how to test lcd display 16x2 factory

Check you connections: Most of the the problem will be your connections. Since we use a pre-tested library for our LCD displays there are very less chance for your code to be wrong. Instead concentrate on your connections make sure you have connected to the correct digital pins of the MCU.

Power up display:After making the connection when you power on the LCD, even if there is no code on the MCU you LCD should display boxes as shown below

Check your contrast pin:Another trouble maker is your contrast pin (3rd pin). Make sure this pin is connected to a potentiometer and vary the pot till you something on the screen. Because sometimes your LCD might be working just fine but your contrast level might be too low or high for you to visualize it.

Have a handy replacement:Sometimes the crude way is the best way. If you are still struggling to get it work. Try replacing it with a new LCD if the new also ones also does not work then the problem is with your code or connections. LCD displays can be easily damaged by normal reverse polarity or over voltage so having a replacement just in case is a good idea

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Previous examples connect the white LED backlight to power. The following example is specifically for those using an LCD with a RGB LED backlight. The only difference between the connection is the LED"s backlight on pins 15-18.

Copy and paste the code below. Just make sure to select the correct board (in this case the Arduino/ Genuino Uno) and the COM port that the Arduino enumerated on. Then upload the code to your Arduino.

After uploading, you will notice the same "Hello, world!" and time since the Arduino was last reset in the first example. The only difference is that the current color of the backlight will be printed as it cycles through each of the primary, secondary, and tertiary colors. You should see something similar to the image below.

The CFA533-***-KC series is a 16x2 I2C LCD with keypad. The I2C interface allows you to use just two lines (SDA & SCL) to have bi-directional communication with the I2C LCD. Other devices can also share those two I2C control lines with the LCD. Only 4 wires are needed to connect this I2C LCD: power, ground, SDA (I2C Serial DAta) and SCL (I2C Serial CLock).

The CFA533 can run on 3.3v to 5.0v directly, with no changes needed, so you do not need to do any level translation between your embedded processor and the I2C LCD. Simply power the CFA533 from the same supply as your processor and the I2C signal levels will match up.

Using only one address on your I2C bus, you can add all the elements that you need for your front panel. The CFA533 I2C LCD can also read up to 32 DS18B20 digital temperature sensors, giving you an easy way to integrate temperature sensing over the I2C bus. No additional firmware or pins are needed on the host system.

This CFA533-TFH variant features crisp dark letters against a white, backlit background. The keypad has a matching white LED backlight. Since the LCD is a backlit positive FSTN, the CFA533-TFH I2C LCD is readable in direct sunlight, as well as complete darkness.

This Service may incorporate or use background Autodesk technology components. For information about these components, click here: http://www.autodesk.com/cloud-platform-components

Permission is hereby granted, free of charge, to any person obtaining a copy of this software and associated documentation files (the "Software"), to deal in the Software without restriction, including without limitation the rights to use, copy, modify, merge, publish, distribute, sublicense, and/or sell copies of the Software, and to permit persons to whom the Software is furnished to do so, subject to the following conditions:

THE SOFTWARE IS PROVIDED "AS IS", WITHOUT WARRANTY OF ANY KIND, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO THE WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE AND NONINFRINGEMENT. IN NO EVENT SHALL THE AUTHORS OR COPYRIGHT HOLDERS BE LIABLE FOR ANY CLAIM, DAMAGES OR OTHER LIABILITY, WHETHER IN AN ACTION OF CONTRACT, TORT OR OTHERWISE, ARISING FROM, OUT OF OR IN CONNECTION WITH THE SOFTWARE OR THE USE OR OTHER DEALINGS IN THE SOFTWARE.

Portions relating to lightbox are licensed under Creative Commons Attribution 2.5 License (http://creativecommons.org/licenses/by/2.5/). Lightbox was authored by Lokesh Dhakar (lokeshdhakar.com).

The 162A is one of our 16 character x 2 row chip on board (COB) alphanumeric displays. These classic LCD modules are available in a multitude of LCD and LED backlight color combinations to achieve the perfect look for your product. Some of our most popular combinations are STN yellow-green LCD with yellow-green LED backlight, STN blue LCD with white LED backlight, and STN grey LCD with either blue, amber or pure green LED backlight.

A while ago, thanks to the joys of eBay and manufacturing in China, I ordered some low-cost 16×2 LCD character screens, and they finally arrived. Yeah, now I can get down to trying to output some text to the LCD screen, just one of the pieces of the puzzle for creating a metro ‘next train’ monitor.

For the first step, I just wanted to see if I could get it to work, so I started with the Hello World tutorial. I wired it up using a breadboard, and put in a header that I had into the breadboard, and then set the LCD screen on top, unsoldered.

At first, I thought it was that I did not have a 10k pot to start with, as some on the forums indicated that you need a minimum resistance, but this did not make sense to me, as really it is just acting as a voltage divider and the actual resistance amount should not matter. However, I did eventually find a 10k pot and used that, but it was unnecessary: once I got it working I replaced the 10k pot with the 1k pot I had at first and it works just fine. The pot resistance does not matter.

Second, the tutorial also did not have the backlight lit, which was a mistake. My LCD was extremely difficult to read without the backlight, so I wired up the backlight by connecting the last two pins to +5v and ground respectively. While the wiring was done correctly (I check multiple times), the LCD would just output square boxes on the top line.

So I went into investigative mode, first pulling out the multimeter to check the voltages (too clumsy as I needed two hands and had to hold wires to the multimeter leads), and instead used the analog in of the Arduino to read the voltage (1023 = 5v, and 0 = ground). After several checks I found the problem: the RW pin was not being successfully pulled to ground. While on the breadboard it was at 0v, and on the header pin sticking up it was at 0v, when I touched to the plated part of the LCD pin ins, I was getting 5v. No idea how, and why it was at 5v exactly and not a floating voltage is beyond me. Either way, obviously not good and despite my attempts to move it around and to hold a wire to it to ground, did not get a change. I was not sure if the LCD screen had been fried (again, forums had indicated this possibility if you used less than a 10k pot).

Solution was to solder it. As soon as I had done that (thanks to learning how to solder earlier), the LCD display made that first output: Hello World!, along with the number of seconds since it started.

To get this to display properly, I needed to adjust the contrast: too much to 0v and you get the boxes developing (you can still read the text, but the boxes are there and make it difficult), while too much to 5v and the display gets washed out completely.

I wanted to experiment, and instead of controlling via a pot, I wanted to control the contrast by a PWM pin. This is also part of my objective in a future project. So I build a display contrast tester, that automatically steps through the different PWM outputs from one of the Arduino PWM pins, changing the contrast based on that output and writing it to the LCD screen and to the serial monitor. Thus the LCD Contrast Tester was created.

And see the LCD Contrast Tester in action. You can see about 120 is the best contrast for this LCD, which approximately half (128 would be 50% of the way).

However, one thing that happens is that after a random amount of time, the LCD screen screws up: it starts scrolling random text, or instead of putting the numbers for the PWM in the right spot, starts changing things elsewhere.

And code for the LCD Contrast Tester. Note that in this code I also added in digital control of the backlight pin, so that it goes through the first cycle with no backlight, then turns it on for the second cycle, off for the third, etc. To avoid using this, just put the backlight positive from the LCD (second last pin in the LCD) to +5V, as opposed to digital pin 7.

The random characters are appearing because of the use of the PWM to control the contrast on V0. Apparently, this causes some issue because of the nature of the PWM signal.

I put the V0 back to the pot output, reset the board, and it ran for an hour without an error or random character appearing. Then I put it to the PWM output and within 2 seconds the error had appeared. Going back to the pot output does not fix it: once the error is there, it is there!

The forum thread seemed to indicate that the PWM needed to be cleaned, so this could be something to evaluated in the future as ideally I would like to control the contrast from the board, not a physical pot.

The 16x2 is the most commonly used LCD display module. It can display 16 characters in a column for 2 rows thus a total of 32 characters. The characters can either be number, alphabets or symbol. It is also possible to create your own custom character and display it if required. The LCD has the HD44780U display driver IC which is responsible for displaying characters on the LCD

This 16x2 LCD display has a blue background and back light which makes it unique and more visible than the commonly used green color. If you need the green backlight you can use this Green Backlight LCD. The required supply voltage is from 4.7V to 5.3V and the LCD can operate either in 8-bit mode or in 4-bit mode allowing you to save more GPIO pins on the controller side. The current consumption is about 1mA without the back light.

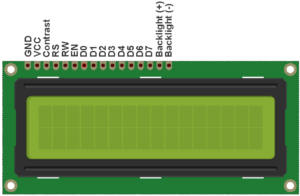

The 16x2 LCD pinout diagram is shown below. As you can see the module has (from right) two power pins Vss and Vcc to power the LCD. Typically Vss should be connected to ground and Vcc to 5V, but the LCD can also operate from voltage between 4.7V to 5.3V. Next, we have the control pins namely Contrast (VEE), Register Select (RS), Read/Write (R/W) and Enable (E). The Contrast pin is used to set the contrast (visibility) of the characters, normally it is connected to a 10k potentiometer so that the contrast can be adjusted. The Read/Write pin will be grounded in most cases because we will only be writing characters to the LCD and not read anything from it. The Register Select (RS) and Enable pin (E) pin are the control pins of the LCD and will be connected to the digital pins GPIO pins of the microcontroller. These pins are used to instruct the LCD where place a character when to clear it etc.

From DB0 to DB7 we have our eight Data Pins which are used to send information about the characters that have to be displayed on the LCD. The LCD can operate in two different modes, in the 4-bit Modeonly pins DB4 to DB7 will be used and the pins DB0 to DB3 will be left idle. In 8-bit Mode, all the eight-pin DB0 to DB7 will be used. Most commonly the 4-bit mode is preferred since it uses only 4 Data pins and thus reduces complexity and GPIO pin requirement on the microcontroller.Finally, we have the LED+ and LED- pins which are used to power the backlight LED inside our Display module. Normally the LED+ pin is connected to 5V power through a 100 ohm current limiting resistor and the LED- pin is connected to Ground.

Lcd stands for liquid crystal display. Character and graphical lcd’s are most common among hobbyist and diy electronic circuit/project makers. Since their interface serial/parallel pins are defined so its easy to interface them with many microcontrollers. Many products we see in our daily life have lcd’s with them. They are used to show status of the product or provide interface for inputting or selecting some process. Washing machine, microwave,air conditioners and mat cleaners are few examples of products that have character or graphical lcd’s installed in them. In this tutorial i am going to discuss about the character lcd’s. How they work? their pin out and initialization commands etc.

Character lcd’s come in many sizes 8×1, 8×2, 10×2, 16×1, 16×2, 16×4, 20×2, 20×4, 24×2, 30×2, 32×2, 40×2 etc .Many multinational companies like Philips, Hitachi, Panasonic make their own custom type of character lcd’s to be used in their products. All character lcd’s performs the same functions(display characters numbers special characters, ascii characters etc).Their programming is also same and they all have same 14 pins (0-13) or 16 pins (0 to 15).

In an mxn lcd. M denotes number of columns and n represents number of rows. Like if the lcd is denoted by 16×2 it means it has 16 columns and 2 rows. Few examples are given below. 16×2, 8×1 and 8×2 lcd are shown in the picture below. Note the difference in the rows and columns.

On a character lcd a character is generated in a matrix of 5×8 or 5×7. Where 5 represents number of columns and 7/8 represent number of rows. Maximum size of the matrix is 5×8. You can not display character greater then 5×8 dimension matrix. Normally we display a character in 5×7 matrix and left the 8th row for the cursor. If we use the 8th row of the matrix for the character display, then their will be no room for cursor. The picture below shows the 5×8 dot matrix pixels arrangement.

To display character greater than this dimension you have to switch to graphical lcd’s. To learn about graphical lcds here is a good tutorialGraphical Lcd’s Working and Pin out.

The picture above shows the pin out of the character lcd. Almost all the character lcd’s are composed of the same pin out. Lcd’s with total pin count equal to 14 does not have back light control option. They might have back light always on or does not have a back light. 16 total pin count lcd’s have 2 extra A and K pins. A means anode and K cathode, use these pins to control the back light of lcd.

Character Lcd’s have a controller build in to them named HD44780. We actually talk with this controller in order to display character on the lcd screen. HD44780 must be properly handled and initialized before sending any data to it. HD44780 has some registers which are initialized and manipulated for character displaying on the lcd. These registers are selected by the pins of character lcd.

When we send commands to lcd these commands go to Command register and are processed their.Commands with their full description are given in the picture below.When Rs=0 command register is selected.

When we select the register Rs(Command and Data) and set Rw(read – write) and placed the raw value on 8-data lines, now its time to execute the instruction. By instruction i mean the 8-bit data or 8-bit command present on Data lines of lcd. For sending the final data/command present on the data lines we use this enable pin.Usually it remains en=0 and when we want to execute the instruction we make it high en=1 for some mills seconds. After this we again make it ground en=0.

To set lcd display sharpness use this pin. Best way is to use variable resistor such as potentiometer a variable current makes the character contrast sharp. Connect the output of the potentiometer to this pin. Rotate the potentiometer knob forward and backward to adjust the lcd contrast.

NOTE: we can not send an integer, float, long, double type data to lcd because lcd is designed to display a character only. Only the characters that are supported by the HD44780 controller. See the HD44780 data sheet to find out what characters can we display on lcd. The 8 data pins on lcd carries only Ascii 8-bit code of the character to lcd. How ever we can convert our data in character type array and send one by one our data to lcd. Data can be sent using lcd in 8-bit or 4-bit mode. If 4-bit mode is used, two nibbles of data (First high four bits and then low four bits) are sent to complete a full eight-bit transfer. 8-bit mode is best used when speed is required in an application and at least ten I/O pins are available. 4-bit mode requires a minimum of seven bits. In 4-bit mode, only the top 4 data pins (4-7) are used.

Command 0x30 means we are setting 8-bit mode lcd having 1 line and we are initializing it to be 5×7 character display.Now this 5×7 is some thing which every one should know what it stands for. usually the characters are displayed on lcd in 5×8 matrices form. where 5 is total number of columns and is number of rows.Thus the above 0x30 command initializes the lcd to display character in 5 columns and 7 rows the last row we usually leave for our cursor to move or blink etc.

The command 0x80 initialize the cursor to the first position means first line first matrix(start point) now if we add 1 in 0x80+1=0x81 the cursor moves to second matrix.

NOTE:You can send commands in hexadecimal or decimal form which one do you like the result is same because the microcontroller translate the command in 8-bit binary value and sends it to the lcd.

Character Lcd’s can be used in 4-bit and 8-bit mode.Before you send commands and data to your lcd. Lcd must first be initialized. This initialization is very important for lcd that are made by Hitachibecause they use HD44780 driver chip sets. Hd44780 Chip set first has to be initialized before using it. If you don’t initialize it properly you will see nothing on your lcd.

In 4-bit mode the high nibble is sent first before the low nibble and the En pin is toggled eachtime four bits is sent to the LCD. To initialize in 4-bit mode:

To learn more about the difference between 4-bit and 8-bit character lcd mode and operation with demo example visit the tutorial link given below. Demo examples are very easy to understand and one can make changes easily in the code. Please also give us your feed back on the post.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey