lcd panel layer thickness for sale

A plasma display panel (PDP) is a type of flat panel display that uses small cells containing plasma: ionized gas that responds to electric fields. Plasma televisions were the first large (over 32 inches diagonal) flat panel displays to be released to the public.

Until about 2007, plasma displays were commonly used in large televisions (30 inches (76 cm) and larger). By 2013, they had lost nearly all market share due to competition from low-cost LCDs and more expensive but high-contrast OLED flat-panel displays. Manufacturing of plasma displays for the United States retail market ended in 2014,

Plasma displays are bright (1,000 lux or higher for the display module), have a wide color gamut, and can be produced in fairly large sizes—up to 3.8 metres (150 in) diagonally. They had a very low luminance "dark-room" black level compared with the lighter grey of the unilluminated parts of an LCD screen. (As plasma panels are locally lit and do not require a back light, blacks are blacker on plasma and grayer on LCD"s.)LED-backlit LCD televisions have been developed to reduce this distinction. The display panel itself is about 6 cm (2.4 in) thick, generally allowing the device"s total thickness (including electronics) to be less than 10 cm (3.9 in). Power consumption varies greatly with picture content, with bright scenes drawing significantly more power than darker ones – this is also true for CRTs as well as modern LCDs where LED backlight brightness is adjusted dynamically. The plasma that illuminates the screen can reach a temperature of at least 1,200 °C (2,190 °F). Typical power consumption is 400 watts for a 127 cm (50 in) screen. Most screens are set to "vivid" mode by default in the factory (which maximizes the brightness and raises the contrast so the image on the screen looks good under the extremely bright lights that are common in big box stores), which draws at least twice the power (around 500–700 watts) of a "home" setting of less extreme brightness.

Plasma screens are made out of glass, which may result in glare on the screen from nearby light sources. Plasma display panels cannot be economically manufactured in screen sizes smaller than 82 centimetres (32 in).enhanced-definition televisions (EDTV) this small, even fewer have made 32 inch plasma HDTVs. With the trend toward large-screen television technology, the 32 inch screen size is rapidly disappearing. Though considered bulky and thick compared with their LCD counterparts, some sets such as Panasonic"s Z1 and Samsung"s B860 series are as slim as 2.5 cm (1 in) thick making them comparable to LCDs in this respect.

Wider viewing angles than those of LCD; images do not suffer from degradation at less than straight ahead angles like LCDs. LCDs using IPS technology have the widest angles, but they do not equal the range of plasma primarily due to "IPS glow", a generally whitish haze that appears due to the nature of the IPS pixel design.

Superior uniformity. LCD panel backlights nearly always produce uneven brightness levels, although this is not always noticeable. High-end computer monitors have technologies to try to compensate for the uniformity problem.

Uses more electrical power, on average, than an LCD TV using a LED backlight. Older CCFL backlights for LCD panels used quite a bit more power, and older plasma TVs used quite a bit more power than recent models.

Fixed-pixel displays such as plasma TVs scale the video image of each incoming signal to the native resolution of the display panel. The most common native resolutions for plasma display panels are 852×480 (EDTV), 1,366×768 and 1920×1080 (HDTV). As a result, picture quality varies depending on the performance of the video scaling processor and the upscaling and downscaling algorithms used by each display manufacturer.

Early high-definition (HD) plasma displays had a resolution of 1024x1024 and were alternate lighting of surfaces (ALiS) panels made by Fujitsu and Hitachi.

A panel of a plasma display typically comprises millions of tiny compartments in between two panels of glass. These compartments, or "bulbs" or "cells", hold a mixture of noble gases and a minuscule amount of another gas (e.g., mercury vapor). Just as in the fluorescent lamps over an office desk, when a high voltage is applied across the cell, the gas in the cells forms a plasma. With flow of electricity (electrons), some of the electrons strike mercury particles as the electrons move through the plasma, momentarily increasing the energy level of the atom until the excess energy is shed. Mercury sheds the energy as ultraviolet (UV) photons. The UV photons then strike phosphor that is painted on the inside of the cell. When the UV photon strikes a phosphor molecule, it momentarily raises the energy level of an outer orbit electron in the phosphor molecule, moving the electron from a stable to an unstable state; the electron then sheds the excess energy as a photon at a lower energy level than UV light; the lower energy photons are mostly in the infrared range but about 40% are in the visible light range. Thus the input energy is converted to mostly infrared but also as visible light. The screen heats up to between 30 and 41 °C (86 and 106 °F) during operation. Depending on the phosphors used, different colors of visible light can be achieved. Each pixel in a plasma display is made up of three cells comprising the primary colors of visible light. Varying the voltage of the signals to the cells thus allows different perceived colors.

The long electrodes are stripes of electrically conducting material that also lies between the glass plates in front of and behind the cells. The "address electrodes" sit behind the cells, along the rear glass plate, and can be opaque. The transparent display electrodes are mounted in front of the cell, along the front glass plate. As can be seen in the illustration, the electrodes are covered by an insulating protective layer.

In a monochrome plasma panel, the gas is mostly neon, and the color is the characteristic orange of a neon-filled lamp (or sign). Once a glow discharge has been initiated in a cell, it can be maintained by applying a low-level voltage between all the horizontal and vertical electrodes–even after the ionizing voltage is removed. To erase a cell all voltage is removed from a pair of electrodes. This type of panel has inherent memory. A small amount of nitrogen is added to the neon to increase hysteresis.phosphor. The ultraviolet photons emitted by the plasma excite these phosphors, which give off visible light with colors determined by the phosphor materials. This aspect is comparable to fluorescent lamps and to the neon signs that use colored phosphors.

Every pixel is made up of three separate subpixel cells, each with different colored phosphors. One subpixel has a red light phosphor, one subpixel has a green light phosphor and one subpixel has a blue light phosphor. These colors blend together to create the overall color of the pixel, the same as a triad of a shadow mask CRT or color LCD. Plasma panels use pulse-width modulation (PWM) to control brightness: by varying the pulses of current flowing through the different cells thousands of times per second, the control system can increase or decrease the intensity of each subpixel color to create billions of different combinations of red, green and blue. In this way, the control system can produce most of the visible colors. Plasma displays use the same phosphors as CRTs, which accounts for the extremely accurate color reproduction when viewing television or computer video images (which use an RGB color system designed for CRT displays).

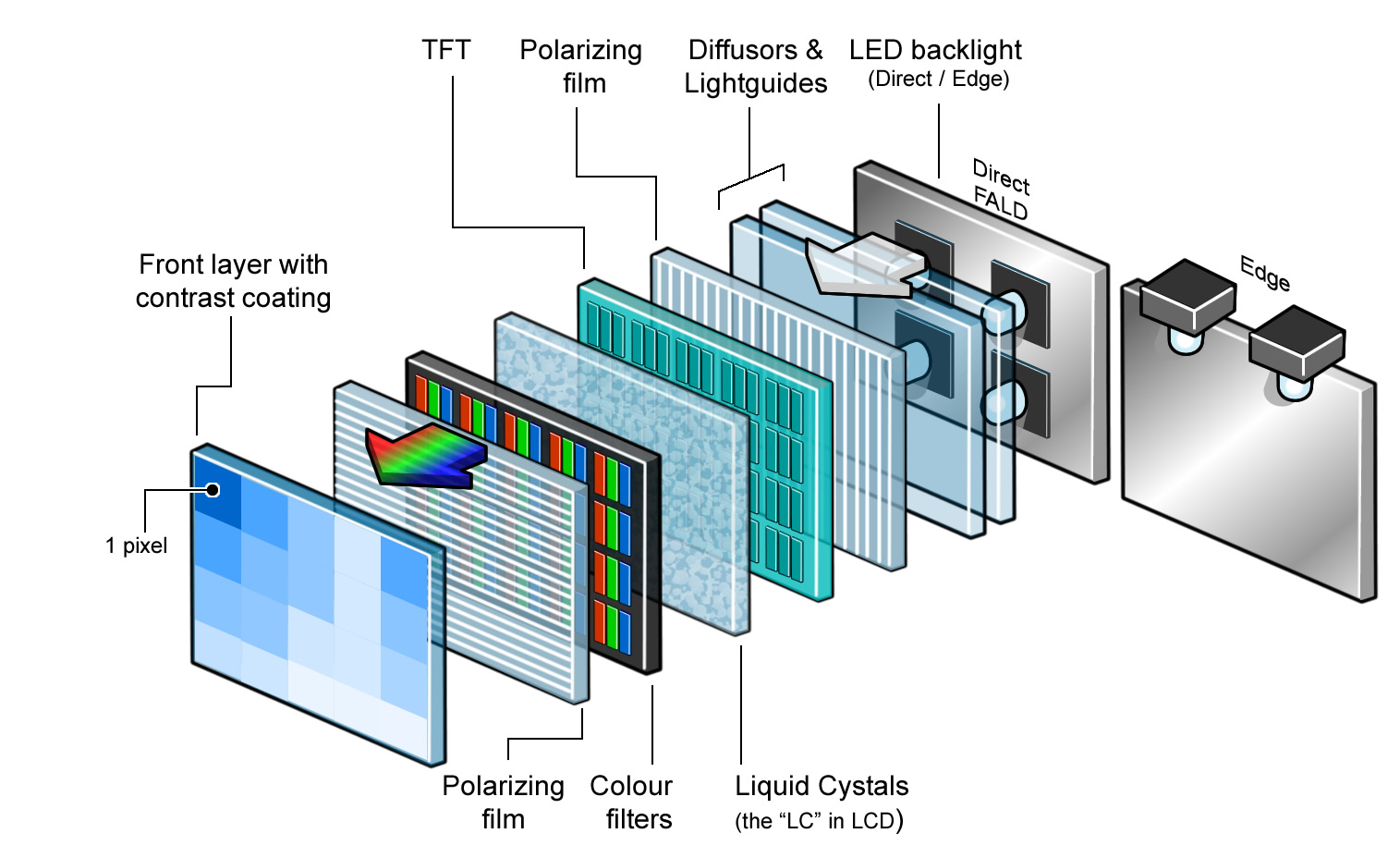

Plasma displays are different from liquid crystal displays (LCDs), another lightweight flat-screen display using very different technology. LCDs may use one or two large fluorescent lamps as a backlight source, but the different colors are controlled by LCD units, which in effect behave as gates that allow or block light through red, green, or blue filters on the front of the LCD panel.

Each cell on a plasma display must be precharged before it is lit, otherwise the cell would not respond quickly enough. Precharging normally increases power consumption, so energy recovery mechanisms may be in place to avoid an increase in power consumption.LED illumination can automatically reduce the backlighting on darker scenes, though this method cannot be used in high-contrast scenes, leaving some light showing from black parts of an image with bright parts, such as (at the extreme) a solid black screen with one fine intense bright line. This is called a "halo" effect which has been minimized on newer LED-backlit LCDs with local dimming. Edgelit models cannot compete with this as the light is reflected via a light guide to distribute the light behind the panel.

Image burn-in occurs on CRTs and plasma panels when the same picture is displayed for long periods. This causes the phosphors to overheat, losing some of their luminosity and producing a "shadow" image that is visible with the power off. Burn-in is especially a problem on plasma panels because they run hotter than CRTs. Early plasma televisions were plagued by burn-in, making it impossible to use video games or anything else that displayed static images.

In 1983, IBM introduced a 19-inch (48 cm) orange-on-black monochrome display (Model 3290 Information Panel) which was able to show up to four simultaneous IBM 3270 terminal sessions. By the end of the decade, orange monochrome plasma displays were used in a number of high-end AC-powered portable computers, such as the Compaq Portable 386 (1987) and the IBM P75 (1990). Plasma displays had a better contrast ratio, viewability angle, and less motion blur than the LCDs that were available at the time, and were used until the introduction of active-matrix color LCD displays in 1992.

Due to heavy competition from monochrome LCDs used in laptops and the high costs of plasma display technology, in 1987 IBM planned to shut down its factory in Kingston, New York, the largest plasma plant in the world, in favor of manufacturing mainframe computers, which would have left development to Japanese companies.Larry F. Weber, a University of Illinois ECE PhD (in plasma display research) and staff scientist working at CERL (home of the PLATO System), co-founded Plasmaco with Stephen Globus and IBM plant manager James Kehoe, and bought the plant from IBM for US$50,000. Weber stayed in Urbana as CTO until 1990, then moved to upstate New York to work at Plasmaco.

In 1995, Fujitsu introduced the first 42-inch (107 cm) plasma display panel;Philips introduced the first large commercially available flat-panel TV, using the Fujitsu panels. It was available at four Sears locations in the US for $14,999, including in-home installation. Pioneer also began selling plasma televisions that year, and other manufacturers followed. By the year 2000 prices had dropped to $10,000.

In late 2006, analysts noted that LCDs had overtaken plasmas, particularly in the 40-inch (100 cm) and above segment where plasma had previously gained market share.

Until the early 2000s, plasma displays were the most popular choice for HDTV flat panel display as they had many benefits over LCDs. Beyond plasma"s deeper blacks, increased contrast, faster response time, greater color spectrum, and wider viewing angle; they were also much bigger than LCDs, and it was believed that LCDs were suited only to smaller sized televisions. However, improvements in VLSI fabrication narrowed the technological gap. The increased size, lower weight, falling prices, and often lower electrical power consumption of LCDs made them competitive with plasma television sets.

At the 2010 Consumer Electronics Show in Las Vegas, Panasonic introduced their 152" 2160p 3D plasma. In 2010, Panasonic shipped 19.1 million plasma TV panels.

LCD monitors struggle with color and speed. Color on an LCD has three layers of colored dots that make up the final pixel. To display a color, a current is applied to each color layer to generate the desired intensity that results in the final color. The problem is that to get the colors, the current must move the crystals on and off to the desired intensity levels. This transition from the on-to-off state is called the response time. For most screens, it rates around 8 to 12 milliseconds.

The problem with response time becomes apparent when LCD monitors display motion or video. With a high response time for transitions from off-to-on states, pixels that should have transitioned to the new color levels trail the signal and result in an effect called motion blurring. This phenomenon isn"t an issue if the monitor displays applications such as productivity software. However, with high-speed video and certain video games, it can be jarring.

Color depth was previously referred to by the total number of colors that the screen can render. When referring to LCD panels, the number of levels that each color can render is used instead.

High-speed LCD monitors typically reduce the number of bits for each color to 6 instead of the standard 8. This 6-bit color generates fewer colors than 8-bit, as we see when we do the math:

The amount of color matters to those that do professional work on graphics. For these people, the amount of color that displays on the screen is significant. The average consumer won"t need this level of color representation by their monitor. As a result, it probably doesn"t matter. People using their displays for video games or watching videos will likely not care about the number of colors rendered by the LCD but by the speed at which it can be displayed. As a result, it is best to determine your needs and base your purchase on those criteria.

TN stands for twisted nematic. This is a type of LED (a form of LCD) panel display technology. TN panels are characterized as being the fastest and cheapest among the other main types of display panels, VA (vertical alignment)and IPS (in-plane switching). As such, they work great for gaming monitors and gaming laptops. However, TN panels also offer the worst viewing angles and color when compared to VA and IPS panels.

Color gamut is a measure of how many colors can be represented on a display. The higher the color gamut, the more colors represented, making color more rich and saturated. While no display can come close to what is seen with the human eye, a 100% color gamut panel is the best available in PC display. When a panel is 100% color gamut, it’s typically described as Adobe RGB. The XPS 15 4K Ultra HD display is factory color measured and color coordinates are saved onto the panel so you can reproduce color accurately. They are vivid, show more shades, higher saturation and more colorfulness. The user sees a more pleasant, colorful and accurate image. The XPS 15 and 17 are the only laptops that are true 100% minimum Adobe RGB, meaning the panel can represent all color in the Adobe color space without compromise. Professionals are able to get a full color representation of their content in the field - they can take a photo with an RGB setting on their camera, use Adobe software, and see that image on their display with exactly the same colors represented.

A laptop with high brightness is easy to see when using outdoors & prefect for watching movies or web surfing. A 500-nit panel, found on XPS laptops, is brighter than a typical laptop panel (200-nit).

Navigation made easy. A panel with multi-touch allows users to interact with their multimedia by directly touching the computer LCD, minimizing the need for a keyboard, touch pad or mouse. A touch screen is a more natural way to interact with your PC. You have the freedom to just touch the screen and manipulate directly. Plus, it is a more collaborative experience — no fighting over the mouse or who has control of the screen. And two people can interact with one application at the same time, with up to ten-finger-touch functionality.

Take full advantage of HDR content’s superior dynamic range with Dolby Vision™, which can deliver colors never before seen on SDR PC displays. Dolby Vision content can deliver highlights that are up to 40 times brighter, and blacks that are up to 10 times darker. Plus, the stunning VESA certified DisplayHDR™ 400 display on the optional 4K+ panel enables over 16 million colors that have more depth and dimension than ever before.

On our touch displays, edge-to-edge Corning® Gorilla® Glass is bonded to the aluminum for a very rigid panel design. The latest Corning® Gorilla® Glass 6 is strong, as well as impact and scratch resistance.

An anti-reflective coating is a multi-layer coating to reduce reflections and provide best customer experience. Most of the portable devices with cover glass have light reflections coming from the internal layers of the display assembly which is due to multi-layer glass structure. Due to this fact, the performance of the device is reduced under high ambient light conditions. By applying this multi-layer AR coating, the internal reflections can be reduced and experience enhanced.

Barco"s video wall display solutions are always the highest quality available on the market. Available in different technologies (LCD, LED rear-projection and RGB laser rear-projection), sizes and resolutions, our portfolio always contains the perfect solution for your application. Our dedicated software and a range of professional services make sure you get the most out of your video wall.

A video wall (also known as display wall) is a large visualization surface consisting of multiple displays. Originally, they consisted of multiple televisions or monitors that were put closely together. The objective was to make it seem as one large display surface. The problem however was the large frame (or bezel) that surrounded the useful display surface of each television. This completely tore down the effect of a single canvas and ruined the visual performance. Therefore, new technologies were introduced to minimize the ‘dead pixel space’ between the different displays. Today’s display wall solutions are generally using tiled LCD panels, rear-projection cubes, or direct LED tiles.

An LCD video wall consists of multiple specifically designed LCD displays. Contrary to the panels used in television sets, these LCD displays have a very narrow bezel. This minimizes the gap between the panels, making it look like one big canvas. Over the years, this gap has gradually decreased. Today, Barco UniSee has the smallest gap in the industry.

LCD video walls are designed for long term and intensive use, often playing in a 24/7 mode — which means they are rarely switched off. Specific measures to prevent burn-in effects are applied to allow them to play for many years, in optimal conditions.

The traditional benefits of LCD video wall solutions include the high brightness, good image quality, and relatively low cost. Also the limited real estate space needed is a plus. The disadvantages are the risk for burn-in and the lower lifetime. Recent models however have successfully reduced these drawbacks.

Typical markets for LCD display walls include meeting and crisis rooms, lobbies, and experience centers. You can also find them in the control rooms of traffic and security centers.

Using projection instead of LCD or direct-view LED technology, rear-projection video walls target different applications. They are mainly used in control rooms that operate in a 24/7 mode. Utilities providers, for example, generally rely on rear-projection technology to monitor their network.

Technology: There are 3 main video wall technologies (described above), all with their specific benefits AND price tag. Historically, ultra narrow bezel LCD is the most economic option, followed by rear-projection cubes and direct-view LED displays. Price erosion on narrow pixel pitch LED video walls in recent years has brought this technology within reach of all corporations, so that new markets (including control rooms, corporate lobbies, television studios, etc.) can also benefit from LED.

Size: The cool thing about video walls is that they are modular, so they really take the size and aspect ratio you want. But it should be no surprise that large video walls cost more than small ones. Not only the price of the panels raises the costs: large video walls also need more driving controllers and processing power to handle the high resolution. This is a significant extra cost that should not be overlooked!

Support: The more panels, the heavier the video wall system becomes. This poses additional requirements on the supporting infrastructure. The heaviest load for rear-projection walls is on the floor, which is only rarely an issue. For LED walls and LCD video walls, on the other hand, it is the supporting wall that catches the full load. It may need some additional support to handle the pressure.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey