tft lcd led amoled factory

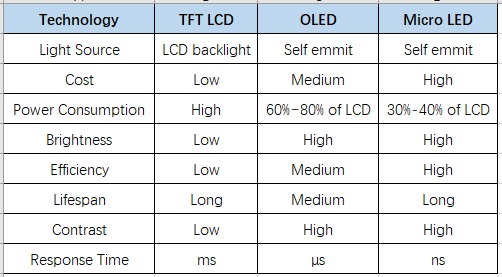

AMOLED and TFT are two types of display technology used in smartphones. AMOLED (active-matrix organic light-emitting diode) displays are made up of tiny organic light-emitting diodes, while TFT (Thin-Film Transistor) displays use inorganic thin-film transistors.

AMOLEDs are made from organic materials that emit light when an electric current is passed through them, while TFTs use a matrix of tiny transistors to control the flow of electricity to the display.

Refresh Rate: Another key difference between AMOLED and TFT displays is the refresh rate. The refresh rate is how often the image on the screen is updated. AMOLED screens have a higher refresh rate than TFT screens, which means that they can display images more quickly and smoothly.

Response Time: The response time is how long it takes for the pixels to change from one colour to another. AMOLED screens have a shorter response time than TFT screens..

Colour Accuracy/Display Quality: AMOLED screens are more accurate when it comes to displaying colours. This is because each pixel on an AMOLED screen emits its own light, which means that the colours are more pure and true to life. TFT screens, on the other hand, use a backlight to illuminate the pixels, which can cause the colours to appear washed out or less vibrant.

Viewing Angle: The viewing angle is the angle at which you can see the screen. AMOLED screens have a wider viewing angle than TFT screens, which means that you can see the screen from more angles without the colours looking distorted.

Power Consumption: One of the main advantages of AMOLED displays is that they consume less power than TFT displays. This is because the pixels on an AMOLED screen only light up when they need to, while the pixels on a TFT screen are always illuminated by the backlight.

Production Cost: AMOLED screens are more expensive to produce than TFT screens. This is because the manufacturing process for AMOLED screens is more complex, and the materials used are more expensive.

Availability: TFT screens are more widely available than AMOLED screens and have been around for longer. They are typically used in a variety of devices, ranging from phones to TVs.

Usage: AMOLED screens are typically used in devices where power consumption is a concern, such as phones and wearable devices. TFT screens are more commonly used in devices where image quality is a higher priority, such as TVs and monitors.

AMOLED and TFT are two different types of display technology. AMOLED displays are typically brighter and more vibrant, but they are more expensive to produce. TFT displays are cheaper to produce, but they are not as bright or power efficient as AMOLED displays.

The display technology that is best for you will depend on your needs and preferences. If you need a screen that is bright and vibrant, then an AMOLED display is a good choice. If you need a screen that is cheaper to produce, then a TFT display is a good choice. However, if you’re worried about image retention, then TFT may be a better option.

TFT is an abbreviation for Thin Film Transistor, a flat panel display used to improve the operation and utility of LCD screens. In order to portray an appearance to the audience, a liquid crystal display (LCD) utilizes a crystalline-filled fluid to modify rear lighting polarized origin through the use of an electromagnetic force among two relatively thin metal wires such as indium oxide (ITO). However, color TFT displays are associated with this method, which can be employed in both divided and pixelated display systems.

With motion pictures displayed on an LCD, the intrinsic sluggish rate of increase between liquid phases over a significant number of pixel components can be an issue due to capacitance impacts, which can create a blurring of the visuals. Placing a high-velocity LCD control device inside the formation of a thin-film transistor immediately next to the cell component just on a glass screen, the issue of LCD picture speed may be substantially improved, and image blur can be eliminated for all useful purposes entirely.

Organic light-emitting diodes (AMOLEDs) are a type of flat light-emitting advanced technologies that are created by interspersing a succession of organic thin sheets over two conducting conductors. An electrical charge causes a brilliant light to be produced when the current flows. AMOLED displays are light-emitting screens that do not require a backlight, making them thinner and more energy-efficient than liquid crystal displays (LCDs) (which will need a white backlight).

AMOLED displays are not only thin and fuel-intensive, but they also deliver the highest image quality available, so they can be made translucent, elastic, bendable, or even rollable and stretchy in the future, allowing for a variety of applications. AMOLEDs are a revolutionary technology in terms of display devices! It is possible to create an AMOLED by sandwiching a sequence of thin films across phase conductors. Electric charge causes a brilliant light to be emitted when the current flows through the coil.

Half-Life has been expanded. TFT displays have a far longer half-life than its LED equivalents, and they are available in a number of sizes, which might have an effect on the device"s half-life based on the phone"s usage as well as other variables. Touch panels for TFT screens can be either resistant or capacitance in nature.

They rely on backlight to give illumination rather than generating their own light. Hence they require constructed light-creating diodes (LEDs) in their backlit display framework to ensure enough brightness.

Backlighting is unnecessary for AMOLEDs. LCDs produce images by selectively blocking parts of the illumination, whereas AMOLEDs produce light. AMOLEDs utilize less energy than LCDs since they don"t need backlighting. This is critical for battery-powered devices such as phones.

While AMOLED light-emitting sheets are lightweight, the substrate can also be elastic rather than stiff. AMOLED films are not limited to glass-like LEDs and LCDs.

AMOLEDs offer 170-degree ranges of vision. LCDs operate by obscuring the light. Hence they have intrinsic viewing obstacles. In addition, AMOLEDs have a substantially wider viewing spectrum.

AMOLEDs outperform LEDs. Since AMOLED organic coatings are less than LED inorganic crystal levels, AMOLED conducting and particle emitters layers can just be multi-layered. Also, LEDs and LCDs need glass backing, which absorbs light. AMOLEDs don"t need it.

AMOLEDs seem to be simpler to implement and larger. AMOLEDs are constructed of polymers and may be produced into big sheets. It takes a lot of extra liquid crystals to build and set down.

While red and green AMOLED sheets have a greater lifespan (46,000 to 230,000 hours), azure compounds have significantly shorter longevity (up to roughly 14,000 hours).

Due to the fact that AMOLED displays inherently emit illumination, they do not need a backlight when used on a monitor screen. Conversely, LCDs require backlights since the liquid crystals themselves are incapable of producing light under their own. Direct light emission from AMOLED displays also allows for the developing of lightweight display devices than others using TFT LCDs.

LCD displays have a higher brightness than AMOLED panels. This is owing to the LCD"s usage of led backlight, which may provide a brilliant illumination of the entire display. Despite the fact that AMOLEDs produce high levels of brilliance from their illumination, they will never be able to match the intensity of LCD lighting.

LCD screens use less power than AMOLED displays, which provides a slight advantage. The amount of energy consumed by AMOLED displays is dependent on the intensity of the screen. Lowered luminance results in lower energy usage, however, it might not be the best solution because the contrast would suffer as a result of the decreased brightness. In some situations, such as when to use an AMOLED device in direct sunlight, it is not an optimal situation.

However, the backlit keys of TFT displays account for the majority of their power usage. TFT screens" efficiency is considerably improved when the backlight is set to a lesser brightness level than the default setting. For example, replacing the light of an LCD TV with just an Led flash will have no effect on the image quality, but will result in lower power usage than replacing the light of an AMOLED TV.

With the exception of phones, numerous other technologies make use of displays to allow customers to engage in direct communication with them. To determine whether or not TFT LCD will be able to withstand the development of AMOLED innovation, we should first review the benefits of LCD technology. The backlighting quality ensures that whites are strong and brightness is superb but will deplete a battery much more quickly than just an AMOLED display. Furthermore, the cost of LCD screens is a considerable consideration. In addition to being less expensive and more easily accessible, they are produced in standard industry sizes, allowing them to be purchased for innovative products with relative ease.

Steven Van Slyke and Ching Wan Tang pioneered the organic OLED at Eastman Kodak in 1979. The first OLED product was a display for a car stereo, commercialized by Pioneer in 1997. Kodak’s EasyShare LS633 digital camera, introduced in 2003, was the first consumer electronic product incorporating a full-color OLED display. The first television featuring an OLED display, produced by Sony, entered the market in 2008. Today, Samsung uses OLEDs in all of its smartphones, and LG manufactures large OLED screens for premium TVs. Other companies currently incorporating OLED technology include Apple, Google, Facebook, Motorola, Sony, HP, Panasonic, Konica, Lenovo, Huawei, BOE, Philips and Osram. The OLED display market is expected to grow to $57 billion in 2026.

AMOLED (Active Matrix Organic Light Emitting Diode) is a type of OLED display device technology. OLED is a type of display technology in which organic material compounds form the electroluminescent material, and active matrix is the technology behind the addressing of individual pixels.

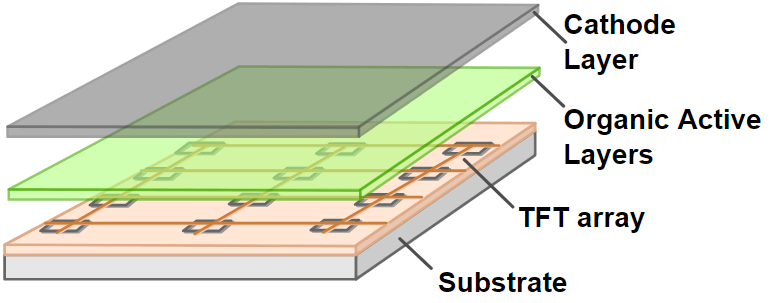

An AMOLED display consists of an active matrix of OLED pixels generating light (luminescence) upon electrical activation that have been deposited or integrated onto a thin-film transistor (TFT) array, which functions as a series of switches to control the current flowing to each individual pixel.

Typically, this continuous current flow is controlled by at least two TFTs at each pixel (to trigger the luminescence), with one TFT to start and stop the charging of a storage capacitor and the second to provide a voltage source at the level needed to create a constant current to the pixel, thereby eliminating the need for the very high currents required for PMOLED.

TFT backplane technology is crucial in the fabrication of AMOLED displays. In AMOLEDs, the two primary TFT backplane technologies, polycrystalline silicon (poly-Si) and amorphous silicon (a-Si), are currently used offering the potential for directly fabricating the active-matrix backplanes at low temperatures (below 150 °C) onto flexible plastic substrates for producing flexible AMOLED displays. Brightness of AMOLED is determined by the strength of the electron current. The colors are controlled by the red, green and blue light emitting diodes. It is easier to understand by thinking of each pixel is independently colored, mini-LED.

IPS technology is like an improvement on the traditional TFT LCD display module in the sense that it has the same basic structure, but with more enhanced features and more widespread usability compared with the older generation of TN type TFT screen (normally used for low-cost computer monitors). Actually, it is called super TFT. IPS LCD display consists of the following high-end features. It has much wider viewing angles, more consistent, better color in all viewing directions, it has higher contrast, faster response time. But IPS screens are not perfect as their higher manufacturing cost compared with TN TFT LCD.

Utilizing an electrical charge that causes the liquid crystal material to change their molecular structure allowing various wavelengths of backlight to “pass-through”. The active matrix of the TFT display is in constant flux and changes or refreshes rapidly depending upon the incoming signal from the control device.

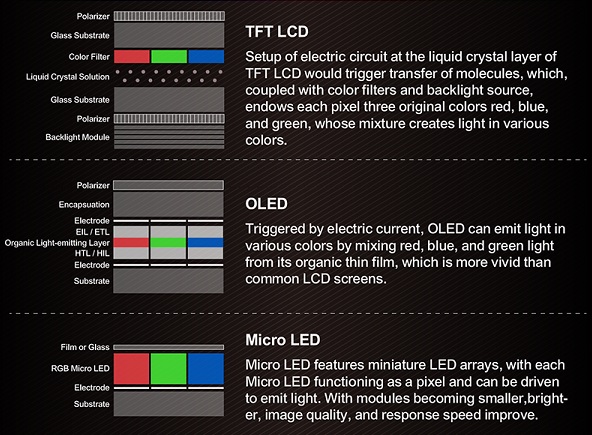

TFT LCD is a mature technology. OLED is a relatively new display technology, being used in more and more applications. As for Micro LED, it is a new generation technology with very promising future. Followings are the pros and cons of each display technology.

TFT Liquid Crystal Display is widely used these days. Since LCD itself doesn"t emit light. TFT LCD relies on white LED backlight to show content. This is an explanation of how TFT LCD works.

Relatively lower contrast:Light needs to pass through LCD glasses, liquid crystal layer, polarizers and color filters. Over 90% is lost. Also, LCD can not display pure black.

Organic Light-Emitting Diode is built from an electro-luminescent layer that contains organic compounds, which emit light in response to an electric current. There are two types of OLED, Passive Matrix OLED (PMOLED) and Active Matrix OLED (AMOLED). These driving methods are similar to LCD"s. PMOLED is controlled sequentially using a matrix addressing scheme, m + n control signals are required to address a m x n display. AMOLED uses a TFT backplane that can switch individual pixels on and off.

Low power consumption and flexible: OLED doesn"t rely on backlight and consumes less power. OLED is essentially created on plastic film. It is bendable and easy to process.

High contrast and vivid color: OLED emits light itself, can produce very bright image with beautiful color. And because OLED can be turned off, it can produce true black.

Stroboscopic effect: most OLED screen uses PWM dimming technology. Some people who are easy perceive stroboscopic frequency may have sore eyes and tears.

Micro LED, sometimes called μLED is made up of tiny LED, measure less than 100μm. Another way of looking at this is that MicroLEDs are simply traditional LEDs shrunk down and placed into an array.

Replacing organic material with inorganic GaN material eliminates the need of polarizing and encapsulation layer, found in OLED. Micro LED is smaller and thinner, consumes less power.

Asia has long dominated the display module TFT LCD manufacturers’ scene. After all, most major display module manufacturers can be found in countries like China, South Korea, Japan, and India.

In this post, we’ll list down 7 best display module TFT LCD manufacturers in the USA. We’ll see why these companies deserve recognition as top players in the American display module industry.

STONE Technologies is a leading display module TFT LCD manufacturer in the world. The company is based in Beijing, China, and has been in operations since 2010. STONE quickly grew to become one of the most trusted display module manufacturers in 14 years.

Now, let’s move on to the list of the best display module manufacturers in the USA. These companies are your best picks if you need to find a display module TFT LCD manufacturer based in the United States:

Planar Systems is a digital display company headquartered in Hillsboro, Oregon. It specializes in providing digital display solutions such as LCD video walls and large format LCD displays.

Planar’s manufacturing facilities are located in Finland, France, and North America. Specifically, large-format displays are manufactured and assembled in Albi, France.

Microtips Technology is a global electronics manufacturer based in Orlando, Florida. The company was established in 1990 and has grown into a strong fixture in the LCD industry.

What makes Microtips a great display module TFT LCD manufacturer in the USA lies in its close ties with all its customers. It does so by establishing a good rapport with its clients starting from the initial product discussions. Microtips manages to keep this exceptional rapport throughout the entire client relationship by:

Displaytech is an American display module TFT LCD manufacturer headquartered in Carlsbad, California. It was founded in 1989 and is part of several companies under the Seacomp group. The company specializes in manufacturing small to medium-sized LCD modules for various devices across all possible industries.

The company also manufactures embedded TFT devices, interface boards, and LCD development boards. Also, Displaytech offers design services for embedded products, display-based PCB assemblies, and turnkey products.

Displaytech makes it easy for clients to create their own customized LCD modules. There is a feature called Design Your Custom LCD Panel found on their site. Clients simply need to input their specifications such as their desired dimensions, LCD configuration, attributes, connector type, operating and storage temperature, and other pertinent information. Clients can then submit this form to Displaytech to get feedback, suggestions, and quotes.

A vast product range, good customization options, and responsive customer service – all these factors make Displaytech among the leading LCD manufacturers in the USA.

Products that Phoenix Display offers include standard, semi-custom, and fully-customized LCD modules. Specifically, these products comprise Phoenix Display’s offerings:

Clients flock to Phoenix Display because of their decades-long experience in the display manufacturing field. The company also combines its technical expertise with its competitive manufacturing capabilities to produce the best possible LCD products for its clients.

True Vision Displays is an American display module TFT LCD manufacturing company located at Cerritos, California. It specializes in LCD display solutions for special applications in modern industries. Most of their clients come from highly-demanding fields such as aerospace, defense, medical, and financial industries.

The company produces several types of TFT LCD products. Most of them are industrial-grade and comes in various resolution types such as VGA, QVGA, XGA, and SXGA. Clients may also select product enclosures for these modules.

All products feature high-bright LCD systems that come from the company’s proprietary low-power LED backlight technology. The modules and screens also come in ruggedized forms perfect for highly-demanding outdoor industrial use.

LXD Incorporated is among the earliest LCD manufacturers in the world. The company was founded in 1968 by James Fergason under the name International Liquid Xtal Company (ILIXCO). Its first headquarters was in Kent, Ohio. At present, LXD is based in Raleigh, North Carolina.

We’ve listed the top 7 display module TFT LCD manufacturers in the USA. All these companies may not be as well-known as other Asian manufacturers are, but they are equally competent and can deliver high-quality display products according to the client’s specifications. Contact any of them if you need a US-based manufacturer to service your display solutions needs.

We also briefly touched on STONE Technologies, another excellent LCD module manufacturer based in China. Consider partnering with STONE if you want top-of-the-line smart LCD products and you’re not necessarily looking for a US-based manufacturer. STONE will surely provide the right display solution for your needs anywhere you are on the globe.

Tried and trusted TFT technology works by controlling brightness in red, green and blue sub-pixels through transistors for each pixel on the screen. The pixels themselves do not produce light; instead, the screen uses a backlight for illumination.

By contrast the Active Matrix OLED (AMOLED) display requires no backlight and can light up or turn off each of their pixels independently. As the name suggests, they are made of organic material.

An AMOLED display has many other benefits which make it a superior looking display including exceptional vieiwng angles and a display that looks practically black when it is switched off.

So, why use a TFT display? Well, it is a mature technology meaning the manufacturing processes are efficient, yields high and cost much lower than AMOLED.

TFT displays also have a much longer lifespan than AMOLED displays and are available in a far greater range of standard sizes, which can be cut down to fit a space restricted enclosure for a relatively low cost adder.

A Thin Film Transistor (TFT) FT display is a form of Liquid Crystal Display with thin film transistors for controlling the image formation. The TFT technology works by controlling brightness in red, green and blue sub-pixels through transistors for each pixel on the screen. The pixels themselves do not produce light; instead, the screen uses a backlight for illumination. Discover our TFT Products

Otherwise knows as the IPS display, this superior version of the TFT provides all round viewing angles and exceptional contrast ratio, however this comes at a premium cost compared to standard TFT models. Read more here.

OLED is increasingly used in smartphones and televisions, but supply is tightening due to size issues and high production costs, making TFT LCD module demand stronger for the next 3 to 5 years. An organic light-emitting diode (OLED) refers to organic LED materials which light up in the presence of electric currents. OLED uses passive-matrix (PMOLED) or active-matrix (AMOLED). Most manufacturers use AMOLED.

OLED creates the deepest black, generating higher color quality than LCD displays. However, organic elements have lower lifespans than LCDs and AMOLED is not suitable for brightly-lit environments. Apple’s high demand has an impact on AMOLED production, among other factors, which has a subsequent positive effect on TFT LCD module demand.

AMOLED demands gets stronger, due to the pursuit for the best color in smartphones and televisions, but its supply is limited because of production factors. Apple is projected to require 100 million AMOLED panels annually for the next three years. Apple’s requirement creates high AMOLED demand in the small and medium display market. Displays are 9-inch in size, which creates a dent on AMOLED supply.

OLED is particularly harder to make than LCD modules because of the complexity in involved in creating substrate materials. OLED manufacturing is costlier than LCD modules, which may also create long-term production issues.

As AMOLED supply remains uncertain, numerous consumer product manufacturers would rather rely on TFT LCD modules. Innovations in TFT LCD can make them more competitive, especially as they cost less than OLED. Stronger TFT LCD demand will come from high-resolution smartphones and consumer electronics with short life cycles.

Though some say that the demand for TFT LCD is likely to contract, they are not considering the increasing use of OLED which already puts greater pressure on its suppliers. Without reducing OLED production costs, they might experience bottleneck problems in the future. Uncertain of OLED supply, some manufacturers of automotive, smartphone, and medical monitors would still prefer TFT LCD over OLED.

While OLED promises deeper colors, TFT LCD module can offer a more reliable, cost-efficient supply. As a result, companies that do not emphasize the demand for high color saturation would opt for TFT LCD. For the next 3 to 5 years, unless OLED vastly improves manufacturing costs and speed, TFT LCD makers are poised for higher demand.

This rise of small, powerful components has also led to significant developments in display technology. The most recent of which, AMOLED, is now the main competitor for the most common display used in quality portable electronics – the TFT–LCD IPS (In-Plane Switching) display. As more factories in the Far East begin to produce AMOLED technology, it seems likely we will enter a battle of TFT IPS versus AMOLED, or LCD vs LED. Where a large percentage of a product’s cost is the display technology it uses, which provides best value for money when you’re designing a new product?

TFT IPSdisplays improved on previous TFT LCD technology, developed to overcome limitations and improve contrast, viewing angles, sunlight readability and response times. Viewing angles were originally very limited – so in-plane switching panels were introduced to improve them.

Modern TFT screens can have custom backlights turned up to whatever brightness that their power limit allows, which means they have no maximum brightness limitation. TFT IPS panels also have the option for OCA bonding, which uses a special adhesive to bond a touchscreen or glass coverlens to the TFT. This improves sunlight readability by preventing light from bouncing around between the layers of the display, and also improves durability without adding excess bulk; some TFT IPS displays now only measure around 2 mm thick.

AMOLED technology is an upgrade to older OLED technology. It uses organic compounds that emit light when exposed to electricity. This means no backlight, which in turn means less power consumption and a reduction in size. AMOLED screens tend to be thinner than TFT equivalents, often produced to be as thin as 1 mm. AMOLED technology also offers greater viewing angles thanks to deeper blacks. Colours tend to be greater, but visibility in daylight is lower than IPS displays.

As manufacturers increasingly focus on smaller devices, such as portable smartphones and wearable technology, the thinness and high colour resolution of AMOLED screens have grown desirable. However, producing AMOLED displays is far more costly as fewer factories offer the technology at a consistent quality and minimum order quantities are high; what capacity there is is often taken up the mobile phone market Full HD TFT IPS displays have the advantage of being offered in industry standard sizes and at a far lower cost, as well as offering superior sunlight visibility.

The competition between displays has benefitted both technologies as it has resulted in improvements in both. For example, Super AMOLED, a marketing brand by Samsung, involves the integration of a touchscreen layer inside the screen, rather than overlaid on it. The backlight in TFT technology means they can never truly replicate the deep blacks in AMOLED, but improvements have been made in resolution to the point where manufacturers like Apple have been happy to use LCD screens in their smartphones, even as they compete with Samsung’s Super AMOLED.

Aside from smartphones, many technologies utilise displays to offer direct interaction with customers. To decide whether TFT LCD will survive the rise of AMOLED technology, we must first recap the advantages of LCD. The backlit quality means that whites are bright and contrast is good, but this will wear down a battery faster than AMOLED. Additionally, cost is a significant factor for LCD screens. They are cheaper, more freely available and are offered in industry standard sizes so can be ordered for new products without difficulty.

It seems hard to deny that AMOLED will someday become the standard for mobile phones, which demand great colour performance and are reliant on battery life. Where size is an issue, AMOLED will also grow to dominance thanks to its superior thinness. But for all other technologies, particularly in industrial applications, TFT-LCD offers bright, affordable display technology that is continually improving as the challenge from AMOLED rises.

Both screens are made up of Pixels. A pixel is made up of 3 sections called sub-pixels. The three sections are red, green and blue (primary colors for display tech).

The light is generated from a “backlight”. A series of thin films, transparent mirrors and an array of white LED Lights that shine and distribute light across the back of the display.

On some lower quality LCD screens, you can see bright spots in the middle or on the perimeters of screens. This is caused by uneven light distribution. The downside to using backlights, is that black is never true black, because no matter what, light has to be coming through, so it will never have as dark of a screen as an AMOLED screen. Its comparable to being able to slow a car down to 2 mph versus coming to a complete stop.

In addition, since each pixel is an OLED (Organic Light Emitting Diode) or individual light, showing black means it shuts off pixels it doesn’t need to generate color.

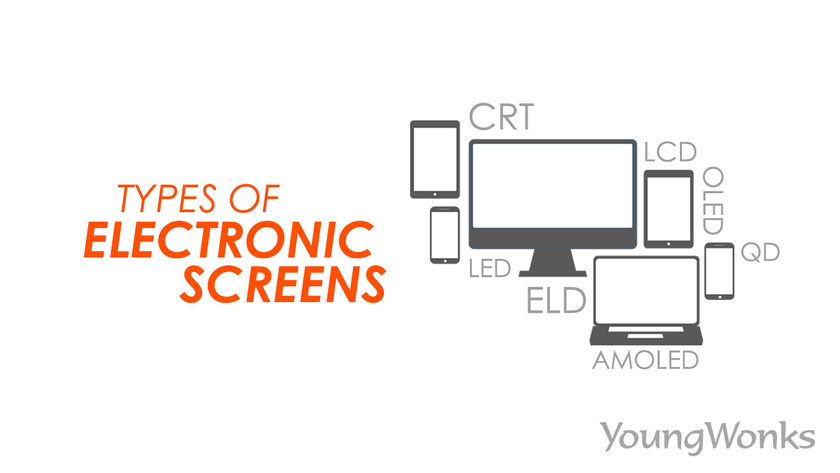

An electronic screen or an electronic visual display, informally called a screen, is basically a device used to display / present images, text, or video transmitted electronically, without creating a permanent record. As mentioned earlier, electronic visual displays include television sets, computer monitors, and digital signage in information appliances. As per the definition, an overhead projector (along with screen onto which the text, images, or video is projected) can also be called an electronic visual display.

1. Cathode Ray Tube (CRT) display:A vacuum tube containing one or more electron guns and a phosphorescent screen, the cathode-ray tube (CRT) is used to display images. It modulates, accelerates, and deflects electron beams onto the screen to make the images. The images could be electrical waveforms (oscilloscope), pictures (television, computer monitor) or radar targets. CRTs have also been used as memory devices, wherein the visible light from the fluorescent material (if any) does not really have any significant meaning to a visual observer, but the visible pattern on the tube face could cryptically represent the stored data. In television sets and computer monitors, the front area of the tube is scanned systematically and repetitively in a pattern called a raster. Thanks to the intensity of each of the three electron beams - one for each additive primary color (red, green, and blue) - being controlled with a video signal as a reference, an image is produced. In modern CRT monitors and TVs, magnetic deflection bends the beams; magnetic deflection is essentially a varying magnetic field generated by coils and driven by electronic circuits around the neck of the tube, although electrostatic deflection is often used in oscilloscopes, a type of electronic test instrument. CRT is one of the older screen/ display technologies.

2. Flat-Panel display: Flat-panel displays are electronic viewing technologies that are used to allow people to see content (still images, moving images, text, or other visual material) in a range of entertainment, consumer electronics, personal computer, and mobile devices, and several kinds of medical, transportation and industrial equipment. They are much lighter and thinner than traditional cathode ray tube (CRT) television sets and video displays and are typically less than 10 centimetres (3.9 in) thick. Flat-panel displays can be classified under two display device categories: volatile and static. Volatile displays need pixels to be periodically electronically refreshed to retain their state (say, liquid-crystal displays). A volatile display only shows an image when it has battery or AC mains power. Static flat-panel displays rely on materials whose color states are bistable (say, e-book reader tablets from Sony), and they retain the text or images on the screen even when the power is off. In recent times, flat-panel displays have almost completely replaced old CRT displays. Most flat-panel displays from the 2010s use LCD and/or LED technologies. Majority of the LCD screens are back-lit as color filters are used to display colors. Being thin and lightweight, flat-panel displays offer better linearity and have higher resolution than the average consumer-grade TV from the earlier decades. The highest resolution for consumer-grade CRT TVs was 1080i, whereas many flat-panels can display 1080p or even 4K resolution.

3. Plasma (P) display: A plasma display panel (PDP) is a type of flat panel display that uses small cells containing plasma; ionized gas that responds to electric fields. Earlier, plasma displays were commonly used in larger televisions (30 inches and larger). But since more than a decade now, they have lost almost all market share due to competition from low-cost LCDs and more expensive but high-contrast OLED flat-panel displays. Companies stopped manufacturing plasma displays for the United States retail market in 2014, and for the Chinese market in 2016.

5. Liquid Crystal Display (LCD): A liquid-crystal display (LCD) is a flat-panel display or other electronically modulated optical device that makes use of the light-modulating properties of liquid crystals. Liquid crystals do not give out light directly; they use a backlight or reflector to create images in color or monochrome. LCDs display arbitrary images like in a general-purpose computer display or fixed images with low information content, that can be displayed or hidden, such as preset words, digits, and seven-segment displays, like in a digital clock. They use the same core technology, apart from the fact that arbitrary images are made up of a large number of small pixels, while other displays have larger elements. LCDs could be on (positive) or off (negative), as per the polarizer arrangement. For instance, a character positive LCD with a backlight has black lettering on a background the same color as the backlight, and a character negative LCD has a black background with the letters matching the backlight color. Blue LCDs typically get their characteristic appearance from optical filters being added to white.

LCD screens are being used in several applications such as LCD televisions, computer monitors, instrument panels, aircraft cockpit displays, and indoor and outdoor signage. Small LCD screens are seen in portable consumer devices such as digital cameras, watches, calculators and mobile telephones, including smartphones. LCDs are also found in consumer electronics products such as DVD players, video game devices and clocks. It is interesting to note that these displays are available in a wide range of screen sizes as compared to CRT and plasma displays. Also, while LCD screens have replaced heavy, bulky cathode ray tube (CRT) displays in almost all applications, they are slowly being replaced by OLEDs, which can be easily made into different shapes, and boast other advantages such as having a lower response time, wider color gamut, virtually infinite color contrast and viewing angles, lower weight for a given display size and a slimmer profile and potentially lower power consumption. OLEDs, however, are more expensive for a given display size and they can suffer from screen burn-in when a static image is displayed on a screen for a long time (for instance, the table frame for an airline flight schedule on an indoor sign), not to mention that there is currently no way to recycle OLED displays. LCD panels, on the other hand, are susceptible to image persistence but they rarely suffer image burn-in as they do not use phosphors, plus they can be recycled, although this technology is not exactly common as yet. Not surprisingly, attempts have been made to increase the lifespan of LCDs in the form of quantum dot displays, which provide performance to that of an OLED display, but the Quantum dot sheet that gives these displays their characteristics can not yet be recycled. LCDs are also more energy-efficient and can be disposed of more safely than a CRT display.

6. Light-Emitting Diode (LED) display:An LED display is a flat panel display that uses an array of light-emitting diodes as pixels for a video display. Their brightness lets them be used outdoors where they are visible in the sun for store signs and billboards. It was in 1962 that LED diodes first came into being; this was when the first practical LED was invented by General Electric’s Nick Holonyak Jr. This was also when they were mainly red in color. While the early models had a monochromatic design, the efficient Blue LED completing the color triad became available in the market only in the late 1980s. Today, large displays use high-brightness diodes to generate a wide spectrum of colors. In fact, recently, LEDs have also become a popular choice among destination signs on public transport vehicles and variable-message signs on highways. LED displays can offer general illumination in addition to visual display, as when used for stage lighting or other decorative (as opposed to informational) purposes. Several big corporations such as Apple, Samsung and LG are currently looking to develop MicroLED displays. These displays are easily scalable, and help with making the production process more streamlined. That said, production costs continue to be quite high and thus remain a limiting factor.

7. Organic Light-Emitting Diode OLED display: An organic light-emitting diode (OLED), also called an organic EL (organic electroluminescent) diode, is a light-emitting diode (LED), where the emissive electroluminescent layer is a film of organic compound that gives out light in response to an electric current. The organic layer is located between two electrodes, at least one of which is transparent. OLEDs are used to build digital displays in devices such as television screens, computer monitors, portable systems such as smartphones, handheld game consoles and digital assistants. Typically, an OLED display works without a backlight because it emits visible light. This means that it can display deep black levels and can be thinner and lighter than a liquid crystal display (LCD). In low ambient light conditions, say in a dark room, an OLED screen can achieve a higher contrast ratio than an LCD, irrespective of whether the LCD uses an LED backlight or cold cathode fluorescent lamps.

Also important to note an OLED display can be driven with a passive-matrix (PMOLED) or active-matrix (AMOLED) control scheme. In the former, each row (and line) in the display is controlled sequentially, one by one, as opposed to in the AMOLED where a thin-film transistor backplane is used to directly control and switch each individual pixel on or off, thus offering higher resolution and larger display sizes.

Lastly, there are two main families of OLED: those based on small molecules and those making use of polymers. A big area of research is the development of white OLED devices for use in solid-state lighting applications.

8. Active-Matrix Organic Light-Emitting Diode (AMOLED) display: AMOLED (Active-Matrix Organic Light-Emitting Diode) is a display device technology being used in smartwatches, mobile devices, laptops, televisions, media players and digital cameras. As mentioned earlier, it is a type of OLED; rather a specific type of thin-film-display technology where organic compounds form the electroluminescent material. What distinguishes it from PMOLED is the active matrix technology behind the addressing of pixels. An AMOLED display basically comprises an active matrix of OLED pixels generating light (luminescence) upon electrical activation that have been positioned or integrated onto a thin-film transistor (TFT) array, which in turn operates as a series of switches to control the current flowing to each individual pixel. AMOLED technology has continued to work towards consuming low power, becoming low-cost and offering scalability (mainly by offering larger sizes.

9. Super AMOLED display: Super AMOLED is essentially an AMOLED display but it is a term coined for marketing purposes by leading device manufacturers. It is used to denote AMOLED displays that come with an integrated digitizer, i.e. the layer that detects touch is integrated into the screen, instead of overlaid on top of it. The display technology however is not an improvement on the AMOLED. For instance, Samsung claims that Super AMOLED displays reflect one-fifth as much sunlight as the first generation AMOLED. In fact, Super AMOLED displays that are part of the Pentile matrix family, are also at times known as SAMOLED. Other variations of this term include Super AMOLED Advanced, Super AMOLED Plus, HD Super AMOLED, HD Super AMOLED Plus and Full HD Super AMOLED.

10. Quantum Dot (QD) display:A quantum dot display is a display device that uses quantum dots (QD), basically semiconductor nanocrystals that can generate pure monochromatic red, green, and blue light. Photo-emissive quantum dot particles are used in a QD layer which converts the backlight to give out pure basic colors that in turn enhance display brightness and color gamut by decreasing light loss and color crosstalk in RGB color filters. This technology is used in LED-backlit LCDs, though it applies to other display technologies as well (such as white or blue/UV OLED).

Among devices employing QD screens, one can find electro-emissive or electroluminescent quantum dot displays, which are currently an experimental type of display based on quantum-dot light-emitting diodes (QD-LED). These displays are similar to active-matrix organic light-emitting diode (AMOLED) and MicroLED displays, as in light is produced directly in each pixel by applying an electric current to inorganic nano-particles. QD-LED displays are supposed to support large, flexible displays and not degrade as readily as OLEDs, making them good bets for flat-panel TV screens, digital cameras, mobile phones and handheld game consoles. As of 2018, all commercial products like LCD TVs that use quantum dots and are called QLED, use photo-emissive particles, whereas electro-emissive QD-LED TVs are only to be found in laboratories today.

Flat-panel displays are thin panels of glass or plastic used for electronically displaying text, images, or video. Liquid crystal displays (LCD), OLED (organic light emitting diode) and microLED displays are not quite the same; since LCD uses a liquid crystal that reacts to an electric current blocking light or allowing it to pass through the panel, whereas OLED/microLED displays consist of electroluminescent organic/inorganic materials that generate light when a current is passed through the material. LCD, OLED and microLED displays are driven using LTPS, IGZO, LTPO, and A-Si TFT transistor technologies as their backplane using ITO to supply current to the transistors and in turn to the liquid crystal or electroluminescent material. Segment and passive OLED and LCD displays do not use a backplane but use indium tin oxide (ITO), a transparent conductive material, to pass current to the electroluminescent material or liquid crystal. In LCDs, there is an even layer of liquid crystal throughout the panel whereas an OLED display has the electroluminescent material only where it is meant to light up. OLEDs, LCDs and microLEDs can be made flexible and transparent, but LCDs require a backlight because they cannot emit light on their own like OLEDs and microLEDs.

Liquid-crystal display (or LCD) is a thin, flat panel used for electronically displaying information such as text, images, and moving pictures. They are usually made of glass but they can also be made out of plastic. Some manufacturers make transparent LCD panels and special sequential color segment LCDs that have higher than usual refresh rates and an RGB backlight. The backlight is synchronized with the display so that the colors will show up as needed. The list of LCD manufacturers:

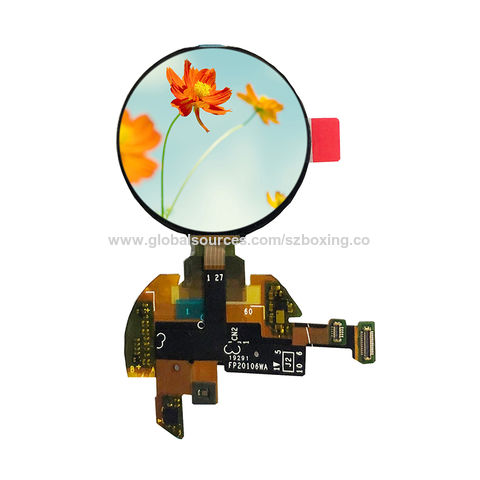

Organic light emitting diode (or OLED displays) is a thin, flat panel made of glass or plastic used for electronically displaying information such as text, images, and moving pictures. OLED panels can also take the shape of a light panel, where red, green and blue light emitting materials are stacked to create a white light panel. OLED displays can also be made transparent and/or flexible and these transparent panels are available on the market and are widely used in smartphones with under-display optical fingerprint sensors. LCD and OLED displays are available in different shapes, the most prominent of which is a circular display, which is used in smartwatches. The list of OLED display manufacturers:

MicroLED displays is an emerging flat-panel display technology consisting of arrays of microscopic LEDs forming the individual pixel elements. Like OLED, microLED offers infinite contrast ratio, but unlike OLED, microLED is immune to screen burn-in, and consumes less power while having higher light output, as it uses LEDs instead of organic electroluminescent materials, The list of MicroLED display manufacturers:

Sony produces and sells commercial MicroLED displays called CLEDIS (Crystal-LED Integrated Displays, also called Canvas-LED) in small quantities.video walls.

LCDs are made in a glass substrate. For OLED, the substrate can also be plastic. The size of the substrates are specified in generations, with each generation using a larger substrate. For example, a 4th generation substrate is larger in size than a 3rd generation substrate. A larger substrate allows for more panels to be cut from a single substrate, or for larger panels to be made, akin to increasing wafer sizes in the semiconductor industry.

"Samsung Display has halted local Gen-8 LCD lines: sources". THE ELEC, Korea Electronics Industry Media. August 16, 2019. Archived from the original on April 3, 2020. Retrieved December 18, 2019.

"TCL to Build World"s Largest Gen 11 LCD Panel Factory". www.businesswire.com. May 19, 2016. Archived from the original on April 2, 2018. Retrieved April 1, 2018.

"Panel Manufacturers Start to Operate Their New 8th Generation LCD Lines". 대한민국 IT포털의 중심! 이티뉴스. June 19, 2017. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"Samsung Display Considering Halting Some LCD Production Lines". 비즈니스코리아 - BusinessKorea. August 16, 2019. Archived from the original on April 5, 2020. Retrieved December 19, 2019.

Herald, The Korea (July 6, 2016). "Samsung Display accelerates transition from LCD to OLED". www.koreaherald.com. Archived from the original on April 1, 2018. Retrieved April 1, 2018.

www.etnews.com (30 June 2017). "Samsung Display to Construct World"s Biggest OLED Plant". Archived from the original on 2019-06-09. Retrieved 2019-06-09.

Colantonio, Andrea; Burdett, Richard; Rode, Philipp (2013-08-15). Transforming Urban Economies: Policy Lessons from European and Asian Cities. Routledge. ISBN 9781134622160. Archived from the original on 2019-01-01. Retrieved 2019-06-09.

Shilov, Anton. "LG"s New 55+ inch OLED Plant in China Opens: Over 1m+ per Year". www.anandtech.com. Archived from the original on 2019-09-14. Retrieved 2019-12-18.

"China"s BOE to have world"s largest TFT-LCD+AMOLED capacity in 2019". ihsmarkit.com. 2017-03-22. Archived from the original on 2019-08-16. Retrieved 2019-08-17.

Shilov, Anton. "JOLED Starts Construction of New Printed OLED Facility". www.anandtech.com. Archived from the original on 2019-06-30. Retrieved 2019-06-30.

TFT displays are also known as an “Active Matrix TFT LCD module” and have an array of thin film transistors fabricated on the glass that makes the LCD. There is one of these transistors for each pixel on the LCD. See our blog post RGB and Color Depth for more on how TFTs show color.

LCDs use voltage applied to a field of microscopic liquid crystals to change the crystal’s orientation. The orientation of the crystals changes the polarization of the liquid crystal creating light or dark pixels on the display.

Beautiful, complex images: All of our TFT modules are full-color graphic displays. Unlike standard monochrome character displays, you can create complex images for an imaginative user experience.

Single Supply: Most of the TFTs use an integrated controller with built-in voltage generation so only a single 3.3v supply is needed for both the panel power and logic voltage.

Many of our character LCD modules use a standard HD44780 compatible controller, so they can be quickly integrated into a new product or used as a replacement in your existing products.

Many of the LCD controllers on board our graphic LCD display modules also include a CGROM (character generator ROM) which allows for easy character information as well as full bit-mapped graphic information to be shown.

Some of the graphic LCD displays have the ability to render graphics in grayscale, enabling you to show images and elements of your UI (user interface) with more depth and definition.

Because OLEDs are emissive, these displays can always be used in dark environments. There is usually a software command or hardware setting that will allow OLEDs to be dimmed.

Some OLED displays are bright enough to be sunlight readable–these models will typically take more current and may have a shorter rated lifetime. Additionally, OLEDs have extremely wide viewing angles.

What makes OLEDs useful for display construction is that they can be fabricated in bulk. Using OLED fabrication techniques, all the diodes can be made at the same time, at a much lower cost. OLEDs also come in a wide variety of colors.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey