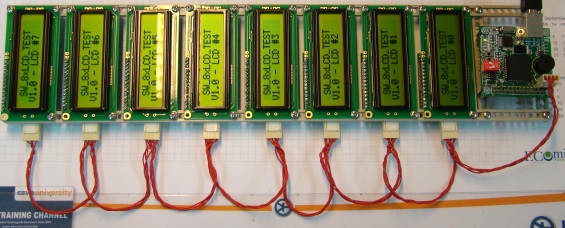

multiple lcd displays in stock

Planar® CarbonLight™ VX Series is comprised of carbon fiber-framed indoor LED video wall and floor displays with exceptional on-camera visual properties and deployment versatility, available in 1.9 and 2.6mm pixel pitch (wall) and 2.6mm (floor).

From cinema content to motion-based digital art, Planar® Luxe MicroLED Displays offer a way to enrich distinctive spaces. HDR support and superior dynamic range create vibrant, high-resolution canvases for creative expression and entertainment. Leading-edge MicroLED technology, design adaptability and the slimmest profiles ensure they seamlessly integrate with architectural elements and complement interior décor.

From cinema content to motion-based digital art, Planar® Luxe Displays offer a way to enrich distinctive spaces. These professional-grade displays provide vibrant, high-resolution canvases for creative expression and entertainment. Leading-edge technology, design adaptability and the slimmest profiles ensure they seamlessly integrate with architectural elements and complement interior decor.

From cinema content to motion-based digital art, Planar® Luxe MicroLED Displays offer a way to enrich distinctive spaces. HDR support and superior dynamic range create vibrant, high-resolution canvases for creative expression and entertainment. Leading-edge MicroLED technology, design adaptability and the slimmest profiles ensure they seamlessly integrate with architectural elements and complement interior décor.

Planar® CarbonLight™ VX Series is comprised of carbon fiber-framed indoor LED video wall and floor displays with exceptional on-camera visual properties and deployment versatility, available in 1.9 and 2.6mm pixel pitch (wall) and 2.6mm (floor).

Carbon fiber-framed indoor LED video wall and floor displays with exceptional on-camera visual properties and deployment versatility for various installations including virtual production and extended reality.

a line of extreme and ultra-narrow bezel LCD displays that provides a video wall solution for demanding requirements of 24x7 mission-critical applications and high ambient light environments

Since 1983, Planar display solutions have benefitted countless organizations in every application. Planar displays are usually front and center, dutifully delivering the visual experiences and critical information customers need, with proven technology that is built to withstand the rigors of constant use.

Planar® CarbonLight™ VX Series is comprised of carbon fiber-framed indoor LED video wall and floor displays with exceptional on-camera visual properties and deployment versatility, available in 1.9 and 2.6mm pixel pitch (wall) and 2.6mm (floor).

From cinema content to motion-based digital art, Planar® Luxe MicroLED Displays offer a way to enrich distinctive spaces. HDR support and superior dynamic range create vibrant, high-resolution canvases for creative expression and entertainment. Leading-edge MicroLED technology, design adaptability and the slimmest profiles ensure they seamlessly integrate with architectural elements and complement interior décor.

From cinema content to motion-based digital art, Planar® Luxe Displays offer a way to enrich distinctive spaces. These professional-grade displays provide vibrant, high-resolution canvases for creative expression and entertainment. Leading-edge technology, design adaptability and the slimmest profiles ensure they seamlessly integrate with architectural elements and complement interior decor.

From cinema content to motion-based digital art, Planar® Luxe MicroLED Displays offer a way to enrich distinctive spaces. HDR support and superior dynamic range create vibrant, high-resolution canvases for creative expression and entertainment. Leading-edge MicroLED technology, design adaptability and the slimmest profiles ensure they seamlessly integrate with architectural elements and complement interior décor.

Planar® CarbonLight™ VX Series is comprised of carbon fiber-framed indoor LED video wall and floor displays with exceptional on-camera visual properties and deployment versatility, available in 1.9 and 2.6mm pixel pitch (wall) and 2.6mm (floor).

Carbon fiber-framed indoor LED video wall and floor displays with exceptional on-camera visual properties and deployment versatility for various installations including virtual production and extended reality.

a line of extreme and ultra-narrow bezel LCD displays that provides a video wall solution for demanding requirements of 24x7 mission-critical applications and high ambient light environments

Since 1983, Planar display solutions have benefitted countless organizations in every application. Planar displays are usually front and center, dutifully delivering the visual experiences and critical information customers need, with proven technology that is built to withstand the rigors of constant use.

Can you or someone else help me understand the relevance of the addresses in relation to the pin out, for example currently I have a single Ic2 LCD working using the following

1.The use of supermarket shelves LCD display can increase the orderly placement of goods. Such as supermarket shelves TFT LCD digital poster, goods new arrivel information on LCD screen, can make the supermarket"s products fresh taste, beautiful display on the shelves, and promote customers" desire to buy.

2. The use of shelves TFT LCD bar type display can reduce the cost of printing advertising poster cost, and updated the digital goods information remotely.

3. The use of ultra thin lcd display on shelf can improve the efficiency of employees. Such as driving into the shelves, can be used with a forklift, reducing the labor intensity of employees, saving the cost of human resources for the company.

4. The use of supermarket shelves lcd digital poster can make the visitors , customer have impact in their minds.And it displays in all sides with intelligent.

Black finished ultra thin stretched bar LCD display for shoes store, perfume store, babies store , retail store, supermarket shelf digital advertising.

A: Hello, our company located in XIAMEN city, our factory cover 1500 Square meters with 48 workers and three production line. XINSENYUE mainly manufacturer Ultra Wide Stretched Bar LCD, TFT LCD monitor, Industrial touch screen all in one PC, industrial LCD monitor, our brand imported from AUO, BOE , LG/SUMSUNG etc. We are manufacturer of stretched LCD, industrial monitor , electric stop-sign, industrial panel pc.

A: Yes. We provide single version and Network version for customer option. LVDs LCD Module , VGA, DVI, HDM1,USB single version main board, Android mainboard supported

ViewStation Universal:Environmentally sealed LCD enclosure for use indoors and outdoors. The ViewStation Universal digital signage enclosure is ideal in high traffic areas where vandalism, theft and various weather concerns pose problems. Available in sizes ranging from 32″ to 75″ in single and double sided configurations.

ViewStation Passively Cooled:Vented LCD enclosure for use indoors or outdoors with limited weather exposure. The ViewStation Passively Cooled display enclosure does not require fans or filters to maintain and is compatible with most popular manufacturer’s LCD mounts. The passively cooled enclosure is made to order based the LCD.

Many healthcare facilities require products that are rated “anti-ligature” (or ligature resistant) to protect patients and prisoners from harming themselves and/or others. It is particularly popular for lounges and activity rooms to have LCD enclosures installed, so that individuals can watch TV and relax. Facilities must take into consideration the area that the LCD will be used and choose the safest possible solution to avoid injury.

ViewStation Full Sun:Outdoor LCD enclosure for use in direct sunlight, all weather environments. The ViewStation Full Sun is designed around the use of a 47″ high bright LCD for visibility in the toughest digital signage applications. Available in landscape orientation, the ViewStation Full Sun LCD enclosure can be mounted on the wall, ceiling or pedestal.

ViewStation Array:House multiple LCDs within one ViewStation Array enclosure. Ideal for video wall applications that require additional protection from high traffic areas, vandalism and/or weather concerns. Many configurations are available for indoor and outdoor digital signage projects. Enclose as few as two LCDs or as many as six LCDs.

The InfoStation Interactive Touchscreen Kiosk brings the world to your fingertips! From wayfinding, to directories, to web pages, the InfoStation is the strongest tool to bring information to consumers. Paired with a 42-inch projected capacitive touchscreen LCD and a PC signage player, the InfoStation kiosk delivers interactive digital signage.

Commonly we show example of getting started with LCD with one LCD and some sensor, like we have guide on Arduino Temperature & Humidity Sensor DHT 11 With LCD 1602A. We Can Easily Run Two to Four 16×2 LCDs On Arduino UNO. In This Article, We Will Supply Same Code and Diagram For Running Multiple LCD Displays On One Arduino UNO. Basic matter is that, when we use LCD without I²C module then it occupies lot of pins. For making easy around basic theory, we discussed about Serial Peripheral Interface, I²C etc topics and shown example setup of 1602A LCD Display I2C Serial Interface. The solution to run multiple LCDs at the same time probably obvious by now – using I²C module. But without I²C module it is also possible to use multiple LCD displays, that is by sharing some of the pins.

Pin 7, 8, 9 and 10 on the Arduino for the data. Pin 12 for RS. Pin 2, 3, 4 and 5 for the signal for display. You can use one common potentiometer. Idea of using four displays is from this website :

Just enable the display you want to talk to and send the data. The other displays will ignore it. Whether that"ll work over the length of cable you"ll need for your use case I don"t know.

I need some advice. A special project of mine needs connecting up to one hundred round LCD panels to one single Raspberry Pi2. The idea is to create a kind of photo wall, each display with a different photo, but "sticky". Refresh is simultaneous over all displays. The application is embedded in a hardware console, and the price needs to be as low as possible, hence my idea to use raw "Chinese" smart watch displays.

You might be able to drive the displays directly, but another option is to send the images to the SD card (optional, on the back of the module) then send a (smaller/shorter/quicker?) command to get the display to show an image from the card. I don"t actually know- the thought just occurred to me. The LCD module may also have a double buffer on-board. I didn"t look at the driver specs.

Yes, I did, but exact numbers are not that important in this case. The project is about creating digital/physical equivalents of handmade switches, in tradition aging centuries back. The displays will be embedded on top of a tubular hand grip, which will be used as a cap for a momentary button. The display functions as both a programmable graphical label and as a status indicator for visual feedback of the logical switch. A small installation would use - say - 25 switches, a large one up to 120 (educated guess), a typical in my estimate would need around 70.

You can hang multiple devices on an SPI bus. Have just one device with SS active. So, you need to work out a way to mux the SS pins of multiple devices so that only one is active at any one time.

Yes, I did, but exact numbers are not that important in this case. The project is about creating digital/physical equivalents of handmade switches, in tradition aging centuries back. The displays will be embedded on top of a tubular hand grip, which will be used as a cap for a momentary button. The display functions as both a programmable graphical label and as a status indicator for visual feedback of the logical switch. A small installation would use - say - 25 switches, a large one up to 120 (educated guess), a typical in my estimate would need around 70.

I did look into various other resources, including the ones in this thread. There is no copy/paste solution I"m afraid. However, I noticed that various display manufacturers add usage sections to their manuals, some of them to include instructions on how to combine multiple displays on a single SPI bus. Perhaps that is enough for you to help you along. If you do, I would like to hear from you. If you can/want to wait, perhaps we can team up. I was thinking of making this a full Open Source project anyway.

I am planing to procure 2 to 3 TFT LCDs and begin my testing with that. Since I am a beginner in this , It might help me to have a better understanding on SPI Interface. I will be looking forward to team up with you on this project.

I was hoping to connect 5 colour LCD displays using spi has anyone done a write up on.something like this? I"m a total beginner coming from a software background and would love some help on how it might work hardware/wiring wise?

Take a look at the integrated circuit on the backpack PWB for my LCD panel - for Philips (now NXP) there are two 8pin-IO devices that are typically used (PCF)8574 and (PCF)8574A (Red outline in photo) and they can each have one of eight different address assignments depending on the settings of three address lines A0-A2 (Yellow outline in photo), on mine there are pull-up resistors (to the 5V supply) and a pair of pads that can be linked together with a blob of solder to short the address line to 0V (Ground) so that the IC takes a different address.

The MCP23017 device provides 16-bit, general purpose parallel I/O expansion for I2C bus. Upto 8 such devices can be connected on to the same I2C bus by varying their slave addresses through the hardware address pins. In his project, Jesus used eight MCP23017 devices (one for each LCD) to control eight LCDs over an I2C bus.

The Serial Monitor is a convenient way to view data from an Arduino, but what if you want to make your project portable and view sensor values without access to a computer? Liquid crystal displays (LCDs) are excellent for displaying a string of words or sensor data.

This guide will help you in getting your 16×2 character LCD up and running, as well as other character LCDs (such as 16×4, 16×1, 20×4, etc.) that use Hitachi’s LCD controller chip, the HD44780.

As the name suggests, these LCDs are ideal for displaying only characters. A 16×2 character LCD, for example, can display 32 ASCII characters across two rows.

Character LCDs are available in a variety of sizes and colors, including 16×1, 16×4, 20×4, white text on a blue background, black text on a green background, and many more.

One advantage of using any of these displays in your project is that they are “swappable,” meaning that you can easily replace them with another LCD of a different size or color. Your code will need to be tweaked slightly, but the wiring will remain the same!

Before we get into the hookup and example code, let’s check out the pinout. A standard character LCD has 16 pins (except for an RGB LCD, which has 18 pins).

Vo (LCD Contrast) pin controls the contrast of the LCD. Using a simple voltage divider network and a potentiometer, we can make precise contrast adjustments.

RS (Register Select) pin is used to separate the commands (such as setting the cursor to a specific location, clearing the screen, etc.) from the data. The RS pin is set to LOW when sending commands to the LCD and HIGH when sending data.

R/W (Read/Write) pin allows you to read data from or write data to the LCD. Since the LCD is only used as an output device, this pin is typically held low. This forces the LCD into WRITE mode.

E (Enable) pin is used to enable the display. When this pin is set to LOW, the LCD ignores activity on the R/W, RS, and data bus lines; when it is set to HIGH, the LCD processes the incoming data.

The LCD has two separate power connections: one for the LCD (pins 1 and 2) and one for the LCD backlight (pins 15 and 16). Connect LCD pins 1 and 16 to GND and 2 and 15 to 5V.

Depending on the manufacturer, some LCDs include a current-limiting resistor for the backlight. It is located on the back of the LCD, close to pin 15. If your LCD does not contain this resistor or if you are unsure whether it does, you must add one between 5V and pin 15. It should be safe to use a 220 ohm resistor, although a value this high may make the backlight slightly dim. For better results, check the datasheet for the maximum backlight current and choose an appropriate resistor value.

Let’s connect a potentiometer to the display. This is necessary to fine-tune the contrast of the display for best visibility. Connect one side of the 10K potentiometer to 5V and the other to Ground, and connect the middle of the pot (wiper) to LCD pin 3.

That’s all. Now, turn on the Arduino. You will see the backlight light up. As you turn the potentiometer knob, you will see the first row of rectangles appear. If you have made it this far, Congratulations! Your LCD is functioning properly.

We know that data is sent to the LCD via eight data pins. However, HD44780-based LCDs are designed so that we can communicate with them using only four data pins (in 4-bit mode) rather than eight (in 8-bit mode). This helps us save 4 I/O pins!

The sketch begins by including the LiquidCrystal library. This library comes with the Arduino IDE and allows you to control Hitachi HD44780 driver-based LCD displays.

Next, an object of the LiquidCrystal class is created by passing as parameters the pin numbers to which the LCD’s RS, EN, and four data pins are connected.

In the setup, two functions are called. The first function is begin(). It is used to initialize the interface to the LCD screen and to specify the dimensions (columns and rows) of the display. If you’re using a 16×2 character LCD, you should pass 16 and 2; if you’re using a 20×4 LCD, you should pass 20 and 4.

In the loop, the print() function is used to print “Hello world!” to the LCD. Please remember to use quotation marks " " around the text. There is no need for quotation marks when printing numbers or variables.

The function setCursor() is then called to move the cursor to the second row. The cursor position specifies where you want the new text to appear on the LCD. It is assumed that the upper left corner is col=0 and row=0.

There are many useful functions you can use with LiquidCrystal Object. Some of them are listed below:lcd.home() function positions the cursor in the upper-left of the LCD without clearing the display.

lcd.scrollDisplayRight() function scrolls the contents of the display one space to the right. If you want the text to scroll continuously, you have to use this function inside a for loop.

lcd.scrollDisplayLeft() function scrolls the contents of the display one space to the left. Similar to the above function, use this inside a for loop for continuous scrolling.

lcd.display() function turns on the LCD display, after it’s been turned off with noDisplay(). This will restore the text (and cursor) that was on the display.

The CGROM stores the font that appears on a character LCD. When you instruct a character LCD to display the letter ‘A’, it needs to know which dots to turn on so that we see an ‘A’. This data is stored in the CGROM.

CGRAM is an additional memory for storing user-defined characters. This RAM is limited to 64 bytes. Therefore, for a 5×8 pixel LCD, only 8 user-defined characters can be stored in CGRAM, whereas for a 5×10 pixel LCD, only 4 can be stored.

After including the library and creating the LCD object, custom character arrays are defined. The array consists of 8 bytes, with each byte representing a row in a 5×8 matrix.

If you’ve ever attempted to connect an LCD display to an Arduino, you’ve probably noticed that it uses a lot of Arduino pins. Even in 4-bit mode, the Arduino requires seven connections – half of the Arduino’s available digital I/O pins.

The solution is to use an I2C LCD display. It only uses two I/O pins that are not even part of the digital I/O pin set and can be shared with other I2C devices.

As the name suggests, these LCDs are ideal for displaying only characters. A 16×2 character LCD, for example, can display 32 ASCII characters across two rows.

At the heart of the adapter is an 8-bit I/O expander chip – PCF8574. This chip converts the I2C data from an Arduino into the parallel data required for an LCD display.

If you have multiple devices on the same I2C bus, you may need to set a different I2C address for the LCD adapter to avoid conflicting with another I2C device.

An important point to note here is that several companies, including Texas Instruments and NXP Semiconductors, manufacture the same PCF8574 chip. And the I2C address of your LCD depends on the chip manufacturer.

So the I2C address of your LCD is most likely 0x27 or 0x3F. If you’re not sure what your LCD’s I2C address is, there’s an easy way to figure it out. You’ll learn about that later in this tutorial.

After wiring the LCD, you will need to adjust the contrast of the LCD. On the I2C module, there is a potentiometer that can be rotated with a small screwdriver.

Now, turn on the Arduino. You will see the backlight light up. As you turn the potentiometer knob, the first row of rectangles will appear. If you have made it this far, Congratulations! Your LCD is functioning properly.

Before you can proceed, you must install the LiquidCrystal_I2C library. This library allows you to control I2C displays using functions that are very similar to the LiquidCrystal library.

As previously stated, the I2C address of your LCD depends on the manufacturer. If your LCD has a PCF8574 chip from Texas Instruments, its I2C address is 0x27; if it has a PCF8574 chip from NXP Semiconductors, its I2C address is 0x3F.

If you’re not sure what your LCD’s I2C address is, you can run a simple I2C scanner sketch that scans your I2C bus and returns the address of each I2C device it finds.

However, before you upload the sketch, you must make a minor change to make it work for you. You must pass the I2C address of your LCD as well as the display dimensions to the LiquidCrystal_I2C constructor. If you’re using a 16×2 character LCD, pass 16 and 2; if you’re using a 20×4 character LCD, pass 20 and 4.

In the setup, three functions are called. The first function is init(). It initializes the interface to the LCD. The second function is clear(). This function clears the LCD screen and positions the cursor in the upper-left corner. The third function, backlight(), turns on the LCD backlight.

The function setCursor(2, 0) is then called to move the cursor to the third column of the first row. The cursor position specifies where you want the new text to appear on the LCD. It is assumed that the upper left corner is col=0 and row=0.

There are many useful functions you can use with LiquidCrystal_I2C Object. Some of them are listed below:lcd.home() function positions the cursor in the upper-left of the LCD without clearing the display.

lcd.scrollDisplayRight() function scrolls the contents of the display one space to the right. If you want the text to scroll continuously, you have to use this function inside a for loop.

lcd.scrollDisplayLeft() function scrolls the contents of the display one space to the left. Similar to the above function, use this inside a for loop for continuous scrolling.

lcd.display() function turns on the LCD display, after it’s been turned off with noDisplay(). This will restore the text (and cursor) that was on the display.

The CGROM stores the font that appears on a character LCD. When you instruct a character LCD to display the letter ‘A’, it needs to know which pixels to turn on so that we see an ‘A’. This data is stored in the CGROM.

CGRAM is an additional memory for storing user-defined characters. This RAM is limited to 64 bytes. Therefore, for a 5×8 pixel LCD, only 8 user-defined characters can be stored in CGRAM, whereas for a 5×10 pixel LCD, only 4 can be stored.

After including the library and creating the LCD object, custom character arrays are defined. The array consists of 8 bytes, with each byte representing a row in a 5×8 matrix.

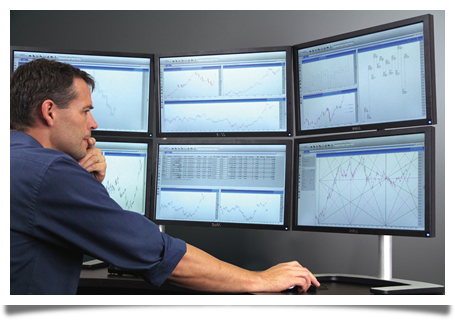

An LCD video wall is a large visualization surface that is built from multiple LCD displays (also known as ‘tiles’). These individual displays are designed specifically for use in these applications, and differ highly from normal television sets. The biggest differences are the bezel width, the mounting system, and the reliability. Normal television sets are designed to play a few hours per day, these specific panels are expected to play much more. Often even 24/7. And because the environments in which these video walls are deployed are sometimes critical, the uptime needs to be as high as possible.

Especially important for video walls, is a perfect calibration. This is not only restricted to a single panel. More critical, is that the color and brightness settings of the complete wall match. This means that the values of all panels need to be synchronized with the surrounding displays. If not, even the slightest deviation in color or brightness will make the wall seem out of balance.

High brightness: The light output of LCD video walls is generally quite high. Especially compared to LED-lit rear-projection cubes, LCD scores better. This allows the use in most lighting conditions - even in daylight.

Low real estate needs: Rear-projection cubes are quite deep, and (unless front access is available) need a rear maintenance area. As such, they need a lot of real estate space. LCD video walls only take the place on the wall of the panel depth and the wall mounting. This is usually less than 20 cm / 7.9”.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey