how to test lcd display 16x2 supplier

Do you want your Arduino projects to display status messages or sensor readings? Then these LCD displays can be a perfect fit. They are extremely common and fast way to add a readable interface to your project.

This tutorial will help you get up and running with not only 16×2 Character LCD, but any Character LCD (16×4, 16×1, 20×4 etc.) that is based on Hitachi’s LCD Controller Chip – HD44780.

When current is applied to these crystals, they become opaque, blocking the backlight that resides behind the screen. As a result that particular area will be dark compared to the others. And this is how the characters are displayed on the screen.

True to their name, these LCDs are ideal for displaying only text/characters. A 16×2 character LCD, for example, has an LED backlight and can display 32 ASCII characters in two rows of 16 characters each.

If you look closely you can see tiny rectangles for each character on the display and the pixels that make up a character. Each of these rectangles is a grid of 5×8 pixels.

The good news is that all of these displays are ‘swappable’, which means if you build your project with one you can just unplug it and use another size/color LCD of your choice. Your code will have to change a bit but at least the wiring remains the same!

Vo (LCD Contrast) controls the contrast and brightness of the LCD. Using a simple voltage divider with a potentiometer, we can make fine adjustments to the contrast.

RS (Register Select) pin is set to LOW when sending commands to the LCD (such as setting the cursor to a specific location, clearing the display, etc.) and HIGH when sending data to the LCD. Basically this pin is used to separate the command from the data.

R/W (Read/Write) pin allows you to read data from the LCD or write data to the LCD. Since we are only using this LCD as an output device, we are going to set this pin LOW. This forces it into WRITE mode.

E (Enable) pin is used to enable the display. When this pin is set to LOW, the LCD does not care what is happening on the R/W, RS, and data bus lines. When this pin is set to HIGH, the LCD processes the incoming data.

D0-D7 (Data Bus) pins carry the 8 bit data we send to the display. For example, if we want to see an uppercase ‘A’ character on the display, we set these pins to 0100 0001 (as per the ASCII table).

Now we will power the LCD. The LCD has two separate power connections; One for the LCD (pin 1 and pin 2) and the other for the LCD backlight (pin 15 and pin 16). Connect pins 1 and 16 of the LCD to GND and 2 and 15 to 5V.

Most LCDs have a built-in series resistor for the LED backlight. You’ll find this near pin 15 on the back of the LCD. If your LCD does not include such a resistor or you are not sure if your LCD has one, you will need to add one between 5V and pin 15. It is safe to use a 220 ohm resistor, although a value this high may make the backlight a bit dim. For better results you can check the datasheet for maximum backlight current and select a suitable resistor value.

Next we will make the connection for pin 3 on the LCD which controls the contrast and brightness of the display. To adjust the contrast we will connect a 10K potentiometer between 5V and GND and connect the potentiometer’s center pin (wiper) to pin 3 on the LCD.

That’s it. Now turn on the Arduino. You will see the backlight lit up. Now as you turn the knob on the potentiometer, you will start to see the first row of rectangles. If that happens, Congratulations! Your LCD is working fine.

Let’s finish connecting the LCD to the Arduino. We have already made the connections to power the LCD, now all we have to do is make the necessary connections for communication.

We know that there are 8 data pins that carry data to the display. However, HD44780 based LCDs are designed in such a way that we can communicate with the LCD using only 4 data pins (4-bit mode) instead of 8 (8-bit mode). This saves us 4 pins!

8-bit mode is much faster than 4-bit mode because it takes half the time. In 8-bit mode you write the data in one go. Whereas in 4-bit mode you have to split a byte into 2 nibbles and perform two write operations.

4-bit mode is often used to save I/O pins. However, 8-bit mode is best used when speed is required in an application and there are at least 10 I/O pins available.

The sketch begins by including the LiquidCrystal library. The Arduino community has a library called LiquidCrystal which makes programming of LCD modules less difficult. You can find more information about the library on Arduino’s official website.

First we create a LiquidCrystal object. This object uses 6 parameters and specifies which Arduino pins are connected to the LCD’s RS, EN, and four data pins.

In the ‘setup’ we call two functions. The first function is begin(). It is used to specify the dimensions (number of columns and rows) of the display. If you are using a 16×2 character LCD, pass the 16 and 2; If you’re using a 20×4 LCD, pass 20 and 4. You got the point!

After that we set the cursor position to the second row by calling the function setCursor(). The cursor position specifies the location where you want the new text to be displayed on the LCD. The upper left corner is assumed to be col=0, row=0.

There are some useful functions you can use with LiquidCrystal objects. Some of them are listed below:lcd.home() function is used to position the cursor in the upper-left of the LCD without clearing the display.

lcd.scrollDisplayRight() function scrolls the contents of the display one space to the right. If you want the text to scroll continuously, you have to use this function inside a for loop.

lcd.scrollDisplayLeft() function scrolls the contents of the display one space to the left. Similar to above function, use this inside a for loop for continuous scrolling.

If you find the characters on the display dull and boring, you can create your own custom characters (glyphs) and symbols for your LCD. They are extremely useful when you want to display a character that is not part of the standard ASCII character set.

As discussed earlier in this tutorial a character is made up of a 5×8 pixel matrix, so you need to define your custom character within that matrix. You can use the createChar() function to define a character.

To use createChar() you first set up an array of 8 bytes. Each byte in the array represents a row of characters in a 5×8 matrix. Whereas, 0 and 1 in a byte indicate which pixel in the row should be ON and which should be OFF.

CGROM is used to store all permanent fonts that are displayed using their ASCII codes. For example, if we send 0x41 to the LCD, the letter ‘A’ will be printed on the display.

CGRAM is another memory used to store user defined characters. This RAM is limited to 64 bytes. For a 5×8 pixel based LCD, only 8 user-defined characters can be stored in CGRAM. And for 5×10 pixel based LCD only 4 user-defined characters can be stored.

Creating custom characters has never been easier! We have created a small application called Custom Character Generator. Can you see the blue grid below? You can click on any 5×8 pixel to set/clear that particular pixel. And as you click, the code for the character is generated next to the grid. This code can be used directly in your Arduino sketch.

Your imagination is limitless. The only limitation is that the LiquidCrystal library only supports eight custom characters. But don’t be discouraged, look at the bright side, at least we have eight characters.

In setup we need to create custom character using createChar() function. This function takes two parameters. The first parameter is a number between 0 and 7 to reserve one of the 8 supported custom characters. The second is the name of the array.

We come across Liquid Crystal Display (LCD) displays everywhere around us. Computers, calculators, television sets, mobile phones, and digital watches use some kind of display to display the time.

An LCD screen is an electronic display module that uses liquid crystal to produce a visible image. The 16×2 LCD display is a very basic module commonly used in DIYs and circuits. The 16×2 translates a display of 16 characters per line in 2 such lines. In this LCD, each character is displayed in a 5×7 pixel matrix.

Contrast adjustment; the best way is to use a variable resistor such as a potentiometer. The output of the potentiometer is connected to this pin. Rotate the potentiometer knob forward and backward to adjust the LCD contrast.

Sends data to data pins when a high to low pulse is given; Extra voltage push is required to execute the instruction and EN(enable) signal is used for this purpose. Usually, we set en=0, when we want to execute the instruction we make it high en=1 for some milliseconds. After this we again make it ground that is, en=0.

A 16X2 LCD has two registers, namely, command and data. The register select is used to switch from one register to other. RS=0 for the command register, whereas RS=1 for the data register.

Command Register: The command register stores the command instructions given to the LCD. A command is an instruction given to an LCD to do a predefined task. Examples like:

Data Register: The data register stores the data to be displayed on the LCD. The data is the ASCII value of the character to be displayed on the LCD. When we send data to LCD, it goes to the data register and is processed there. When RS=1, the data register is selected.

Generating custom characters on LCD is not very hard. It requires knowledge about the custom-generated random access memory (CG-RAM) of the LCD and the LCD chip controller. Most LCDs contain a Hitachi HD4478 controller.

CG-RAM is the main component in making custom characters. It stores the custom characters once declared in the code. CG-RAM size is 64 bytes providing the option of creating eight characters at a time. Each character is eight bytes in size.

CG-RAM address starts from 0x40 (Hexadecimal) or 64 in decimal. We can generate custom characters at these addresses. Once we generate our characters at these addresses, we can print them by just sending commands to the LCD. Character addresses and printing commands are below.

LCD modules are very important in many Arduino-based embedded system designs to improve the user interface of the system. Interfacing with Arduino gives the programmer more freedom to customize the code easily. Any cost-effective Arduino board, a 16X2 character LCD display, jumper wires, and a breadboard are sufficient enough to build the circuit. The interfacing of Arduino to LCD display is below.

The combination of an LCD and Arduino yields several projects, the most simple one being LCD to display the LED brightness. All we need for this circuit is an LCD, Arduino, breadboard, a resistor, potentiometer, LED, and some jumper cables. The circuit connections are below.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

16×2 LCD is named so because; it has 16 Columns and 2 Rows. There are a lot of combinations available like, 8×1, 8×2, 10×2, 16×1, etc. But the most used one is the 16*2 LCD, hence we are using it here.

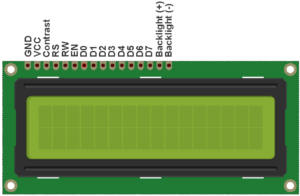

All the above mentioned LCD display will have 16 Pins and the programming approach is also the same and hence the choice is left to you. Below is the Pinout and Pin Description of 16x2 LCD Module:

These black circles consist of an interface IC and its associated components to help us use this LCD with the MCU. Because our LCD is a 16*2 Dot matrix LCD and so it will have (16*2=32) 32 characters in total and each character will be made of 5*8 Pixel Dots. A Single character with all its Pixels enabled is shown in the below picture.

So Now, we know that each character has (5*8=40) 40 Pixels and for 32 Characters we will have (32*40) 1280 Pixels. Further, the LCD should also be instructed about the Position of the Pixels.

It will be a hectic task to handle everything with the help of MCU, hence an Interface IC like HD44780 is used, which is mounted on LCD Module itself. The function of this IC is to get the Commands and Data from the MCU and process them to display meaningful information onto our LCD Screen.

The LCD can work in two different modes, namely the 4-bit mode and the 8-bit mode. In 4 bit mode we send the data nibble by nibble, first upper nibble and then lower nibble. For those of you who don’t know what a nibble is: a nibble is a group of four bits, so the lower four bits (D0-D3) of a byte form the lower nibble while the upper four bits (D4-D7) of a byte form the higher nibble. This enables us to send 8 bit data.

Now you must have guessed it, Yes 8-bit mode is faster and flawless than 4-bit mode. But the major drawback is that it needs 8 data lines connected to the microcontroller. This will make us run out of I/O pins on our MCU, so 4-bit mode is widely used. No control pins are used to set these modes. It"s just the way of programming that change.

As said, the LCD itself consists of an Interface IC. The MCU can either read or write to this interface IC. Most of the times we will be just writing to the IC, since reading will make it more complex and such scenarios are very rare. Information like position of cursor, status completion interrupts etc. can be read if required, but it is out of the scope of this tutorial.

The Interface IC present in most of the LCD is HD44780U,in order to program our LCD we should learn the complete datasheet of the IC. The datasheet is given here.

There are some preset commands instructions in LCD, which we need to send to LCD through some microcontroller. Some important command instructions are given below:

Monochrome character, graphic and static displays require different input voltages. All the different LCD voltage symbols can be confusing, but believe it or not, there is a system to the madness.

The voltages VCC, VDD, VSS and VEE are used in describing voltages at various common power supply terminals. The differences between these voltages stem from their origins in the transistor circuits they were originally used for.

This LCD voltage terminology originated from the terminals of each type of transistor and their common connections in logic circuits. In other words, VCC is often applied to BJT (Bipolar Junction Transistor) collectors, VEE to BJT emitters, VDD to FET (Field-Effect Transistor) drains and VSS to FET sources. Most CMOS (Complementary metal–oxide–semiconductor) IC data sheets now use VCC and GND to designate the positive and negative supply pins.

In the Pleistocene era (1960’s or earlier), logic was implemented with bipolar transistors. NPN (Negative-Positive-Negative) were used because they were faster. It made sense to call positive supply voltage VCC where the “C” stands for collector. The negative supply was called VEE where “E” stands for emitter.

When FET transistor logic came around a similar naming convention was used, but now positive supply was VDD where “D” stands for drain. The negative supply was called VSS where “S” stands for source. Now that CMOS is the most common logic this makes no sense. The “C” in CMOS is for “complementary” but the naming convention still persists. In practice today VCC/VDD means positive power supply voltage and VEE/VSS is for negative supply or ground.

The convention of VAB means the voltage potential between VA and VB. The convention of using 3 letters was used to show power supply and ground reference voltages as well. In some cases a processor may have both an analog and digital power supply. In this case VCCA/VCCD and VSSA/VSSD are used. Another reason for the 3 letters is in an NPN circuit with a load resister between the collector and VCC. VC would be the collector voltage. In this case VCC is the positive power supply voltage and would be higher than VC.

Note: Most Segment, Character and Graphic displays will operate with a VDD of 5V or 3.3V. It may be possible to drive the display with as little as 3.0V, but the module may not perform very well in colder temperatures. The colder the ambient temperature, the more power is required to drive the segments.

Pin three (3) is Vo and is the difference in voltage between VDD and VSS. This LCD voltage is adjusted to provide the sharpest contrast. The adjustment can be accomplished through a fixed resistor or a variable potentiometer. Many products have firmware that monitor the temperature and automatically adjust the contrast voltage.

In a Liquid Crystal Display (LCD), V0 is used to vary the screen brightness or contrast. Contrast, simply put is the ratio of the light areas to the dark areas in a LCD. This is usually done in a production setting with values which are optimized for most users. Temperature can have an undesirable effect on the display brightness and for this reason a varying resister or potentiometer is used to accommodate the desires of the user.

Below is a data sheet of a 16x2 Character LCD module that shows various recommended driving voltages. The LCD voltage can range from MIN (minimum) to TYP (Typical) to Max (maximum).

If the supplied LCD voltage drops too low, the display is ‘under-driven’ and will produce segments that are ‘grey’. The lower the LCD voltage falls below the acceptable threshold, the lower the contrast will be.

If the LCD is over-driven, you may see ghosting. This is where segments that should not be ‘on’ are gray. They are not as dark as the segments that should be on, but they can be seen and may cause confusion for the end user.

There are times when a customer needs to replace a display that has been discontinued or EOL (End-Of -Life) by their previous LCD supplier. The previous LCD’s pin-outs may be different than Focus’ standard, off-the-shelf display. This is not a large problem to overcome.

Focus Displays will redesign the PCB to match the customer’s old pin out. This will save the customer time and cost so that they will not need to redesign their PCB.

LED backlights are DC (Direct Current) driven and can be supplied from any one of three locations. The most popular is from pins 15 and 16. The second most popular option is to draw power from the ‘A’ and ‘K’ connections on the right side of the PCB.

The third option is to pull power from pins one and two. This is the same location from which the LCD is pulling its power. Focus does not recommend this option and can modify the PCB for the customer to connect the backlight from a different location.

Many LCD Modules will require more than one internal voltage/current. This may make it necessary for the customer to supply the needed inputs. They may need to supply 3V, 5V, 9V, -12V etc.

The solution for this is to integrate a charge pump (or booster circuit) into the LCD circuitry. This solution works in most applications, but if the product will be operating in an intrinsic environment, care must be taken with layout of the circuit board.

Intrinsically-safe LCDs are Liquid Crystal Displays that are designed to operate in conditions where an arc or spark can cause an explosion. In these cases, charge pumps cannot be employed. In fact, the total capacitive value of the display needs to be kept to a minimum.

Focus Display Solutions does not build a display that is labeled ‘Intrinsically safe’ but we do design the LCD to meet the requirements of the engineer. In meeting the design engineer’s requirements, the display may need to contain two or three independent inputs. Focus can redesign the PCB and lay out the traces to allow for these additional inputs.

Almost all electronics have some sort of human interface, from blinking lights and beeping speakers to seven segment alphanumeric and Liquid Crystal Displays. This Instructable is about salvaging and testing Liquid Crystal Displays, and a couple tricks I know to make salvaging them more successful.

I salvage; components can get expensive, LCDs can run $10.00 and up even SCRs and mosfets can cost over $100.00 so I salvage everything of reusable value as well as recyclable. Scrap metals like copper, gold, silver, and aluminum can bring you money as well.

Liquid Crystal Displays can be found on CD players, Phones, and printers just to mention a few. In this Instructable I will be dissembling an HP combination printer, scanner, fax machine.

This printer display is parallel data input to the circuit board and parallel data input to the COG LCD, I know this by reverse engineering the circuit board and checking the components datasheets.

You can just pull the LCD however finding just the right ribbon socket can be hard, so the only part I need from the circuit board to use this COG LCD else where is the ribbon socket. (Inside the yellow rectangle) I do this by placing my large soldering iron on the back of the circuit board and when the solder melts I lift off the socket.

Using Arduino to test the 16x1 modules and check the functions; I found that the 16x2 code needed to be modified because the IC looked at the 16x1 LCD as two lines and all you see is the first eight segments of the display.

Demonstrates the use a 16x1 LCD display; the LiquidCrystal library works with all LCD displays that are compatible with the Hitachi HD44780 driver. There are many of them out there, and you can usually tell them by the 16-pin interface however these are 16x1 LCD, 14 pin interface.

Demonstrates the use a 16x1 LCD display; the LiquidCrystal library works with all LCD displays that are compatible with the Hitachi HD44780 driver. There are many of them out there, and you can usually tell them by the 16-pin interface however these are 16x1 LCD, 14 pin interface.

Using Arduino to test the 16x1 10 pin modules again I found a few differences; the same code used for the 16x1 14 pin is used for the 10 pin LCD, this is the hookup and code for the 16x1 10 pin LCD.

Demonstrates the use a 16x1 LCD display; the LiquidCrystal library works with all LCD displays that are compatible with the Hitachi HD44780 driver. There are many of them out there, and you can usually tell them by the 16-pin interface however these are 16x1 LCD, 14 pin interface.

This circuit board came from a compact disk player; I start by tracing out the circuitry and looking up the LCD driver IC. The IC is a PT6533 general purpose LCD driver this part is important and it makes salvaging the LCD easier, other than the backlight LEDs the driver and the LCD are separate from the push button switches. Now I know what I need to cut away from the circuit board to salvage the LCD.

Be careful during this part; safety glasses and heavy leather gloves, while I was shaping this circuit board the dremel jumped and hit my hand cutting my thumb through the leather gloves causing me to get three stiches. It would have been worse had I not been wearing the gloves.

I scrape clean the ends of the conductors and solder the white wire to the white conductor and so on until all six wires are soldered to the circuit board.

Although the wires are soldered in place with movement they can break free from the circuit board. To prevent this I glue the wires in place with Goop glue and wait 24 hours before testing.

Many of the members at Instructables and our visitors use Arduino and Raspberry Pi for their projects. I connected the new LCD to my Arduino UNO, the LED backlights work but I am still working on the Arduino code to run serial input LCDs.

I have a tm162b9dcwu6 LCD display which I salvaged from a DSC PK5500 control panel. Do you by any chance have the schematic diagram showing the input/output labels? I want to use the display on an Arduino project

I have a couple oF Honeywell alarm Keypad with Function Buttons and I have started hacking them (Buttons, Leds, Piezo). I have questions concerning the LCD.

From photo 2 , you can see that the LCD is without a PCB/controller but only a strip that when press on the PCB"s traces, connect to the MCU directly.

It looks like a copy of the 128x64 graphic LCD, but I don"t know the model of the chip and I don"t know if it works with the communication protocol "spi or i2c" and which of the 7 cables is for power, clock and data.

de una impresora Epson tx235 rescate un lcd muy chico con 20 pines y quisiera reutilizarla en un proyecto de arduino. te dejo las imagenes para que veas la pantalla y me digas si se puede hacer algo con ella. muchas gracias por todo.

I have the exact same LCD, but I am unable to find any referrence or schematics for this particular model. I would like to use it in my arduino project, do you think you can help me with a datasheet for it?

I love to read about people with a passion for salvaging items. I have loads of components I have salvaged and even fixed a few electronic devices which is very satisfying. Most LCDs I salvage are the standard 16x2 which are fairly straightforward but I have one that I am struggling with. It was removed from an Avaya 5410 desk phone and it has a 22 pin interface with 6 buttons on the PCB.

I have powered it up to do some live reverse engineering and even made a small interface board with patch leads and unplugged them one by one and observed the behaviour. However even with the data I don"t really know where to go next. Is this something you might be able to give me some pointers on? Or if it is even worth pursuing?

Update: So I dropped this project for a while but then got back to it yesterday. Long story short I ended up finding a part number from a spare parts listing as LM4068 which I now have a datasheet/pinout for. From this I found the driver is an SED1560 made by Epson.

These displays are straightforward to use and are a great way to provide a user interface on many projects where you need more info than simple LED indicators or 7-Segment displays can provide since these are full alphanumeric displays with 2 lines of 16 characters each for a total of 32 characters. For an interactive display, pairing this type of display with a rotary encoder to navigate and select menu items on the display can provide a very nice user interface.

The display is composed of a 16 character x 2 line LCD display with a blue backlight and white characters. Each of the characters are composed of a 5 x 8 dot matrix for good character representation. Custom characters can be defined and used with the display.

The backlight has a VO (Display Contrast) input for connecting a potentiometer for adjustment of the contrast of the display for best viewing. The potentiometer can be somewhere in the 10K-50K range and should connect between 5V and ground. The wiper output of the potentiometer feeds the VO pin with a variable voltage that sets the contrast. If this is not adjusted correctly the display may not show any characters or solid blocks may be displayed.

The backlight is powered off the A (Anode) and K (Cathode) pins. Normally 5V is applied to ‘A’ and ground to ‘K’. The backlight includes a 51 ohm current limiting resistor, so an external resistor is not required.

The backlight can go down to about 3.2V before it goes out. It can be operated off the 3.3V line if a lower brightness is desired for the application. The backlight can be driven by a logic pin using a transistor if PWM brightness or ON/OFF control is desired

This display incorporates a parallel interface that can operate using an 8-bit (byte) mode or a 4-bit (nibble) mode. 8-bit mode uses data pins D0-D7 and 4-bit mode uses the upper data pins of D4-D7.

In practice, the 4-bit mode is normally used as it saves 4 pins on the MCU and maximizing communication speeds with the display are generally not a concern. The LiquidCrystal.h library makes the difference between using the two modes transparent to the user.

If it is desirable to minimize the pins used on the MCU even further, check out the version with an I2C interface down below which uses only 2 pins plus power and ground.

The module ships with the male header strip loose. This allows the header to be soldered to the top or bottom of the module depending on the planned use or wires can be used to make the connections.

For breadboard use, put the headers on the bottom. Soldering is easiest if the header is first inserted into a solderless breadboard to hold it in position and keep it aligned during the soldering process.

These are good quality modules and should be in the parts bin of any hobbyist. Because of the interactivity they provide, they are both fun to play with and useful for more serious projects.

Connections to the module are outlined in the program comments. The MCU data lines used can be changed and redefined in the following line if needed.

A potentiometer is required between 5V and ground to feed the VO line to set the display contrast or else the text may not be visible. Also be sure to connect 5V and ground to the backlight A / K pins and ground the R/W pin to put the module into write mode

Grove - 16 x 2 LCD is a perfect I2C LCD display for Arduino and Raspberry Pi with high contrast and easy deployment. 16x2 means two lines and each line has 16 columns, 32 characters in total. With the help of Grove I2C connector, only 2 signal pins and 2 power pins are needed. You don"t even need to care about how to connect these pins. Just plug it into the I2C interface on Seeeduino or Arduino/Raspberry Pi+baseshield via the Grove cable. There won"t be complicated wiring, soldering, worrying about burning the LCD caused by the wrong current limiting resistor.

The Grove - LCD RGB Backlight has been well received since its inception. Based on customer feedback, now, we bring more cost-effective monochrome backlight derivative for you.

Except for RGB backlights, these three products are almost identical to the the Grove - LCD RGB Backlight, they are all 16 characters wide, 2 rows with high brightness backlight.

An introduction of What is a Grove - 16 x 2 LCD and How does it work is strongly recommended reading ahead if you are not familiar with it. Please visit our

The platforms mentioned above as supported is/are an indication of the module"s software or theoritical compatibility. We only provide software library or code examples for Arduino platform in most cases. It is not possible to provide software library / demo code for all possible MCU platforms. Hence, users have to write their own software library.

NotePlease plug the USB cable gently, otherwise you may damage the port. Please use the USB cable with 4 wires inside, the 2 wires cable can"t transfer data. If you are not sure about the wire you have, you can click here to buy.

The first version of Grove - 16 x 2 LCD series does not have a built-in pull-up resistor, nor does it provide a pad to solder the optional pull-up resistor. We have redesigned the module, and the new version has built-in pull-up resistors.

If you have an older version on your hand, you can solder a 10kΩ DIP resistor yourself on the back pad of the Grove connector. Please follow the picture below, solder a 10kΩ DIP resistor between VCC and SCL pins and a 10kΩ DIP resistor between VCC and SDA pins.

The Grove - 16 x 2 LCD shares the same library with the Grove-LCD RGB Backlight. Their usage is almost the same, except that the Grove - 16 x 2 LCD does not support the RGB color API, such as setRGB().

2). Open it in your computer by click the HelloWorld.ino which you can find in the folder XXXX\Arduino\libraries\Grove_LCD_RGB_Backlight-master\examples\HelloWorld, XXXX is the location you installed the Arduino IDE.

Since the Grove - 16 x 2 LCD series are all monochrome backlight, you need to comment out the RGB color related code. In the demo code above, i.e., line 6 and line 17.

Step 2. Make sure that the ArduPy firmware contains the Grove - 16 x 2 LCD ArduPy library using the following commands. For more information, please follow here.

Step 4. Save the ArduPy-LCD1602.py in a location that you know. Run the following command and replace

Range tests made easy with the RE-Mote and LCD:Reduce the number of equipment and preparations required for field testing (2.4GHz and 868MHz), pack everything you need in your hand.

Established in 1998, Winstar Display Co., Ltd. is a reliable LCD Display Module Manufacturer and LCD Panel Supplier. Winstar has development of high-quality display module products. We operate worldwide, configure, service products, and also provide logistics support to deliver products and services competitively. We provide LCM Modules including monochrome TN/STN/FSTN LCM, COG LCD, TFT LCM / TFT panels, FSC-LCD, graphic LCM, character LCD displays, OLED display modules (PMOLED), custom LCD displays, OLED and LCD panel.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

GST No.27ACQPN3169B1ZG We are one of the leading distributors of LCD display"s, TFT display"s OLED display"s, and CCTV monitors, touch monitors , touch panelsProcured from reliable vendors. our products are widely known for high quality features. Read More

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey