how to check 16x2 lcd display with arduino brands

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

In this digital age, we come across LCDs all around us from simple calculators to smartphones, computers and television sets, etc. The LCDs use liquid crystals to produce images or texts and are divided into different categories based on different criteria like type of manufacturing, monochrome or colour, and weather Graphical or character LCD. In this tutorial, we will be talking about the 16X2 character LCD Modules.

The 16x2 LCDs are very popular among the DIY community. Not only that, but you can also find them in many laboratory and industrial equipment. It can display up to 32 characters at a time. Each character segment is made up of 40 pixels that are arranged in a 5x8 matrix. We can create alphanumeric characters and custom characters by activating the corresponding pixels. Here is a vector representation of a 16x2 LCD, in which you can see those individual pixels.

As the name indicates, these character segments are arranged in 2 lines with 16 characters on each line. Even though there are LCDs with different controllers are available, The most widely used ones are based on the famous HD44780 parallel interface LCD controller from Hitachi.

The 16x2 has a 16-pin connector. The module can be used either in 4-bit mode or in 8-bit mode. In 4-bit mode, 4 of the data pins are not used and in 8-bit mode, all the pins are used. And the connections are as follows:

Vo / VEE Contrast adjustment; the best way is to use a variable resistor such as a potentiometer. The output of the potentiometer is connected to this pin. Rotate the potentiometer knob forward and backwards to adjust the LCD contrast.

EnableSends data to data pins when a high to low pulse is given; Extra voltage push is required to execute the instruction and EN (enable) signal is used for this purpose. Usually, we set en=0, when we want to execute the instruction, we make it high en=1 for some milliseconds. After this we again make it ground that is, en=0.

The 16x2 LCD modules are popular among the DIY community since they are cheap, easy to use and most importantly enable us to provide information very efficiently. With just 6 pins, we can display a lot of data on the display.

The module has 16 pins. Out of these 16 pins, two pins are for power, two pins are for backlight, and the remaining twelve pins are for controlling the LCD.

If you look at the backside of the module you can simply see that there are not many components. The main components are the two controller chips that are under the encapsulation. There is an onboard current limiting resistor for the backlight. This may vary from different modules from different manufacturers. The only remaining components are a few complimentary resistors for the LCD controller.

In the module PCB, you may have noticed some unpopulated footprints. These footprints are meant for charge pump circuits based on switched capacitor voltage converters like ICL7660 or MAX660. You can modify your LCD to work with 3.3V by populating this IC and two 10uF capacitors to C1 and C2 footprint, removing Jumper J1 and adding jumper J3. This modification will generate a negative contrast voltage of around 2.5V. This will enable us to use the LCD even with a VCC voltage of 3.3V.

Another issue to be concerned about is the oscillator frequency, i.e. when the supply voltage is reduced, the built-in clock frequency will also get reduced. The Rosc should be changed to a suitable value if any timing issues or command execution issues occur. The typical value of the Rosc for 5V VCC is 91KOhms.

To test whether a 16x2 LCD works or not, connect the VDD, GND and backlight pins to 5v and GND. Connect the centre terminal of a 10K variable resistor to the VEE pin. Connect the other two terminals to VCC and GND. Simply rotate the variable resistor you will see that the contrast will be adjusted and small blocks are visible. If these rectangles are visible, and you were able to adjust the contrast, then the LCD is working

There are 16 pins on the display module. Two of them are for power (VCC, GND), one for adjusting the contrast (VEE), three are control lines (RS, EN, R/W), eight pins are data lines(D0-D7) and the last two pins are for the backlight (A, K).

The 16x2 LCD has 32 character areas, which are made up of a 5x8 matrix of pixels. By turning on or off these pixels we can create different characters. We can display up to 32 characters in two rows.

Yes, we can. We can store up to eight custom characters in the CGRAM (64 bytes in size) area. We can create load the matrix data for these characters and can recall when they need to be displayed.

Controlling the LCD module is pretty simple. Let’s walk through those steps. To adjust the contrast of the LCD, the Vo/ VEE pin is connected to a variable resistor. By adjusting the variable resistor, we can change the LCD contrast.

The RS or registry select pin helps the LCD controller to know whether the incoming signal is a control signal or a data signal. When this pin is high, the controller will treat the signal as a command instruction and if it’s low, it will be treated as data. The R/W or Read/Write pin is used either to write data to the LCD or to read data from the LCD. When it’s low, the LCD module will be in write mode and when it’s high, the module will be in reading mode.

The Enable pin is used to control the LCD data execution. By default, this pin is pulled low. To execute a command or data which is provided to the LCD data line, we will just pull the Enable pin to high for a few milliseconds.

To test the LCD module, connect the VDD, GND, and backlight pins to 5v and GND. Connect the center terminal of a 10K variable resistor to the VEE pin. Connect the other two terminals to VCC and GND as per the below connection diagram-

Simply rotate the variable resistor you will see that the contrast will be adjusted and small blocks are visible. If these rectangles are visible, and you were able to adjust the contrast, then the LCD is working.

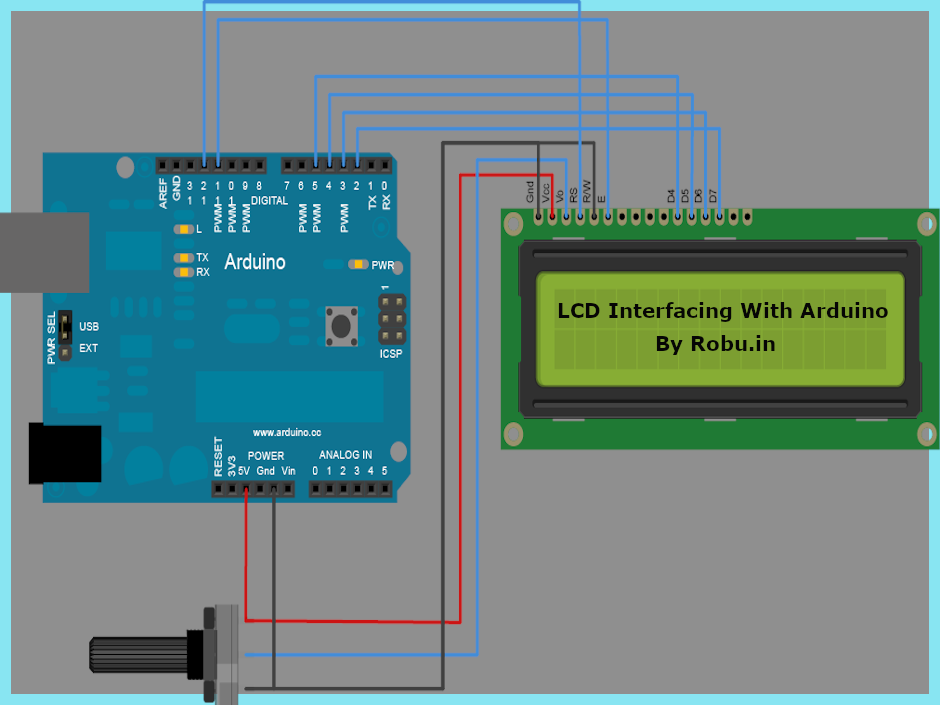

Let’s see how to connect the LCD module to Arduino. For that first, connect the VSS to the GND and VDD to the 5V. To use the LCD backlight, connect the backlight Anode to the 5V and connect the backlight cathode to the GND through a 220Ωresistor. Since we are not using the read function connect the LCD R/W pin to the GND too. To adjust the contrast, connect the centre pin of a 10KΩ trimmer resistor to the VEE pin and connect the side pins to the VCC and GND. Now connect the registry select pin to D12 and Enable pin to D11.

Now let’s connect the data pins. The LCD module can work in two modes, 8-bit and 4-bit. 8-bit mode is faster but it will need 8 pins for data transfer. In 4-bit mode, we only need four pins for data. But it is slower since the data is sent one nibble at a time. 4-bit mode is often used to save I/O pins, while the 8-bit mode is used when speed is necessary. For this tutorial, we will be using the 4-bit mode. For that connect the D4, D5, D6 and D7 pins from the LCD to the D5, D4, D3 and D2 pins of the Arduino.

Here is the actual circuit. It is built as per the connection diagram provided. All the connections are made using standard male to male jumper wires.

The following Arduino 16x2 LCD code will print Hello, World! on the first line of the display and the time the Arduino was running in seconds on the second line.

Now let’s discuss the code. As usual, the sketch starts by including the necessary libraries. For this tutorial, we will be including the LiquidCrystal library from Arduino. This library is compatible with LCDs based on the Hitachi HD44780, or any compatible chipset. You can find more details about this library on the Arduino website.

Let’s create an object to use with the LiquidCrystal library. The following line of code will create an object called lcd. We will be using this object in the entire code to access the library functions. The object is initialized with the pin numbers.

Now let’s look at the setup()function. The lcd.begin function is used to initialize the LCD module. This function will send all the initialization commands. The parameters used while calling this function are the number of columns and the number of rows. And the next function is lcd.print. with this function, we have printed the word Circuit Digest! to the LCD. Since the LCD cursor is set to home position within the lcd.begin, we don’t need to set any cursor position. This text will stay there for two seconds. After that, the text will scroll from left to right until the entire text is out of the display. To scroll the display to the right, we have used the function lcd.scrollDisplayRight. After that, to clear display, we used lcd.clear, this will clear any characters on the display.

Now let’s look at theloop function. The for loop will count from 0 to 9, and when it reaches 9, it will reset the count and repeat the process all over again. lcd.setCursor is used to set the cursor position. lcd.setCursor(8, 1) will set the LCD cursor to the eighth position in the second row. In the LCD, the first row is addressed as 0 and the second row is addressed as 1. And the lcd.print(i) will print the count value stored in the variable i to the display.

Wrong characters are displayed: This problem occurs usually when the LCD is not getting the correct data. Make sure you are sending the correct ASCII value. If you are sending the correct ASCII characters, but still showing the wrong one on the LCD, check your connections for loose contact or short circuits.

Display shows Black boxes or does not show anything: First thing to do in these situations is to adjust the contrast voltage by rotating the variable resistor. This will correct the contrast value and will give you a visible readout.

Contrast is Ok, but still no display: Make sure to provide a sufficient time delay in between sending each character. Because if you don’t give enough time to process the data the display will malfunction.

Contrast and delay are ok, but still no display: Make sure you are powering the LCD from a 5V source. By default, these displays won’t work with a supply voltage below 5V. So if you are using the display with a 3.3V microcontroller make sure to power the display from 5V and use level shifters in between the display and the microcontroller.

In this project we will provide the input voice using Google Voice Keyboard via a Android App (BlueTerm) and print the text on 16x2 LCD using Raspberry Pi.

In this tutorial we are interfacing a Liquid Crystal Display (LCD) module with the Raspberry Pi Pico using Micropython to display strings, and characters on the LCD.

We used some Python scripts to find the local IP address of your Raspberry Pi on the network and display it on the 16x2 LCD Screen. We also added the script in the Crontab so that it can be run on every 10 minutes and we will have the updated IP address every time.

If you’ve ever attempted to connect an LCD display to an Arduino, you’ve probably noticed that it uses a lot of Arduino pins. Even in 4-bit mode, the Arduino requires seven connections – half of the Arduino’s available digital I/O pins.

The solution is to use an I2C LCD display. It only uses two I/O pins that are not even part of the digital I/O pin set and can be shared with other I2C devices.

As the name suggests, these LCDs are ideal for displaying only characters. A 16×2 character LCD, for example, can display 32 ASCII characters across two rows.

At the heart of the adapter is an 8-bit I/O expander chip – PCF8574. This chip converts the I2C data from an Arduino into the parallel data required for an LCD display.

There is a jumper on the board that provides power to the backlight. To control the intensity of the backlight, you can remove the jumper and apply external voltage to the header pin labeled ‘LED’.

If you have multiple devices on the same I2C bus, you may need to set a different I2C address for the LCD adapter to avoid conflicting with another I2C device.

For this purpose, the adapter comes with three solder jumpers/pads (A0, A1, and A2). The address is set when a jumper is shorted with a blob of solder.

An important point to note here is that several companies, including Texas Instruments and NXP Semiconductors, manufacture the same PCF8574 chip. And the I2C address of your LCD depends on the chip manufacturer.

According to the Texas Instruments’ datasheet, the three address selection bits (A0, A1, and A2) are located at the end of the 7-bit I2C address register.

When you short a solder jumper, you pull that address input LOW. If you were to short all three jumpers, the address would be 0x20. So the range of all possible addresses spans from 0x20 to 0x27.

According to the NXP Semiconductors’ datasheet, the three address selection bits (A0, A1, and A2) are located at the end of the 7-bit I2C address register. However, the remaining bits in the address register are different.

When you short a solder jumper, you pull that address input LOW. If you were to short all three jumpers, the address would be 0x38. So the range of all possible addresses spans from 0x38 to 0x3F.

So the I2C address of your LCD is most likely 0x27 or 0x3F. If you’re not sure what your LCD’s I2C address is, there’s an easy way to figure it out. You’ll learn about that later in this tutorial.

Now we are left with the pins that are used for I2C communication. Note that each Arduino board has different I2C pins that must be connected correctly. On Arduino boards with the R3 layout, the SDA (data line) and SCL (clock line) are on the pin headers close to the AREF pin. They are also referred to as A5 (SCL) and A4 (SDA).

After wiring the LCD, you will need to adjust the contrast of the LCD. On the I2C module, there is a potentiometer that can be rotated with a small screwdriver.

Now, turn on the Arduino. You will see the backlight light up. As you turn the potentiometer knob, the first row of rectangles will appear. If you have made it this far, Congratulations! Your LCD is functioning properly.

Before you can proceed, you must install the LiquidCrystal_I2C library. This library allows you to control I2C displays using functions that are very similar to the LiquidCrystal library.

To install the library, navigate to Sketch > Include Library > Manage Libraries… Wait for the Library Manager to download the library index and update the list of installed libraries.

As previously stated, the I2C address of your LCD depends on the manufacturer. If your LCD has a PCF8574 chip from Texas Instruments, its I2C address is 0x27; if it has a PCF8574 chip from NXP Semiconductors, its I2C address is 0x3F.

If you’re not sure what your LCD’s I2C address is, you can run a simple I2C scanner sketch that scans your I2C bus and returns the address of each I2C device it finds.

However, before you upload the sketch, you must make a minor change to make it work for you. You must pass the I2C address of your LCD as well as the display dimensions to the LiquidCrystal_I2C constructor. If you’re using a 16×2 character LCD, pass 16 and 2; if you’re using a 20×4 character LCD, pass 20 and 4.

The next step is to create an object of LiquidCrystal_I2C class. The LiquidCrystal_I2C constructor accepts three inputs: I2C address, number of columns, and number of rows of the display.

In the setup, three functions are called. The first function is init(). It initializes the interface to the LCD. The second function is clear(). This function clears the LCD screen and positions the cursor in the upper-left corner. The third function, backlight(), turns on the LCD backlight.

The function setCursor(2, 0) is then called to move the cursor to the third column of the first row. The cursor position specifies where you want the new text to appear on the LCD. It is assumed that the upper left corner is col=0 and row=0.

There are many useful functions you can use with LiquidCrystal_I2C Object. Some of them are listed below:lcd.home() function positions the cursor in the upper-left of the LCD without clearing the display.

lcd.scrollDisplayRight() function scrolls the contents of the display one space to the right. If you want the text to scroll continuously, you have to use this function inside a for loop.

lcd.scrollDisplayLeft() function scrolls the contents of the display one space to the left. Similar to the above function, use this inside a for loop for continuous scrolling.

lcd.display() function turns on the LCD display, after it’s been turned off with noDisplay(). This will restore the text (and cursor) that was on the display.

If you find the default font uninteresting, you can create your own custom characters (glyphs) and symbols. They come in handy when you need to display a character that isn’t in the standard ASCII character set.

As previously discussed in this tutorial, a character is made up of a 5×8 pixel matrix; therefore, you must define your custom character within this matrix. You can define a character by using the createChar() function.

To use createChar(), you must first create an 8-byte array. Each byte in the array corresponds to a row in a 5×8 matrix. In a byte, the digits 0 and 1 indicate which pixels in a row should be OFF and which should be ON.

The CGROM stores the font that appears on a character LCD. When you instruct a character LCD to display the letter ‘A’, it needs to know which pixels to turn on so that we see an ‘A’. This data is stored in the CGROM.

CGRAM is an additional memory for storing user-defined characters. This RAM is limited to 64 bytes. Therefore, for a 5×8 pixel LCD, only 8 user-defined characters can be stored in CGRAM, whereas for a 5×10 pixel LCD, only 4 can be stored.

Creating custom characters has never been easier! We’ve developed a small application called Custom Character Generator. Can you see the blue grid below? You can click on any pixel to set or clear that pixel. And as you click, the code for the character is generated next to the grid. This code can be used directly in your Arduino sketch.

There’s no limit to what you can create. The only limitation is that the LiquidCrystal_I2C library only supports eight custom characters. But don’t be sad, look at the bright side; at least we have eight characters.

After including the library and creating the LCD object, custom character arrays are defined. The array consists of 8 bytes, with each byte representing a row in a 5×8 matrix.

This sketch contains eight custom-characters. Take, for example, the Heart[8] array. You can see that the bits (0s and 1s) are forming the shape of a heart. 0 turns the pixel off, and 1 turns it on.

In the setup, we use the createChar() function to create a custom character. This function accepts two parameters: a number between 0 and 7 to reserve one of the eight supported custom characters, and the name of the array.

We come across Liquid Crystal Display (LCD) displays everywhere around us. Computers, calculators, television sets, mobile phones, and digital watches use some kind of display to display the time.

An LCD screen is an electronic display module that uses liquid crystal to produce a visible image. The 16×2 LCD display is a very basic module commonly used in DIYs and circuits. The 16×2 translates a display of 16 characters per line in 2 such lines. In this LCD, each character is displayed in a 5×7 pixel matrix.

Contrast adjustment; the best way is to use a variable resistor such as a potentiometer. The output of the potentiometer is connected to this pin. Rotate the potentiometer knob forward and backward to adjust the LCD contrast.

Sends data to data pins when a high to low pulse is given; Extra voltage push is required to execute the instruction and EN(enable) signal is used for this purpose. Usually, we set en=0, when we want to execute the instruction we make it high en=1 for some milliseconds. After this we again make it ground that is, en=0.

A 16X2 LCD has two registers, namely, command and data. The register select is used to switch from one register to other. RS=0 for the command register, whereas RS=1 for the data register.

Command Register: The command register stores the command instructions given to the LCD. A command is an instruction given to an LCD to do a predefined task. Examples like:

Data Register: The data register stores the data to be displayed on the LCD. The data is the ASCII value of the character to be displayed on the LCD. When we send data to LCD, it goes to the data register and is processed there. When RS=1, the data register is selected.

Generating custom characters on LCD is not very hard. It requires knowledge about the custom-generated random access memory (CG-RAM) of the LCD and the LCD chip controller. Most LCDs contain a Hitachi HD4478 controller.

CG-RAM is the main component in making custom characters. It stores the custom characters once declared in the code. CG-RAM size is 64 bytes providing the option of creating eight characters at a time. Each character is eight bytes in size.

CG-RAM address starts from 0x40 (Hexadecimal) or 64 in decimal. We can generate custom characters at these addresses. Once we generate our characters at these addresses, we can print them by just sending commands to the LCD. Character addresses and printing commands are below.

LCD modules are very important in many Arduino-based embedded system designs to improve the user interface of the system. Interfacing with Arduino gives the programmer more freedom to customize the code easily. Any cost-effective Arduino board, a 16X2 character LCD display, jumper wires, and a breadboard are sufficient enough to build the circuit. The interfacing of Arduino to LCD display is below.

The combination of an LCD and Arduino yields several projects, the most simple one being LCD to display the LED brightness. All we need for this circuit is an LCD, Arduino, breadboard, a resistor, potentiometer, LED, and some jumper cables. The circuit connections are below.

The LCDduino board enables users to create many applications/projects that require a 16×2 LCD display and Arduino. The board has the exact size of 16×2 LCD and can be installed on the backside of the LCD. This is a low-cost solution that has onboard Arduino + LCD so no extra Arduino Nano or Arduino board is required. The Arduino compatible hardware includes onboard programming and boot-loader connectors, Atmega328 microcontroller, and 16×2 LCD interface. Each Arduino I/O Pin including the VCC and GND is exposed to the connectors for easy connection with sensors and other devices. The board enables the easy interface of many devices and sensors. The operating power supply is 7 to 15V DC.

After the board assembly, the brand new Atmega328 microcontroller requires burning the bootloader before it can be programmed using Arduino IDE. Refer to the connection diagram and follow the links below to learn more about bootloader and Arduino IDE programming.

Arduino example code is provided below to test the project. This code will help you to convert this board into a 0 to 5V Voltmeter. Just connect the DC source at analog in A0 to measure the DC voltage.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Hello friends welcome back to Techno-E-solution, In previous video we see how to interface LCD 16×2 to Arduino Uno, but there are very complicated circuits, so in this tutorial, I"ll show you how to reduce circuitry by using I2C module which is very compact & easy to connection. Simply connect I2C module with LCD parallel & connect I2C modules 4 pins to Arduino. I2C module has 4 output pins which contains VCC, GND, SDA, SCL where 5V supply gives to I2C module through VCC & GND to GND of Arduino. SDA is a data pin & SCL is clock pin of I2C module. To interface LCD and I2C with Arduino we need Liquid Crystal I2C Library in Arduino IDE software.

To make this project we need Arduino Liquidcrystal library in Arduino IDE. Follow following steps to add this library in Arduino IDE software.Open Arduino IDE Software.

A PCB Design Problems Detector, An Engineering Solution ProviderImport the Gerber file with one click. No need for complicated file reading steps to review easily and improve efficiency.

In this Arduino LCD I2C tutorial, we will learn how to connect an LCD I2C (Liquid Crystal Display) to the Arduino board. LCDs are very popular and widely used in electronics projects for displaying information. There are many types of LCD. This tutorial takes LCD 16x2 (16 columns and 2 rows) as an example. The other LCDs are similar.

Please note: These are affiliate links. If you buy the components through these links, We may get a commission at no extra cost to you. We appreciate it.

In the previous tutorial, we had learned how to use the normal LCD. However, wiring between Arduino and the normal LCD is complicated. Therefore, LCD I2C has been created to simplify the wiring. Actually, LCD I2C is composed of a normal LCD, an I2C module and a potentiometer.

We are considering to make the video tutorials. If you think the video tutorials are essential, please subscribe to our YouTube channel to give us motivation for making the videos.

lcd.print() function supports only ASCII characters. If you want to display a special character or symbol (e.g. heart, angry bird), you need to use the below character generator.

Depending on manufacturers, the I2C address of LCD may be different. Usually, the default I2C address of LCD is 0x27 or 0x3F. Try these values one by one. If you still failed, run the below code to find the I2C address.

※ OUR MESSAGESYou can share the link of this tutorial anywhere. Howerver, please do not copy the content to share on other websites. We took a lot of time and effort to create the content of this tutorial, please respect our work!

ArduinoGetStarted.com is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to Amazon.com, Amazon.it, Amazon.fr, Amazon.co.uk, Amazon.ca, Amazon.de, Amazon.es and Amazon.co.jp

Тhis time I will present you a simple way to control 16x2 LCD Display via Windows PC software. For this purpose, we use an Arduino microcontroller, which in this case has the function of an interface between the Display and the USB port of the Computer. Also the LCD display can be controlled directly through the LPT port, but nowadays that port is no longer used and has been replaced by USB.

- Arduino microcontroller, and LCD display which are connected according to the given schematic diagram, and it is powered directly from the USB port.

I mounted the device in a box from a previous project, and is a stand-alone device that can be placed on top of the computer case or somewhere else. Оtherwise the original idea was to mount the LCD screen to the plastic of 5.25-Inch drive bay and be an integral part of the PC.

First, we unpack the.zip archive into a specific folder. Then the LCDT.dll matrix orbital driver should be placed in the "displays" folder. This is actually a driver for the 16x2 LCD display. You can download these archives at the link below. Next, we start the program and select the LCD display plugin, then we set the startup parameters according to the port occupied by the Arduino microcontroller. Now the simplest option is to enter some text in these fields which actually represent the two rows of the LCD display. If we have connected everything exactly according to the instructions, when we press the apply button, the written text should appear on the LCD display. Lcd Smartier has built in support for many systems statistics (i.e. cpu load, network utilization, free disk space, Winamp integration, BBC World News, Email details, game stats, and many more. It is also possible to integrate several different plugins that can be downloaded from the official site and forums. As for the Arduino, the given code should be uploaded, but I should mention that the code is compiled with the LiquidCrystal-1.0.0 Library which you can also download from the link below. LCD Smartie also has support for the popular Winamp player software.

16×2 LCD Module which can display 32 ASCII characters in 2 lines (16 characters in 1 line). Other commonly used LCD displays are 20×4 Character LCD, Nokia 5110 LCD module, 128×64 Graphical LCD Display, and 2.4 inch TFT Touch screen LCD

An infrared (IR) sensor is an electronic device that measures and detects infrared radiation in its surrounding environment. When an object comes close to the sensor, the infrared light from the LED reflects off of the object and is detected by the receiver.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Previous examples connect the white LED backlight to power. The following example is specifically for those using an LCD with a RGB LED backlight. The only difference between the connection is the LED"s backlight on pins 15-18.

Copy and paste the code below. Just make sure to select the correct board (in this case the Arduino/ Genuino Uno) and the COM port that the Arduino enumerated on. Then upload the code to your Arduino.

After uploading, you will notice the same "Hello, world!" and time since the Arduino was last reset in the first example. The only difference is that the current color of the backlight will be printed as it cycles through each of the primary, secondary, and tertiary colors. You should see something similar to the image below.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey