how to make a lcd screen price

Once it’s recognized that a custom display will be a better design and lead to a lower overall system-level cost it’s time to dive into the actual tooling costs.

There are many factors that go into determining the upfront tooling. There’s also due diligence to be performed prior to making this commitment to ensure that this new custom display supplier will effectively support you over the long term.

Customization can either be semi-custom or fully custom. Semi-custom is where some attributes of a standard product are modified to fit the application. In contrast, fully custom is where the design is started from scratch and each component is designed from the ground up.

Semi-custom is typically the preferred option to start with. And in the case of color TFT, it’s typically the only option, as the TFT panel comes with a significant tooling and minimum order quantity (MOQ) such that the customization costs outweigh the drawbacks of using the closest standard TFT glass platform available.

b) Custom color TFT displays— the bulk of this cost comes from the TFT glass cell at $70K–$200K depending on the type of TFT cell used (standard TN or IPS). The balance of the module is an additional $5,000 – $15,000.

f) Touch panels— resistive touch panels cost approximately $2,500, while capacitive touch panels can range between $4,000 and $10,000. If a standard capacitive touch sensor can be used, and only a custom top surface is customized, the tooling can be reduced to only $1,500.

g) Backlights— monochrome display backlights are less complex and cheaper to tool at $2,000 – $4,000. The color counterpart, due to its high brightness requirement, will run between $4,000 and $10,000.

i) Overlays— this can vary significantly depending on the complexity of the screen printing, as well as any additional features, such as button or LED indicators. The overlay will typically range from $1,500 - $4,500.

Now that we’ve reviewed some of the costs associated with custom displays, here are some tips you can use to make sure that you move forward with the right partner that will then support this custom display for the long term.

Many LCD display manufacturers try to accommodate all order volumes they receive. While this allows them to serve a wider range of customers, it makes them less specialized for serving certain types of customers. As a result, your specific production volumes may be prohibitively expensive.

Seek out a display manufacturer who is optimized to handle your specific production needs for LCD displays. This is necessary to get the display for the right cost and the appropriate level of support.

Always start with a semi-custom approach. Use the available standard products to base the new design on, and then keep modifying as needed. This results in the lowest tooling costs and an easier design process. And in the case of color TFT, unless you are developing the next iPhone, design your display based on one of the standard glass platforms readily available. Then from there, redesign the backlight and the mechanical and electrical interface for your specific application.

Behind every great company are happy customers. Find out whether your supplier has them. Make sure that when this experience is handed off from your supplier’s sales and design team, the production team is just as good and accommodating. This can be accomplished through references and audits.

Initiating a successful relationship for a new custom display is all about having an open and transparent relationship with the right partner. And by designing the ideal custom or semi-custom display with this partner, you can ensure you’re getting the best possible solution for your company.

Looking to take your project to the next level in terms of functionality and appearance? A custom LCD display might be the thing that gets you there, at least compared to the dot-matrix or seven-segment displays that anyone and their uncle can buy from the usual sources for pennies. But how does one create such a thing, and what are the costs involved? As is so often the case these days, it’s simpler and cheaper than you think, and [Dave Jones] has a great primer on designing and specifying custom LCDs.

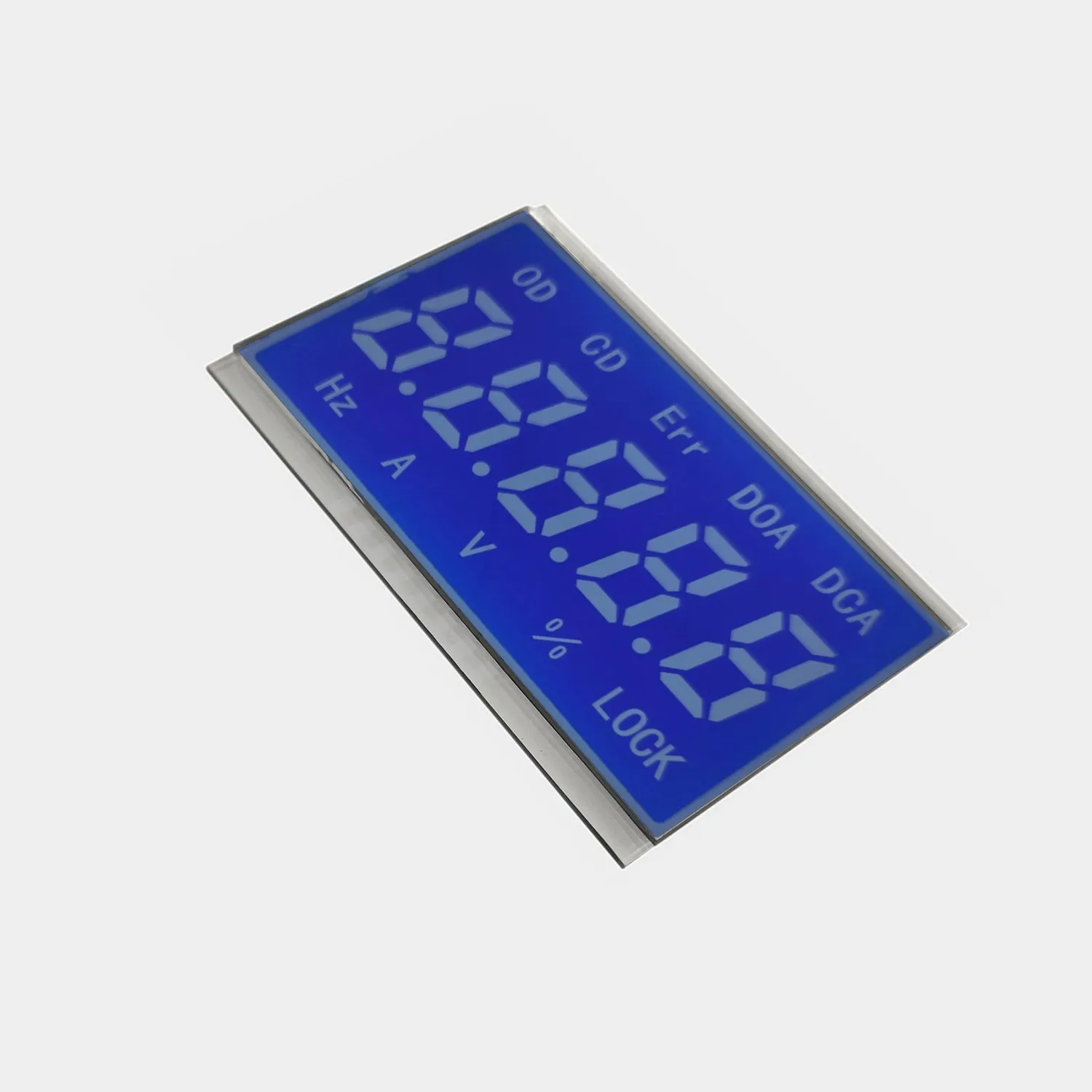

The video below is part of an ongoing series; a previous video covered the design process, turning the design into a spec, and choosing a manufacturer; another discussed the manufacturer’s design document approval and developing a test plan for the module. This one shows the testing plan in action on the insanely cheap modules – [Dave] was able to have a small run of five modules made up for only $138, which included $33 shipping. The display is for a custom power supply and has over 200 segments, including four numeric sections, a clock display, a bar graph, and custom icons for volts, amps, millijoules, and watt-hours. It’s a big piece of glass and the quality is remarkable for the price. It’s not perfect – [Dave] noted a group of segments on the same common lines that were a bit dimmer than the rest, but was able to work around it by tweaking the supply voltage a bit.

We’re amazed at how low the barrier to entry into custom electronics has become, and even if you don’t need a custom LCD, at these prices it’s tempting to order one just because you can. Of course, you can also build your own LCD display completely from scratch too.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

LCD panel prices have risen for 4 months in a row because of your home gaming? Since this year, the whole LCD panel market has smoked. Whether after the outbreak of the epidemic, LCD panel market prices rose for four months, or the panel giants in Japan and South Korea successively sold production lines, or the Chinese mainland listed companies frequently integrated acquisition, investment, and plant construction, all make the industry full of interesting.

LCD panel prices are already a fact. Since May this year, LCD panel prices have risen for four months in a row, making the whole industry chain dynamic. Why are LCD panels going up in price in a volatile 2020? The key factor lies in the imbalance between supply and demand.

The 43 inches and 55 inches rose more than double digits in August, reaching 13.7% each, and rose another $7 and $13, respectively, to $91 and $149, respectively, in September.

For larger sizes, overseas stocks remained strong, with prices for 65 inches and 75 inches rising $10 on average to $200 and $305 respectively in September.

The price of LCDS for large-size TVs of 70 inches or more hasn’t budged much. In addition, LTPS screens and AMOLED screens used in high-end phones have seen little or no increase in price.

As for October, LCD panel price increases are expected to moderate. The data shows that in October 32 inches or 2 dollars; Gains of 39.5 to 43 inches will shrink to $3;55 inches will fall back below $10; The 65-inch gain will narrow to $5.

During the epidemic, people stayed at home and had no way to go out for entertainment. They relied on TV sets, PCS, and game consoles for entertainment. After the resumption of economic work and production, the market of traditional home appliances picked up rapidly, and LCD production capacity was quickly digested.

However, due to the shutdown of most factories lasting 1-2 months during the epidemic period, LCD panel production capacity was limited, leading to insufficient production capacity in the face of the market outbreak, which eventually led to the market shortage and price increase for 4 consecutive months.

In fact, the last round of price rise of LCD panels was from 2016 to 2017, and its overall market price has continued to fall since 2018. Even in 2019, individual types have fallen below the material cost, and the whole industry has experienced a general operating loss. As a result, LCD makers have been looking for ways to improve margins since last year.

A return to a reasonable price range is the most talked about topic among panel makers in 2019, according to one practitioner. Some manufacturers for the serious loss of the product made the decision to reduce production or even stop production; Some manufacturers planned to raise the price, but due to the epidemic in 2020, the downstream demand was temporarily suppressed and the price increase was postponed. After the outbreak was contained in April, LCD prices began to rise in mid-to-late May.

This kind of price correction is in line with the law of industrial development. Only with reasonable profit space can the whole industry be stimulated to move forward.

In fact, the market price of LCD panels continued to decline in 2018-2019 because of the accelerated rise of China’s LCD industry and the influx of a large number of local manufacturers, which doubled the global LCD panel production capacity within a few years, but there was no suitable application market to absorb it. The result of excess capacity is oversupply, ultimately making LCD panel prices remain depressed.

Against this background, combined with the impact of the epidemic in 2020, the operating burden of LCD companies in Japan and South Korea has been further aggravated, and it is difficult to make profits in the production of LCD panels, so they have to announce the withdrawal of LCD business.

business in June 2022. In August, Sharp bought JDI Baishan, a plant in Ishikawa prefecture that makes liquid crystal display panels for smartphones. In early September, Samsung Display sold a majority stake in its SUZHOU LCD production plant to Starlight Electronics Technology, a unit of TCL Technology Group. LGD has not only pulled out of some of its production capacity but has announced that it will close its local production line in 2020. According to DSCC, a consultancy, the share of LCD production capacity in South Korea alone will fall from 19% to 7% between 2020 and 2021.

It is worth mentioning that in industry analysis, in view of the fact that Korean companies are good at using “dig through old bonus – selling high price – the development of new technology” the cycle of development mode, another 2020 out of the LCD production capacity, the main reason may be: taking the advantage of China’s expanding aggressively LCD manufacturers, Korean companies will own LCD panel production line hot sell, eliminating capacity liquid to extract its final value, and turning to the more profitable advantage of a new generation of display technologies, such as thinner, color display better OLED, etc. Samsung, for example, has captured more than 80% of the OLED market with its first-mover advantage.

From the perspective of production capacity, the launch of LCD tracks by major manufacturers in Japan and South Korea must reduce some production capacity in the short term, which to some extent induces market price fluctuations. In the long run, some of the Japanese and Korean LCD production capacity has been bought by Chinese manufacturers, coupled with frequent investment in recent years, the overall capacity is sure to recover as before, or even more than before. But now it will take time to expand the production layout, which more or less will cause supply imbalance, the industry needs to be cautious.

The LCD panel industry started in the United States and then gradually moved to Japan, South Korea, China, and Taiwan. At present, the proportion of production capacity in The Chinese mainland has reached 52% in 2020, and there are leading LCD panel products in China represented by BOE, Huxing Optoelectronics. Meanwhile, the production capacity layout of BOE, Huike, Huxing Optoelectronics, and other manufacturers has been basically completed, making industrial integration a necessity.

On the one hand, South Korean enterprises out of the LCD track, the domestic factory horse enclosure, plant expansion action. While LCDs may not sell as well as “upstart” flexible screens, respondents believe they are still strong enough in the traditional home appliance market to warrant continued investment. Zhao Bin, general manager of TCL Huaxing Development Center, has said publicly that the next-generation display technology will be mature in four to five years, but the commercialization of products may not take place until a decade later. “LCD will still be the mainstream in this decade,” he said.

On the other hand, there is no risk of neck jam in China’s LCD panel industry, which is generally controllable. In mainland China, there will be 21 production lines capable of producing 32-inch or larger LCD panels by 2021, accounting for about two-thirds of the global total. In terms of the proportion of production capacity, the Chinese mainland accounted for 42% of the global LCD panel in 2019, 51% this year, and will continue to climb to 63% next year.

Of course, building factories and expanding production cannot be accomplished overnight. In the process of production capacity recovery, it is predicted that there will be several price fluctuations, and the cost may be passed on to the downstream LCD panel manufacturers or consumers when the price rises greatly, which requires continuous attention.

Whether you stepped on it, leaned on it, dropped it, closed it on your keys, or subjected it to extreme temperatures, one thing’s for sure: right now you can barely see anything on your laptop screen!

Some other issues people may have with their screens are vertical lines or bars; these may be white, a bright color, or solid black, as below, and commonly result from a failure of tiny electrical connections within the screen’s body.

In all these situations, the screen itself has been ruined – the glass cannot be repaired, and humans are incapable of fixing the tiny connections that have broken.

But all is not lost!Replacements for PC laptop LCDs are usually fairly inexpensive – around $150-200 in most cases. We can find the perfect matching part for your screen and install it in short order (our primary vendor is in Apex and can usually get screens to us the next day), and all will be as good as new!

We also can replace Apple MacBook displays! We source entire display assemblies from a vendor in Virginia which means you can get your Mac screen replaced in as little as 24 hours! Try getting service that fast anywhere else!

Liquid Crystal Display (LCD) screens are a staple in the digital display marketplace and are used in display applications across every industry. With every display application presenting a unique set of requirements, the selection of specialized LCDs has grown to meet these demands.

LCD screens can be grouped into three categories: TN (twisted nematic), IPS (in-plane switching), and VA (Vertical Alignment). Each of these screen types has its own unique qualities, almost all of them having to do with how images appear across the various screen types.

This technology consists of nematic liquid crystal sandwiched between two plates of glass. When power is applied to the electrodes, the liquid crystals twist 90°. TN (Twisted Nematic) LCDs are the most common LCD screen type. They offer full-color images, and moderate viewing angles.

TN LCDs maintain a dedicated user base despite other screen types growing in popularity due to some unique key features that TN display offer. For one,

TN TFTs remain very popular among competitive PC gaming communities, where accuracy and response rates can make the difference between winning and losing.

Refresh rates and response times refer to the time it takes pixels to activate and deactivate in response to user inputs; this is crucial for fast-moving images or graphics that must update as fast as possible with extreme precision.

VA, also known as Multi-Domain Vertical Alignment (MVA) dislays offer features found in both TN and IPS screens. The Pixels in VA displays align vertically to the glass substrate when voltage is applied, allowing light to pass through.

Displays with VA screens deliver wide viewing angles, high contrast, and good color reproduction. They maintain high response rates similar to TN TFTs but may not reach the same sunlight readable brightness levels as comparable TN or IPS LCDs. VA displays are generally best for applications that need to be viewed from multiple angles, like digital signage in a commercial setting.

IPS (In-Plane Switching) technology improves image quality by acting on the liquid crystal inside the display screen. When voltage is applied, the crystals rotate parallel (or “in-plane”) rather than upright to allow light to pass through. This behavior results in several significant improvements to the image quality of these screens.

IPS is superior in contrast, brightness, viewing angles, and color representation compared to TN screens. Images on screen retain their quality without becoming washed out or distorted, no matter what angle they’re viewed from. Because of this, viewers have the flexibility to view content on the screen from almost anywhere rather than having to look at the display from a front-center position.

IPS displays offer a slightly lower refresh rate than TN displays. Remember that the time for pixels to go from inactive to active is measured in milliseconds. So for most users, the difference in refresh rates will go unnoticed.

Based on current trends, IPS and TN screen types will be expected to remain the dominant formats for some time. As human interface display technology advances and new product designs are developed, customers will likely choose IPS LCDs to replace the similarly priced TN LCDs for their new projects.

Nowadays, phones are being updated all the time. Some phones are cheaper than others and sometimes the parts, like internal LCDs are more expensive than a cheaper end phone is to buy.

As there are so many phones coming out all the time, the LCD range that is stocked needs to cover the majority of these models. An ever increasing selection of mobile phone LCD screens are now available to the public.

Often, people will ask why one would want to change the broken LCD screen and not just buy a new phone? Well, firstly, the LCD price represents the price of the phone it is for.

An example being, If a phone cost ?50 new, an LCD for that phone would be available for around ?15 whereas a ?100 phones LCD screen would more likely cost about ?35. So it is always going to be a cheaper option to replace the LCD than the phone. Nowadays, some phones cost up to ?500 when purchased sim free. The LCDs again, reflect this and can cost up to ?180 or more. So, you may think that for the price of a new LCD, you can get a new phone for, right? Right, but it would not be the same phone as it costs ?500 to replace that model. People would rather spend x amount on repairing the current phone they have than spending the money on a new phone instead as the phone would be inferior to the broken phone. Not many people step down a model in a phone, like many other things in life, like a car, the desired model normally inclines rather than declines.

The fact that LCD"s are getting easier to fit with the correct tools openly available, many people are buying the parts needed and fixing the phone themselves rather than pay a qualified engineer to do the job and being without the phone whilst the work is carried out.

The majority of people with a high end phone would have bought it with an airtime contract from a network provider. The phones cost is heavily subsidised by the network when taken with a contract. So many people are unaware of the true cost or value of the phone if it needed to be replaced because it was free with a contract via a network. So when it needs a new LCD screen replaced, these people often suggest that its not worth spending money on as it was free. Then they learn that to replace the phone like for like it would cost ?200, a new LCD for ?55 is better than any new ?55 phone would be.

Many people find that they would rather repair the mobile phones LCD over buying a new phone because they have finally just got used to using it and it"s now discontinued so it"s hard to find an exact replacement and the thought of learning another mobile phone set up, just not appeal to them.

Other people need to repair the current phone that just has a broken LCD, as they have all their contacts stored on the phone so its vital to get the phone working again, even if it is just to retrieve the data stored on the phone. This data is often priceless information and if it’s a toss up between losing the data or spending ?100 plus for a new LCD part then its often ?100 or so well spent. As if you were unable to get the information then you would have lost numbers of people you would never get again.

The price of LCDs do drop as do the phone prices themselves. As a new phone comes out, the older model drops in price, so do the parts for it drop accordingly.

I can recommend a couple of items available to help out if such an event happens to you, firstly though, I feel that the most important thing to do is always keep a backup of your phone book. There is a range of SIM card back up devices available. Some copy from SIM card to a small stand alone device where no PC is needed. You can then put in a new sim card and copy all the entries over to the new sim card. Other devices come with PC software that can be linked up to a PC and entry details can be edited on the PC. This would be a better option as more data can be stored on here like calendar entries and text messages.

Once you have found the correct part number, see HP Consumer Notebook PCs - Ordering HP certified replacement parts. Use the instructions in this document to order a replacement part.

HP recommends that you only order parts from an authorized HP repair parts dealer. Parts ordered from third-party companies might not perform as expected and might cause additional

To create an LCD, you take two pieces ofpolarized glass. A special polymer that creates microscopic grooves in the surface is rubbed on the side of the glass that does not have the polarizing film on it. The grooves must be in the same direction as the polarizing film. You then add a coating of nematic liquid crystals to one of the filters. The grooves will cause the first layer of molecules to align with the filter"s orientation. Then add the second piece of glass with the polarizing film at a right angle to the first piece. Each successive layer of TN molecules will gradually twist until the uppermost layer is at a 90-degree angle to the bottom, matching the polarized glass filters.

As light strikes the first filter, it is polarized. The molecules in each layer then guide the light they receive to the next layer. As the light passes through the liquid crystal layers, the molecules also change the light"s plane of vibration to match their own angle. When the light reaches the far side of the liquid crystal substance, it vibrates at the same angle as the final layer of molecules. If the final layer is matched up with the second polarized glass filter, then the light will pass through.

If we apply an electric charge to liquid crystal molecules, they untwist. When they straighten out, they change the angle of the light passing through them so that it no longer matches the angle of the top polarizing filter. Consequently, no light can pass through that area of the LCD, which makes that area darker than the surrounding areas.

Building a simple LCD is easier than you think. Your start with the sandwich of glass and liquid crystals described above and add two transparent electrodes to it. For example, imagine that you want to create the simplest possible LCD with just a single rectangular electrode on it. The layers would look like this:

The LCD needed to do this job is very basic. It has a mirror (A) in back, which makes it reflective. Then, we add a piece of glass (B) with a polarizing film on the bottom side, and a common electrode plane (C) made of indium-tin oxide on top. A common electrode plane covers the entire area of the LCD. Above that is the layer of liquid crystal substance (D). Next comes another piece of glass (E) with an electrode in the shape of the rectangle on the bottom and, on top, another polarizing film (F), at a right angle to the first one.

The electrode is hooked up to a power source like a battery. When there is no current, light entering through the front of the LCD will simply hit the mirror and bounce right back out. But when the battery supplies current to the electrodes, the liquid crystals between the common-plane electrode and the electrode shaped like a rectangle untwist and block the light in that region from passing through. That makes the LCD show the rectangle as a black area.

Product Description: Our company is the foremost known for offering LCD Display to the clients. This product is available in various specifications and can be customized as per the needs of the clients. LCD Display is best known for different attributes like compact design, less in maintenance, light weight and soread more...

Ganpathi Nagar, Samalkot, Dist. East Godavari St Marys Nilayam, Plidarigarithota D. No. 18-13-14/A, Ganpathi Nagar, Samalkot - 533440, Dist. East Godavari, Andhra Pradesh

Goregaon West, Mumbai Shop No. 4, A Wing, Neptune CHS, Vasant Galaxy Bangur Nagar, Goregaon West, Goregaon West, Mumbai - 400104, Dist. Mumbai, Maharashtra

Pataudi Road, Gurgaon, Dist. Gurugram Shop No. 6, Nikhil Complex Near Capt. Umang Bharadwaj Chowk, Pataudi Road, Gurgaon - 122001, Dist. Gurugram, Haryana

A Graphic LCD display is just as its name implies. This LCD module is able to display images, letters and numbers that are generated through the customer’sread more...

Thane Shop No Sb-33, 2nd Floor, High Street Mall , High Land Corporate Centre Near Goenka International School , Majiwade Gb Road, Kapur Bawdi, Thane - 400607, Dist. Thane, Maharashtra

Adyar, Chennai No. 13, F- 3, 2nd Floor, 2nd Main Road, Nehru Nagar, Adyar, H.D.F.C. Bank A.T.M., Ground Floor Near Nalli Silks, Opposite To SBI Indra Nagar Branch, Adyar, Chennai - 600020, Dist. Chennai, Tamil Nadu

Grand Road (East), Mumbai 7/16, Ground Floor, Kamat Building, Shamrao Vitthal Lane, Lemington Road, Grand Road (East), Mumbai - 400007, Dist. Mumbai, Maharashtra

Photo: A trick of the polarized light: rotate one pair of polarizing sunglasses past another and you can block out virtually all the light that normally passes through.

Photo: A less well known trick of polarized light: it makes crystals gleam with amazing spectral colors due to a phenomenon called pleochroism. Photo of protein and virus crystals, many of which were grown in space. Credit: Dr. Alex McPherson, University of California, Irvine. Photo courtesy of NASA Marshall Space Flight Center (NASA-MSFC).

Photo: Prove to yourself that an LCD display uses polarized light. Simply put on a pair of polarizing sunglasses and rotate your head (or the display). You"ll see the display at its brightest at one angle and at its darkest at exactly 90 degrees to that angle.

Photo: How liquid crystals switch light on and off. In one orientation, polarized light cannot pass through the crystals so they appear dark (left side photo). In a different orientation, polarized light passes through okay so the crystals appear bright (right side photo). We can make the crystals change orientation—and switch their pixels on and off—simply by applying an electric field. Photo from liquid crystal research by David Weitz courtesy of NASA Marshall Space Flight Center (NASA-MSFC).

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey