tft lcd polarizer free sample

The Transmissive polarizer is best used for displays that run with the backlight on all the time. This polarizer provides the brightest backlight possible. If you have a need for a bright backlight with lower power drain, transmissive is a good choice for this TFT LCD display module.

Focus LCDs can provide many accessories to go with your display. If you would like to source a connector, cable, test jig or other accessory preassembled to your LCD (or just included in the package), our team will make sure you get the items you need.Get in touch with a team member today to accessorize your display!

Focus Display Solutions (aka: Focus LCDs) offers the original purchaser who has purchased a product from the FocusLCDs.com a limited warranty that the product (including accessories in the product"s package) will be free from defects in material or workmanship.

The Transmissive polarizer is best used for displays that run with the backlight on all the time. This polarizer provides the brightest backlight possible. If you have a need for a bright backlight with lower power drain, transmissive is a good choice for this thin-film transistor.

Focus LCDs can provide many accessories to go with your display. If you would like to source a connector, cable, test jig or other accessory preassembled to your LCD (or just included in the package), our team will make sure you get the items you need.Get in touch with a team member today to accessorize your display!

Focus Display Solutions (aka: Focus LCDs) offers the original purchaser who has purchased a product from the FocusLCDs.com a limited warranty that the product (including accessories in the product"s package) will be free from defects in material or workmanship.

As an option, you can order this TFT pre-assembled onto a breakout/carrier board. The board allows easy prototyping through its 0.1" headers. You can also include the carrier board in your end product to simplify construction and assembly.

This kit consists of a CFAF320240F-035T a 320x240 3.5" Full Color TFT LCD module mounted on a carrier board (CFA-10074). The carrier board supports a current driver for the LED backlight of the display.

This TFT LCD display module is perfect for the designer who"s looking to have a graphic and audio processor already embedded in the display unit. Powered by an FTDI/BridgeTek FT810 Embedded Video Engine (EVE) graphics accelerator chip, simply send over a few commands via SPI or I2C and the EVE will put your stored image up on the display. Need to draw a line, create dials/knobs/buttons, or rotate an image? Send a handful of bytes and the EVE will take care of it.

Full-color (262K) 800x480 RGB display module consists of a TFT panel, a driver IC, an FFC/FPC flexible cable, and an LED backlight. This TFT LCD display module does not include an on-board LCD controller.

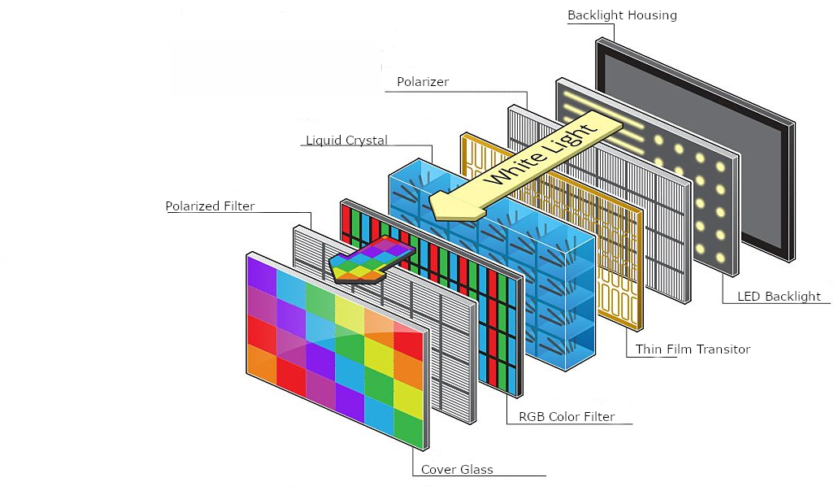

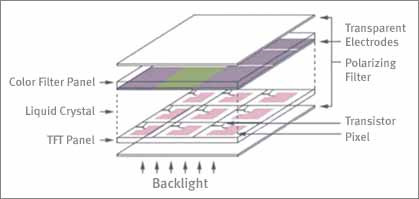

A TFT LCD, or a thin film transistor liquid crystal display, is one of the fastest growing forms of display technology today. The thin film transistor (TFT) is a type of semiconductor device used in display technology to enhance efficiency, compactness, and cost of the product. In conjunction with its semiconductor properties, the TFT LCD is an active matrix display, controlling pixels individually and actively rather than passively, furthering the benefits of this semiconductor device.

The TFT LCD is built with three key layers. Two sandwiching layers consist of glass substrates, though one includes TFTs while the other has an RGB, or red green blue, color filter. The layer between the glass layers is a liquid crystal layer.

The Architecture of a TFT Pixelbelow) from the other substrate layer of the device and control the amount of voltage applied to their respective sub-pixels. This layer also has pixel electrodes between the substrate and the liquid crystal layer. Electrodes are conductors that channel electricity into or out of something, in this case, pixels.

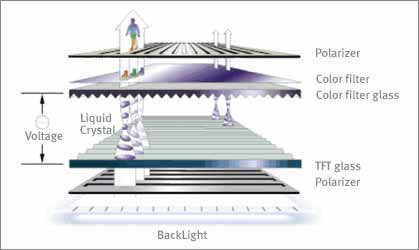

The outer sides of the glass substrates (closest to the surface or closest to the back) have filter layers called polarizers. These filters allow only certain beams of light to pass through if they are polarized in a specific manner, meaning that the geometric waves of the light are appropriate for the filter. If not polarized correctly, the light does not pass through the polarizer which creates an opaque LCD screen.

Before applying an electric field to the crystals between the electrodes, the alignment of the crystals is in a 90 degree twisted pattern, allowing a properly crystal-polarized light to pass through the surface polarizer in a display’s “normal white” mode. This state is caused by electrodes that are purposely coated in a material that orients the structure with this specific twist.

However, when the electric field is applied, the twist is broken as the crystals straighten out, otherwise known as re-aligning. The passing light can still pass through the back polarizer, but because the crystal layer does not polarize the lights to pass through the surface polarizer, light is not transmitted to the surface, thus an opaque display. If the voltage is lessened, only some crystals re-align, allowing for a partial amount of light to pass and creating different shades of grey (levels of light). This effect is called the twisted nematic effect.

Fig. 2: On the left is the twisted liquid crystal layer in which polarized light passes freely; on the right is after the electric field is charged into the layer, completely re-aligning the molecule orientations so that light is not polarized and cannot pass through the surface polarizer.

The twisted nematic effect is one of the cheapest options for LCD technology, and it also allows for fast pixel response time. There are still some limits, though; color reproduction quality may not be great, and viewing angles, or the direction at which the screen is looked at, are more limited.

The light that passes through the device is sourced from the backlight which can shine light from the back or the side of the display. Because the LCD does not produce its own light, it needs to use the backlight in the OLED) have come into use as well. Typically white, this light, if polarized correctly, will pass through the RGB color filter of the surface substrate layer, displaying the color signaled for by the TFT device.

Within an LCD, each pixel can be characterized by its three sub-pixels. These three sub-pixels create the RGB colorization of that overall pixel. These sub-pixels act as capacitors, or electrical storage units within a device, each with their own independent structural and functional layers as described earlier. With the three sub-pixels per pixel, colors of almost any kind can be mixed from the light passing through the filters and polarizer at different brightness based on the liquid crystal alignment.

From its structure, LCD is a flat display device. It looks like a sandwich that consists of a layer of liquid crystal, front and back ITO glasses, and front and back polarizer films. A liquid crystal cell is composed of front and back ITO glasses and is filled with liquid crystal and surrounded by the sealing glue (typically epoxy resin), only a liquid crystal entrance is left. There is a tiny gap between two glasses, only about a few um, which is filled by liquid crystal in vacuum conditions through the entrance. When the gap is full, the entrance will be sealed with epoxy resin, and the liquid crystal cell is done. And the front and back polarizer films are attached to the surface of the liquid crystal cell. There is an ITO conductive film between the liquid crystal and the glass. The function of the film is to bring the signal from the outside to the liquid crystal. The liquid crystal is arrayed systematically and orderly in the cell when the power is off. When the power is on, it will rearrange according to the rules we have predesigned, so it has special optical properties and electrical properties at the same time.

One of my German clients told me there was an unexpected segment on 6321 LCD screen. That was because we haven’t completely cleaned the useless parts of ITO film. I have to protect my client’s privacy, so I can’t reveal the blueprint of 6321 LCD screen in this post.

Two, we need additional production processes and labour costs to make the view direction. Please see my post to learn more about view direction. In other words, the view direction of LCD screen is achieved and controlled by ITO glass.

As we talk about the tooling fee, we have to refer to the quantity of the first batch. We usually send 5~20 pieces of LCD screen samples to our customers. If you have received our samples, and you want a small batch of order like 100 pieces or 500 pieces, I am sorry to inform you that we can’t make it because the quantity you demand is below the MOQ (Minimum Order Quantity) and the wastage of starting up the machine is great. Only in mass production will the machine which makes ITO glass begin to operate. Therefore, if you want a small batch of orders, I strongly suggest that it goes with the sample order.

See the picture above. It has a black background and 3 colors, hasn’t it? The background is purely black, so it is a VA LCD screen. But LED backlight for this LCD screen has only one color (white), all the other three colors (blue, green and red) are silver printed on the front of ITO glass.

Polarizer film is composed of a series of plastic films (PVA, TAC, PSA film, Release film and Protective film) which are coated with a layer of optical adhesive film which can be attached to the surface of the ITO glass.

If one polarizer film is missing, we can see nothing. When the power is turned off, the color we see on the surface of LCD screen is the color of the polarizer film; when the power is turned on, the light we see is the color of the LED backlight.

9. Positive and Negative displays of LCD screens depend on the front polarizer film while Transmissive, Reflective and Transflective displays of LCD screens rely on the back polarizer film.

There are three different kinds of back polarizer film: transmissive back polarizer film, reflective back polarizer film and transflective back polarizer film. But there is only one kind of front polarizer film. If a LCD screen is a positive display, as long as we flip over the front polarizer film and attach it to the surface of the ITO glass, it’ll become a negative display LCD screen.

All the features of LCD screens are achieved by ITO glasses, polarizer films and other optical films. But the switch function of liquid crystal is extremely important for LCD displays. Otherwise, it can’t display any image.

3. Temperature testing of LCD screen is under certain conditions and we can’t guarantee the testing results if you don’t follow the temperature testing rules.

Do you have any questions about ITO glass, polarizer film and liquid crystal? You are welcome to email me and leave some comments. I also would love for the comments of those who are experienced in the LCD industry to comment as well.

Korea Nitto Optical makes polarizing films for TFT-LCD screens. The films are a key element in displays used in TVs, computer monitors and mobile phones. Provided by the company

The display has emerged as something that consumers now consider before making purchases. And even the most tech-illiterate person will know about LCDs, LEDs and PDPs when searching for a new TV.

The company makes the polarizing film used in TFT-LCD screens. TFT-LCD is a variant on LCD screens with improved image quality and is used in televisions, computer monitors and mobile phones.

Polarizing films are a key ingredient in TFT-LCDs. Basically, these films help convert light with undefined polarization into light with well-defined polarization.

Those that are not familiar with Korea Nitto Optical will most likely have heard of Nitto Denko. The Japanese technology powerhouse based in Osaka has been making optical films for LCDs, functional automotive materials and surgical tape since 1918.

With operations in 27 countries, Nitto Denko’s sales for fiscal 2009 reached $7.27 billion. Nitto Denko had long been the No. 1 supplier of TFT-LCD polarizers in the world but was overtaken by Korea’s LG Chem in 2009.

One could say that Korea Nitto Optical was ahead of its time. It was around 2004 that the world’s major suppliers of TFT-LCD polarizers - such as Taiwan’s Optimax, Japan’s Sanritz and Sumitomo - began to make inroads into the Korean market amid the booming LCD business.

Korea Nitto Optical started mass production of TFT-LCD polarizers in 2000. By 2005 it had already completed construction of its second production facility in Hyeon-gok District with an investment of some 100 billion won ($89.2 million). The first production facility was built in Eoyeon District. Both facilities are within the industrial park in Pyeongtaek, Gyeonggi.

“The TFT-LCD sector is extremely cost-conscious with highly elastic demand; therefore, it depends on the continuation of falling cost structures and product prices to drive new demand,” wrote Kerry L. Cunningham, a product marketing engineer at AKT - an Applied Materials company - in Solid State Technology Magazine.

Korea Nitto Optical has yet to announce its 2010 earnings, but last year was not a good year for the LCD industry. Prices of most LCD panels fell during the second half of last year, as weaker-than-expected demand for TVs and personal computers caused an oversupply in the market.

“We expect increased oversupply and price declines in the memory market, as well as the possibility of further declines in LCD panels,” Robert Yi, head of investor relations at Gartner, a U.S. market researcher, said recently in a teleconference. “Combining these with a possible appreciation of the won, we expect fourth-quarter conditions to be difficult.”

“The LCD market will rebound around March or April and a rise in [panel] prices will likely precede the market rebound,” Chang told reporters in Las Vegas on the sidelines of the Consumer Electronics Show.

Gartner estimates that global TFT-LCD polarizer sales in 2010 were $5.95 billion and expects the figure to surge to $6.25 billion this year and $6.34 billion in 2012.

A polymeric polarizer is a crucial part of thin-film transistor (TFT) liquid crystal display (LCD) panels. Its physical defects have a serious impact on the quality of TFT-LCD panels, so quality problems associated with the polarizer cannot be ignored. At present, defects are detected by using manual work and few methods based on traditional image processing. It is a promising and challenging task to implement the detection of defects in the polarizer using the deep learning method, so a method…Expand

Liquid crystal (LC) based photonic devices are important in light modulated applications including amplitude modulation and phase modulation. [Yang et al. (2006)] The anisotropic properties of LC result in employing two polarizers in most of LC devices. The optical efficiency (~3%) and the viewing angle are limited. Therefore, it is highly desirable to develop polarizer-free LC devices. [Yang et al. (2006); Lin et al. (2008)] In polarizer-free liquid crystal displays (LCDs), two types are demonstrated. One is polarizer-free Guest-Host LCD which obtains dark state by doping small amount of dichroic dye molecules into LC host. [White et al. (1974); Cole et al. (1977); Bahadur (1992); Wu et al. (2001); Yang (2008)] However, the contrast ratio and reflectance are low due to the dichroic ratio (~10:1) of dyes. The other is scattering-absorption type, which combines light scattering and absorption. The second type is to mimic the display shown in white paper. In a printed paper, the printed areas turn out dark because the ink absorbs light and light is scattered by the fibers in the white paper. In order to obtain scattering effect, the polymer and liquid crystal complex system is used, including polymer dispersed liquid crystals (PDLCs), polymer networks liquid crystals or liquid crystal gels. [Drzaic (1995)] The scattering mainly results from the mismatch of refractive indices of polymer networks and liquid crystal molecules. To further increase light absorption, dye molecules are doped into the polymer and liquid crystal complex system, for example, dye-doped PDLCs [Drzaic (1995); Lin et al. (2004)], and dye-doped LC gels. [Lin et al. (2005); Lin et al. (2006); Lin et al. (2008); Lin et al. (2009)] Contrast ratio (CR) of dye-doped PDLC is still not good enough because the dye solubility with polymer matrix, the order parameter of dye and dichroic ratio (typically ~10:1) of dye. [Drzaic (1995); Lin et

al. (2004)] In 2005, we have developed a polarizer-free LCD using a dye-doped dualfrequency liquid crystal (DFLC) gel on the ITO-only glass substrates [Lin et al. (2005); Lin et

al. (2006)]. Although its contrast ratio reaches ~150:1 and response time ~6 ms under frequency modulation and the laser-based measurement, the frequency driving scheme, high driving voltage (~30 Vrms) and unavoidable dielectric heating effect. [Wen et al. (2005); Yin et al. (2006)] need to be overcome for TFT-LCDs and flexible displays applications.

To avoid the dielectric heating effect of DFLC, negative LC within vertical alignment layer is a good alternative and it is suitable for making a transflective LCD [Lin et al. (2006)]. The gel-like feature of materials, vertically aligned polymer network and low temperature processes drives us to realize a trim-able and bendable polarizer-free flexible display in reflective mode. In 2008, we demonstrated a polarizer-free flexible electro-optical switch using dye-doped LC gels which is polarizer-free, fast response, high contrast. [Lin et al. (2008)] Many parameters affect the phase separation process [Yang et al. (2006); Ren et al. (2008)]and then have influence on the electro-optical properties of dye-doped LC gels, such as curing temperature effect. The normally white gels exhibit ~55% reflectance, ~450:1 contrast ratio, ~6.4 ms response time, and ~30 Vrms at f=1 kHz driving voltage at curing temperature 10 ºC. A single pixel flexible reflective display using such dye-doped LC gels are also demonstrated under bending and trimming. To further realize a display with multi-pixels, the substrate is patterned by pixilated indium-tin-oxide (ITO) in general. However, the involved fabrication and driving are complicated. It also causes problems especially in the fabrication process of flexible displays, such as chemical stability of plastic substrates, failure of ITO under tension and so on. [Crawford (2005)] In order to achieve a simple and easy process for flexible displays, we developed a multiple-step switch using distinct dye-doped LC gels without patterning ITO layers in 2009. [Lin et al. (2009)] Moreover, the switch should provide extra information states besides voltage-on and voltage-off states for the applications of the decorative displays within a simple driving and manufacturing process. The distinct dye-doped LC gels can display information by the spatial distribution of polymer network density without patterned ITO layers. The different regions of polymer network densities have different threshold voltages, but the similar bright and dark states. The distinct dye-doped LC gel is transparent (or in bright state) at 0 Vrms and opaque (or in dark state) at 30 Vrms. At 9 Vrms, it shows the colored pattern (or information) because of distinct polymer networks. The response time is ~10 ms and contrast ratio is ~200:1. We can also extend the concept for a polarizer-free four step switch. The potential applications are for decorative displays, electrically tunable diaphragm, and electrically tunable low pass or high pass filter.

In this book chapter, we introduce a polarizer-free LCD using dye-doped LC gels whose the physical mechanism is mainly the combination of both light scattering and absorption. In the beginning, we introduce the structure and mechanism of our dye-doped liquid crystal gels. Second, the experimental setups, results (morphologies, electro-optical properties, response time) and mathematical model are also discussed. Third, the performance of such a polarizer-free liquid crystal display is shown. Finally, we will introduce multiple step switches using distinct dye-doped LC gels for the application of decorative displays. The potential applications are flexible displays, electrically tunable light shutters, and decorative displays.

After we removed the polarizer, the incident light then was unpolarized green laser beam. Fig. 5 (a) is the measured voltage-dependant reflectance of the dye-doped LC gels at various curing temperatures. The reflectance was normalized to that of a pure LC cell with the same cell gap. The reflectance decreases gradually with the applied voltage V>Vth due to the increases of the scattering and the absorption. As curing temperature decreases, the increases (~40% to ~55%) of maximum reflectance at V=0 and that is because of the better vertical alignment of LC directors, dye molecules and polymer networks at a low curing temperature. The contrast ratio (CR) is defined as a reflectance ratio of 0 Vrms to 30 Vrms. The CRs are ~450: 1 at 10 ºC, ~250: 1 at 20 ºC, ~200: 1 at 30 ºC, and ~300: 1 at 40 ºC. The contrast ratio decreases as T< 30ºC and then increases as T>30ºC. That is because the increase of a curing temperature results in larger polydomains; therefore, the CR and threshold voltage decrease. Moreover, the decay time increases, as shown in Fig. 5(b). When the temperature is higher than 30ºC, we found the cell has dynamic scattering, a fluctuation of liquid crystal directors in polymer domains, to help rebooting the contrast ratio in spite of the larger domain size. To lower the driving voltage, a high birefringence and high absolute value of dielectric anisotropy (Δε) of a negative LC and slightly lower polymer concentration could be considered.

Roll-able, bendable, trim-able, and conformable paper-like flexible displays are useful for electronic paper, electronic tag, and decorative displays. [Crawford (2005)] Many liquid crystal (LC) technologies, such as polymer-dispersed liquid crystals (PDLC) [Mach et al. (2001); Sheraw et al. (2002); Hohnholz et al. (2005); Buyuktanir et al. (2006); Wang et al. (2007)], cholesteric liquid crystals [Wu et al. (2001); Yang et al. (1994); Chari et al. (2006); Khan et al. (2005); Khan et al. (2007)], and single-substrate LCDs using photoenforced stratification [Penterman et al. (2002); Raynes (2002); Vogels et al. (2004)] or using LC/polymer composites [Kim et al. (2002); Kim et al. (2004); Lin et al. (2006); Ren et al. (2007)], and non-liquid crystal technologies, such as electrophoretic imaging [Comiskey et al. (1998); Gelinck et al. (2004); Daniel et al. (2007)], Gyricon [Crowley et al. (2002)], and organic light-emitting diode (OLED) [Gu et al. (1997); Burrows et al. (1997); Krasnov (2002); Sugimoto et al. (2004); Zhou et al. (2006)], have been carried out to achieve transmissive type or reflective type flexible displays. In liquid crystal-based flexible displays, bistability and colors of cholesteric liquid crystals limits the application due to the complexity of driving and color shift at off angle. Instead of cholesteric liquid crystals, dye-doped LC gels can be used in flexible displays because the dye-doped LC gels is gel-like and the polymer networks of dye-doped LC gels are perpendicular to the glass substrates.

The images of a single pixel of the polarizer-free LCD using dye-doped LC gels at V=0 and V=30 Vrms are shown in Fig. 10(a). By replacing glass substrates with flexible substrate, dye-doped LC gel is not only bendable but also trim-able because our material is gel-like, as shown in Fig. 10(b). The flexible substrates are provided by EOL/ITRI (Electronics& Optoelectronics Research Laboratories, Industrial Technology Research Institute, Taiwan). IZO was over coated on the top of flexible substrates made by polycarbonate with thickness 120 μm. The cross shaped microstructures made by photo-spacers, resins, were developed on the flexible substrates by photolithography process. The width of photo-spacers is 10 μm and the pitch of photo-spacers is 430 μm. The ambient white light was used to illuminate the cells. However, the CR is degraded. The CR is higher under laser-based measurement because of the collimation of the laser beam. Figure 10(c) is the transmission as a function of radius of curvature under bending at 0 and 30 Vrms. The measurement method is two-point bending technique. The transmission of dye-doped LC gels is almost the same as the radius of curvature larger than 21 mm. The dye-doped LC gel is trim-able as well because our material is gel-like, as shown in Fig. 10 (d) and (e). The flexible display performance remains almost the same after cutting by a scissor. Since no polarizer in needed, the residual birefringence of polycarbonate does not affect the performance of our flexible display.

a) A single pixel polarizer-free reflective LCD using the dye-doped LC gels in glass substrates and (b) in flexible substrates. (c) The transmission as a function of bending radius of curvature. (d)The dye-doped LC gel is trim-able. (e) The voltage dependent transmission before and after trimming. A piece of white paper was used as a diffusive reflector.

In conclusion, we have introduced and demonstrated polarizer-free LCDs using dye-doped LC gels. These polarizer-free dye-doped LC gels exhibit high reflectance, high contrast ratio, wide viewing angle, and fast response time. Especially the low temperature process is favorable for flexible displays. The gel-like materials assist stabilizing the flexible display under trimming. Our dye-doped LC gels provide a stable LC mode and open a new window in paper-like flexible displays. A polarizer-free three step switch using distinct dye doped LC gels is also demonstrated. The distinct dye-doped LC gels can display information by the spatial distribution of polymer network densities without patterned ITO layer. The advantages of such polarizer-free switches are 1) polarizer-free, 2) simple fabrication without ITO patterning, and 3) simple driving. However, the issues we have to overcome are high driving voltages, low resolution, non-black colors and long term stability of dye molecules due to photobleach. This concept can also be extended for making a polarizer-free multiple-switch. The potential applications are decorative displays, electrically tunable iris, and electrically tunable low pass or high pass filter.

NEW YORK CITY, NEW YORK, UNITED STATES, November 16, 2022 /EINPresswire.com/ -- The Global Polarizer Film Market size is estimated to reach USD 19.70 Billion by 2028 from USD 12.38 Billion in 2020, growing at a CAGR of 6.05% through the forecast period, according to a new report by Reports and Data. This can be mainly associated due to the high use of these films; especially in LCDs. Increase in environmental concerns due to hazards caused by the disposal of electronic products is expected to drive this application segment. Implementation of stringent government regulations in packaging is estimated to be a vital driver of the polarizing film’s market. Similarly, an increase in demand for reflective polarizing films, especially in emerging economies; technological advancements; and rise in R&D activities are also fuelling market growth. Furthermore, the reflective properties offered by polarizing films are propelling the market globally. Based on statistics, increasing demand for mobile phone and television displays, growing demand for larger panel size, increasing penetration of quantum dot displays (QD-LED) for better visibility, and growth in the need for high quality organic light-emitting diode (OLED) displays in smart phones are also significant factors stimulating market demand.

North America region is projected to grow at a CAGR of 6.5% during the forecast period with the largest share of 33.80% in 2020. The improving countries are the primary consumers of TFT LCD Display Modules in this region. The polarizing films market in the Asia Pacific has been expanding owing to the rise in technological advances in the area.

In the polarizer film market, the television segment accounts for the largest share of ~31.0% in 2020 because of the growing demand for LED display and larger display size.

Polarizer films are used as super twisted nematic (STN), thin film transistor (TFT) and twisted nematic (TN) display technologies. TFT film accounts for the largest market share of 42.88% in 2020 due to its winning characteristics of energy efficiency, delivering better resolution and low price.

The constant change in technology has enhanced the demand for global thin film transistor displays. However, the high cost of manufacturing and less availability of high resolutions TFTs for professional applications are some of the major factors which may affect the market growth.

Rising trends, which have a direct impact on the dynamics of the polarizer film industry, include development of ultra-thin polarizer film and the development of blue light high transmission polarizer film.

The high contrast type is expected to grow at the highest CAGR of 6.1% during the forecast period. High Contrast Polarizer is known for increased durability. When unpolarized light penetrates a linear polarizer, the light that is polarized perpendicular to the polarization axis is absorbed, and light parallel to the polarization axis is transmitted.

APAC is considered to be the second largest market for Polarizer Film with a share of 21.20% in 2020, due to the increasing participation in various sports and enhanced consumption. Europe is estimated to register the highest CAGR of 6.7%, during the forecast period.

Liquid crystal display (LCD) is a technology being widely used across many end equipments such as smartphones, TVs, automotive infotainment systems, and in smart home or factory environments.

Start with this video to understand the key physical and electrical principles behind a single LCD pixel before moving onto the next video linked below.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey