is tft display easier to see in the sun manufacturer

When display devices are brought outside, oftentimes they face the brightness of sunlight or any other form of high ambient light sources reflecting off of and overwhelming the LED backlight’s image.

With the growth of the LCD panel industry as a whole, it has become more important than ever to prevent the sun’s wash out of displays used outdoors, such as automobile displays, digital signage, and public kiosks. Hence, the sunlight readable display was invented.

One solution would be to increase the luminance of the TFT LCD monitor’s LED backlight to overpower the bright sunlight and eliminate glare. On average, TFT LCD screens have a brightness of about 250 to 450 Nits, but when this is increased to about 800 to 1000 (1000 is the most common) Nits, the device becomes a high bright LCDand a sunlight readable display.

Doing this is an affordable option for enhancement of image quality in the outdoors, including features like contrast ratio and viewing angle, in a common use setting like with phones.

Since many of today’s TFT LCD display devices have shifted to touchscreens, the touch panels on the surface of LCD screens already block a small percentage of backlighting, decreasing the surface brightness and making it so that the sunlight can even more easily wash out the display. Resistive touch panels use two transparent layers above the glass substrate, but the transparent layers can still block up to 5% of the light.

In order to optimize the high brightness of the backlight, a different type of touchscreen can be used: the capacitive touchscreen. Though it is more expensive than the resistive touch screen, this technology is more ideal for sunlight readable displays than the resistive due to its usage of a thinner film or even in-cell technologies rather than two layers above the glass of the display, and therefore, light can pass more efficiently.

However, with this method comes a list of potential problems. Firstly, high brightness displays result in much greater power consumption and shorter battery life. In order to shed more light, more power will be needed which can also consequently result in device overheating which can also shorten battery life. If the backlight’s power is increased, the LED’s half-life may also be reduced.

While in bright exterior light settings, these devices reduce eye strain as the user attempts to view the image on screen, the brightness of the display itself can also cause eye strain, seen as the brightness may overwhelm your eyes. Many devices allow the user to adjust brightness, so this concern is oftentimes not too severe.

A recent technology falling into the sunlight readable display category is the transflective TFT LCD, coming from a combination of the word transmissive and reflective. By using a transflective polarizer, a significant percentage of sunlight is reflected away from the screen to aid in the reduction of wash out. This optical layer is known as the transflector.

In transflective TFT LCDs, sunlight can reflect off the display but can also pass through the TFT cell layer and be reflected back out off a somewhat transparent rear reflector in front of the backlight, illuminating the display without as much demand and power usage from the transmissive nature of the backlight. This addresses both the issues of wash out and the disadvantages of high brightness TFT LCDs in high ambient light environments. Because of its transmissive and reflective modes, this type of device is very useful for devices that will be used outdoors but also indoors.

While it does greatly reduce power consumption, transflective LCDs are much more expensive than high brightness LCDs. In recent years, the cost has decreased, but transflective LCDs continue to be more costly.

In addition to adjustments to the internal mechanics of LCDs, it is possible to make devices more sunlight-readable using surface treatments. The most common are anti-reflective (A/R) films/coatings and anti-glare processing.

Anti-reflective focuses on depositing multiple transparent thin film layers. With the thicknesses, structures, and properties of each individual layer composing the film, reflecting light wavelengths are changed, and thus less light is reflected.

When anti-glare is used, reflected light is fragmented. Using a rough surface as opposed to a smooth one, anti-glare treatments can reduce the reflection’s disruption of the actual image of the display.

Often paired with other methods of creating sunlight readable displays is optical bonding. By gluing the glass of a display to the TFT LCD cells beneath it, optical bonding eliminates the air gap that traditional LCD displays have in them using an optical grade adhesive.

This adhesive reduces the amount of reflection between the glass and LCD cell as well as the reflection of external ambient light. Doing this helps provide a clearer image with an increased contrast ratio, or the difference in the light intensity of the brightest white pixel color and darkest black pixel color.

With this contrast ratio improvement, optical bonding addresses the root issue with unreadable outdoor displays: the contrast. Though an increase in brightness can improve contrast, by fixing the contrast itself, LCD display images in outdoor environments will not be as washed out and will require less power consumption.

Besides the visual display advantages that optical bonding provides, this adhesive improves the display in many other ways. The first being durability, optical bonding eliminates the air gap within the device and replaces it with a hardened adhesive that can act as a shock absorber.

Touch screens with optical bonding gain, accuracy in where the point of contact is between the touch and screen. What is known as parallax, the refraction angle of light, can make it seem that the point of contact and the actual point on the display are different. When the adhesive is used, this refraction is minimized, if not reduced.

The optical bonding adhesive’s elimination of the air gap also protects the LCD from moisture/fogging and dust, as there is no space for impurities to penetrate and remain under the glass layer. This especially helps with maintaining the state of LCDs in transport, storage, and humid environments.

Compiling the various methods of improving LCD screens for sunlight readability, these devices can be optimized in high ambient light settings. An anti-glare coating is applied to the surface of the glass and anti-reflective coatings are applied to both the front and back. The transflector is also used in front of the backlight. These features can result in 1000 Nit or more display lighting, without the excessive power consumption and heat production through a high brightness backlight, consequently allowing for a longer lasting and better performing LCD

Unfortunately, the process of building a reflector inside TFT LCD is complicated and transflective TFT LCD is normally several times higher cost compared with normal transmissive TFT LCD.

To further improve and enhance the qualities of the LCD, LED and cold cathode fluorescent lamp (CCFL) backlights are used. Both these create bright displays, but the LED specifically can do so without as much power consumption and heat generation as compared to the CCFL option. Optical bonding is also applied in order to improve display contrast, leading to a more efficient and better quality sunlight readable display.

There are more and more TFT displays used in outdoor applications, such as automobile display, digital signage and kiosks. High ambient light in outdoor environment often causes wash-out image and renders the screen not readable. Readability & sustainability of TFT display under direct sunlight is becoming vital. Topway Display has been developing sunlight readable LCD display solution for years. The company understands the ins and outs of sunlight readable TFT LCD.

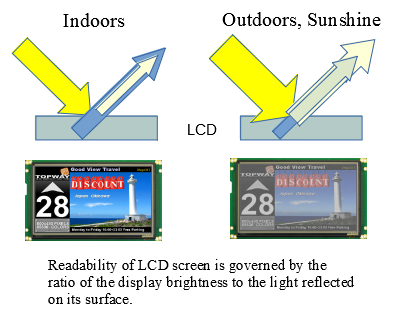

Visibility is the ease with which a viewer can detect an object, or in more scientific term: the relationship between luminance contrast and human eye’s threshold. Therefore, the higher an object’s contrast is, the better is its visibility.

For an LCD to be readable in outdoor environment with very bright ambient light, the LCD screen’s brightness needs to exceed the intensity of light that is reflected from the display surface. To be comfortably viewed by human eyes, the LCD’s brightness needs to exceed its reflected light by a factor of 2.5 at minimum. Naturally, to make an LCD sunlight readable, we can work on two areas, increasing brightness or reducing reflectance.

On a clear day in direct sunlight, the ambient brightness is about 6000 cd/m2. And a typical TFT LCD with touch screen reflects about 14% of ambient light, which is around 840 cd/m2. These days, most LCD displays use LED backlight as light source. It is not too difficult to increase an LCD’s brightness to 800 ~ 1000 Nits, to overpower the bright reflected sunlight. Thus, you have a sunlight readable TFT LCD.

However, this method requires more backlight LEDs and/or higher driving current. The drawbacks are high power consumption, more heat dissipation, increased product size and shorter LED backlight lifespan. Apparently, increasing backlight to make TFT LCD sunlight-readable is not a very good solution.

Transflective TFT LCD is a TFT LCD with both transmissive and reflective characteristics. A partially reflective mirror layer is added between LCD and backlight. This change turns part of the reflected ambient light into LCD’s light source, increasing the TFT display’s brightness. However, transflective TFT LCD is more expensive than transmissive one. At the same time, the partially reflective mirror layer will block some of the backlight, making it not ideal in indoor or low ambient light environment.

What causes light reflection? When light traveling in one transparent medium encounters a boundary with another transparent medium, a portion of the light bounces off the border. Through the simplest version of Fresnel’s equation, we can calculate the amount of reflected light.

The total reflectance on a TFT LCD with touch panel is the sum of reflected light on any interface where two materials meet. As an example, between polarizer and display glass, the difference in index of refractions for the two materials is very small, around 0.1. So the reflected light on this interface is only 0.1%. As Fresnel’s equation points out, we should focus reflection reduction on air interfaces. For air, its index of refraction is 1; for glass, it is 1.5. And that results in a reflectance of 4.5%. Therefore, the three air interfaces contribute majority of TFT LCD’s reflectance, at about 13%.

The quick and easiest thing we can do to reduce air-glass interface reflectance is to use an Anti-Reflection and Anti-Glare film or apply AR coating. An external film with AR properties not only reduces reflected light, but also brings other benefits.

For food industry application, shattered glass is a serious problem. An LCD screen with external film solves this issue nicely. As for automotive applications, in an accident, broken LCD with top AR film won’t produce sharp edge glass that could harms auto occupant. Nevertheless, a top film always reduces TFT LCD’s surface hardness. And it is susceptible to scratches. On the other hand, AR coating retains LCD’s hardness and touch performance. But it comes with a bigger price tag.

Another quick and easy way to tackle reflectance is to affix a linear polarizer on the top of TFT screen. When ambient light gets to the top polarizer, only half of the light passes through. Which results in reflection light cutting to half. This is a very low cost way to increase TFT LCD’s contrast, such that making it more sunlight readable.

Laminating a circular polarizer in TFT LCD will get rid of a lot of reflectance. That is because when ambient light passes through circular polarizer it gets circularly polarized. And when it is reflected, the polarization direction flips by 180 degrees. So when reflected light comes back to the circular polarizer, nothing goes through to viewer’s eyes.

This method is very effective for an LCD display with resistive touch panel. We know resistive touch LCD has two air gaps: air gap between two ITO layers and air gap between touch panel and LCD display. Reflectance caused by the two air gaps is very high. Applying circular polarizer blocks off most of the reflected light, and makes the LCD display sunlight readable.

The disadvantage of such solution is its cost. Since we need not only a circular polarizer, but also a retarder film on the top of LCD display, making sure light originates from within LCD is not blocked by external circular polarizer.

Add AR films on both interfaces of internal air gap. The add-ons can reduce this area’s reflection from 8.5% to 2%. And since the AR films are not outside facing, they are much cheaper than the one used outside. Keeping the air gap also retains the ease of service, in case either touch panel or LCD display needs to be repaired.

The most effective way is to eliminate air gap totally, by using optical bonding. In plain language, we fill air gap with special optical adhesive, to smooth out the area’s refraction index differences. Such that reflectance caused by internal air gap drops from 8.5% to 0.5%. Optical bonding is expensive but effective way to improve TFT LCD sunlight readability. It enhances durability and resistance to impact. Moreover, no air gap means no moisture condensation and fogging.

There are many ways to make TFT LCDsunlight readable. They all have their own pros and cons. With 20+ years" LCD design and manufacturing experience, Topway knows how to create the best sunlight readable TFT LCD for challenging environments. Leave us a message and let"s start the conversation of creating suitable sunlight readable TFT LCD for your project.

degrees. So, in this range we are safe, we can go very low with the temperature, and it will not become solid, and we can go very high with the temperature up to 110 degrees and it will not become isotropic.

Maybe you have even seen some displays that were used outdoors and sometimes they become black. We call that the blackening effect. If they become black, that means the crystals become isotropic. You can sometimes see that the part of the display is black or sometimes the whole display becomes black, depending on the temperature. The good thing is that it is not damaging the display, so once the temperature drops it goes back to the nematic phase and the display is working again, but in a high temperature you cannot see anything on the display, it is not working.

On the picture above, we have an example from a data sheet of a display with high temperatures. As we said it’s a liquid crystal from -40 to +110 degrees, and this is the latest technology. But you need to be careful! This is only about the surface of a display, the TFT glass itself. If we have the sunlight going to the display it can increase the temperature of the whole display as a module.

For the whole display module, the operating temperature range can be as low as 0 to +50 degrees or -20 to 70 degrees. We can have two operating temperatures, that means if we use the display outdoors, we are safe from the sunlight, the surface of the display can go very high, but we need to control the ambient temperature inside the display housing to not go too high. +50 or +70 will be maximum, usually we need fans to remove the heat from inside. Typically, in our case we have a computer inside and we have more devices that cannot work at high temperatures like +100 degrees, so we control the temperature anyway. So, the temperature cannot be too high inside and for sure cannot be that high as a liquid crystal itself can withstand, which is +110 degrees.

And that will be all in this article about contrast, brightness, and temperatures. Just one more thing: if you are planning on buying a laptop today, you can find brightness in the specification. Look at this number because this will determine how good your laptop will be outdoors. There are laptops on the market today that will have 1000 candelas or even more. If you are looking for a new device my recommendation also goes for mobile phones. Low brightness mobile phones can have 300, maybe 500 candelas, but nowadays the standard will be around 1000 candelas, but there are phones on the market that already have 1500 or even 1800 candelas. That means if you are in the sunlight you will still be able to see the image clearly. Of course, the battery will be drained faster, but sometimes it is not so important, maybe you just want to check something quickly, to read something and you want to have a clear image just be aware that this number is pretty important when you buy new devices!

Before answering the questions below, it would be helpful to provide a simple overview of how a TFT LCD works. Every monitor or touchscreen computer includes an LCD panel. The LCD panel is the component that you are viewing at this very moment. This panel includes a thin layer of TFT LCD pixels, where each pixel includes a red, blue, and green rectangle. You can actually see the individual pixels on a display if you place a drop of water on it. The drop will magnify the pixel area and reveal a pixel with a red, blue, and green rectangle. Each red, blue, and green rectangle is a small lens that can be adjusted to allow varying amounts of light to pass through. The colors you see on your screen are determined by how much light is passing through each adjustable red, green, and blue element of each pixel.

The light that you see does not come from the pixels themselves, but from the backlight behind the pixels, which is a series of carefully placed LEDs that emit white light that projects through the LCD pixels. You cannot see the individual backlight LEDs when you look at your monitor, because there is layer of light diffusing material between the LED backlight and the LCD pixel layer. The light diffusing material scatters the light from each individual backlight LED, so they do not show up as bright spots on your monitor.

To summarize, the three layers of an LCD panel are the TFT LCD pixel layer, the diffuser layer, and the LED backlight layer. Note that some LCDs have edge-lit backlighting, but there is no need to go into detail about this, as the same principles apply. That completes LCD panel course 101. Now, what makes a display sunlight readable?

There are two general ways to make an LCD brighter and therefore readable in sunlight. The first and simplest way is to increase the brightness of the backlight. LCD brightness is measured in Nits. Typical LCD panels have a screen brightness between 250 Nits to 450 Nits. LCD brightness of 800 Nits or higher is generally considered sunlight readable, but most sunlight readable displays are 1000 nits. Increasing the brightness of the LCD panel backlight is the most common method of making an LCD panel sunlight readable. Most of Teguar’s industrial panel PCs and touchscreen monitors are available with this type of high brightness LCD.

Another way to make an LCD sunlight readable is to change the diffuser material between the LED backlight and the LCD pixels to a “transflective” material. The transflective material is similar to reflective sunglasses or a one way window, where the shiny side is facing the LCD surface. When transflective material is used, the sunlight entering the LCD panel travels through the pixels, bounces off the transflective material, and is reflected back through the pixels to your eyes. In this case, the sunlight has much less of an impact on viewability than a traditional LCD panel, as the sunlight is reflecting back through the LCD pixels and contributing to the LCD brightness. One drawback of transflective diffuser LCDs is that they don’t allow for as much of the backlight to pass through the diffuser material, so in low light conditions the LCD does not appear as bright. Transflective diffuser LCDs are not as common as high brightness backlight LCDs.

Optical bonding improves viewability of touchscreen PCs in sunlight or other high-bright environments. In a touchscreen computer, the touchscreen sensor and the LCD panel are separate components. The touchscreen is mounted in front of the LCD surface and there is a small air gap between these two components. When sunlight passes through the touchscreen layer, some amount of the light is reflected between the LCD surface and the touchscreen; this reflection reduces LCD viewability.

Optical bonding is a process where a clear adhesive gel is placed between the LCD to the touchscreen. The gel hardens and bonds the touchscreen to the LCD to eliminate the air gap, improving contrast and clarity. Optical bonding is available on many of Teguar’s touchscreen computers and industrial monitors.

The brightness of a sunlight readable display may be overwhelming at night, when there is little or no ambient light. Most industrial computers with sunlight readable LCDs are available with an optional auto-dimming feature. With this feature, an ambient light sensor on the front bezel measures incoming light and adjusts the backlight brightness to match the current light conditions. This is typically a requirement for industrial touchscreen computers that are used in both sunlight and moonlight.

Sunlight also comes with a high amount of UV radiation that can damage the components used in touch screens. PCAP touch screens resist UV damage better than Resistive, but even a PCAP screen must be protected from too much UV exposure. Teguar computers are best suited for environments that provide some level of shade, such as a roof or overhang above the computer, or a structure that blocks the screen from direct exposure to the sun. Most outdoor computer manufactures, Teguar included, will offer a specialized shroud/hood that mounts directly to the unit to provide some level of shade.

Most of our products can handle a few hours of direct sun exposure per day, but full exposure to direct sunlight will cause damage to most touch screens in around 1 year. Contact a knowledgeable Teguar sales rep to discuss the details of your own environment and we can help determine the best solution.

Touchscreen computers in vehicles commonly require high brightness LCDs, because of the ambient sunlight coming through the windows. Sunlight readable LCDs are also used in many indoor applications surrounded by windows, such as air traffic control centers, railroad cars, marine vessels, agriculture machinery, and public kiosks.

You could find more details about the comparision of transflective tft lcd and high brightness tft lcd :https://www.szmaclight.com/new/How-to-choose-Sunlight-readable-tft.html

The surface treatment could reduce reflectance on the screen surface. the display are made by many materials layers, such as a Sunlight readable tft lcd display with capacitive touch, from the top layer to bottom layer,it is made by top cover lens --> touch sensors layer-->OCA layer or air gap layer --> top polarizer --> top glass --> bottom glass-->bottom polarizer-->backlight films.

when the ambient light go through the display, the refraction and reflection happened in each layer. the refraction and reflection light combine to diffuse lights inside the display, it lead to display blur to the screen, the situation would be worse under the sunlight that with strong incident light to the screen.

and Anti-Glare film or apply AR coating. it could reduce 2%~3% surface reflectance on the top surface of sunlight readable display. the surfact treatment could be made by additional materials coating on the screen"s surface or an external film on the screen.

An additional linear polarizer on the top of tft screen would also decrease the surface reflectance from ambient light.Or a circular polarizer (O-film) to block reflected light. when

to viewer’s eyes.But the additional polarizers would make the more thickness to the screen, and reducing the brightness of the lcd screen, a surface coating with AR or AG treatment are more effective and popular for the sunlight readable lcd display.

The brightness will be reduced if the module require touch panel or O-Film on it). meanwhile,high brightness displays will generate more heat and use more power than a traditional LCD.

causing worse sunlight readability. We can improve it from two directions.Add AR films or AR surface treatment on both interfaces of internal air gap. it could reduce thereflection ratio from 8.5% to 2%.

Traditional LED display can be in higher brightness when in outdoor working, but common LED screen is hard to make with high resolution(PPI). so it is hard to get a high quality display effect. To the OLED display, even the organic led display(OLED) can be in high resolution, but its cost is more expensive than lcd display. in the same time, LCD"s lifetime is more longer than oled display.

Monochrome lcd display can be used forsunlight readable screen, Its display modes have TN or stn lcd with Positive mode,they are withdark display letters on lighter background. the sunlihgt readable lcd can be reflective or transreflective display mode, the costs are similar for monochrome reflective lcd, transflective lcd, andtransmissive lcd, Transflective or reflective monochrome lcd are the common and economy solution for sunlight readable lcd displays.Since the reflective lcd and transflective lcd has the lowest power consumption than other sunlight readable display, reflective lcd doesn"t need backlight, while transflective lcd only need the backlight in dark environment. the monochrome lcd is easily to custom make, its tooling cost is also cheaper than other custom tft display or oled display.

For lcd displays in daylight and outdoor application, if you"d like color displays, we would suggest sunlight readable tft displays, because the cost of sunlight readable tft is lower than color OLED display, the color tft displays have longer lifetime than OLED display. Different to traditional monochrome lcd, tft lcd screen have full display colors, the high brightness TFT and transflective tft lcd display would be good solutions for sunlight readable outdoor display,

Maclight"s high brightness TFT LCD panels are featured with brightness up to 1000 nits. high brightness tft bychoosing a very bright backlight to keep the display visible even when the sun is on it.we could upgrade the backlight to dramatically increase brightness with our high-quality LED backlights.

Maclight"s sunlight readable display models are available in resistive touch panel and capacitive touch screen, but the brightness would be affected after adding the touch panel. Maclight Sunlight Readable LCD Modules (High Brightness TFT Display and transflecitve tft lcd display module) are suitable for outdoor applications. Maclight transflective tft including 1.8 " , 2.2" transflective tft, 2.4" tranflective tft display, 2.8", 3.0, 3.5" transflective. Maclight"s high backlighting sunlight viewable TFT display sizes including 2.4 “ tft , 2.8” tft lcd, 3.5"tft LCD, 4.3”, 5",7" and 10.1 inch tft lcd, the sunlight readable display sizes are up to 85" , the upgraded backlight brightness can be up to 3000 nits in maximum.

Most standard TFT display and monitors are rated between 200 and 300 (cd/m²). If it installed indoors, these displays are usually of sufficient brightness to be easily read. But for use in outdoor environment or even direct sunlight, you will find that content on TFT displays with normal brightness is often difficult to read. Reflection is the major reason. It is difficult to read your screen in bright sunlight, as the strong light reflecting off the screen"s surface washes out the display.

There are many technologies to increase the outdoor viewing ability of an LCD display such as high brightness backlight, transflective LCD, optical bonding and surface treatment. However, each has benefits and drawbacks depending on the specific application.

Increasing the brightness is the most common method to improve readability. High Brightness TFT LCD Module features powerful LED backlights, providing the brightness up to 1,000(cd/m²). Typically, LCD brightness of 800 (cd/m²) or higher is considered sunlight readable, but most sunlight readable displays are 1,000(cd/m²). It is possible to change the display brightness by applying more LED backlights without modifying the size or dimensions of the TFT-LCD. However, adding more backlights result in much greater power consumption and shorter battery life. It"s not a perfect solution, but it does help improve the visibility in bright condition.

The other option to enhance visibility is using Transflective TFT Displays. Transflective is a form of LCD that is able to reflect most of the ambient light allowing it to be visible in bright sunlight without using a backlight. It is one of the most flexible solutions as it allows daylight to pass through with lower power consumption in bright environments and readability in any lighting condition.

Optical bonding decreases light refraction (from both LCD backlight and outside light), thus improves TFT screen"s readability. Optical bonding is the process of laminating cover glass or touchscreens to the LCD cell with a layer of resin (Liquid-OCR) or film(Dry-bond process OCA). It enables the connection of the touch sensor, cover glass and display to one unit. One of benefits is to completely fill the air gap and eliminate two reflective surfaces between them.

• Greater durability:It creates an air gap between the LCD cell and the screen glass with air bonding* technology. Full bonding technology filling of the gap prevents this problem from arising and provides high durability for use in factories, or other harsh environments.

• Dust & Moisture Protection:Condensation can cause screens to become foggy from moisture that penetrates the air gap. The most obvious benefit of optical bonding technology is that it physically prevents dust and liquid ingress from getting between the glass and LCD.

• Improved touch experience:A touch panel with optical bonding maintains a more accurate touch response by eliminating air gap between the cover glass and the display.

To further improve readability under direct sunlight, Anti-Reflection and Anti-Glare coating can be applied to the surface reducing ambient light reflectance. AR/AG coatings can be applied directly to an LCD or a substrate material such as a protective cover lens or touch sensor.

• AG(Anti-Glare Coating):This type of treatment is often described as a matte coating that reduces surface reflection on the front of the LCD panel and softens the direct light source. Therefore, it has some impact on contrast and color vibrancy because of the matte surface.

• AR(Anti-Reflection Coating):AR (anti-reflective) film can reduce unwanted surface reflections caused by ambient light and enable you to see the screen with great clarity.

Sunlight can make the screen of the display hard to read. When a touch screen is added to the display, the ability to properly see the display image becomes increasingly difficult. A touch screen on an LCD display adds extra reflections.

A reflection is caused by a mismatch between air and glass or plastic. This mismatch makes whites brighter, while it tempers blacks and other colours. This quickly reduces the contrast of the display. Contrast is a tremendous influence on the sunlight readability of the display.

acts as joining two optical elements, such as the display screen and a (protective) overlay or the display and a touch screen – involves transparent adhesive which also provides vandal resistance

For many years now, transmissive TFT displays have been the dominating technology in visualization. With more and more screens being used outdoors and in portable applications, sunlight readability has become a critical factor in the display market. One way many LCD manufacturers address this issue is to increase the display’s backlight luminance. Although this works well for many applications, it also increases the power consumption and bulkiness of the display making it a non-ideal solution for some portable or small-size applications.

As an alternative to high-brightness TFTs, New Vision Display offers transflective TFT solutions which offer readability in any lighting condition without increasing power consumption or bulkiness. However, the more complex structure of transflective displays increases the manufacturing costs.

Simple, low-resolution LCDs routinely are offered in reflective, transmissive, and transflective (partially transmissive and partially reflective) modes. This is achieved simply by choice of the reflector behind the display, which is usually attached to the rear polarizer. This method is not feasible for TFT displays due to the inherently much lower transmission of these devices.

Transflective TFT displays have a unique cell architecture compared to standard TFT display modules. This is necessary to accommodate for the fact that, in transmissive mode, light passes only once through the liquid crystal layer before reaching an analyzer, while in reflective mode it passes the liquid crystal layer twice.

In the transflective cell architecture, every single pixel is divided into a transmissive and a reflective section. The reflective sections are based on a polymer film with micro-metal mirrors within the glass cell. The size and partition of both transmissive and reflective sections are flexible and depend on the desired focus of the final display. Typically, the liquid crystal layer thickness in the reflective part is only half of the cell gap in the transmissive part. The front polarizer acts as both polarizer and analyzer for the reflective portion of each pixel. This requires selection of a liquid crystal mode that works with parallel polarizers, unlike transmissive displays where the polarizer and analyzer are usually crossed. Furthermore, in order to achieve satisfactory picture performance in reflective mode, the front surface reflection must be suppressed, which is achieved by coating an anti-reflective or an anti-glare layer on the front polarizer.

Within transflective LCDs, transmissive and reflective modes work together for enhanced performance:In dimly lit environments, the display’s transmissive modeis dominant: Light emitted from the display’s backlight illuminates the display image for the viewer (see Image 2 below).

In bright environments, such as direct sunlight, the display’s reflective mode is more dominant: The display image is illuminated via bright ambient light reflected off the internal mirror structure, rather than emitted light from the module’s backlight (see Image 3 below).

The major difference to other manufacturer’s transflective LCD products is that NVD combines the sunlight readability with its wide viewing angle technology, Amplified Intrinsic Fringe-Field (AIFF), which is a variation of Multi-Vertical-Alignment (MVA). The result is stunning viewing angles of typically 80 degrees into all four directions and under all environmental light conditions.

The contrast ratio in reflective mode is still 30:1 versus 300:1 in transmissive mode. Color gamut is specified with 60% coverage of the NTSC triangle and the liquid crystal’s response time is 30ms from black to black.

The operating temperature range is designed at -30 to +80 degrees Celsius. Storage temperature is even larger from -40 to +90 Celsius so that the product easily complies with outdoor and industrial requirements. 2”, 3.5” and 4.3” are pre-tooled.

Transflective TFT display modules can be manufactured in a wide range of sizes and for diverse applications. NVD focuses its efforts in transflective displays on portable applications, currently up to 4.3 inches with resolutions in the 230ppi range. Other sizes are available as custom designs.

Call one of our LCD experts to discuss your project, or complete the below contact form and we’ll put you in touch with the right representative. We look forward to helping you choose the right display solution for your application.

Ready to get started or learn more about how we can help your business? Call us at +1-855-848-1332 or fill out the form below and a company representative will be in touch within 1 business day.

Before you get a new monition for your organization, comparing the TFT display vs IPS display is something that you should do. You would want to buy the monitor which is the most advanced in technology. Therefore, understanding which technology is good for your organization is a must. click to view the 7 Best Types Of Display Screens Technology.

Technology is changing and becoming advanced day by day. Therefore, when you are looking to get a new monitor for your organization, LCD advantages, and disadvantage, you have to be aware of the pros and cons of that monitor. Moreover, you need to understand the type of monitor you are looking to buy.

Now, understanding the technology from the perspective of a tech-savvy person may not be the ideal thing to do unless you are that tech-savvy person. If you struggle to understand technology, then understanding it in a layman’s language would be the ideal thing to do.

That is why it is important to break it down and discuss point by point so that you can understand it in a layman’s language devoid of any technical jargon. Therefore, in this very article, let’s discuss what exactly TFT LCDs and IPS LCDs are, and what are their differences? You will also find out about their pros and cons for your organization.

The word TFT means Thin-Film-Translator. It is the technology that is used in LCD or Liquid Crystal Display. Here you should know that this type of LCD is also categorically referred to as active-matrix LCDs. It tells that these LCDs can hold back some pixels while using other pixels. So, the LCD will be using a very minimum amount of energy to function. TFT LCDs have capacitors and transistors. These are the two elements that play a key part in ensuring that the display monitor functions by using a very small amount of energy without running out of operation.

Now, it is time to take a look at its features that are tailored to improve the experience of the monitor users significantly. Here are some of the features of the TFT monitor;

The display range covers the application range of all displays from 1 inch to 40 inches as well as the large projection plane and is a full-size display terminal.

Display quality from the simplest monochrome character graphics to high resolution, high color fidelity, high brightness, high contrast, the high response speed of a variety of specifications of the video display models.

No radiation, no scintillation, no harm to the user’s health. In particular, the emergence of TFT LCD electronic books and periodicals will bring humans into the era of a paperless office and paperless printing, triggering a revolution in the civilized way of human learning, dissemination, and recording.

It can be normally used in the temperature range from -20℃ to +50℃, and the temperature-hardened TFT LCD can operate at low temperatures up to -80 ℃. It can not only be used as a mobile terminal display, or desktop terminal display but also can be used as a large screen projection TV, which is a full-size video display terminal with excellent performance.

The manufacturing technology has a high degree of automation and good characteristics of large-scale industrial production. TFT LCD industry technology is mature, a mass production rate of more than 90%.

It is a perfect combination of large-scale semiconductor integrated circuit technology and light source technology and has great potential for further development.

TFT LCD screen from the beginning of the use of flat glass plate, its display effect is flat right angles, let a person have a refreshing feeling. And LCDs are easier to achieve high resolution on small screens.

The word IPS refers to In-Plane-Switching which is a technology used to improve the viewing experience of the usual TFT displays. You can say that the IPS display is a more advanced version of the traditional TFT LCD module. However, the features of IPS displays are much more advanced and their applications are very much widespread. You should also know that the basic structure of the IPS LCD is the same as TFT LCD if you compare TFT LCD vs IPS.

As you already know, TFT displays do have a very quick response time which is a plus point for it. But, that does not mean IPS displays a lack of response time. In fact, the response time of an IPS LCD is much more consistent, stable, and quick than the TFT display that everyone used to use in the past. However, you will not be able to gauge the difference apparently by watching TFT and IPS displays separately. But, once you watch the screen side-by-side, the difference will become quite clear to you.

The main drawback of the TFT displays as figured above is the narrow-angle viewing experience. The monitor you buy for your organization should give you an experience of wide-angle viewing. It is very much true if you have to use the screen by staying in motion.

So, as IPS displays are an improved version of TFT displays the viewing angle of IPS LCDs is very much wide. It is a plus point in favor of IPS LCDs when you compare TFT vs IPS. With a TFT screen, you cannot watch an image from various angles without encountering halo effects, blurriness, or grayscale that will cause problems for your viewing.

It is one of the major and remarkable differences between IPS and TFT displays. So, if you don’t want to comprise on the viewing angles and want to have the best experience of viewing the screen from wide angles, the IPS display is what you want. The main reason for such a versatile and wonderful viewing angle of IPS display is the screen configuration which is widely set.

Now, when you want to achieve wide-angle viewing with your display screen, you need to make sure it has a faster level of frequency transmittance. It is where IPS displays overtake TFT displays easily in the comparison because the IPS displays have a much faster and speedier transmittance of frequencies than the TFT displays.

Now the transmittance difference between TFT displays and IPS displays would be around 1ms vs. 25ms. Now, you might think that the difference in milliseconds should not create much of a difference as far as the viewing experience is concerned. Yes, this difference cannot be gauged with a naked eye and you will find it difficult to decipher the difference.

However, when you view and an IPS display from a side-by-side angle and a TFT display from a similar angle, the difference will be quite evident in front of you. That is why those who want to avoid lagging in the screen during information sharing at a high speed; generally go for IPS displays. So, if you are someone who is looking to perform advanced applications on the monitor and want to have a wider viewing angle, then an IPS display is the perfect choice for you.

As you know, the basic structure of the IPS display and TFT displays are the same. So, it is quite obvious that an IPS display would use the same basic colors to create various shades with the pixels. However, there is a big difference with the way a TFT display would produce the colors and shade to an IPS display.

The major difference is in the way pixels get placed and the way they operate with electrodes. If you take the perspective of the TFT display, its pixels function perpendicularly once the pixels get activated with the help of the electrodes. It does help in creating sharp images.

But the images that IPS displays create are much more pristine and original than that of the TFT screen. IPS displays do this by making the pixels function in a parallel way. Because of such placing, the pixels can reflect light in a better way, and because of that, you get a better image within the display.

As the display screen made with IPS technology is mostly wide-set, it ensures that the aspect ratio of the screen would be wider. This ensures better visibility and a more realistic viewing experience with a stable effect.

As you already know the features of both TFT and IPS displays, it would be easier for you to understand the difference between the two screen-types. Now, let’s divide the matters into three sections and try to understand the basic differences so that you understand the two technologies in a compressive way. So, here are the difference between an IPS display and a TFT display;

Now, before starting the comparison, it is quite fair to say that both IPS and TFT displays have a wonderful and clear color display. You just cannot say that any of these two displays lag significantly when it comes to color clarity.

However, when it comes to choosing the better display on the parameter of clarity of color, then it has to be the IPS display. The reason why IPS displays tend to have better clarity of color than TFT displays is a better crystal oriental arrangement which is an important part.

That is why when you compare the IPS LCD with TFT LCD for the clarity of color, IPS LCD will get the nod because of the better and advanced technology and structure.

IPS displays have a wider aspect ratio because of the wide-set configuration. That is why it will give you a better wide-angle view when it comes to comparison between IPS and TFT displays. After a certain angle, with a TFT display, the colors will start to get a bit distorted.

But, this distortion of color is very much limited in an IPS display and you may see it very seldom after a much wider angle than the TFT displays. That is why for wide-angle viewing, TFT displays will be more preferable.

When you are comparing TFT LCD vs. IPS, energy consumption also becomes an important part of that comparison. Now, IPS technology is a much advanced technology than TFT technology. So, it is quite obvious that IPS takes a bit more energy to function than TFT.

Also, when you are using an IPS monitor, the screen will be much larger. So, as there is a need for much more energy for the IPS display to function, the battery of the device will drain faster. Furthermore, IPS panels cost way more than TFT display panels.

1. The best thing about TFT technology is it uses much less energy to function when it is used from a bigger screen. It ensures that the cost of electricity is reduced which is a wonderful plus point.

2. When it comes to visibility, the TFT technology enhances your experience wonderfully. It creates sharp images that will have no problems for older and tired eyes.

1. One of the major problems of TFT technology is that it fails to create a wider angle of view. As a result, after a certain angle, the images in a TFT screen will distort marring the overall experience of the user.

Although IPS screen technology is very good, it is still a technology based on TFT, the essence of the TFT screen. Whatever the strength of the IPS, it is a TFT-based derivative.

Finally, as you now have a proper understanding of the TFT displays vs IPS displays, it is now easier for you when it comes to choose one for your organization. Technology is advancing at a rapid pace. You should not be surprised if you see more advanced display screens in the near future. However, so far, TFT vs IPS are the two technologies that are marching ahead when it comes to making display screens.

STONE provides a full range of 3.5 inches to 15.1 inches of small and medium-size standard quasi TFT LCD module, LCD display, TFT display module, display industry, industrial LCD screen, under the sunlight visually highlight TFT LCD display, industrial custom TFT screen, TFT LCD screen-wide temperature, industrial TFT LCD screen, touch screen industry. The LCD module is very suitable for industrial control equipment, medical instruments, POS system, electronic consumer products, vehicles, and other products.

TFT stands for thin-film transistor, which means that each pixel in the device has a thin-film transistor attached to it. Transistors are activated by electrical currents that make contact with the pixels to produce impeccable image quality on the screen. Here are some important features of TFT displays.Excellent Colour Display.Top notch colour contrast, clarity, and brightness settings that can be adjusted to accommodate specific application requirements.Extended Half-Life.TFT displays boast a much higher half-life than their LED counterparts and they also come in a variety of size configurations that can impact the device’s half-life depending on usage and other factors.TFT displays can have either resistive or capacitive touch panels.Resistive is usually the standard because it comes at a lower price point, but you can also opt for capacitive which is compatible with most modern smartphones and other devices.TFT displays offer exceptional aspect ratio control.Aspect ratio control contributes to better image clarity and quality by mapping out the number of pixels that are in the source image compared to the resolution pixels on the screen.Monitor ghosting doesn’t occur on TFT displays.This is when a moving image or object has blurry pixels following it across the screen, resembling a ghost.

TFT displays are incredibly versatile.The offer a number of different interface options that are compatible with various devices and accommodate the technical capabilities of all users.

There are two main types of TFT LCD displays:· Twisted nematic TFT LCDs are an older model. They have limited colour options and use 6 bits per each blue, red, and green channel.

In-plane switching TFT LCDs are a newer model. Originally introduced in the 1990s by Hitachi, in-plane switching TFT LCDs consist of moving liquid pixels that move in contrast or opposite the plane of the display, rather than alongside it.

Relies on backlighting to provide brightness rather than producing its own light, hence, they need built-in light emitting diodes (LEDs) in their backlighting structure

The type of TFT LCD monitor or industrial display you choose to purchase will depend on the specifications of your application or project. Here are a few important factors to consider when selecting an appropriate TFT LCD display technology:Life expectancy/battery life.Depending on the length of ongoing use and the duration of your project, you’re going to want to choose a device that can last a long time while maintaining quality usage.

Touch type and accuracy.What type of activities are you planning on using your device for? If it’s for extended outdoor use, then you should go with projected capacitive touch as this is more precise and accurate. Touch accuracy is important for industrial and commercial applications.

Image clarity.Some TFT displays feature infrared touchscreens, while others are layered. The former is preferable, especially in poor lighting conditions or for outdoor and industrial applications, because there’s no overlay and therefore no obstructions to light emittance.

The environmental conditions make a difference in operation and image clarity. When choosing a TFT for outdoor or industrial applications, be sure to choose one that can withstand various environmental elements like dust, wind, moisture, dirt, and even sunlight.

As a leading manufacturer and distributor of high-quality digital displays in North America, Nauticomp Inc. can provide custom TFT LCD monitor solutions that are suitable for a multitude of industrial and commercial indoor and outdoor applications. Contact us today to learn more.

As you might already be aware, there’s a large variety of versatile digital display types on the market, all of which are specifically designed to perform certain functions and are suitable for numerous commercial, industrial, and personal uses. The type of digital display you choose for your company or organization depends largely on the requirements of your industry, customer-base, employees, and business practices. Unfortunately, if you happen to be technologically challenged and don’t know much about digital displays and monitors, it can be difficult to determine which features and functions would work best within your professional environment. If you have trouble deciphering the pros and cons of using TFT vs. IPS displays, here’s a little guide to help make your decision easier.

TFT stands for thin-film-transistor, which is a variant of liquid crystal display (LCD). TFTs are categorized as active matrix LCDs, which means that they can simultaneously retain certain pixels on a screen while also addressing other pixels using minimal amounts of energy. This is because TFTs consist of transistors and capacitors that respectively work to conserve as much energy as possible while still remaining in operation and rendering optimal results. TFT display technologies offer the following features, some of which are engineered to enhance overall user experience.

The bright LED backlights that are featured in TFT displays are most often used for mobile screens. These backlights offer a great deal of adaptability and can be adjusted according to the visual preferences of the user. In some cases, certain mobile devices can be set up to automatically adjust the brightness level of the screen depending on the natural or artificial lighting in any given location. This is a very handy feature for people who have difficulty learning how to adjust the settings on a device or monitor and makes for easier sunlight readability.

One of the major drawbacks of using a TFT LCD instead of an IPS is that the former doesn’t offer the same level of visibility as the latter. To get the full effect of the graphics on a TFT screen, you have to be seated right in front of the screen at all times. If you’re just using the monitor for regular web browsing, for office work, to read and answer emails, or for other everyday uses, then a TFT display will suit your needs just fine. But, if you’re using it to conduct business that requires the highest level of colour and graphic accuracy, such as completing military or naval tasks, then your best bet is to opt for an IPS screen instead.

Nonetheless, most TFT displays are still fully capable of delivering reasonably sharp images that are ideal for everyday purposes and they also have relatively short response times from your keyboard or mouse to your screen. This is because the pixel aspect ration is much narrower than its IPS counterpart and therefore, the colours aren’t as widely spread out and are formatted to fit onto the screen. Primary colours—red, yellow, and blue—are used as the basis for creating brightness and different shades, which is why there’s such a strong contrast between different aspects of every image. Computer monitors, modern-day HD TV screens, laptop monitors, mobile devices, and even tablets all utilize this technology.

IPS (in-plane-switching) technology is almost like an improvement on the traditional TFT display module in the sense that it has the same basic structure, but with slightly more enhanced features and more widespread usability. IPS LCD monitors consist of the following high-end features.

IPS screens have the capability to recognize movements and commands much faster than the traditional TFT LCD displays and as a result, their response times are infinitely faster. Of course, the human eye doesn’t notice the difference on separate occasions, but when witnessing side-by-side demonstrations, the difference is clear.

Wide-set screen configurations allow for much wider and versatile viewing angles as well. This is probably one of the most notable and bankable differences between TFT and IPS displays. With IPS displays, you can view the same image from a large variety of different angles without causing grayscale, blurriness, halo effects, or obstructing your user experience in any way. This makes IPS the perfect display option for people who rely on true-to-form and sharp colour and image contrasts in their work or daily lives.

IPS displays are designed to have higher transmittance frequencies than their TFT counterparts within a shorter period of time (precisely 1 millisecond vs. 25 milliseconds). This speed increase might seem minute or indecipherable to the naked eye, but it actually makes a huge difference in side-by-side demonstrations and observations, especially if your work depends largely on high-speed information sharing with minimal or no lagging.

Just like TFT displays, IPS displays also use primary colours to produce different shades through their pixels. The main difference in this regard is the placement of the pixels and how they interact with electrodes. In TFT displays, the pixels run perpendicular to one another when they’re activated by electrodes, which creates a pretty sharp image, but not quite as pristine or crisp as what IPS displays can achieve. IPS display technologies employ a different configuration in the sense that pixels are placed parallel to one another to reflect more light and result in a sharper, clearer, brighter, and more vibrant image. The wide-set screen also establishes a wider aspect ratio, which strengthens visibility and creates a more realistic and lasting effect.

When it comes to deciphering the differences between TFT vs. IPS display technologies and deciding which option is best for you and your business, the experts at Nauticomp Inc. can help. Not only do we offer a wide variety of computer displays, monitors, and screen types, but we also have the many years of experience in the technology industry to back up our recommendations and our knowledge. Our top-of-the-line displays and monitors are customized to suit the professional and personal needs of our clients who work across a vast array of industries. For more information on our high-end displays and monitors, please contact us.

This 800x480 resolution LCD TFT is equipped with a powerful backlight, providing visibility in bright lighting conditions including the direct sun. The 24-bit sunlight readable display has RGB interface and allows optimal viewing up to 70° from any direction. The Liquid Crystal Display has a built-in ILI6122 controller, FFC connection, is RoHS compliant and has a 10-point mulit-touch capacitive touchscreen.

Adjust the length, position, and pinout of your cables or add additional connectors. Get a cable solution that’s precisely designed to make your connections streamlined and secure.

Enhance your user experience with capacitive or resistive touch screen technology. We’ll adjust the glass thickness or shape of the touch panel so it’s a perfect fit for your design.

Choose from a wide selection of interface options or talk to our experts to select the best one for your project. We can incorporate HDMI, USB, SPI, VGA and more into your display to achieve your design goals.

Equip your display with a custom cut cover glass to improve durability. Choose from a variety of cover glass thicknesses and get optical bonding to protect against moisture and debris.

Visible in sunlight-readable display TFT LCD Module does not fully recover its color in sunlight, but it can still be seen clearly, with only a slight change in color.TFT is divided into semi-penetrating and reflective types. In the sunlight, the semi-transparent brightness will have a certain degree of reduction, the color deviation will also have a certain degree of change, which is generally acceptable.

The outdoor sunlight-readable display effect of reflective TFT is better than that of semi-penetrating TFT because the former is displayed by the brightness of a complete backrest light plate, while reflective TFT is similar to the mirror, which can improve the display brightness by borrowing the ambient brightness. Therefore, the higher the ambient brightness is, the higher the screen brightness will be.

This paper makes a comprehensive comparison between high brightness TFT LCD and horizontal TFT LCD from the aspects of technical parameters, display performance, and cost evaluation. After reading this article, you will have a deep understanding of sun-readable TFT and how to select sun-readable TFT LCD to select the most suitable commutating TFT LCD or high-brightness TFT LCD for your outdoor display.

As can be seen from the parameters, STONE STVA035WT-01 is a sunlight readable TFT LCD module with a brightness of 1000 CD /m2. The color TFT LCD has a 320×240 resolution, supports RS232/USB ports, has a 3.5-inch diagonal size, and has resistive and capacitive touch screens. The TFT model has a built-in Cortex M4 driver chip.

The 3.5-inch daylight readable TFT LCD has a logical power supply voltage (V) ranging from 6V to 12v, with a maximum of 40V. With led backlight, the Angle of view is 70/70/50/70, when the grayscale is reversed 12, the aspect ratio is 4:3. It can work at -20℃~ +70℃, and the storage temperature is -30℃~ +80℃.STONE daylight readable TFT LCD is an ideal choice for outdoor industrial measuring instruments, testing equipment, measuring tools, outdoor display, and other industrial electronic equipment.

Because of the requirement of the display that works in a bright environment and direct sunlight, the requirement of a TFT LCD screen is higher and higher.

Horizontal reflection TFT displays have a layer of reflectors in front of the backlight. Incident light bounces off the reflective layer and is used to illuminate the TFT display. T

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey