heat tolerance of an lcd touch screen manufacturer

There are several industrial applications that require LCD displays to operate in extreme temperature environments such as in military, food processing, gas/fuel pumps, medical, manufacturing, and non-climate-controlled facilities, among others. Take note that typical monitors can only be used in environments with 0�C~50�C temperature range. UV exposure, moisture, and humidity also affect the overall temperature within a specific environment. iTech Company offers a range of LCD monitors that can function properly in a wide working temperature range from -30℃ to +80℃. These products are already proven and tested to maintain its original luminance under such temperatures.

While the range of operating temperature is a relevant consideration for the device to withstand extreme hot or cold environments, other factors must also be taken into account for the overall performance of the device. These includethe clarity of the image, environmental protection, LED backlighting, quality of the components, andvarious options available.

iTech Company’s products are equipped with these useful features to deliver great performance even in harsh working conditions. These are available in different monitor sizes and resolutions. It offers superior image quality with wide viewing angle. Some of the optional features include the touch screen functionality for interactive application and the level of brightness to ensure that the screen content is highly visible in all lighting conditions. Moreover, these wide operating temperature LCD displays are available in different types including open frame, panel mount, andchassis mount.

On the other hand, iTech Company also provides a customized design for its clients, which is a perfect solution for OEM customers. Just give us your specifications and we’ll come up with a product that will work great for your application.

ImportantAnalogue resistive touch screens are rarely designed for temperatures well above or below zero. Our ULTRA GFG Touch is specified for temperatures from -40 degrees up to +75 degrees Celsius.

Many manufacturers specify their touch panels for standard temperature ranges from 0 degrees up to +35 degrees Celsius. This is usually sufficient for interior applications. Extended temperature requirements are generally defined from 0 degrees up to +50 degrees Celsius. Some manufacturers go even further and declare their standard resistive touch screens from -10 degrees up to +55 degrees Celsius.

Such touch screen are not suitable for outdoor use or the use in some desert or industrial environment, where temperatures can easily reach even higher or lower levels. Even in the extended temperature range, our patented ULTRA glass-film-glass technology is quite unique: already in the standard version, it is specified from -40 degrees up to +75 degrees Celsius and can be further protected by applying various filters to meet specific customer requirements.

Recent test reports, which we prepare on request of the customer, can be downloaded below. In this particular case, the customer selected the temperature range of -25 up to +70 to be tested.

Liquid crystal displays (LCD) have become an essential component to the industry of display technology. Involved in a variety of contexts beyond the indoors like LCD TVs and home/office automation devices, the LCD has expanded its usage to many environments, such as cars and digital signage, and, thus, many temperature variations as well.

As with any substance that requires a specific molecular characteristic or behavior, LCDs have an operating temperature range in which the device, if within, can continue to function properly and well. In addition to that, there is also an ideal storage temperature range to preserve the device until used.

This operating temperature range affects the electronic portion within the device, seen as falling outside the range can cause LCD technology to overheat in hot temperatures or slow down in the cold. As for the liquid crystal layer, it can deteriorate if put in high heat, rendering it and the display itself defective.

In order for the LCD panel to avoid defects, a standard commercial LCD’s operation range and storage range should be kept in mind. Without adaptive features, a typical LCD TV has an operating range from its cold limit of 0°C (32°F) to its heat limit of 50°C (122°F) (other LCD devices’ ranges may vary a bit from these numbers).

The storage range is a bit wider, from -20°C (-4°F) to 60°C (140°F). Though these ranges are quite reasonable for many indoor and even outdoor areas, there are also quite a few regions where temperatures can drop below 0°C or rise above 32°C, and in these conditions, LCDs must be adapted to ensure functionality.

Heat, can greatly affect the electronics and liquid crystals under an LCD screen. In consideration of heat, both external heat and internally generated heat must be taken into consideration.

Seen as the liquid crystals are manipulated in a device by altering their orientations and alignments, heat can disrupt this by randomizing what is meant to be controlled. If this happens, the LCD electronics cannot command a certain formation of the liquid crystal layer under a pixel, and the LED backlighting will not pass through as expected, which can often lead to dark spots, if not an entirely dark image. This inevitably disrupts the display’s readability.

Depending on the upper limit of the operation temperature range, LCD device can be permanently damaged by extreme heat. With long exposure to extreme heat, besides the destruction of the liquid crystals, battery life can shorten, hardware can crack or even melt, response time may slow to prevent even more heat generation from the device.

The LED backlight and the internal circuitry, typically TFT-based in the common TFT LCDs, are components that can generate heat that damages the device and its display. To address this concern with overheating, many devices use cooling fans paired with vents.

Some devices that are used in extremely high ambient temperatures may even require air conditioning. With air vents to carry the heat out, the device can expel it into the surroundings.

But this leads to another problem: how can moisture be prevented from entering through the vent? If moisture enters the device and high heat is present, condensation can occur, fogging the display from inside, and in some cases, short-circuiting may cause the device to turn off. In order to circumvent this issue, the shapes of the air vents are specific in a way that allows only for air movement, not forms of moisture.

In the opposite direction is extreme cold. What typically occurs in the cold is “ghosting” (the burning of an image in the screen through discoloration) and the gradual slowing and lagging of response times. Like heat-affected LCD modules, the extreme temperature can affect the liquid crystals. This layer is a medium between the liquid and solid state, so it is still susceptible to freezing.

An LCD device can be left in freezing temperatures because it will likely not be permanently damaged like in the heat, but it is important to understand the device’s limits and how to take precautions when storing the device. The standard and most common lower-bound storage range limit is -20°C, below freezing, but if possible, it would be best to keep it above that limit, or else there is still a risk of permanent damage.

If the device is not adapted for the cold, it would be good to keep it bundled up, trapping the heat within layers. However, this is only a temporary solution. Adapted, rugged devices have advantages such as screen enclosure insulation for heat level preservation and, in more extreme cases, heaters to generate extra heat to raise the internal temperature to a level above the minimum.

When selecting the appropriate module, it is necessary to understand the device’s expected primary application. The application will decide factors such as display type, environmental conditions, whether or not power consumption is a factor, and the balance between performance and cost. These factors can have an effect on the operation and storage temperature ranges for the device.

Display types have a lot of variation. Choices like alphanumeric or graphic LCD, human-machine interactive LCD modules and touchscreen panels capabilities, the width of the viewing angle, level of contrast ratios, types of backlighting, and liquid crystal alignment methods are often considered. For example, the twisted nematic LCD provides for the fastest response time at the lowest cost, but cannot offer the highest contrast ratio or widest viewing angle.

Environment-based factors must consider things besides the obvious temperature like UV exposure and humidity/moisture, as they all are necessary in finding the perfect fit extreme temperature LCD module.

Besides the LCD modules, recent new products have opened doors in wide temperature range displays, such as OLED displays. OLED displays offer better displays in regard to contrast, brightness, response times, viewing angles, and even power consumption in comparison to traditional LCD displays.

These benefits, in addition to its ability to achieve a wide temperature range, provide more options for consumers in search of high quality displays for extreme climates.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Noritake’s electronics division has been around since the creation of the Vacuum Fluorescent Display(VFD). We have grown to provide a wide array of products and services to ensure a smooth and efficient development cycle for your application. Our customer support staff will gladly provide you with technical support to assist with your needs.

We offer an expanding set of support tools for each of our product series, including code libraries and design programs. These tools work to accelerate the evaluation and integration procedures in order to have your prototype up and running as quickly as possible.

We are very aware of how important long-term support is for our customers and continue to strive to maintain a strong supply chain. Please see our GT Series Long Term Supply Policy.

The fact that you are seeing this page indicates that the website you just visited is either experiencing problems, or is undergoing routine maintenance.

If you would like to let the administrators of this website know that you"ve seen this page instead of the page you expected, you should send them e-mail. In general, mail sent to the name "webmaster" and directed to the website"s domain should reach the appropriate person.

Ingress Protection (IP) Rating is critical to evaluate the environments in which our full range of LCD monitors will be used. This rating classifies the amount of protection our enclosed LCD monitor has against the intrusion of foreign objects that could cause damage, falter, and safety issues. IP Rating is two numeral designation rate protection based on solid objects (dust, soil, contaminants, etc.) and liquid ingress (water, or other fluid substance). With this rating, users can know exactly how protected our LCD monitor is. IP ratings are specified with two digits, IPXX. The first digit defines the protection from solids, and the second digit defines the protection from liquids. For instance, our Panel Mount Sunlight Readable display has a front IP rating of 65 meaning that it would be completely protected from dust, and low water jet spraying in all directions.

•3.5”, 320x240, 800 nits brightness, resistive touch screen option • 4.3”, 480x272, 650 nits brightness, resistive touch screen option •5.7”, 640x480, 900 nits brightness, resistive touch screen, LVDS options •7”, 800x480, 500~1000 nits brightness, resistive touch screen, LVDS options

By utilizing a double film compensation process, our FFSTN LCD solution can achieve high contrast (120:1) and wide viewing angle (120+ degrees L/R, U/D) for all our dot matrix graphic displays

Whether your application is an indoor control or an outdoor instrument used under direct sunlight, our reliable backlights are proven so excel in all lighting conditions.

These energy efficient modules consume about 1/4 to 1/2 of the power of traditional LED"s while exhibiting unbelievable color saturation without color filters, transistors or enhancement films.

Hantronix Optical Bonding Technology enables sunlight readabilityby reducing reflectivity as low as 0.2% in a high ambient light environment.Our solution improves optical performance and provides extra protection against shock, vibration, and moisture.

Elo takes great pride in controlling many aspects of an LCD display, including brightness, contrast, color and other parameters. For more information about some of the parameters and tolerance expected from one monitor to the next, even when comparing identical monitors, please read the information below.

Analog video signal:Scalar needs to convert the analog to a digital signal and it’s unavoidable that there will be distortion of color performance in this process.

Color format:Different color formats can cause different color performance. RGB uses additive color mixing because it describes what kind of light needs to be emitted to produce a given color. RGB stores individual values for red, green and blue. RGBA is RGB with an additional channel, alpha, to indicate transparency.

Elo includes some basic settings in the On-Screen Display (OSD) to control the appearance of the display. The available adjustments vary with the type of monitor. Please reference the “User Guides” located under the “Resource” section on the product’s webpage. Check the following settings and any other options that can affect the picture:

Furthermore, the age and use of a monitor will affect its LCD screen. It is important to keep in mind that monitor manufacturers can use multiple part suppliers for the same products—two “identical” monitors might have LCD panels that are not from the same supplier.

You don"t necessarily want to set the monitors to the same settings. Even though they are usually close, two of the same exact monitors can show colors slightly different. You may need to adjust the RGB settings on one monitor to match the other. The best way to adjust them is to bring up a perfectly red screen on both monitors (use MS Paint because you can set the color just the way you want) and then adjust them till they look the same. Repeat for blue and green. Once you get it the way you want, write down the RGB settings just in case your monitor resets and you lose your settings.

Each monitor is tested at the factory, and the color is manually calibrated to ensure it is within an allowable range. Please note, the Elo warranty does not cover color uniformity differences between two monitors. In fact, both are in the manufacturer specification for uniformity.

Elo does “White Balance” to make sure all color temperatures (5500K, 6500K, 7500K and 9300K) are within the spec and records all of the data for each Elo monitor on the production line

Onboard TFT LCD displays the screen in our life more and more applications, so do you know what the requirements of the car LCD screen? The following is a detailed introduction:

First of all, the working environment of cars is relatively complicated. In the morning, in the evening, in the summer, in the autumn and in the winter, in different parts of the world, cars are required to work. Cars are often exposed to the sun in the summer, and the cabin temperature can reach more than 60 degrees. The electronics inside must be able to work properly with the car. In some northern areas, the winter is so cold that regular LCD screens don’t work. These need to resist the high and low temperature of the LCD screen, for the owner to display driving information, escort.

You can see from this, the requirement of the automobile LCD screen is very tall. Under extreme conditions from -40 ° c to 105 ° c, it must be kept intact for more than 300 hours.

While the highlighted LCD display screen can work normally in extreme temperatures, it also needs to be visible and waterproof under ultra-bright direct sunlight. In addition, the GPU and the display screen of the LCD module will generate heat during use, and the higher the resolution of the LCD screen, the greater the heat. Therefore, it is also a big technical problem to develop a set of hardware products that meet the requirements of the vehicle. For these reasons, compared with the LCD display screen resolution of mobile phones, computers, televisions, etc., the display screen of cars is relatively conservative.

Now the LCD display screen technology has become more and more mature, the on-board LCD screen applications are more and more, the LCD display screen has been able to fully meet the changing working environment and work requirements ofthe car.LCD display screenshave made a big shift in automotive applications. With the development of science and technology, the development momentum of the onboard LCD screen will be very rapid.

The on-board LCD display screen adopts LCD technology, GSM/GPRS technology, low-temperature technology, anti-static technology, anti-interference technology, onboard electronic technology, and so on to display the information bar LCD display screen on the mobile vehicle, which is different from the ordinary strip LCD display screen installed in a fixed position. On the technical level, due to its special application environment, the requirements for the on-board long strip LCD display screen are much higher than the traditional LED display screen, which requires moisture-proof, rain-proof, lightning-proof, sun-proof, dustproof, cold-proof, anti-corrosion, anti-static, anti-interference, anti-seismic, anti-ultraviolet, anti-oxidation. At the same time must have over the current, short circuit, over-voltage, under-voltage protection, and other functions, in order to become a qualified vehicle screen.

As a more novel communication media of advertising information, the on-board LCD screen can not only store a large amount of text information, but also control the display mode of text and font through the built-in microprocessor to realize the display function of timing, and can also be moved and spread everywhere. It has completely got rid of the shackles of the traditional display screen and has the characteristics of mobile display, so it is highly praised by new media advertisers.

Through market investigation and analysis, it can be found that the audience of the onboard display screen is concentrated. Taking the on-board LCD screen of the bus as an example, it can provide important travel information and route information for passengers. In addition, the advertising effect is outstanding. Buses in cities are still one of the main means of public transportation, with millions of passengers taking them every day. It carries a large number of people, more than ten minutes on the bus “leisure time” is leisurely and boring. If it has a mobile screen in front to play news, entertainment, weather, advertising information, etc., then the active “cramming” media in front of it can attract passengers’ attention to the greatest extent, and it must be able to achieve good advertising effect.

Both subway strip screens and taxi car LCD screens have the common characteristics of a wide audience and huge market potential. Once the on-board LCD screen products are promoted and launched on a large scale, the media with large audiences and low advertising costs will surely attract the attention of many enterprises and advertisers. Government departments can also use the on-board Lcd display screen to promote public welfare, which has important significance and role.

Clearview™ transparent heating elements are an optically clear variation of our wire-wound heater that provides superior light transfer with higher durability than comparable technologies.

The wire-wound design brings high heating efficiency and quick thermal response with minimal power consumption. This makes Clearview LCD screen heaters ideal for applications such as computers, battery powered hand scanners, and touch screens.

Optically clear heaters are typically used in applications that require a high degree of light transmission. Clearview"s ultra-fine wire construction gives high optical clarity and ensures optimal light transmission for scanning and imaging applications.

Clearview provides controlled, direct heat to displays, lenses and clear panels, allowing continuous high definition operation of device monitors in low temperature environments. With an LCD screen heater, displays and touch screens remain usable in cold, high humidity/low dew point environments and locations where ambient temperature can change quickly.

Engineering services and consultation are available on every custom heating element order. Contact a specialist today for details about Clearview optically clear transparent LCD screen heaters.

Touch Think" industrial-grade capacitive touch screen monitors have an elegant and modern sleek look with true-flat edge-to-edge front panels. Capacitive touch screens offer you the perfect touch experience even in harsh environments.

- Excellent Heat conductivity: Touch Think fanless monitors are built from Aluminun alloy and arc-shaped designhousing, helps to keep the industrial monitor within a safe temperature range, even in extreme wide temperatures.

This touch screen monitor is designed with IP65-rated ruggedized front metal frame. Touchscreens are resistant to industrial contaminants such as water, dirt, oil and grease, and are often built with durability.

Equipped with REALTEK industrial-grade display chips, multi-ports with anti-static, anti-surge performance. Support VGA, HDMI, and DVI automatic recognition signals channels.

- Suitable for various industrial equipment, such as Textile Machinery, Woodworking Machinery, Paper Industries Machinery, Printing Trades Machinery, Food Products Machinery, Metalworking Machinery (Cutting Tools, Rolling Mill Machinery, Electric, and Gas Welding and Soldering Equipment), Packaging Machinery, etc.

In This Whitepaper:Outdoor use places extensive demands on the performance of touchscreen technology. Discover the issues to be aware of when choosing outdoor touchscreens, how each type of touch technology functions outdoors and finally, discover the ideal technology for incorporating efficient touch performance into your outdoor products.

Picture an ATM situated on a rain-soaked high-street, or a touchscreen panel in a graffiti-scrawled public telephone box. In each, the touch panel remains perfectly functional, allowing users to interact unhindered by weather or damage.That is the Zytronic difference.

All technology, regardless of purpose or application, must be carefully designed when used in an outdoor environment. From inclement weather conditions to security risks, placing commercial technology outdoors means additional demands are placed on the manufacturer to ensure that products remain functional and safe to use.

Poorly implemented touchscreen panels can quickly become defective due to the outdoor conditions. If the touchscreen fails, the entire product essentially fails until an engineer can be deployed to either repair or replace the screen. For this reason, it’s essential that manufacturers must source and install touch panels that are built with the demands of outdoor use in mind.

We live in a touchscreen generation – where even children are used to multi-touch devices and multi-screen entertainment. In an Ofcom survey, it was reported that 71% of 3-4-year olds use tablets to go online – and 35% of 5-7 year olds owned their own tablets. [1] In adulthood, this adoption is even greater: 85% of those aged 16-75 now own or have access to a smartphone. [2]

This means touchscreens are now an expectation rather than a luxury, and as such, consumers expect touch panels to respond intuitively no matter what environment they appear in. For a business, incorporating a touch element helps add a layer of interactivity to your product – giving users a way to literally ‘get to grips’ with your brand, service or products. However, this technology must also function as smoothly and intuitively as the tablet and smartphone devices consumers are now used to.

This means that touchscreens placed outdoors must not only withstand inclement conditions but must also adhere to the expectations of the smartphone generation. They should be responsive and hardwearing, regardless of the conditions they are subjected to. Quality touch performance is no longer a luxury – it is a demand.

With these demands in mind, what are the benefits of touch panels in outdoor technology? Here are a few examples of popular applications that can incorporate touch technology.

ATM/Bank Terminals: Nowadays, technology is an expectation in personal banking. From mobile banking to contactless payment, customers expect the latest innovations to be applied to their banking. With these new technologies in mind, touchscreen is now almost a forgone conclusion for ATMs, with customers expecting it as a minimum.

Digital Signage:Signage and advertising boards benefit heavily from touch panels, allowing users to interact with an advertisement, learn more about a brand or even answer questions in a quiz format. Touch gives an extra dimension to advertisers and is an invaluable tool for generating engagement with the public.

Retail:Retailers are increasingly incorporating touch into their point of sale displays – whether that’s an in-store garment finder or a touch panel on the glass exterior, allowing users to browse the latest trends before they even step into the shop.

Communications:Whether it’s a telephone or a touchscreen map to help the public navigate a city, touchscreens are becoming increasingly useful in outdoor communication applications.

By giving users more ways to interact with your product, touchscreens are rapidly becoming a must in almost every form of user technology. Do not avoid creating products that utilise outdoor touchscreens – instead understand the considerations that must be undertaken and use a touchscreen that can deliver responsive, user-friendly performance regardless of conditions.

When choosing touchscreen technology for use in outdoor environments, there are key factors that must be considered and prepared for. Failing to understand any of these elements can lead to a damaged touchscreen and a non-functioning product.

The first and most pressing risk for any outdoor technology is rain. Waterproofing is now common in almost all commercial applications – but for touch panels being ‘proof’ against water is not enough. They must also function when wet, which can be a challenge for many forms of capacitive touch panel popular in consumer electronics. Because they rely on electricity, typically from the skin of a user’s finger, water can disrupt the performance of the screen.

Zytronic’s patented Projected Capacitive Technology (PCT™) prevents this issue by allowing the touch panel sensors to be fully sealed within the glass, complying with NEMA a, 12 and IP 65 standards. This also protects against sleet, snow and humidity. The controller offers low resistance, which means water droplets that land on the screen will not register as a touch. Compared to competing touch controllers that use Indium Tin Oxide coatings, which are high resistance and can be confused by water on screens, Zytronic’s copper coating remains accurate even as rain pools on the screen.

Direct sunlight causes glare on any screen, which can distract or dissuade users from interacting with your product. While the display you place under a touch panel is the main factor in promoting good sunlight readability, an uncoated touchscreen will cause harsh reflection that prevents even the brightest display from offering good readability.

Designers must therefore consider the glass they use in touchscreens. At Zytronic, we can create outdoor touchscreen panels that use chemically-etched anti-glare glass that diffuses light, allowing a user to concentrate on the screen as opposed to reflection. In addition, coated anti-reflective glass allows light reflection to be reduced by around 75% - making displays easier to read in direct light.

From freezing cold shopping malls in The Baltic states, to hot and humid conditions in South-East Asia, touchscreen technology is used in all temperatures and all conditions. Designers and systems integrators must plan to ensure the survival and functionality of electronic systems, this includes touchscreen enabled human-machine interfaces, in all their forms.

Heat from sunlight, as well as causing glare, can also heat up the sensor in a touchscreen and cause issues. An infra-red film can be fitted to the rear of the sensor to reduce the transmission of IR energy, providing designers with a useful tool for cooling.

In extremely hot environments, cooling can also be provided with an active cooling system – which is an additional “force fed” fan system which pulls in cool air and forces out warm air, creating circulation of air directly over hot components to cool them. However, a problem with this method is when the ambient temperature is too hot, the air being pulled into the system is not sufficiently cold enough to provide any cooling effect. In extremely hot environments, thermoelectric conditioning units would be more effective. These air conditioning units pull warm air over compressed gas to produce a cooling effect.

Zytronic touchscreens can be manufactured to function perfectly up to 70°C – ensuring performance in some of the world’s hottest climates. Humidity is also a non-issue, as long as the system is fully sealed, and the unit does not permit moisture ingress. Displays must be carefully selected by manufacturers to ensure they function in this level of heat.

Temperature tolerance is important in cold environments for a number of reasons. Freezing temperatures can damage glass touch panels – so any glass specified for use in cold must be incredibly robust. Zytronic’s glass can withstand temperatures down to -35°C.

Cold also means users are likely to wear gloves. On some touchscreens that rely solely on electricity, gloves create a barrier between skin and screen and therefore prevent a user’s touch being detected. Any touchscreen produced for use in the cold must therefore function even when a user is wearing gloves.

Snow and ice, like rain, carry the same moisture issues. However, due to the heat of the display below the touch panel, neither are likely to impact performance as they will melt to water – which is ignored by Zytronic’s unique technology.

One of the main considerations of touchscreens placed outdoors is their vulnerability to damage and vandalism. Whether your product is exposed to accidental scrapes as part of its service life, or it is exposed to intentional damage, tampering or theft, a touchscreen used outdoors should be able to mitigate risks as efficiently as possible.

To protect against damage, the glass that houses a touch panel must be tough enough to withstand direct impact and to not compromise performance. Achieving this is made possible by thermally or chemically strengthening the glass fronted touch sensor.

Chemically toughening glass is a process whereby glass is submerged into a heated, potassium salt bath. This causes the sodium ions in the glass to be replaced with larger potassium ions, creating compression on the surface of the glass as well as traction stresses in the core.

This process creates glass that is up to 8 times stronger than float glass. However, when broken, the glass will shatter into large splinters which could cause severe injury to any nearby users. To ensure health and safety, outdoor units may therefore need to choose a different option.

Thermal toughening is perhaps a more suitable alternative for outdoor applications where health and safety is a concern. The process involves raising the temperature of glass to near melting point, and then rapidly cooling it. This creates tension within the glass and compression on its exterior. When it breaks, it will instead break into small granular pieces rather than dangerous shards.

Impacts and scratching are both issues faced by outdoor touchscreens – and are again issues that can be mitigated by selecting the right glass. Thick, toughened glass touch panels such as our ZyBrid multi-touch sensor can withstand impacts and abrasions that would cause damage in thinner glass, so manufacturers must ensure they select the appropriate thickness. In addition, touchscreens can be sealed in different styles at their edges to further protect against breakage.

Many outdoor units are left in unprotected areas, and as such as sadly subject to vandalism. Whether this is a direct attempt to break a screen, graffiti or theft, a touchscreen must be able to offer protection. At a minimum, strengthened glass helps prevent possible legal issues that may arise if a vandal injures themselves on shards.

Zytronic’s touchscreen technology can still function even if the glass breaks under a particularly determined damage attempt, which means users can still interact with a unit until a fix is available.

In banking and other data-sensitive applications, touchscreens may also need to be encrypted to provide total user security. This means selecting a touchscreen with chipset and firmware that adheres to Payment Card Industry (PCI) compliant systems.

When specifying a touchscreen for a product that will be used outdoors, it is important to consider and mitigate the above issues. You should contact a manufacturer early on in your design process, who can then work with you to design the right touch panel for your needs.

To avoid rain or moisture ingress, touchscreens should be fully sealed within glass and given an IP rating to ensure reliable performance in all weathers. The controller itself must be able to ignore rain on a screen to ensure good performance even when wet. You must also ensure that if you are using a front metal bezel to seal the unit, a plastic frame must be installed to create insulation between the screen and controller that is unaffected by water.

To provide functional performance when under direct light,a touchscreen can be specified with anti-glare measures, and fitted to a display such as a TFT-LCD that offers high brightness settings. In fact, the actual LCD chosen is very important – as only bright, full colour screens will attract the right attention in the outdoor space. This is another factor a touchscreen manufacturer can assist with, allowing you to work together to choose the right touch panel for your specific LCD’s specification.

Temperature requires implementing a touch panel and a display that can withstand the temperature range of your target location. For example, if creating a range of units for use in a middle-eastern country, heat is more of a focus and may necessitate installing air cooling systems with in your products. Zytronic’s projective capacitance technology automatically adjusts capacitance to ensure performance during temperature changes.

Manufacturers will likely already be aware of the risk of damageandvandalismin any outdoor product -but must consider that the visibility and ‘first point of contact’ nature of touch panels makes them a prime target for vandalism.

As such, manufacturers must design a product whereby the touchscreen is seamlessly integrated and utilises thick, toughened glass that does not shatter. This makes it less likely to be tampered with, and harder to vandalise. At Zytronic we offer responsive touch experiences that function perfectly even with glass that is up to 10mm thick, making it resistant to almost any form of impact.

Despite this, a determined vandal may still be able to break a touch panel, especially in an unattended outdoor space where they have the time to do so, but by preventing shatter you are protecting your system and also avoiding any legal ramifications.

Many of the factors that govern touchscreen design for outdoor use are concerned with the glass that protects the actual technology. However, the technology itself is also important in delivering lasting performance in all weathers.

There are multiple touchscreen technologies that all have their own strengths and weaknesses. However, some of those weaknesses are glaringly apparent when utilised in an outdoor environment. For that reason, it is important that manufacturers understand what each technology offers and how outdoor usage may affect your final product.

Resistive touch screens have a pliable front layer and a solid rear layer separated by insulating dots, the inside surface of each layer is coated with a transparent conductive coating. Voltage applied to the layers produces a gradient across each layer. Pressing the flexible top sheet creates electrical contact between the resistive layers, essentially closing a switch in the circuit. Resistive technology offers manufacturers a cost-efficient touch panel.

Advantages:Resistive technology can be used with any input, from a stylus to a gloved hand. It is a low cost technology and offers low power consumption. The system can be sealed for water resistance.

Weaknesses for Outdoor Use: While resistive sensors are inexpensive, the technology’s main disadvantage is its vulnerability to vandalism. The flexible front layer is susceptible to impact damage, scratches and even long term wear. This makes the sensors unfit for use in unattended areas and outdoors. Worse still, the screen will cease functioning in any area of damage.

Infra-red (IR) touch technology is based on light-beam interruption: light emitting diodes on one side of the sensor, and light detectors on the opposite side, create an optical grid across the screen. The touch point is recognised when an object interrupts the beam of light.

Advantages: Can be used in very large displays and is a relatively low-cost technology. The display’s brightness and image clarity are not affected by the sensor.

Weaknesses for Outdoor Use: The light sensing technology required for using in IR touch sensors, must be manufactured with large bezels, making sleek modern designs impossible, and creating the opportunity for dirt and water particles to gather along the edges of the sensor. This creates both problems for the responsiveness of the sensor, but also creates an un-inviting platform to touch and interact with. Further still, sunlight, which contains IR rays, can interfere with the display and cause it to malfunction.

Surface capacitive touch sensors operate by placing a transparent electrode layer on top of a glass panel. When finger touches the monitor screen, it reacts to the electrical capacity of the human body; some of the electrical charge is transferred from the screen to the user and the touch is registered. This decrease in capacitance is detected by sensors located at the four corners of the screen, allowing the controller to determine the touch point.

Advantages: Superior image clarity when compared to resistance panels. It is unaffected by dirt or dust on its surface, which will be a significant factor outdoors.

Weaknesses for Outdoor Use: Designers choosing Surface capacitive sensors are extremely limited in the customisations and visual enhancements the technology can offer. Due to the construction of the sensors, custom printed borders or glass cut-outs are not possible, and like IR touch sensors, Surface Capacitive sensors also require cumbersome bezels, which can collect dirt and water, interfering with the performance of the sensor. The sensor’s operation can be compromised by damage or liquids on the surface – which means rain on the screen can cause havoc for a user trying to interact with a product.

Zytronic’s single/dual touch capable self-capacitive PCT™ technology is the ideal solution for outdoor use. Our technology detects and locates touch, senses a peak change in frequency and submits the data. When a user touches the screen, capacitance occurs between the finger and the sensor grid, whereupon the sensor’s electromagnetic field is disrupted. The peak change in frequency is measured, and by determining which row and column is closest to this peak change in frequency, the position of the user’s touch can be very accurately determined.

The sole disadvantage of this technology is that generally, it can be more expensive than other formats. However, when specifying touchscreens for outdoor use – often in products that demand longevity and durability, compromising on cost and selecting a subpar touch sensor will lead to inferior final products.

The benefits of this technology for outdoor use are extensive. The sensing technology is located behind a glass substrate, which can be toughened or strengthened according to your application – meaning your touchscreen will resist accidental impact and scratch damage.

We offer both single and multi-touch sensors that can be supplied with glass up to 10mm thick. This also means the screen is resistant to vandalism. The technology does offer custom printed borders, which can help seal the sensor and again protect against tampering.

Projective capacitive membranes work well in all weather and when wet, functioning even when users are wearing heavy gloves. ‘False’ (accidental) touches are also minimised due to the low resistance of our electrodes, giving users a responsive experience in all weathers. PCT screens are typically unaffected by dirt, grease or water – and can be set up bespoke to your requirements if there are concerns over other materials that may impact touch performance.

Outdoor use often coincides with large-scale displays. Whether it’s a banking terminal or a large digital signage product, Zytronic’s PCT touchscreens are available in sizes up to 100” diagonally that can detect touch through the thickest glass available. Due to the physical characteristics of how or touch technology is laid on the glass, PCT ensures a display’s brightness and image clarity remain good – aiding the final aesthetic impact of your project.

Offering a range of customisation options, a responsive touch experience in all conditions and the ability to utilise thick strengthened glass without compromising performance, Projective Capacitive Touchscreen technology is our suggested solution for outdoor use.

When utilising our PCT touchscreen technology, installers benefit from our ZyConfig tool, which allows installers to quickly set up our touchscreen controllers in a sequential approach.

The software allows you to tweak your touchscreen’s performance to cater specifically for its application. However, for manufacturers who want a ‘plug and play’ solution it’s important to note that our screens all work intuitively from the moment you begin using them.

When you first load the software, it will perform a ‘pass’, ‘warning’ or ‘fail’ check on system noise levels, controller and sensor operation – enabling you to quickly diagnose any potential issues. This is a time-saving feature both during an initial installation and during any future maintenance checks.

After an initial check, ZyConfig enables semi-automatic modification of touch controller settings. These settings can be applied across a single screen or thousands – benefitting projects of any scale. The tool allows a custom active area, which may be useful on an outdoor advertising unit where the manufacturer only wants the left hand-side of the screen to be touch-active - ZyConfig enables you to deactivate part of the screen. You can manually alter sensitivity to suit your outdoor usage and program in palm rejection.

ZyConfig essentially gives you more control over your touchscreen. Our controllers are already adaptive without having to manually program anything – but for those who desire an additional level of control, ZyConfig provides a simple platform for ensuring your touchscreen functions exactly as intended outdoors or in.

As touchscreen uptake grows, it is obvious that touchscreen technology in outdoor products will continue to grow in popularity. However, this technology must offer both quality and protection against the elements…

As our society grows increasingly accustomed to responsive touch experiences, it is no longer enough to provide a touchscreen simply withstands bad weather. Now, a screen must withstand weather, resist damage and also offer a smooth, responsive user experience that can register all manner of touch inputs.

Zytronic are proud to design and supply our unique, UK-manufactured touchscreen panels specifically for use in outdoor environments. Zytronic’s patented PCT™ and MPCT™ multitouch projected capacitive touch sensors can operate through toughened glass substrates of thicknesses up to 20mm. Not only does this create a dependable, weather resistant, touch interface, it also offers unrivalled protection against a wide range of physical, mechanical and chemical abuse. Our panels ensure the smooth, responsive performance expected by the smartphone generation in all weathers and all environments.

Whether you are interested in creating interactive digital signage or a more security-led application such as banking, our touchscreens are the perfect solution for your product’s touch panel requirement. We will work together with you to design the perfect touchscreen, testing it thoroughly to ensure it functions outdoors.

Better yet, we have no minimum order quantity – enabling us to create anything from a single point of sale touch panel through to thousands of units for an ATM chain.

If you’d still like to know more about our touchscreens in action in an outdoor application, read the next page to discover how our ZyBrid sensors were implemented in Seoul, South Korea.

Seoul, South Korea - Zytronic’s rugged ZyBrid® touch sensors provide an intuitive and informative new public transport experience in the South Korean capital

Terminal (BIT) project. BIT replaces existing non-interactive digital signage and offers Seoul’s commuters engaging, easy-to-access real time information about traffic, transit routes and local amenities, with the touch of a finger.

Both the overall robustness and high degree of scalability afforded by Zytronic’s patented Projected Capacitive Technology (PCT™) are underlined in its latest outdoor touchscreen project. The company’s ZyBrid® touch sensors have, via Dutch distributor Telerex, been selected by Surtronic for integration into a public information/digital signage unit that it has developed and is now starting to deploy in busy retail areas across Europe.

The units are purpose designed for use in all locations, including demanding public outdoor environments such as ski resorts, marinas, golf clubs, amusement parks, filling stations and fairgrounds. The very large display is presented in a choice of portrait or landscape orientation, and in optional 65” or 46” sizes.

The system’s creator, Infinitus of Slovenia, conceived iMotion® to deliver the advantages of cutting-edge technology with complete reliability, drawing standards from the military and automotive industries to achieve its goal.

Touch panel technologies are a key theme in current digital devices, including smartphones, slate devices like the iPad, the screens on the backs of digital cameras, the Nintendo DS, and Windows 7 devices. The term touch panel encompasses various technologies for sensing the touch of a finger or stylus. In this session, we"ll look at basic touch panel sensing methods and introduce the characteristics and optimal applications of each.

Note: Below is the translation from the Japanese of the ITmedia article "How Can a Screen Sense Touch? A Basic Understanding of Touch Panels"published September 27, 2010. Copyright 2011 ITmedia Inc. All Rights Reserved.

A touch panel is a piece of equipment that lets users interact with a computer by touching the screen directly. Incorporating features into the monitor like sensors that detect touch actions makes it possible to issue instructions to a computer by having it sense the position of a finger or stylus. Essentially, it becomes a device fusing the two functions of display and input.

It"s perhaps not something we think of often, but touch panels have integrated themselves into every aspect of our lives. People who enjoy using digital devices like smartphones interact with touch panels all the time in everyday life—but so do others, at devices like bank ATMs, ticket vending machines in railway stations, electronic kiosks inside convenience stores, digital photo printers at mass merchandisers, library information terminals, photocopiers, and car navigation systems.

A major factor driving the spread of touch panels is the benefits they offer in the way of intuitive operation. Since they can be used for input through direct contact with icons and buttons, they"re easy to understand and easily used, even by people unaccustomed to using computers. Touch panels also contribute to miniaturization and simplification of devices by combining display and input into a single piece of equipment. Since touch panel buttons are software, not hardware, their interfaces are easily changed through software.

While a touch panel requires a wide range of characteristics, including display visibility above all, along with precision in position sensing, rapid response to input, durability, and installation costs, their characteristics differ greatly depending on the methods used to sense touch input. Some typical touch-panel sensing methods are discussed below.

As of 2010, resistive film represented the most widely used sensing method in the touch panel market. Touch panels based on this method are called pressure-sensitive or analog-resistive film touch panels. In addition to standalone LCD monitors, this technology is used in a wide range of small to mid-sized devices, including smartphones, mobile phones, PDAs, car navigation systems, and the Nintendo DS.

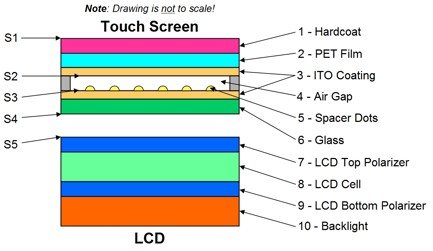

With this method, the position on screen contacted by a finger, stylus, or other object is detected using changes in pressure. The monitor features a simple internal structure: a glass screen and a film screen separated by a narrow gap, each with a transparent electrode film (electrode layer) attached. Pressing the surface of the screen presses the electrodes in the film and the glass to come into contact, resulting in the flow of electrical current. The point of contact is identified by detecting this change in voltage.

The advantages of this system include the low-cost manufacture, thanks to its simple structure. The system also uses less electricity than other methods, and the resulting configurations are strongly resistant to dust and water since the surface is covered in film. Since input involves pressure applied to the film, it can be used for input not just with bare fingers, but even when wearing gloves or using a stylus. These screens can also be used to input handwritten text.

Drawbacks include lower light transmittance (reduced display quality) due to the film and two electrode layers; relatively lower durability and shock resistance; and reduced precision of detection with larger screen sizes. (Precision can be maintained in other ways—for example, splitting the screen into multiple areas for detection.)

Capacitive touch panels represent the second most widely used sensing method after resistive film touch panels. Corresponding to the terms used for the above analog resistive touch panels, these also are called analog capacitive touch panels. Aside from standalone LCD monitors, these are often used in the same devices with resistive film touch panels, such as smartphones and mobile phones.

With this method, the point at which the touch occurs is identified using sensors to sense minor changes in electrical current generated by contact with a finger or changes in electrostatic capacity (load). Since the sensors react to the static electrical capacity of the human body when a finger approaches the screen, they also can be operated in a manner similar to moving a pointer within an area touched on screen.

Two types of touch panels use this method: surface capacitive touch panels and projective capacitive touch panels. The internal structures differ between the two types.

Surface capacitive touch panels are often used in relatively large panels. Inside these panels, a transparent electrode film (electrode layer) is placed atop a glass substrate, covered by a protective cover. Electric voltage is applied to electrodes positioned in the four corners of the glass substrate, generating a uniform low-voltage electrical field across the entire panel. The coordinates of the position at which the finger touches the screen are identified by measuring the resulting changes in electrostatic capacity at the four corners of the panel.

While this type of capacitive touch panel has a simpler structure than a projected capacitive touch panel and for this reason offers lower cost, it is structurally difficult to detect contact at two or more points at the same time (multi-touch).

Projected capacitive touch panels are often used for smaller screen sizes than surface capacitive touch panels. They"ve attracted significant attention in mobile devices. The iPhone, iPod Touch, and iPad use this method to achieve high-precision multi-touch functionality and high response speed.

The internal structure of these touch panels consists of a substrate incorporating an IC chip for processing computations, over which is a layer of numerous transparent electrodes is positioned in specific patterns. The surface is covered with an insulating glass or plastic cover. When a finger approaches the surface, electrostatic capacity among multiple electrodes changes simultaneously, and the position were contact occurs can be identified precisely by measuring the ratios between these electrical currents.

A unique characteristic of a projected capacitive touch panel is the fact that the large number of electrodes enables accurate detection of contact at multiple points (multi-touch). However, the projected capacitive touch panels featuring indium-tin-oxide (ITO) found in smartphones and similar devices are poorly suited for use in large screens, since increased screen size results in increased resistance (i.e., slower transmission of electrical current), increasing the amount of error and noise in detecting the points touched.

Larger touch panels use center-wire projected capacitive touch panels in which very thin electrical wires are laid out in a grid as a transparent electrode layer. While lower resistance makes center-wire projected capacitive touch panels highly sensitive, they are less suited to mass production than ITO etching.

Above, we"ve summarized the differences between the two types of capacitive touch panels. The overall characteristics of such panels include the fact that unlike resistive film touch panels, they do not respond to touch by clothing or standard styli. They feature strong resistance to dust and water drops and high durability and scratch resistance. In addition, their light transmittance is higher, as compared to resistive film touch panels.

On the other hand, these touch panels require either a finger or a special stylus. They cannot be operated while wearing gloves, and they are susceptible to the effects of nearby metal structures.

Surface acoustic wave (SAW) touch panels were developed mainly to address the drawbacks of low light transmittance in resistive film touch panels—that is, to achieve bright touch panels with high levels of visibility. These are also called surface wave or acoustic wave touch panels. Aside from standalone LCD monitors, these are widely used in public spaces, in devices like point-of-sale terminals, ATMs, and electronic kiosks.

These panels detect the screen position where contact occurs with a finger or other object using the attenuation in ultrasound elastic waves on the surface. The internal structure of these panels is designed so that multiple piezoelectric transducers arranged in the corners of a glass substrate transmit ultrasound surface elastic waves as vibrations in the panel surface, which are received by transducers installed opposite the transmitting ones. When the screen is touched, ultrasound waves are absorbed and attenuated by the finger or other object. The location is identified by detecting these changes. Naturally, the user does not feel these vibrations when touching the screen. These panels offer high ease of use.

The strengths of this type of touch panel include high light transmittance and superior visibility, since the structure requires no film or transparent electrodes on the screen. Additionally, the surface glass provides better durability and scratch resistance than a capacitive touch panel. Another advantage is that even if the surface does somehow become scratched, the panel remains sensitive to touch. (On a capacitive touch panel, surface scratches can sometimes interrupt signals.) Structurally, this type of panel ensures high stability and long service life, free of changes over time or deviations in position.

Weak points include compatibility with only fingers and soft objects (such as gloves) that absorb ultrasound surface elastic waves. These panels require special-purpose styluses and may react to substances like water drops or small insects on the panel.

All in all, however, these touch panels offer relatively few drawbacks. Recent developments such as improvements in manufacturing technology are also improving their cost-performance.

The category of optical touch panels includes multiple sensing methods. The number of products employing infrared optical imaging touch panels based on infrared image sensors to sense position through triangulation has grown in recent years, chiefly among larger panels.

A touch panel in this category features one infrared LED each at the left and right ends of the top of the panel, along with an image sensor (camera). Retroreflective tape that reflects incident light along the axis of incidence is affixed along the remaining left, right, and bottom sides. When a finger or other object touches the screen, the image sensor captures the shadows formed when the infrared light is blocked. The coordinates of the location of contact are derived by triangulation.

While this type differs somewhat from the above touch panels, let"s touch on the subject of electromagnetic induction touch panels. This method is used in devices like LCD graphics tablets, tablet PCs, and purikura photo sticker booths.

This input method for graphics tablets, which originally did not feature monitors, achieves high-precision touch panels by combining a sensor with the LCD panel. When the user touches the screen with a special-purpose stylus that generates a magnetic field, sensors on the panel receive the electromagnetic energy and use it to sense the position of the pen.

Since a special-purpose stylus is used for input, input using a finger or a general-purpose stylus is not possible, and the method has limited applications. Still, this has both good and bad points. It eliminates input errors due to the surrounding environment or unintended screen manipulation. Since the technology was intended for use in graphics tablets, it offers superior sensor precision—making it possible, for example, to change line width smoothly by precisely sensing the pressure with which the stylus is pressed against the screen (electrostatic capacity). This design approach also gives the screen high light transmittance and durability.

The table below summarizes the characteristics of the touch panels we"ve looked at. Keep in mind that even in devices based on the same sensing method, performance and functions can vary widely in the actual products. Use this information only as an introduction to general product characteristics. Additionally, given daily advances in touch-panel technological innovations and cost reductions, the information below is only a snapshot of current trends as of September 2010.

Each touch-panel type offers its own strengths and weaknesses. No single sensing method currently offers overwhelming superiority in all aspects. Choose a product after considering the intended use and environmental factors.

The use of liquid crystal displays (LCDs) in user interface assemblies is widespread across nearly all industries, locations, and operating environments. Over the last 20 years, the cost of LCD displays has significantly dropped, allowing for this technology to be incorporated into many of the everyday devices we rely on.

The odds are high you are reading this blog post on a laptop or tablet, and it’s likely the actual screen uses LCD technology to render the image onto a low-profile pane of glass. Reach into your pocket. Yes, that smartphone likely uses LCD technology for the screen. As you enter your car, does your dashboa

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey