tft display structure in stock

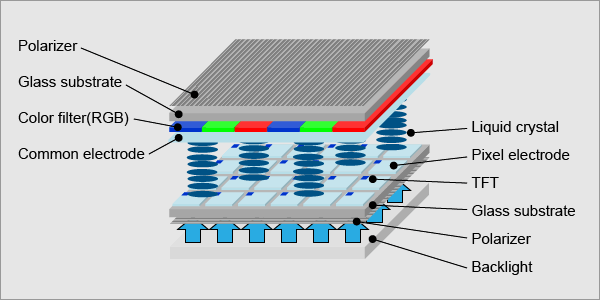

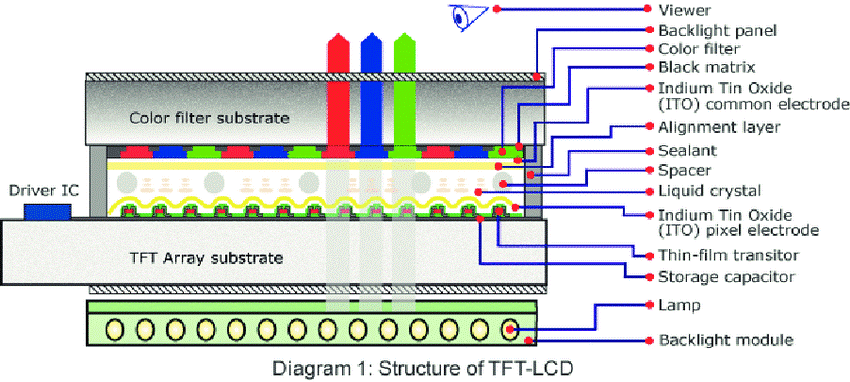

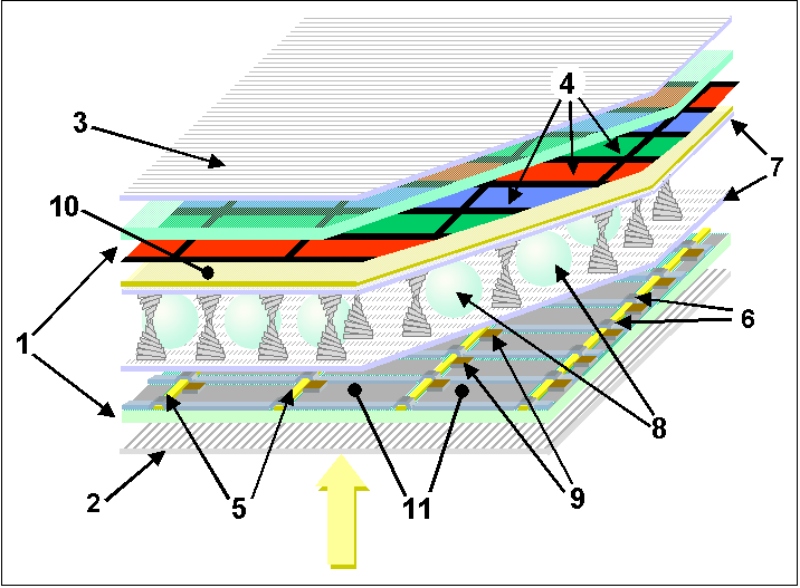

TFT LCD screen is mainly composed of three parts: rear panel module, LCD layer and front panel module. A layer of liquid crystal is sandwiched between two glass substrates. A color filter is attached to the front LCD panel, and a thin film transistor (TFT) is made on the back TFT panel. When a voltage is applied to the transistor, the liquid crystal turns, and light passing through the liquid crystal produces pixels on the front panel. As shown in the figure:

The rear plate module refers to the part behind the liquid crystal layer, which is mainly composed of the rear polarizer , the rear glass layer, the pixel unit (pixel electrode, TFT tube), the rear directional film, etc.

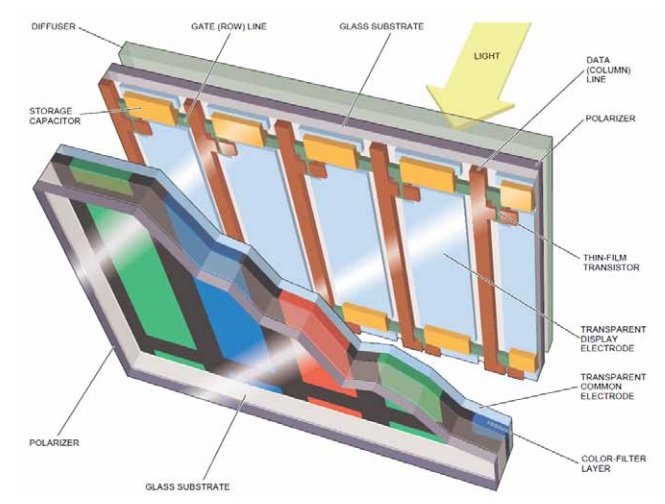

The rear glass substrate is divided into many tiny grids, called pixel units (or sub-pixels), by a number of transparent metal film wires arranged horizontally and vertically and insulated from each other. Each cell has a transparent metal film electrode, called the pixel electrode, which is insulated from the surrounding wire. One corner of the pixel electrode is connected with two vertical and horizontal wires through a TFT thin film field effect tube made on glass substrate by printing method to form a matrix structure:

The gate of the TFT field effect tube is connected with the horizontal line, the horizontal line is called the gate scan line or the X electrode, because it plays the role of TFT pass selection, also called the pass selection line; The source pole of the TFT tube is connected with the vertical line, which is called the source line or Y electrode. The drain of the TFT is integrated with the transparent pixel electrode. The function of the TFT tube is a switch tube, using the gate voltage applied to the TFT switch tube, can control the conduction and cut-off of the TFT switch tube.

The LCD screen has a pixel electrode and a thin film transistor (TFT) on the rear glass plate, and a color filter on the front glass plate. The liquid crystal layer is sandwiched between the front and back glass layers.

For TFT LCD screen, each pixel unit can be regarded as a layer of TN liquid crystal sandwiched between the pixel electrode and the common electrode. The liquid crystal layer can be equivalent to a liquid crystal capacitor (CLc), whose size is about 0.1pF. In practice, this capacitor cannot hold the voltage until the next time the picture data is updated, that is, when the TFT tube is fully charged to this capacitor, it cannot hold the voltage until the next time the TFT tube is charged to this point (at the usual 60Hz picture update frequency, it needs to hold the voltage for about 16ms). As a result, if the voltage changes, the gray scale will be incorrect. Therefore, when designing the panel, a storage capacitor Cs (usually formed by the wiring of the pixel electrode and the common electrode) will be added, with a value of about 0.5pF, so that the charged voltage can be maintained until the next image updated.

Red, blue, and green are the so-called three primary colors. That is to say, with these three colors, different colors can be mixed together. The three RGB colors are divided into three independent units, each of which has different gray-scale changes. Then the three adjacent RGB display units are taken as a basic display unit — pixel, and the pixel can have different color changes.

In the figure, the black part between each RGB point, called the black-matrix, is mainly used to cover the part that is not intended to transmit light, such as the pixel electrode wire, TFT tube, etc.

A TFT LCD, or a thin film transistor liquid crystal display, is one of the fastest growing forms of display technology today. The thin film transistor (TFT) is a type of semiconductor device used in display technology to enhance efficiency, compactness, and cost of the product. In conjunction with its semiconductor properties, the TFT LCD is an active matrix display, controlling pixels individually and actively rather than passively, furthering the benefits of this semiconductor device.

The TFT LCD is built with three key layers. Two sandwiching layers consist of glass substrates, though one includes TFTs while the other has an RGB, or red green blue, color filter. The layer between the glass layers is a liquid crystal layer.

The Architecture of a TFT Pixelbelow) from the other substrate layer of the device and control the amount of voltage applied to their respective sub-pixels. This layer also has pixel electrodes between the substrate and the liquid crystal layer. Electrodes are conductors that channel electricity into or out of something, in this case, pixels.

Between the two substrate layers lie liquid crystals. Together, the liquid crystal molecules may behave as a liquid in terms of movement, but it holds its structure as a crystal. There are a variety of chemical formulas available for use in this layer. Typically, liquid crystals are aligned to position the molecules in a certain way to induce specific behaviors of passing light through the polarization of the light waves. To do this, either a magnetic or electric field must be used; however, with displays, for a magnetic field to be usable, it will be too strong for the display itself, and thus electric fields, using very low power and requiring no current, are used.

Before applying an electric field to the crystals between the electrodes, the alignment of the crystals is in a 90 degree twisted pattern, allowing a properly crystal-polarized light to pass through the surface polarizer in a display’s “normal white” mode. This state is caused by electrodes that are purposely coated in a material that orients the structure with this specific twist.

However, when the electric field is applied, the twist is broken as the crystals straighten out, otherwise known as re-aligning. The passing light can still pass through the back polarizer, but because the crystal layer does not polarize the lights to pass through the surface polarizer, light is not transmitted to the surface, thus an opaque display. If the voltage is lessened, only some crystals re-align, allowing for a partial amount of light to pass and creating different shades of grey (levels of light). This effect is called the twisted nematic effect.

Fig. 3:The top row characterizes the nature of alignment in using IPS as well as the quality of viewing angles. The bottom row displays how the twisted nematic is used to align the crystals and how viewing angles are affected by it.

The light that passes through the device is sourced from the backlight which can shine light from the back or the side of the display. Because the LCD does not produce its own light, it needs to use the backlight in the OLED) have come into use as well. Typically white, this light, if polarized correctly, will pass through the RGB color filter of the surface substrate layer, displaying the color signaled for by the TFT device.

TFT-LCD was invented in 1960 and successfully commercialized as a notebook computer panel in 1991 after continuous improvement, thus entering the TFT-LCD generation.

Simply put, the basic structure of the TFT-LCD panel is a layer of liquid crystal sandwiched between two glass substrates. The front TFT display panel is coated with a color filter, and the back TFT display panel is coated with a thin film transistor (TFT). When a voltage is applied to the transistor, the liquid crystal turns and light passes through the liquid crystal to create a pixel on the front panel. The backlight module is responsible for providing the light source after the TFT-Array panel. Color filters give each pigment a specific color. The combination of each different color pixel gives you an image of the front of the panel.

The TFT panel is composed of millions of TFT devices and ITO (In TI Oxide, a transparent conductive metal) regions arranged like a matrix, and the so-called Array refers to the region of millions of TFT devices arranged neatly, which is the panel display area. The figure below shows the structure of a TFT pixel.

No matter how the design of TFT display board changes or how the manufacturing process is simplified, its structure must have a TFT device and control liquid crystal region (if the light source is penetration-type LCD, the control liquid crystal region is ITO; but for reflective LCD, the metal with high reflection rate is used, such as Al).

The TFT device is a switch, whose function is to control the number of electrons flowing into the ITO region. When the number of electrons flowing into the ITO region reaches the desired value, the TFT device is turned off. At this time, the entire electrons are kept in the ITO region.

The figure above shows the time changes specified at each pixel point. G1 is continuously selected to be turned on by the driver IC from T1 to TN so that the source-driven IC charges TFT pixels on G1 in the order of D1, D2, and Dn. When TN +1, gATE-driven IC is selected G2 again, and source-driven IC is selected sequentially from D1.

Many people don’t understand the differences between generations of TFT-LCD plants, but the principle is quite simple. The main difference between generations of plants is in the size of glass substrates, which are products cut from large glass substrates. Newer plants have larger glass substrates that can be cut to increase productivity and reduce costs, or to produce larger panels (such as TFT display LCD TV panels).

The TFT-LCD industry first emerged in Japan in the 1990s, when a process was designed and built in the country. The first-generation glass substrate is about 30 X 40 cm in size, about the size of a full-size magazine, and can be made into a 15-inch panel. By the time Acer Technology (which was later merged with Unioptronics to become AU Optronics) entered the industry in 1996, the technology had advanced to A 3.5 generation plant (G3.5) with glass substrate size of about 60 X 72 cm.Au Optronics has evolved to a sixth-generation factory (G6) process where the G6 glass substrate measures 150 X 185 cm, the size of a double bed. One G6 glass substrate can cut 30 15-inch panels, compared with the G3.5 which can cut 4 panels and G1 which can only cut one 15-inch panel, the production capacity of the sixth generation factory is enlarged, and the relative cost is reduced. In addition, the large size of the G6 glass substrate can be cut into large-sized panels, which can produce eight 32-inch LCD TV panels, increasing the diversity of panel applications. Therefore, the global TFT LCD manufacturers are all invested in the new generation of plant manufacturing technology.

The TRANSISTor-LCD is an acronym for thin-film TFT Display. Simply put, TFT-LCD panels can be seen as two glass substrates sandwiched between a layer of liquid crystal. The upper glass substrate is connected to a Color Filter, while the lower glass has transistors embedded in it. When the electric field changes through the transistor, the liquid crystal molecules deflect, so as to change the polarization of the light, and the polarizing film is used to determine the light and shade state of the Pixel. In addition, the upper glass is fitted to the color filter, so that each Pixel contains three colors of red, blue and green, which make up the image on the panel.

The luminescence principle is tied to the vapor electroplating organic film between the transparent anode and the metal cathode. The electron and electric hole are injected, and the energy is converted into visible light by the composite between the organic film. And can match different organic materials, emit different colors of light, to achieve the requirements of the full-color display.

The organic light display can be divided into Passive Matrix (PMOLED) and Active Matrix (AMOLED) according to the driving mode. The so-called active driven OLED(AMOLED) can be visualized in the Thin Film Transistor (TFT) as a capacitor that stores signals to provide the ability to visualize the light in a grayscale.

Although the production cost and technical barriers of passive OLED are low, it is limited by the driving mode and the resolution cannot be improved. Therefore, the application product size is limited to about 5″, and the product will be limited to the market of low resolution and small size. For high precision and large picture, the active drive is mainly used. The so-called active drive is capacitive to store the signal, so when the scanning line is swept, the pixel can still maintain its original brightness. In the case of passive drive, only the pixels selected by the scan line are lit. Therefore, in an active-drive mode, OLED does not need to be driven to very high brightness, thus achieving better life performance and high resolution.OLED combined with TFT technology can realize active driving OLED, which can meet the current display market for the smoothness of screen playback, as well as higher and higher resolution requirements, fully display the above superior characteristics of OLED.

The technology to grow The TFT on the glass substrate can be amorphous Silicon (A-SI) manufacturing process and Low-Temperature Poly-Silicon (LTPS). The biggest difference between LTPS TFT and A-SI TFT is the difference between its electrical properties and the complicated manufacturing process. LTPS TFT has a higher carrier mobility rate, which means that TFT can provide more current, but its process is complicated.A-si TFT, on the other hand, although a-Si’s carrier movement rate is not as good as LTPS’s, it has a better competitive advantage in cost due to its simple and mature process.Au Optronics is the only company in the world that has successfully combined OLED with LTPS and A-SI TFT at the same time, making it a leader in active OLED technology.

Polysilicon is a silicon-based material about 0.1 to several um in size, composed of many silicon particles. In the semiconductor manufacturing industry, polysilicon should normally be treated by Low-Pressure Chemical Vapor Deposition. If the annealing process is higher than 900C, this method is known as SPC. Solid Phase Deposition. However, this method does not work in the flat display industry because the maximum temperature of the glass is only 650C. Therefore, LTPS technology is specifically applied to the manufacture of flat displays.

The LTPS membrane is much more complex than a-SI, yet the LTPS TFT is 100 times more mobile than A-SI TFT. And CMOS program can be carried out directly on a glass substrate. Here are some of the features that p-SI has over A-SI:

2. Vehicle for OLED: High mobility means that the OLED Device can provide a large driving current, so it is more suitable for an active OLED display substrate.

The “reflective” architecture USES an external light source to display the image via a reflector, which saves electricity but is harder to see in the absence of an external light source.

Display screen is everywhere nowadays. Do you still remember the TVs or computer monitors 20 years ago? They were quadrate, huge and heavy. Now let’s look at the flat, thin and light screen in front of you, have you ever wondered why is there such a big difference?

Actually, the monitors 20 year ago were CRT (Cathode Ray Tube) displays, which requires a large space to run the inner component. And now the screen here in your presence is the LCD (Liquid Crystal Display) screen.

As mentioned above, LCD is the abbreviation of Liquid Crystal Display. It’s a new display technology making use of the optical-electrical characteristic of liquid crystal.

Liquid crystal is a state of substance that has both the characteristics of liquid and solid crystal. It don’t emit light itself, but it can let the light pass perfectly in specific direction. Meanwhile, liquid crystal molecule will rotate under the influence of a electric field, and then the light goes through it will rotate too. That said, liquid crystal can be a switch of light, which is the key in display technology.

STN LCD: STN is for Super-twisted Nematic. The liquid crystal in STN LCD rotate more angles than that in TN LCD, and have a different electrical feature, allowing STN LCD to display more information. There are many improved version of STN LCD like DSTN LCD (double layer) and CSTN LCD (color). This LCD is used in many early phones, computers and outdoor devices.

TFT LCD: TFT is for Thin Film Transistor. It’s the latest generation of LCD technology and has been applied in all the displaying scenario including electronic devices, motor cars, industrial machines, etc. When you see the word ‘transistor’, you may realize there’s integrated circuits in TFT LCD. That’s correct and the secret that TFT LCD has the advantage of high resolution and full color display.

In a simple way, we can divide TFT LCD into three parts, from bottom to top they are: light system, circuit system and light and color control system.In manufacturing process, we’ll start from inner light and color control system and then stretch out to whole module.

It’s accustomed to divide TFT LCD manufacturing process into three main part: array, cell and module. The former two steps are about the production of light and color control system, which contains TFT, CF (color filter) and LC (liquid crystal), named a cell. And the last step is the assembly of cell, circuit and light system.

Now let’s turn to the production of TFT and CF. Here is a common method called PR (photoresist) method. The whole process of PR method will be demonstrated in TFT production.

The global TFT-LCD display panel market attained a value of USD 148.3 billion in 2022. It is expected to grow further in the forecast period of 2023-2028 with a CAGR of 4.9% and is projected to reach a value of USD 197.6 billion by 2028.

The current global TFT-LCD display panel market is driven by the increasing demand for flat panel TVs, good quality smartphones, tablets, and vehicle monitoring systems along with the growing gaming industry. The global display market is dominated by the flat panel display with TFT-LCD display panel being the most popular flat panel type and is being driven by strong demand from emerging economies, especially those in Asia Pacific like India, China, Korea, and Taiwan, among others. The rising demand for consumer electronics like LCD TVs, PCs, laptops, SLR cameras, navigation equipment and others have been aiding the growth of the industry.

TFT-LCD display panel is a type of liquid crystal display where each pixel is attached to a thin film transistor. Since the early 2000s, all LCD computer screens are TFT as they have a better response time and improved colour quality. With favourable properties like being light weight, slim, high in resolution and low in power consumption, they are in high demand in almost all sectors where displays are needed. Even with their larger dimensions, TFT-LCD display panel are more feasible as they can be viewed from a wider angle, are not susceptible to reflection and are lighter weight than traditional CRT TVs.

The global TFT-LCD display panel market is being driven by the growing household demand for average and large-sized flat panel TVs as well as a growing demand for slim, high-resolution smart phones with large screens. The rising demand for portable and small-sized tablets in the educational and commercial sectors has also been aiding the TFT-LCD display panel market growth. Increasing demand for automotive displays, a growing gaming industry and the emerging popularity of 3D cinema, are all major drivers for the market. Despite the concerns about an over-supply in the market, the shipments of large TFT-LCD display panel again rose in 2020.

North America is the largest market for TFT-LCD display panel, with over one-third of the global share. It is followed closely by the Asia-Pacific region, where countries like India, China, Korea, and Taiwan are significant emerging market for TFT-LCD display panels. China and India are among the fastest growing markets in the region. The growth of the demand in these regions have been assisted by the growth in their economy, a rise in disposable incomes and an increasing demand for consumer electronics.

The report gives a detailed analysis of the following key players in the global TFT-LCD display panel Market, covering their competitive landscape, capacity, and latest developments like mergers, acquisitions, and investments, expansions of capacity, and plant turnarounds:

A thin-film-transistor liquid-crystal display (TFT LCD) is a variant of a liquid-crystal display that uses thin-film-transistor technologyactive matrix LCD, in contrast to passive matrix LCDs or simple, direct-driven (i.e. with segments directly connected to electronics outside the LCD) LCDs with a few segments.

In February 1957, John Wallmark of RCA filed a patent for a thin film MOSFET. Paul K. Weimer, also of RCA implemented Wallmark"s ideas and developed the thin-film transistor (TFT) in 1962, a type of MOSFET distinct from the standard bulk MOSFET. It was made with thin films of cadmium selenide and cadmium sulfide. The idea of a TFT-based liquid-crystal display (LCD) was conceived by Bernard Lechner of RCA Laboratories in 1968. In 1971, Lechner, F. J. Marlowe, E. O. Nester and J. Tults demonstrated a 2-by-18 matrix display driven by a hybrid circuit using the dynamic scattering mode of LCDs.T. Peter Brody, J. A. Asars and G. D. Dixon at Westinghouse Research Laboratories developed a CdSe (cadmium selenide) TFT, which they used to demonstrate the first CdSe thin-film-transistor liquid-crystal display (TFT LCD).active-matrix liquid-crystal display (AM LCD) using CdSe TFTs in 1974, and then Brody coined the term "active matrix" in 1975.high-resolution and high-quality electronic visual display devices use TFT-based active matrix displays.

The liquid crystal displays used in calculators and other devices with similarly simple displays have direct-driven image elements, and therefore a voltage can be easily applied across just one segment of these types of displays without interfering with the other segments. This would be impractical for a large display, because it would have a large number of (color) picture elements (pixels), and thus it would require millions of connections, both top and bottom for each one of the three colors (red, green and blue) of every pixel. To avoid this issue, the pixels are addressed in rows and columns, reducing the connection count from millions down to thousands. The column and row wires attach to transistor switches, one for each pixel. The one-way current passing characteristic of the transistor prevents the charge that is being applied to each pixel from being drained between refreshes to a display"s image. Each pixel is a small capacitor with a layer of insulating liquid crystal sandwiched between transparent conductive ITO layers.

The circuit layout process of a TFT-LCD is very similar to that of semiconductor products. However, rather than fabricating the transistors from silicon, that is formed into a crystalline silicon wafer, they are made from a thin film of amorphous silicon that is deposited on a glass panel. The silicon layer for TFT-LCDs is typically deposited using the PECVD process.

Polycrystalline silicon is sometimes used in displays requiring higher TFT performance. Examples include small high-resolution displays such as those found in projectors or viewfinders. Amorphous silicon-based TFTs are by far the most common, due to their lower production cost, whereas polycrystalline silicon TFTs are more costly and much more difficult to produce.

The twisted nematic display is one of the oldest and frequently cheapest kind of LCD display technologies available. TN displays benefit from fast pixel response times and less smearing than other LCD display technology, but suffer from poor color reproduction and limited viewing angles, especially in the vertical direction. Colors will shift, potentially to the point of completely inverting, when viewed at an angle that is not perpendicular to the display. Modern, high end consumer products have developed methods to overcome the technology"s shortcomings, such as RTC (Response Time Compensation / Overdrive) technologies. Modern TN displays can look significantly better than older TN displays from decades earlier, but overall TN has inferior viewing angles and poor color in comparison to other technology.

Most TN panels can represent colors using only six bits per RGB channel, or 18 bit in total, and are unable to display the 16.7 million color shades (24-bit truecolor) that are available using 24-bit color. Instead, these panels display interpolated 24-bit color using a dithering method that combines adjacent pixels to simulate the desired shade. They can also use a form of temporal dithering called Frame Rate Control (FRC), which cycles between different shades with each new frame to simulate an intermediate shade. Such 18 bit panels with dithering are sometimes advertised as having "16.2 million colors". These color simulation methods are noticeable to many people and highly bothersome to some.gamut (often referred to as a percentage of the NTSC 1953 color gamut) are also due to backlighting technology. It is not uncommon for older displays to range from 10% to 26% of the NTSC color gamut, whereas other kind of displays, utilizing more complicated CCFL or LED phosphor formulations or RGB LED backlights, may extend past 100% of the NTSC color gamut, a difference quite perceivable by the human eye.

In 2004, Hydis Technologies Co., Ltd licensed its AFFS patent to Japan"s Hitachi Displays. Hitachi is using AFFS to manufacture high end panels in their product line. In 2006, Hydis also licensed its AFFS to Sanyo Epson Imaging Devices Corporation.

A technology developed by Samsung is Super PLS, which bears similarities to IPS panels, has wider viewing angles, better image quality, increased brightness, and lower production costs. PLS technology debuted in the PC display market with the release of the Samsung S27A850 and S24A850 monitors in September 2011.

TFT dual-transistor pixel or cell technology is a reflective-display technology for use in very-low-power-consumption applications such as electronic shelf labels (ESL), digital watches, or metering. DTP involves adding a secondary transistor gate in the single TFT cell to maintain the display of a pixel during a period of 1s without loss of image or without degrading the TFT transistors over time. By slowing the refresh rate of the standard frequency from 60 Hz to 1 Hz, DTP claims to increase the power efficiency by multiple orders of magnitude.

Due to the very high cost of building TFT factories, there are few major OEM panel vendors for large display panels. The glass panel suppliers are as follows:

External consumer display devices like a TFT LCD feature one or more analog VGA, DVI, HDMI, or DisplayPort interface, with many featuring a selection of these interfaces. Inside external display devices there is a controller board that will convert the video signal using color mapping and image scaling usually employing the discrete cosine transform (DCT) in order to convert any video source like CVBS, VGA, DVI, HDMI, etc. into digital RGB at the native resolution of the display panel. In a laptop the graphics chip will directly produce a signal suitable for connection to the built-in TFT display. A control mechanism for the backlight is usually included on the same controller board.

The low level interface of STN, DSTN, or TFT display panels use either single ended TTL 5 V signal for older displays or TTL 3.3 V for slightly newer displays that transmits the pixel clock, horizontal sync, vertical sync, digital red, digital green, digital blue in parallel. Some models (for example the AT070TN92) also feature input/display enable, horizontal scan direction and vertical scan direction signals.

New and large (>15") TFT displays often use LVDS signaling that transmits the same contents as the parallel interface (Hsync, Vsync, RGB) but will put control and RGB bits into a number of serial transmission lines synchronized to a clock whose rate is equal to the pixel rate. LVDS transmits seven bits per clock per data line, with six bits being data and one bit used to signal if the other six bits need to be inverted in order to maintain DC balance. Low-cost TFT displays often have three data lines and therefore only directly support 18 bits per pixel. Upscale displays have four or five data lines to support 24 bits per pixel (truecolor) or 30 bits per pixel respectively. Panel manufacturers are slowly replacing LVDS with Internal DisplayPort and Embedded DisplayPort, which allow sixfold reduction of the number of differential pairs.

The bare display panel will only accept a digital video signal at the resolution determined by the panel pixel matrix designed at manufacture. Some screen panels will ignore the LSB bits of the color information to present a consistent interface (8 bit -> 6 bit/color x3).

With analogue signals like VGA, the display controller also needs to perform a high speed analog to digital conversion. With digital input signals like DVI or HDMI some simple reordering of the bits is needed before feeding it to the rescaler if the input resolution doesn"t match the display panel resolution.

Kawamoto, H. (2012). "The Inventors of TFT Active-Matrix LCD Receive the 2011 IEEE Nishizawa Medal". Journal of Display Technology. 8 (1): 3–4. Bibcode:2012JDisT...8....3K. doi:10.1109/JDT.2011.2177740. ISSN 1551-319X.

Brody, T. Peter; Asars, J. A.; Dixon, G. D. (November 1973). "A 6 × 6 inch 20 lines-per-inch liquid-crystal display panel". 20 (11): 995–1001. Bibcode:1973ITED...20..995B. doi:10.1109/T-ED.1973.17780. ISSN 0018-9383.

K. H. Lee; H. Y. Kim; K. H. Park; S. J. Jang; I. C. Park & J. Y. Lee (June 2006). "A Novel Outdoor Readability of Portable TFT-LCD with AFFS Technology". SID Symposium Digest of Technical Papers. AIP. 37 (1): 1079–82. doi:10.1889/1.2433159. S2CID 129569963.

Kim, Sae-Bom; Kim, Woong-Ki; Chounlamany, Vanseng; Seo, Jaehwan; Yoo, Jisu; Jo, Hun-Je; Jung, Jinho (15 August 2012). "Identification of multi-level toxicity of liquid crystal display wastewater toward Daphnia magna and Moina macrocopa". Journal of Hazardous Materials. Seoul, Korea; Laos, Lao. 227–228: 327–333. doi:10.1016/j.jhazmat.2012.05.059. PMID 22677053.

![]()

The LCD TFT screens are built of thin-film transistors. The transistor is produced by chemical vapor deposition (CVD), based on the use of liquid hydrogen mixture and silicon mixture in an organic solvent, and using the rotation application method of the thin semiconductor.

In the TFT matrix, each pixel is controlled by four transistors, whereone of them is responsible for brightness, and three remain for basic color (red, blue, green). As a result, this solution allows the high resolution, better color and generally higher parameters of displayed images – comparing to common LCD matrix.

Because of the material the TFT is built from, which isglass, TFT displays havelow mechanical toughness,so can be easily damaged. The most popular damage of TFT is:

The majority of damage occurs during the assembly process in the end user devices. Too much pressure on the fragile TFT construction can damage the structure of the liquid crystal or electric lines.

We recommend that you are always careful during the process of assembling the module. This special treatment is necessary to protect the matrix of the display against being hit or put under too much pressure.

The module can be held strictly by the housing, and the unnecessary thrust on display should be avoided. The disassembling of the display housing is not recommended, because this process is very destructive and in most cases, it will leave you with a damaged TFT .

This bar-type EVE TFT development kit includes everything to get started prototyping and building with the 480x128 accelerated display module. This development kit includes the bar-type display module with the accelerator board connected to an EVE Breakout Board connected to a Seeeduino loaded with demo code. Once you receive the development kit, all you need to do to get the demo kit running is check the connections and plug in the included USB cable.

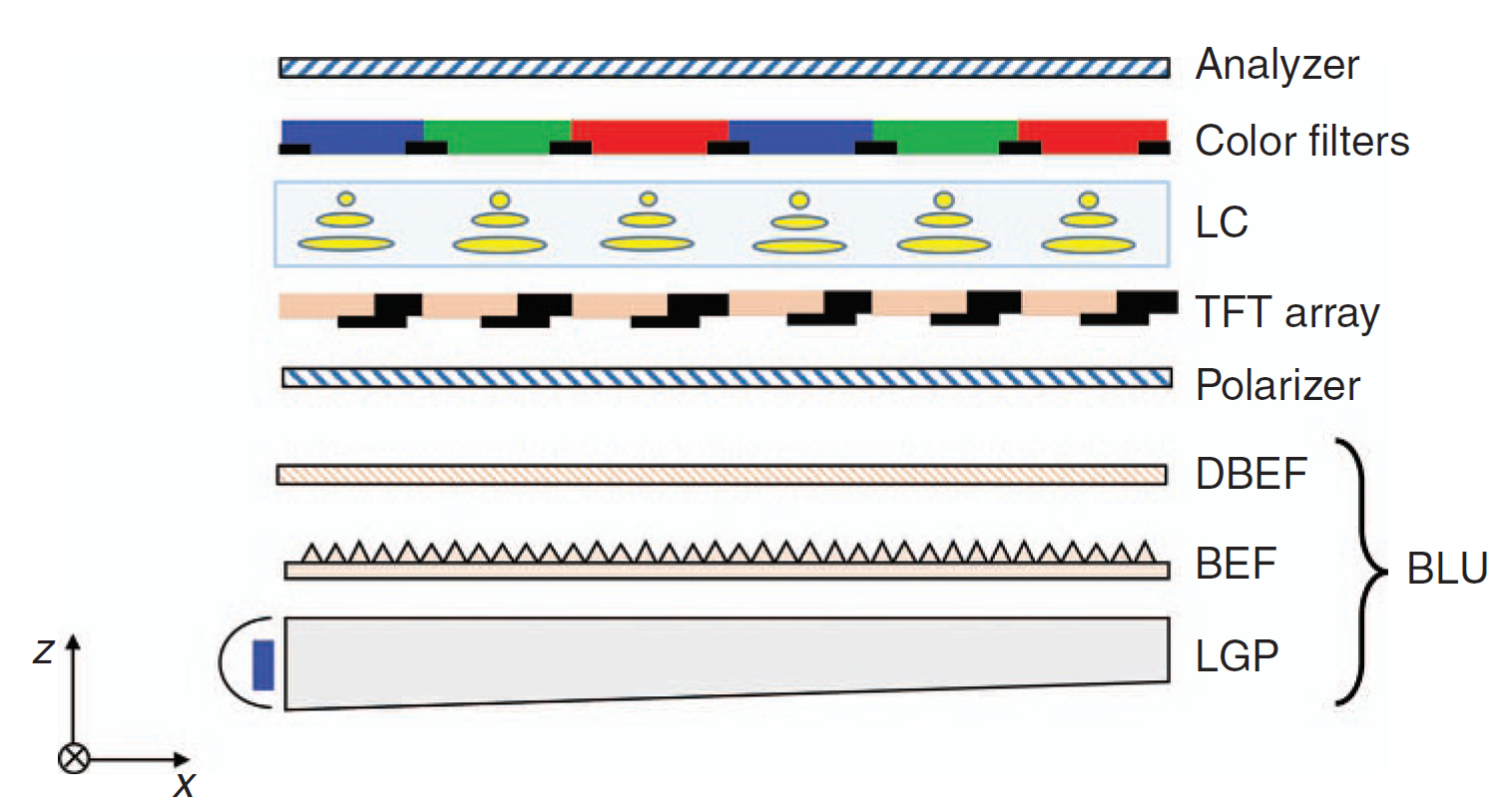

Thin-Film Transistor Liquid Crystal Displays use thin-film transistors to control the voltage applied to the liquid crystal layer at a sub-pixel level. The structure of TFT LCDs consists of a TFT “sandwich” and a BLU (Backlight Unit). A typical configuration is shown in the schematic diagram below.

Firstly, between the back and front polarizers, TFT LCD cells are made with two glass substrates – one for color filters, the other for a TFT array – and a liquid crystal layer sandwiched in between.

For normally black TFT LCDs, if we follow along a piece of light setting off from its backlight source, it will bea)guided uniformly by LGP;b)reflected and enhanced by BEF and DBEF;c)polarized by the back polarizer;d)polarization changed by twisted LC under the voltage applied by TFT arrays;e)“tinted” red/green/blue by corresponding color filter of the subpixel;f)let through the front polarizer by matched polarization; andg)finally, it will reach the surface and appears in viewer’s eyes.

For normally white panels, processd)will be the opposite – known as the polarization rotation effect, light is twisted in a voltage-off stage and can pass through the front polarizer by default, thus displaying white normally. However, when the voltage applied increases, this polarization rotation effect would be gradually diminished. And the light would not be able to pass through the front polarizer anymore without changing its polarization. In this way, certain pixels will appear in different colors.

Normally black LCDs have higher contrast and wider viewing angles without grayscale inversion phenomenon compared to their normally white relatives. And whether TFT LCDs are normally black or white depends on their LC switching mode:

2Chen, HW., Lee, JH., Lin, BY.et al.Liquid crystal display and organic light-emitting diode display: present status and future perspectives.Light Sci Appl7,17168 (2018).https://doi.org/10.1038/lsa.2017.168

As previously mentioned, TN mode functions with the polarization rotation effect. Under traditional TN/VA display mode, the liquid crystal molecules are vertically arranged, with a relatively narrow visual angle. When an external force is exerted on the screen, the liquid crystal molecular structure will sink in a herringbone pattern to slowly recover – a pattern called vertical alignment. Therefore, an evident “water ripple” usually appears when the display surface is touched and impacts the user experience. In comparison, the VA mode provides higher contrast. And MVA (multi-domain vertical alignment) is an upgraded version of VA with improved viewing angles.

TFT stands for thin-film transistor, which means that each pixel in the device has a thin-film transistor attached to it. Transistors are activated by electrical currents that make contact with the pixels to produce impeccable image quality on the screen. Here are some important features of TFT displays.Excellent Colour Display.Top notch colour contrast, clarity, and brightness settings that can be adjusted to accommodate specific application requirements.Extended Half-Life.TFT displays boast a much higher half-life than their LED counterparts and they also come in a variety of size configurations that can impact the device’s half-life depending on usage and other factors.TFT displays can have either resistive or capacitive touch panels.Resistive is usually the standard because it comes at a lower price point, but you can also opt for capacitive which is compatible with most modern smartphones and other devices.TFT displays offer exceptional aspect ratio control.Aspect ratio control contributes to better image clarity and quality by mapping out the number of pixels that are in the source image compared to the resolution pixels on the screen.Monitor ghosting doesn’t occur on TFT displays.This is when a moving image or object has blurry pixels following it across the screen, resembling a ghost.

TFT displays are incredibly versatile.The offer a number of different interface options that are compatible with various devices and accommodate the technical capabilities of all users.

There are two main types of TFT LCD displays:· Twisted nematic TFT LCDs are an older model. They have limited colour options and use 6 bits per each blue, red, and green channel.

In-plane switching TFT LCDs are a newer model. Originally introduced in the 1990s by Hitachi, in-plane switching TFT LCDs consist of moving liquid pixels that move in contrast or opposite the plane of the display, rather than alongside it.

Relies on backlighting to provide brightness rather than producing its own light, hence, they need built-in light emitting diodes (LEDs) in their backlighting structure

The type of TFT LCD monitor or industrial display you choose to purchase will depend on the specifications of your application or project. Here are a few important factors to consider when selecting an appropriate TFT LCD display technology:Life expectancy/battery life.Depending on the length of ongoing use and the duration of your project, you’re going to want to choose a device that can last a long time while maintaining quality usage.

Image clarity.Some TFT displays feature infrared touchscreens, while others are layered. The former is preferable, especially in poor lighting conditions or for outdoor and industrial applications, because there’s no overlay and therefore no obstructions to light emittance.

The environmental conditions make a difference in operation and image clarity. When choosing a TFT for outdoor or industrial applications, be sure to choose one that can withstand various environmental elements like dust, wind, moisture, dirt, and even sunlight.

As a leading manufacturer and distributor of high-quality digital displays in North America, Nauticomp Inc. can provide custom TFT LCD monitor solutions that are suitable for a multitude of industrial and commercial indoor and outdoor applications. Contact us today to learn more.

TFT LCD screen has good brightness, high contrast, strong sense of hierarchy, and bright colors. The disadvantage is that it consumes more electricity and costs more. The main components of the TFT-type liquid crystal display include fluorescent tubes, light guide plates, polarizing plates, filter plates, glass substrates, alignment films, liquid crystal materials, thin mode transistors, and the like. But what is its structure?

TFT LCDs are made up of multiple layers, just like sandwiches. The outermost layer on both sides is a highly transparent glass layer. In the middle of the glass layer is a film capacitor, a color filter necessary for generating the three primary colors of red, blue, and green, and a liquid crystal layer. A fluorescent back light source illuminates behind the screen power to complete the LCD display.

Just like a conventional cathode ray tube display, red, green and blue three-color liquid crystals are mixed to form one pixel. Control the voltages of the three color points red, green, and blue, and mix three colors of different concentrations to form the desired colors.

The screen power of the entire TFT display is composed of a grid of pixels. The first point has a transistor control. The resolution is formed by these points. If the resolution of a liquid crystal display is 1024*768 pixels (SVGA), then it really has many points.

Liquid crystal refers to the intermediate status of a substance between solid (crystal) and liquid. When crystals with a high level of order in molecular sequence are melted, they generally turn liquid, which has fluidity but no such order at all. However, thin bar-shaped organic molecules, when they are melted, keep their order in a molecular direction although they lose it in molecular positions. In the state in which molecules are in a uniform direction, they also have refractive indices, dielectric constants and other physical characteristics similar to those of crystals, depending on their direction, even though they are liquid. This is why they are called liquid crystal. The diagram below shows the structure of 5CB (4-pentyl-4’-Cyanobiphenyl) as an example of liquid crystal molecules.

A liquid crystal display (LCD) has liquid crystal material sandwiched between two sheets of glass. Without any voltage applied between transparent electrodes, liquid crystal molecules are aligned in parallel with the glass surface. When voltage is applied, they change their direction and they turn vertical to the glass surface. They vary in optical characteristics, depending on their orientation. Therefore, the quantity of light transmission can be controlled by combining the motion of liquid crystal molecules and the direction of polarization of two polarizing plates attached to the both outer sides of the glass sheets. LCDs utilize these characteristics to display images.

An LCD consists of many pixels. A pixel consists of three sub-pixels (Red/Green/Blue, RGB). In the case of Full-HD resolution, which is widely used for smartphones, there are more than six million (1,080 x 1,920 x 3 = 6,220,800) sub-pixels. To activate these millions of sub-pixels a TFT is required in each sub-pixel. TFT is an abbreviation for "Thin Film Transistor". A TFT is a kind of semiconductor device. It serves as a control valve to provide an appropriate voltage onto liquid crystals for individual sub-pixels. A TFT LCD has a liquid crystal layer between a glass substrate formed with TFTs and transparent pixel electrodes and another glass substrate with a color filter (RGB) and transparent counter electrodes. In addition, polarizers are placed on the outer side of each glass substrate and a backlight source on the back side. A change in voltage applied to liquid crystals changes the transmittance of the panel including the two polarizing plates, and thus changes the quantity of light that passes from the backlight to the front surface of the display. This principle allows the TFT LCD to produce full-color images.

The report delivers a comprehensive overview of the crucial elements of the market and elements such as drivers, current trends of the past and present times, supervisory scenario & technological growth. This report also includes the overall and comprehensive study of the TFT LCD Display Modules market with all its aspects influencing the growth of the market. This reports an exhaustive quantitative analysis of the TFT LCD Display Modules industry and provides data for making strategies to increase market growth and effectiveness.

The report presents the market competitive landscape and a corresponding detailed analysis of the major vendor/key players in the market. Top Companies in the Global TFT LCD Display Modules Market: Panasonic Corporation, Schneider Electric, Siemens AG, LG Display, HannStar Display Corporation, AU Optronics Corp., Chi Mei Corporation, SAMSUNG Display, SHARP CORPORATION, Mitsubishi Electric Corporation, Displaytech, Innolux Corporation, Apollo Display

- Analytical Tools: The Global TFT LCD Display Modules Market report includes the accurately studied and assessed data of the key industry players and their scope in the market by means of a number of analytical tools. Analytical tools such as Porter’s five forces analysis, SWOT analysis, feasibility study, and investment return analysis have been used to analyze the growth of the key players operating in the market.

TFT LCD Display ModulesMarket:Where are the opportunities? What does the future look like for TFT LCD Display Modules Market? What will be the market size in the next 5 years?

The TFT Display Glass Substrate industry’s market size, characteristics, and growth are detailed in this report, which is broken down by type, application, and consumption area of TFT Display Glass Substrate. The report also describes the leading companies and introduces players in the industry from the standpoint of the industry chain and marketing chain.

The study examines and assesses the global TFT Display Glass Substrate Market ‘s potential, including facts and data on market size, share, and growth variables. In addition, the research identifies and analyses developing trends in the global blood ingredients market, as well as main drivers, challenges, and opportunities. The market has had significant growth at a notable rate in recent years and is expected to continue to rise as a result of its increasing use in products. Furthermore, increased industry knowledge in China, the launch of new and specialised products, rising population, and significant increases in spending are expected to support market growth in the future. However, the high cost of treatment and rising demand for such products are projected to limit market expansion.

The global TFT Display Glass Substrate Market 2022 research analyses market size, share, and growth, as well as trends, pricing structure, and statistics and detailed data. The examination of several aspects that contribute to the market’s growth has been included in the research report. This section also discusses the many sectors and applications that may have an impact on the market in the future. This section also includes a breakdown of production volume on the global market and by kind from 2022 to 2028. The market is categorised in this research report based on the source of their production technique, type, and application.

![]()

These are our stock items and all of these products will have the same quality control as Winstar standard. These products are on sale and once stocks are gone, some of the products will no longer be available. These products are fine to use as demonstration, product testing and engineering samples. They are also ideal for small run projects and hobbyists. We will provide the best service and best price discount. Don’t miss out the Special Offer; it"s on Sale including OLED display, TFT, Mono LCM. Come to contact sales@winstar.com.tw for special price now!

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey