microchip tft lcd quotation

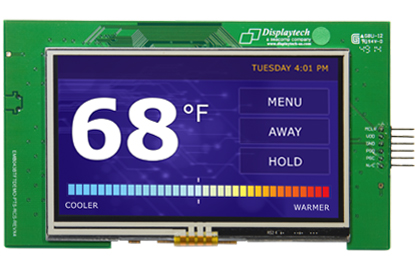

The Displaytech EMB043TFTDEMO is a demonstration and development board for the Displaytech DT043BTFT 4.3 inch color TFT display. The display is controlled by a Microchip PIC24FJ256DA210 microcontroller with integrated graphics controller. Furthermore, the demonstration board includes on-board external SRAM for extra frame-buffer memory as well as SPI flash for storing fonts and images.

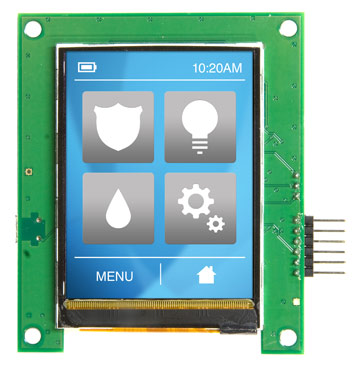

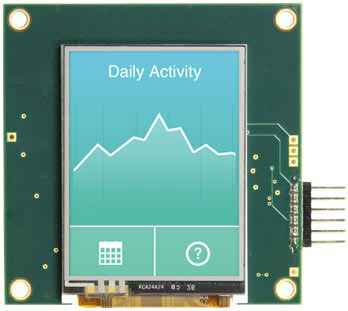

The Displaytech EMB035TFTDEMO is a demonstration and development board for the Displaytech 3.5 inch color TFT display. The display is controlled by a Microchip PIC24FJ256DA210 microcontroller with integrated graphics controller. Furthermore, the demonstration board includes on-board external SRAM for extra frame-buffer memory as well as SPI flash for storing fonts and images. Capacitive touch screen is available for the 3.5" TFT display.

The report presents the market competitive landscape and a corresponding detailed analysis of the major vendor/key players in the market. Top Companies in the Global TFT LCD Driver ICs Market: Texas Instruments, Maxim Integrated, Microchip, Renesas Electronics, ROHM Semiconductor, Analog Devices, NXP Semiconductors, Infineon Technologies, ON Semiconductor, LAPIS Technology, Sitronix Technologoy, Hantronix

TFT LCD Driver ICsMarket Country Level Break-Up:United States, Canada, Mexico, Brazil, Argentina, Colombia, Chile, South Africa, Nigeria, Tunisia, Morocco, Germany, United Kingdom (UK), the Netherlands, Spain, Italy, Belgium, Austria, Turkey, Russia, France, Poland, Israel, United Arab Emirates, Qatar, Saudi Arabia, China, Japan, Taiwan, South Korea, Singapore, India, Australia, and New Zealand, etc.

- Key Strategic Developments:The study also includes the key strategic developments of the market, comprising R&D, new product launches, M&A, agreements, collaborations, partnerships, joint ventures, and regional growth of the leading competitors operating in the TFT LCD Driver ICs market on a global and regional scale.

- Key Market Features:The report evaluated key market features, including revenue, price, capacity, capacity utilization rate, gross, production, production rate, consumption, import/export, supply/demand, cost, market share, CAGR, and gross margin. In addition, the study offers a comprehensive study of the key market dynamics and their latest trends, along with pertinent TFT LCD Driver ICs market segments and sub-segments.

- Analytical Tools:The Global TFT LCD Driver ICs Market report includes the accurately studied and assessed data of the key industry players and their scope in the market by means of a number of analytical tools. Analytical tools such as Porter’s five forces analysis, SWOT analysis, feasibility study, and investment return analysis have been used to analyze the growth of the key players operating in the market.

Add some dazzle to your project with this 1.45" diagonal graphic TFT LCD display module. You"ll often see this display advertised as a 1.44" Color TFT but we rounded up instead. This small display packs 128x128 full-color pixels into one square inch of active display area. It is a great choice when you need color and sharp detail while using minimal front panel space. At less than 5 grams, the display adds very little weight to handheld or wearable devices.

While the SPI interface requires only a few lines to control this TFT LCD module, it is still possible to transfer data at a rate that supports 20 FPS (Frames Per Second) screen updates -- fast enough to play a full motion video.

ER-TFTM050-3 is 800x480 dots 5" color tft lcd module display with RA8875 controller board,superior display quality,super wide viewing angle and easily controlled by MCU such as 8051, PIC, AVR, ARDUINO,and ARM .It can be used in any embedded systems,industrial device,security and hand-held equipment which requires display in high quality and colorful image.

It supports 8080 6800 8-bit,16-bit parallel,3-wire,4-wire,I2C serial spi interface. Built-in MicroSD card slot. It"s optional for 4-wire resistive touch panel (IC RA8875 built-in touch controller),capacitive touch panel with controller,font chip, flash chip and microsd card. We offer two types connection,one is pin header and the another is ZIF connector with flat cable.Mounting on board by default. There is no capacitive touch panel connection on the board of ER-TFTM050-3,its capacitive touch panel needs to be connected with your external board.Now we design another new board with capacitive touch connection named_ER-TFTM050A2-3.

Of course, we wouldn"t just leave you with a datasheet and a "good luck!".Here is the link for5" TFT capacitive touch shield with libraries,examples,schematic diagram for Arduino Due,Mega 2560 and Uno. For 8051 microcontroller user,we prepared the detailed tutorial such as interfacing, demo code and development kit at the bottom of this page.

TFT-LCD technology is based on semiconductor IC manufacturing processes, and is unique in that it uses glass substrates rather than traditional silicon wafers. For the TFT manufacturing process, thin film formation, such as CVD and PVD processes, is a very important part. The ODF process has been developed for the assembly of color filters and TFT substrates, and is used in large size LCDs.

First of all, the movement and arrangement of liquid crystal molecules need electrons to drive, so in the carrier of liquid crystal – TFT glass, there must be able to conduct the part to control the movement of liquid crystal, here will use ITO (Indium TIn Oxide, transparent conductive metal) to do this thing. ITO is transparent, also known as thin film conductive crystal so that it will not block the backlight.

The different arrangement of liquid crystal molecules and the rapid movement changes to ensure that each pixel accurately display the corresponding color, and the image changes precisely and quickly, which requires precision control of the liquid crystal molecules. ITO film requires special processing, as if printed circuitry on a PCB board, drawing conductive lines throughout the LCD board.

For array panels with back-channel etched TFT structure.The main process can be divided into 5 steps (5 lightings) according to the sequence of the layers to be made and the interrelationship between the layers.

The process includes: PECVD triple layer continuous film formation, island lithography, island dry lithography and other processes. After these processes, the final amorphous silicon island for TFT is formed on the glass substrate. The graphics obtained after the process is completed are shown in the following figure.

Specific processes include: S/D metal layer sputtering into a film, S/D lithography, S/D wet lithography, channel dry lithography and other processes. After these processes, the source, drain, channel and data lines of the TFT are finally formed on the glass substrate. At this point, the TFT has been produced. The graphics obtained after the process is completed are shown in the following figure.

The process includes PECVD, photolithography, and dry lithography of vias. After these processes, the final TFT channel protective insulation layer and guide through the hole are formed on the glass substrate. The graphics obtained after the process is completed are shown in the following figure.

Color filters can be produced by various methods; photolithography is a typical method. In photolithography, color filters are produced by exposing a glass substrate coated with a photographic color resist through a photomask. The resist is hardened to form the RGB pattern of the LCD.

When making LCD panels it is impossible to produce them one by one, which is too inefficient, so multiple pieces are processed at once and separated by cutting.

Compared with ordinary LCDs, TFT LCDs provide very clear images/text with shorter response times. TFT LCDs are increasingly being used to bring better visual effects to products.

TFT stands for “thin film transistor”. The transistor of a color TFT LCD is composed of a thin film of amorphous silicon deposited on glass. It acts as a control valve to provide the appropriate voltage to the liquid crystal for each sub-pixel. This is why TFT LCDs are also known as active matrix displays.

TFT LCDs have a liquid crystal layer between a glass substrate formed by the TFT and transparent pixel electrodes and another glass substrate with a color filter (RGB) and a transparent counter electrode. Each pixel in the active matrix is paired with a transistor that includes a capacitor, which gives each sub-pixel the ability to retain its charge without sending a charge every time it needs to be replaced. This means that TFT LCDs are more responsive.

To understand how a TFT LCD works, we must first grasp the concept of a field effect transistor (FET), which is a transistor that uses an electric field to control the flow of current. It is a component with three terminals: source, gate and drain. fet controls the flow of current by applying a voltage to the gate, thereby changing the conductivity between the drain and source.

Using the FET, we can build a circuit as follows. The data bus sends a signal to the source of the FET, and when SEL SIGNAL applies a voltage to the gate, a drive voltage is generated on the TFT LCD panel. A sub-pixel is lit. A TFT LCD display contains thousands or millions of such driver circuits.

Color TFT LCD from 1.8 inch ~ 15 inch, there are different resolutions and interfaces. How to choose the right TFT LCD, you can refer to the previous article “LCD | How to choose a liquid crystal display module

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey