screen from a Brookstone clock. I think it may be an LCD. The black pads show where a ribbon cable was connected and I see not transmission paths from the pads into the screen. How does this work? Is it really an LCD?

Are the paths in this ribbon cable covered on both sides as mine is and can you adhere the ribbon without removing any covering by applying heat? And what do I do on the LCD side where there appears to be no pads on the LCD but the ribbon cable was apparently applied in this manner?0

If this was a VW from when I use to drive them back in the 80"s, I would insert a comment here regarding "European automotive electrical systems, a love hate relationship". But since you posted "Modern" VW camper van, I"m assuming the electrical parts have little to do with "Where" the vehicle was manufactured. But back in the day (yeah, I said "Back in the day". I"m old...lol) I was having to fix something electrical on my VW"s once or twice a year on average...lol. But I loved my VW camper vans and continued to buy them. :-)0

I have two items to add, kapton tape and sil-pads used to isolate heat-sinks from semiconductor devices. With kapton tape it brings the means to secure the ribbon to the board, place the tape over the whole connection area, and kapton resists heat very well, ( try and melt it with your soldering iron). This means an average soldering iron turned down will allow heat to be applied to each joint. With experience a rework can be done in a few minutes. The bond can also be renewed on the LCD glass as well, kapton also works here. Sil-pads allow heat to be passed to the joint with some pressure applied at the same time. The sil-pad can be dragged up and down all the ribbon connections allowing uniform heating. Once the bond is resurrected the sil-pad is discarded. http://goo.gl/mpZNkm0

It"s pretty cheap and easier to solder, then you just have to clamp the cable into the connector. Maybe you are interested in reworking that to get all lines back.

Sorry, the connector on the link doesn"t match the board design... you must search for FFC, FPC connectors with the number of vias of your cable and look for the real dimensions on the datasheet.

I just thought the same way, adding aLCD flat connector... then you can swap chinese or VDO oem screens. Seems the VDO LCD(as for Audi A3-Vw golf/jetta4) have 50 pins and the ribbons is 48mm width. Then you have to look to modify the metal bracket to avoid pressure on ribbon.

i would not rule out a connector fix totally but its nice if you can fix for zero cost if possible. Also you then have to manage the mechanical constraints as well as choosing a suitable connector. Usually only the semi flexi PCB circuits ribbons go into connectors not the carbon screen printed sort so may not be so desirable.0

I think........you are a good electronics engineer ...........but I am not as you ......rather I have damaged my 3 calculator by this action.....................!..........................................but you have written very good............!0

I simply lifted the clear tape off from the top of the ribbon, then slowly stroked the ribbon contacts in turn a couple of times with the hot glue gun tip. Not hot enough to cause any damage.

My recommendation is to use a T-iron (see eBay .. about $35USD) which has the added advantage of having a heat shield that protects the insulation leading up to the solder pads.

In the photo i am only using a soldering iron covered in tin foil to heat the plastic ribbon. There is no solder used in this setup. The tin foil is there only to provide a better surface to apply heat to the ribbon (does not stick to the ribbon!!).

Actual Electrical connectivity is provided by carbon lines which are printed in the ribbon. The carbon lines only make contact via the adhesion of the ribbon.

The solder iron method technique is actually too hot and so i dip the solder iron in a sponge to cool it down before pressing down on the ribbon. If you have a temperature controlled soldering iron it would be much better.

i have an alarm clock which doesn"t have a ribbon, but instead some sort of rubbery contact strip against which the display should be pressed. You can find pics of it on google images for "lcd rubber contact strip", it seems to be called a zebra rubber. Any idea on how to glue/solder the display to that rubbery contact strip?More CommentsPost Comment

Parts-People began as a small company 20 years ago in an extra bedroom of my house. I had saved a small sum of money to purchase some computer parts and began selling them on eBay. After a few months I realized that people needed a place to go for Dell parts so I began building our website. Since we are located in Austin, Texas, where Dell.com was founded, I was able to set up a solid supply line with Dell. From the start, we focused on customer satisfaction and selling quality parts. We have grown a lot since 2002 but still and always the customer will come first. You will find that we go above and beyond with every order and offer free resources and support before and after the sale.

The newer ribbon type DMDs are notorious for being unrepairable. This is due to the carbon traces used on the display glass. If a ribbon cable gets damaged, it"s otherwise not a big deal to replace it and run jumpers. This has been tried before many times but nobody has reported they have fixed dead lines on these things. I read soldering the carbon pads on the glass could not be done.

I got this one from a bulk trade and figured I would try and fix it since it"s otherwise a paperweight. I suspected the top left ribbon cable but then realized after gently flexing the cable various directions that was not the case. So I carefully used a spudger tool to separate the glass from the PCB and gently remove the row ribbon cable a little bit at a time.

I narrowed the issue down to a column driver IC in the immediate area of the affected lines. I put this under a component microscope and found all 16 legs on the ribbon cable side closest to the top of the DMD were separated from the board. A quick drag solder technique with plenty of flux cleaned that up.

Now the fabled un-fixable ribbon cable. Legend has it that many aspiring techs have tried to tackle this wild beast in the past and have failed. I dug up this quote from another thread which pinpoints exactly why:

So I tried to convince myself to leave the ribbon cable in place, as I was able to tin all 32 leads on the board without trouble. But I realized the cable was trashed at the section where it meets the board. I tried to solder but the plastic cable started melting immediately.

After scraping off what appeared to be conductive adhesive, I tried to tin the pads on the glass with solder. At first I had no luck, but with enough flux and scraping away the remaining residue I was actually able to tin one the leads. Yay!!

Now the really nerve wracking part... soldering all 32 jumper wires and crossing my fingers. I used silicone wire because of its flexibility, trying to avoid any stress on any of the carbon pads. At first this was working pretty well. But the occasional wire would become desoldered as I moved along tacking on the neighboring ones. What really killed my momentum was seeing the desoldered wires take the actual carbon pads with them. When trying to re-attach the jumpers, there was no carbon left at all to grab on to. NOOO!!

So even though I was I able to solder to the carbon pads on the glass itself, the adhesion of the carbon after 24 years on this 1996 Cherry display was compromised and it lifted right off the glass. Not sure why, maybe it was heat during operation or heat when soldering that caused it. Or maybe just a poor printing process in general. Since I knew this was a failure I removed the remaining jumpers from the glass. Some were connected well, others didn"t take much force to pull off.

PO Box, APO/FPO, Afghanistan, Africa, Alaska/Hawaii, Albania, American Samoa, Andorra, Anguilla, Antigua and Barbuda, Armenia, Aruba, Australia, Austria, Azerbaijan Republic, Bahamas, Bahrain, Bangladesh, Barbados, Belarus, Belize, Bhutan, Bosnia and Herzegovina, British Virgin Islands, Bulgaria, Cayman Islands, China, Cook Islands, Costa Rica, Cyprus, Dominica, Dominican Republic, El Salvador, Fiji, France, French Polynesia, Georgia, Germany, Gibraltar, Grenada, Guadeloupe, Guam, Guatemala, Guernsey, Haiti, Honduras, Iceland, India, Iraq, Jamaica, Japan, Jersey, Jordan, Kazakhstan, Kiribati, Kuwait, Kyrgyzstan, Lebanon, Liechtenstein, Luxembourg, Maldives, Marshall Islands, Martinique, Micronesia, Moldova, Monaco, Mongolia, Montenegro, Montserrat, Nauru, Nepal, Netherlands Antilles, New Caledonia, Nicaragua, Niue, North America, Oman, Pakistan, Palau, Panama, Papua New Guinea, Poland, Qatar, Russian Federation, Saint Kitts-Nevis, Saint Lucia, Saint Vincent and the Grenadines, San Marino, Saudi Arabia, Serbia, Solomon Islands, South America, Southeast Asia, Spain, Sri Lanka, Svalbard and Jan Mayen, Sweden, Switzerland, Tajikistan, Tonga, Trinidad and Tobago, Turkey, Turkmenistan, Turks and Caicos Islands, Tuvalu, US Protectorates, Ukraine, United Arab Emirates, United Kingdom, Uzbekistan, Vanuatu, Vatican City State, Virgin Islands (U.S.), Wallis and Futuna, Western Samoa, Yemen

As often as you use your smartphone, it’s almost inevitable that you’ll eventually drop it. You may be extremely careful, but it only takes one fumble for your phone to tumble. While iPhone screens are designed to withstand impact, you might still end up with a shattered screen.

The good news: a broken screen doesn’t mean your phone is kaput. In fact, if only the glass is broken, the fix is quick and inexpensive. The bad news: if the LCD screen is broken, you’re looking at a pricier repair.

If you’ve looked into replacement parts, you’ve likely come across two very different options: a glass screen, and an LCD screen. While the first option is cheap, the second is definitely not. Here’s the difference:

1. The glass screen is the exterior layer on your phone’s display. While it is specially engineered for durability, it’s still just glass (between layers of plastic film), which is why it’s not very pricey to replace.

Most of the time, the damage to your screen will be pretty obvious. You’ll see the spider web patterns of shattered glass across the front of your iPhone. Occasionally, however, the glass screen will be intact, and you might not realize the damage until you try to use it. Whether the damage is visible or not, it’s a good idea to run a quick diagnostic to determine the extent of it.

If you encounter any of these problems, you’re dealing with a broken LCD screen. If the glass is shattered, but the display is clear and touch capability is working, that’s a good sign. The problem is probably just the glass screen.

Whether you’re dealing with cracked glass or a broken LCD screen, you can find a quick, reliable repair service at FastPhoneRepair.com. Our qualified technicians will get your iPhone repaired and up and running again in record time and at reasonable rates.

iPhone 14 Plus Teardown iFixit News Skip to main content Fix Your Stuff Community Store Teardowns The iPhone 14 Plus Is More Repairable Too Article by: Sam Goldheart @sam October 7, 2022 Filed under: Teardowns, Tech News Add Comment Facebook Twitter Reddit Linkedin Email Copy Link Share Did you forget there was another iPhone 14 coming out? We don’t blame you

The good news is that the iPhone 14 Plus follows in the repairable footsteps of the basic 14, spurning the outmoded, less-repairable 14 Pro form-factor

Heating, prying and a little suction get us a solid foothold on the screen, and opening it up grants us the view we’ve come to love: a protective shield, and easily-accessed set of screen connectors

Basic smartphone construction has remained virtually unchanged since the iPhone 5 a decade ago, with most Android phones relying on even older rear-opening patterns

While that consistent design heritage makes manufacturing easier, it does feel a bit stagnant, and more importantly, hasn’t done much to improve repairability

Better late than never! Allowing the screen and rear case to open independently does three things: 1) It minimizes the chance of collateral damage to high value components, ie you won’t accidentally break the screen on your way to a battery swap

2) You get immediate access to the two most breakable components: the screen and back glass and 3) battery replacement is just as easy as before—a must since all li-ion batteries are consumable components

Speaking of batteries, a slick screen removal is nice but we really care about battery access, so it’s time to pry open that previously-unrepairable back glass! Aside from a decidedly more gigantic battery (weighing in at 16

Removable front and back panels effectively doubles the ingress points, but Apple is clearly confident in the design as they used it on the Plus—their biggest phone in the lineup

We’ve also got a bright glimmer of hope for the other half of the product lineup in the coming models, and that’s about the best holiday gift we could ask for

Although, if we can ask one more thing, maybe Apple can focus their ingenuity on their Apple Watch line, too? Exposed screws and dual entry is great, but unlike the 14 and 14 Plus, the changes didn’t get us much

Here’s hoping for more intrepid exploration on Apple’s part! Check out the video versions of the iPhone 14 teardown and 14 Pro, too, to get the scoop on the latest phones, most of the vanilla 14 info applies to the Plus as wellTarih: s-4:27 -d14:2:2023x

Repair Roundup Week of October 2 iFixit News Skip to main content Fix Your Stuff Community Store Roundups As Midterms Loom Repair is off the Radar Repair Roundup Week of October 2 Article by: Paul Roberts @repairnews October 14, 2022 Filed under: Consumer Rights, Legislation, Right to Repair, Roundups, Tech News One Comment Facebook Twitter Reddit Linkedin Email Copy Link Share Each week, we bring you the top repair news from around the world, curated by the folks over at FightToRepair

Sharice Davids, a Democratic Party candidate for Kansas third congressional district, for example, talks about the need to “repair our aging infrastructure” and “make more here in America

Esther Joy-King, a Republican candidate for Illinois’ 17th Congressional District argues that Congress needs to work to “repair this broken system,” but she’s talking about immigration, not ubiquitous restrictions on repairing home appliances, agricultural machinery, and other critical implements

To be sure, there are some candidates who are giving right to repair airtime—and those voices often scramble conventional thinking about the boundary lines separating “progressive” from “conservative

Mehmet Oz, Fetterman promises that he will “fight for farmers’ rights to repair their own equipment and take on Big Ag so Pennsylvania’s small farmers can have a fair shot,” one of the most overt references to right to repair anywhere this election cycle

Greg Pence (former Vice President Mike Pence’s older brother), who represents Indiana’s 6th Congressional District, recently weighed in on concerns he has about consumers’ rights to data privacy and the right to repair agricultural equipment

There’s a right to repair bill that I actually sponsored, but this is all under that same Big Tech blanket: the right to privacy, your data, who owns it

Indeed, while voters scrutinize their candidates’ positions ahead of November’s election, positions on repair restrictions do not figure in midterm 2022 calculations

In fact, a review of campaign websites in 10 of the most competitive House races in the country found not a single mention of repair restrictions or pending federal right to repair laws affecting automobiles, agricultural equipment, and electronics

Pennsylvania’s Democratic candidate, John Fetterman, was the only candidate—Democrat or Republican—in the ten most competitive Senate races to mention the right to repair on his campaign website

In other words, despite ample attention to the growing power and influence of “Big Tech” players like Google and Facebook, repair, as an issue, is off the radar in the 2022 midterms

Already, there are a number of right to repair bills languishing in Congress, including a Senate bill focused on agricultural equipment and the REPAIR Act, legislation introduced in the House that seeks to federalize a right to repair automobiles, which is currently guaranteed only by virtue of an auto industry memorandum of understanding (MOU) signed after Massachusetts voters overwhelmingly passed a state automobile right to repair in 2012

With politicians free to ignore right to repair as an issue on the campaign trail, supporters may find it more difficult to twist arms in support of proposed right to repair legislation when Congress resumes work in January

While opening up the Sony WH-1000MX3 isn’t too difficult (it’s just a few clips and screws), you’ll still need a guide to show you where everything is, and once again, I had to turn to a third party

There’s an unholy amount of adhesive used to fix the WH-1000XM3 battery down too, which doesn’t pair well with thin delicate wires and batteries that explode when punctured or bent

That’s no good to consumers more than a couple of years down the line who find themselves in need of a cheap, simple, and quick repair to keep their product working

Hearing the familiar “power on” phrase and successfully pairing my headphones with my smartphone felt like a major win, but I’ve realized it shouldn’t have felt like the big deal it turned out to be

View Device Montana Farmers Union Attends DC Fly-in Event Lobbies for Farm Bill KRTV com Federal lawmakers met with Montanans to discuss what is affecting farms and ranches throughout the state

Fourteen members of Montana Farmers Union, two of them Great Falls High School students, participated in National Farmers Union 2022 Fall Legislative fly-in held in September

Within the bill falls important legislation that directly affects Montana: The Meat and Poultry Special Investigator Act, The Cattle Price Discover and Transparency Act, American Beef Labeling Act, and rulemaking by the USDA to strengthen the Packers and Stockyards Act and the Right to Repair Legislation

Insurers Show Support for Right to Repair aftermarketnews com The American Property Casualty Insurance Association (APCIA) has issued a statement supporting two recently released white papers focused on the impact of right to repair legislation in the auto industry

6570,” authored by Aaron Perzanowski, professor of law at the University of Michigan, emphasizes that restrictions to consumers choice of repair shops could increase the cost of vehicle repairs

According to Perzanowski, “By denying consumers and their preferred independent repair providers access to this crucial information, carmakers and dealers can reduce competition and increase the cost of vehicle repairs

” He also notes, “The REPAIR Act offers a sensible, forward-looking, nationwide solution that protects the rights of vehicle owners and promotes a robustly competitive repair industry

” Google Pixel 7 Teardown Reveals Repairability Concerns Gizbot com The Google Pixel 7 Pro has hit the shelves and the device has already been put through a stringent teardown by YouTube channel PBKreviews

And, while screen and battery replacements appear to be easy enough, intentional design and hardware layout choices mean the phone may not be DIY repair-friendly

View Device Why Do We Trash Things That Can Be Fixed Marketwatch com Why is it that so many of us no longer get creative about fixing things? Is it the allure of a one-click solution or the conviction that undertaking a household repair ourselves is too intimidating and frankly, too much trouble? Yet we all know it is not environmentally reasonable to be endlessly replacing items that could easily be given a second life

Study in UK Estimates Nation s Closets Hold 1 6 Billion Unworn Items Circular co uk The largest study into clothing habits ever undertaken by climate action NGO WRAP shows changes over the last 8 years around how long we retain our clothes, and how our openness to new ways of clothes ‘shopping’ could significantly reduce the environmental cost of clothing the nation—and save shoppers millions of pounds

In Australia Millions in Grants to Support Circular Economy Initiatives Wastemanagementreview com au In Australia, Victorian community groups have been given a boost to creatively tackle waste and create new jobs

Lily D’Ambrosio, Minister for the Environment and Climate Action, has announced funding of more than $3 million to be shared by 39 organisations through the Circular Economy Communities Fund

The Circular Economy Communities Fund will keep about 3000 tonnes of waste out of landfill, with 60,000 volunteers taking part and creating 100 paid jobs

Funded projects include bicycle recycling, repair and reuse, a soap re-purposing project, recycling and re-purposing of recreational fishing gear, and several innovative food rescue and community garden programs

Related Stories Activism Small Business Owners Fight for the Right to Repair in the US House This Week Consumer Rights Attacks on Right to Repair Fall Flat Repair Roundup Week of July 11 Legislation U S Watchdog Digs in on Automotive Right to Repair Repair Roundup Week of June 27 One Comment Add Comment Unfortunately there’s not much any ordinary person can really do, which is quite sadTarih: s-4:27 -d14:2:2023x

NFL fans rip into Kyler Murray for screaming "calm the f**k down" at Cardinals coaches Notifications New User posted their first comment this is comment text Approve Reject & ban Delete Logout NFL fans rip into Kyler Murray for screaming calm the f**k down at Cardinals coaches Kyler Murray yells at sideline Image Credit: Amazon Prime Video and the were off to a rough start during their Week 7 Thursday Night Football clash against the

The frustrated Cardinals offense finally found its groove late in the second quarter and was in the RedZone when Kliff Kingsbury called a timeout after Murray called an audible to avoid a delay of game penalty

Kyler: “Calm the f*** down” Kyler: “Calm the f*** down” NFL fans were less than impressed with the quarterback"s outburst and ripped into him on social media: How anyone likes this dude is beyond me

What happens when you pay a child $250 million What happens when you pay a child $250 million Told his coach to stfu ? Kyler: “Calm the f*** down” Kyler: “Calm the f*** down” Told his coach to stfu ? Fans did not pass up the opportunity to roast Murray for his Call of Duty obsession: He"s just mad he can"t play call of duty right now He"s just mad he can"t play call of duty right now he trynna get home and play that new Cod campaign he trynna get home and play that new Cod campaign Guys mad he missed the CoD campaign release today Guys mad he missed the CoD campaign release today when your internet goes down on double XP weekend when your internet goes down on double XP weekend Kliff Kingsbury wasn"t spared from the memes either: Kingsbury soon Kingsbury soon Good on Kyler, Kliff is fraud and he’s only in the league cuz he’s white

Andy Dalton and Kyler Murray help Cardinals pull ahead on the scoreboard The heated moment between Kyler Murray and the coaches seemingly woke up the Cardinals

crosses the goal line for his 1st career TD! on Prime VideoAlso available on NFL+ In the subsequent drive, Marco Wilson picked off a bobbled pass and returned it for a touchdown to give the Cardinals the lead

Pick-6! Wait for the flip… take the lead! on Prime VideoAlso available on NFL+ Pick-6! Wait for the flip… take the lead! on Prime VideoAlso available on NFL+ A minute later, Isaiah Simmons picked off Dalton and ran into the endzone for another pick-6 to push the Cardinals" lead to 14 at the half

Greg Dortch: You get a touchdown! on Prime VideoAlso available on NFL+ Greg Dortch: You get a touchdown! on Prime VideoAlso available on NFL+ But the Saints weren"t about to go down without a fight

Who started in ? on Prime VideoAlso available on NFL+ The Saints finished the game with a 10-0 run, but it was too little, too late as the Cardinals won 42-34

NFL Injuries: Find out about ? Poll : 0 votes Quick Links More from Sportskeeda Thank You! Show More Comments No thanks Delete Cancel Update Reply ❮ ❯ No thanks Delete Cancel Update Reply ❮ ❯ Be the first one to comment on this story More from Sportskeeda Fetching more contentTarih: s-4:27 -d14:2:2023x

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey