lcd panel damage fade supplier

LCDs used in outdoor situations have many concerns to deal with in addition to any that they might normally encounter during indoor use. Initially some concerns are weather related such as moisture in the air or extreme temperatures. Another concern that is often not understood or just not known about at all is sunlight damage.

Liquid crystal displays use organic components that are susceptible to UV (<400 nm) and IR (>750 nm). These bandwidths of radiation have an observable impact on the organic components in LCDs. Extended exposure has been known to cause a color shift and a washed out look to images displayed with the LCD.

In any case it is important to protect your display from the elements, especially if it is going to be exposed to harsh environments not intended by the manufacturer. One way to do this would be to utilize a Hot Mirror with a UV blocker. This will significantly reduce the amount of IR radiation between 750 nm and 1200 nm, as well as the UV radiation below 400 nm. If the LCD is going to be used outdoors for extended periods then an extended hot mirror may be necessary, which extends the bandwidth protection out to 1600 nm and will help reduce some of the longer wavelength IR damage.

Another concern with liquid crystal displays are their susceptibility to overheating due to excess IR radiation. The LCD is intended to operate within a certain range of temperatures according to the manufacturer’s instructions and outdoor use can lead to higher than normal temperatures. The display being exposed to excessive heat can cause the crystal to become isotropic and fail to perform properly. A hot mirror can help alleviate these concerns as well by reducing the amount of infrared radiation that heats the display.

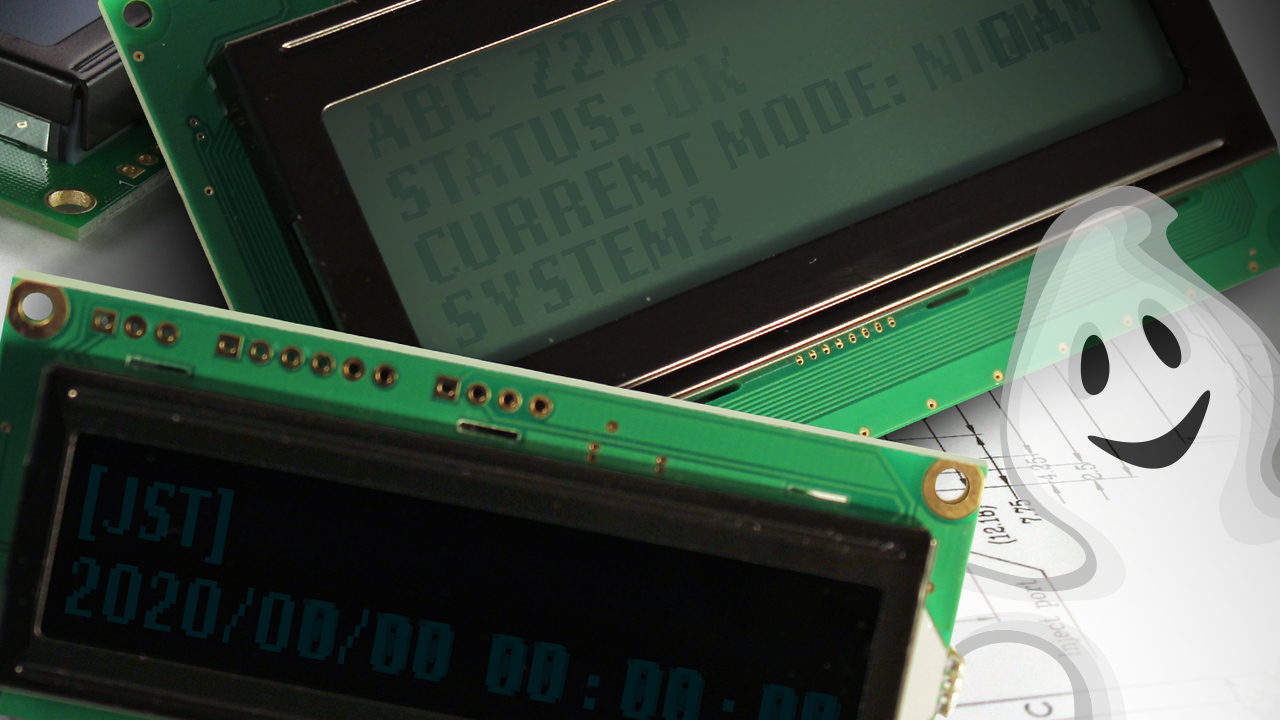

Display: Not sure model of the display, but it is a back-lit monochrome (passive matrix, I think) LCD that displays the climate control settings as well as the trip computer"s output. The foreground is black, and the background is off-white. Sort of like a 90s-era calculator display. See attached image.

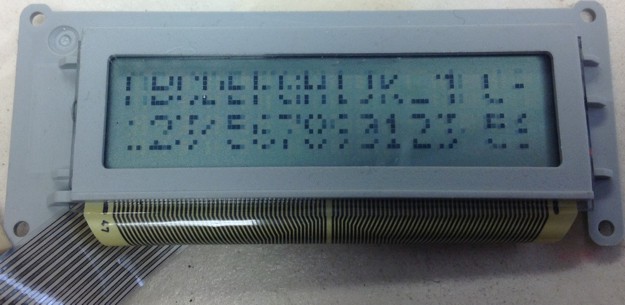

Kind of fade: Digits and other visual elements appear less and less dark as the temperature rises. See attached image. Notice the inconsistent darkness of the 7-segment number display segments as well as the fan speed gauge bars. Ultimately, as the outside temperature reaches 90F, the display completely fades out. The back light works fine no matter what the temperature, as do all other visual elements of the dashboard, etc. This is the only LCD display on the dashboard. The radio is aftermarket and has an active matrix LCD touchscreen. All other dashboard displays appear to be LED.

Why do monitors and TVs get image burn? Why can"t manufacturers prevent LCDs and plasma screens from a burnt image imprint? Moreover, what can you do to fix an image burn?

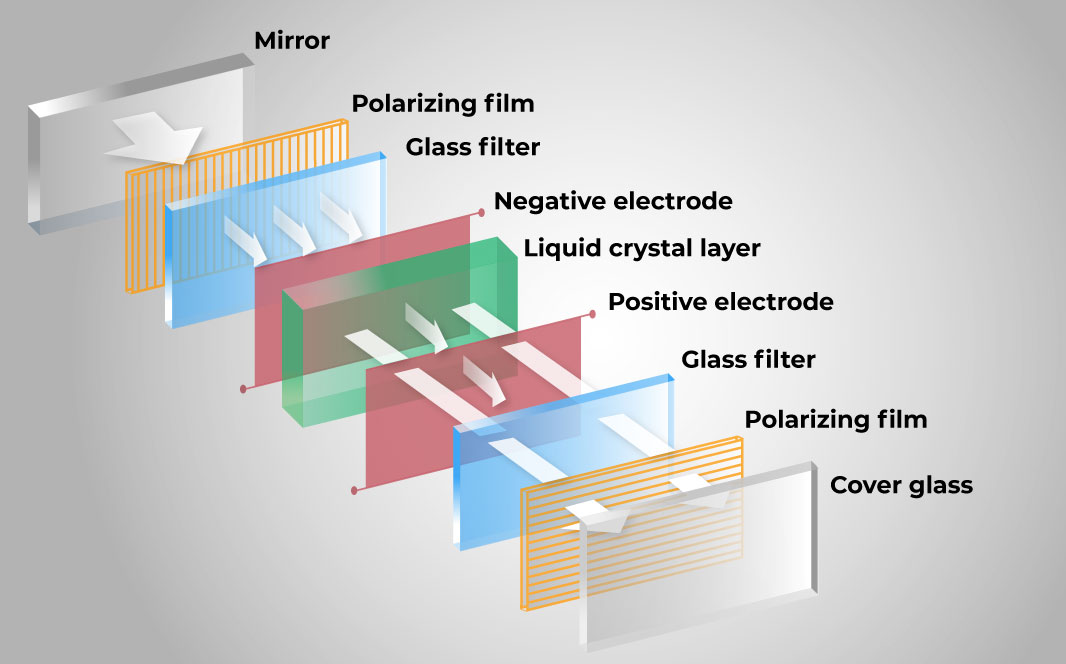

LCD and LED do not work in the same way as CRTs, either. LCD and LED screens use backlit liquid crystals to display colors. Although manufacturers market screens using LED and LCD, an LED screen is still a type of LCD. The white backlight filters through the liquid crystals, which extract particular colors per pixel.

LCD and LED displays don"t suffer from the same type of image burn as CRTs and plasma screens. They"re not completely clear, though. LCD and LED screens suffer from image persistence. Read on to find out more about image persistence.

Before you can fix screen burn-in, take a second to understand why these images burn in the first place. LCDs and LEDs don"t suffer from burn-in as seriously as plasma screens. But static images can leave an imprint on both display types if left alone for too long. So, why does image burn happen?

Plasma screens also suffer from phosphor deterioration. Plasma burning occurs when pixels on the screen are damaged through long exposure. The phosphor loses its intensity and only shows the light it was fed repeatedly. In this case, the still image, which causes the burn.

LCD and LED screens can also experience image burn, though the image burn process can take longer to develop into a permanent issue. In addition, LCD and LED screens suffer from another issue, known as image retention (also known as image persistence or an LCD shadow).

Image retention is a temporary issue that you are more likely to notice before it becomes a permanent issue. However, proper image burn can still affect LCD, LED, and OLED screens.

Image burn-in fixes exist for LCD and plasma screens. How effective an image burn-in fix is depends on the screen damage. Depending on the length and severity of the image burn, some displays may have permanent damage.

The best fix for screen burn is to prevent it in the first place. Okay, that isn"t super useful if your screen is already experiencing image burn. However, you should always try not to leave your screen on a still image for too long. The time it takes for an image to burn-in varies from screen to screen, between manufacturers, sizes, and panel type.

If your plasma or LCD screen already has image burn-in, you can try turning on white static for 12 to 24 hours. The constant moving of white-and-black across your screen in random patterns can help remove the ghost image from your screen.

Pixel-shift constantly slightly adjusts the image on your screen, which varies the pixel usage to counteract image burn. You might have to enable a pixel or screen shift option in your screen settings. Pixel-shift is a handy feature for LED and OLED screens that cannot recover from image burn and should help counteract an LCD shadow.

While the Deluxe version uses advanced algorithms to repair burned screens and prolong plasma and LCD longevity, the official site is no longer up and running, and there is no way to download the full version officially.

Liquid crystal displays (LCDs) are the most widely used display technology. Their applications cover TV, mobile phone, appliances, automotive, smart home, industrial meters, consumer electronics, POS, marine, aerospace, military etc. LCD screen display problem can occur for several reasons.

Effect of environmental conditions on the LCD assembly. Environmental conditions include both the effects of temperature and humidity, and cyclic loading.

Effect of manufacturing process. With the development of LCD for more than 40 years and the modern manufacturing equipment, this kind if defects are getting rear.

Common failures seen in LCDs are a decrease in screen contrast, non-functioning pixels or the whole display, and broken glass. Different kinds of LCD display problem need to have different kinds of fix methods or make the decision not worthwhile to repair.

Broken glassIf you accidently drop the LCD and you find it broken on the surface but the display still works. You might just break the touch panel; you can find a repair house or find a youtube video to replace the touch panel. If you find the display not showing, especially you find the fluid leaking out. You need to reply the whole display modules.

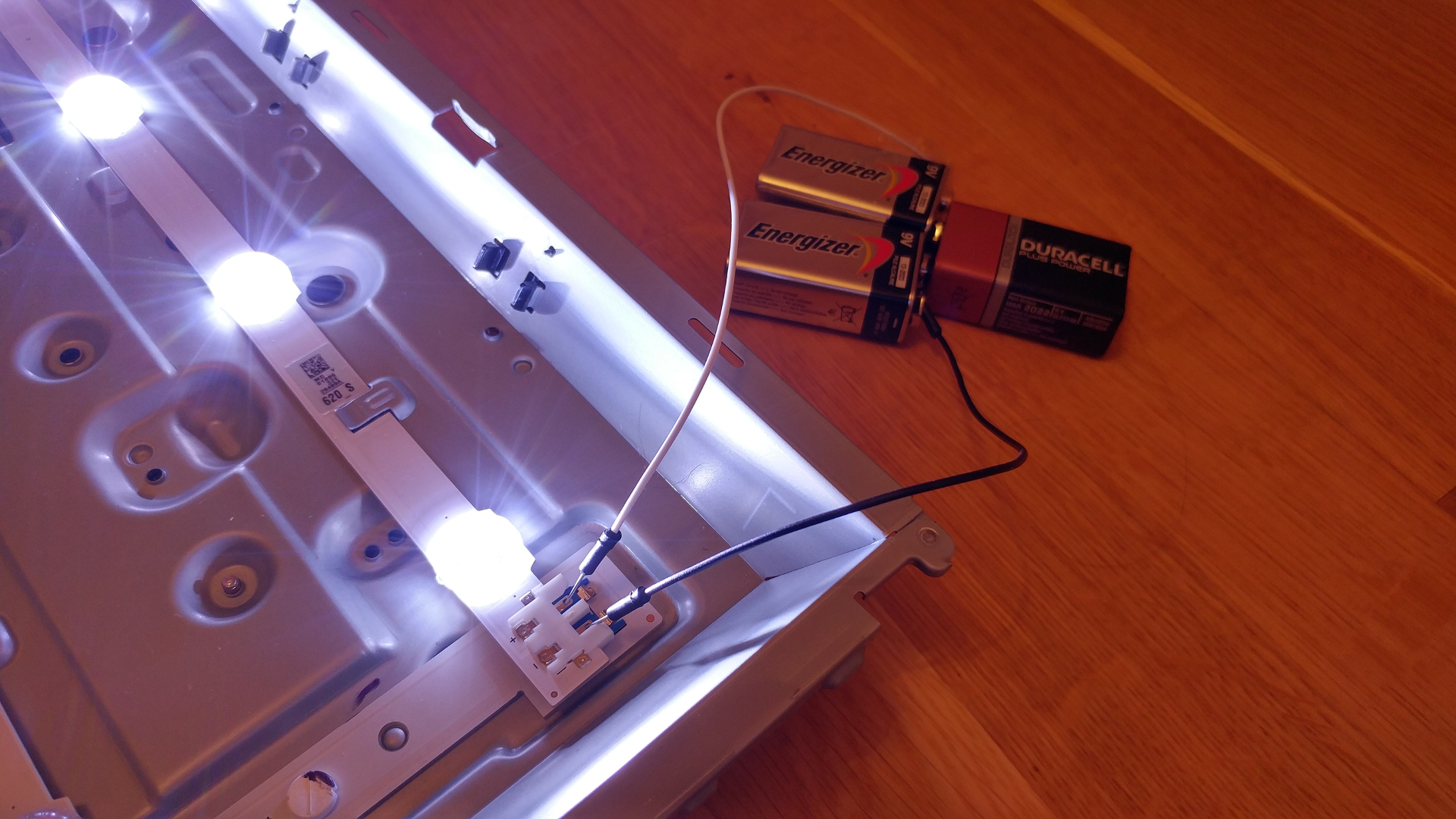

Dim LCD displayLCD can’t emit light itself. It uses backlight. Normally, the backlight is not fully driven, you can increase the LED backlight to make a dim LCD display brighter. But if you LCD display has been used for a long time, it is possible that the LED backlight has to be the end of life (not brightness enough) if you turn on 100% backlight brightness. In that case to fix LCD screen, you have to find a way to change the backlight. For some display, it is an easy job but it can be difficult for other displays depending on the manufacturing process.

LCD has white screen – If a LCD has a white screen which means the backlight is good. Simply check your signal input sources which are the most causes. It can also be caused by the display totally damaged by ESD or excess heat, shock which make the LCD controller broken or the connection failure which has to be repaired by professionals.

Blur ImagesAs the LCD images are made of RGB pixels, the screen shouldn’t be blur like old CRT displays. If you do see blur images, they might be caused by two reasons. 1) LCD has certain response time, if you are playing games or watch fast action movies, some old LCD displays can have image delays. 2) The surface of the LCD is made of a layer of plastic film with maximum hardness of 3H. If you clean the surface often or use the wrong detergent or solvent which cause the surface damage. To fix damage on LED screen it’s need to be changed with professionals.

If you have any questions about Orient Display displays and touch panels. Please feel free to contact: Sales Inquiries, Customer Service or Technical Support.

In LCD the light transit through two polarizers, which are arranged perpendicular, then through the liquid crystal layer. The layer can block the transition of the light or change polarization. Finally, the light falls on the color filters, which give it a set colorcreating the image.

The LCD TFT screens are built of thin-film transistors. The transistor is produced by chemical vapor deposition (CVD), based on the use of liquid hydrogen mixture and silicon mixture in an organic solvent, and using the rotation application method of the thin semiconductor.

In the TFT matrix, each pixel is controlled by four transistors, whereone of them is responsible for brightness, and three remain for basic color (red, blue, green). As a result, this solution allows the high resolution, better color and generally higher parameters of displayed images – comparing to common LCD matrix.

Because of the material the TFT is built from, which isglass, TFT displays havelow mechanical toughness,so can be easily damaged. The most popular damage of TFT is:

The majority of damage occurs during the assembly process in the end user devices. Too much pressure on the fragile TFT construction can damage the structure of the liquid crystal or electric lines.

The module can be held strictly by the housing, and the unnecessary thrust on display should be avoided. The disassembling of the display housing is not recommended, because this process is very destructive and in most cases, it will leave you with a damaged TFT .

Many Apple products use liquid crystal displays (LCD). LCD technology uses rows and columns of addressable points (pixels) that render text and images on the screen. Each pixel has three separate subpixels—red, green and blue—that allow an image to render in full color. Each subpixel has a corresponding transistor responsible for turning that subpixel on and off.

Depending on the display size, there can be thousands or millions of subpixels on the LCD panel. For example, the LCD panel used in the iMac (Retina 5K, 27-inch, 2019) has a display resolution of 5120 x 2880, which means there are over 14.7 million pixels. Each pixel is made up of a red, a green, and a blue subpixel, resulting in over 44 million individual picture elements on the 27-inch display. Occasionally, a transistor may not work perfectly, which results in the affected subpixel remaining off (dark) or on (bright). With the millions of subpixels on a display, it is possible to have a low number of such transistors on an LCD. In some cases a small piece of dust or other foreign material may appear to be a pixel anomaly. Apple strives to use the highest quality LCD panels in its products, however pixel anomalies can occur in a small percentage of panels.

In many cases pixel anomalies are caused by a piece of foreign material that is trapped somewhere in the display or on the front surface of the glass panel. Foreign material is typically irregular in shape and is usually most noticeable when viewed against a white background. Foreign material that is on the front surface of the glass panel can be easily removed using a lint free cloth. Foreign material that is trapped within the screen must be removed by an Apple Authorized Service Provider or Apple Retail Store.

"Following our telephone discussion earlier, I have been in discussion with apple and this type of fault or defect unfortunately is not covered on warranty. They have cited certain probabilities which you cannot ascertain if they did happen or notPressure on the LCD – this could happen when the product is carried in a bag

If the picture responds to input but displays a messy image, such as jumbled multicolored squares, the AV (audio visual) board may be damaged. This is usually a rectangular circuit board located near the audio and visual cables. Replace obviously damaged parts using a soldering iron, or order a replacement board and carefully install it to the same screws and ribbon cables.

Check input cables for damage, or try other cables of the same type. If necessary, inspect the circuit board they are attached to and re-solder damaged connections.

If you notice vertical lines on your TV screen, this is a serious issue and should not be neglected. This problem usually occurs if there’s a loose cable wiring, loose or faulty board or a damaged screen.

This is a common problem in TVs and is a sign that your TV panel is failing. But before you call an expert to check the TV, you could try following these steps and check if they work:

If it continues to show lines, you may mostly have to get the panel replaced and replacing the panel can be a costly affair, depending on the TV and its model. LED panels range anywhere between Rs 8,000 to Rs 85,000, while LCD panels range between Rs 6,000 to Rs 25,000.

When the TV has speakers that work perfectly fine but it has no picture, there is mostly an issue with the back-lighting system or the power supply board, which will need to be replaced. In the case of an LCD TV, it works with the help of a backlight that is used to illuminate the picture on the screen. When the backlight begins to have problems, the screen turns blank.

To fix this issue, the backlight will have to be replaced by a TV expert. Another possible reason is that the backlight on the LCD TV which has a power inverter has failed. When this happens, you may need to replace the inverter or the capacitor.

Be it a panel issue or a major technical issue with the TV, resolving these problems is a costly affair. It’s best not to ignore any of these signs and call an authorized TV expert before the problem worsens.

Light is a very common cause of damage to collections. Many materials are particularly sensitive to light: paper, cloth, leather, photographs, and media (inks, colorants, dyes, and many other materials used to create objects and art). Aside from fading, there may be damage to the physical and chemical structure of materials. Light and ultraviolet radiation (UV) provides energy to fuel the chemical reactions that lead to deterioration and while UV is blamed for most of this damage, visible light is also problematic.

Intensity and long exposure times can lead to fading or changing colors in dyes and colorants. Ultraviolet radiation will lead to weakening, bleaching, and yellowing of paper and other organic materials. All of these changes can diminish readability, affect the aesthetic appreciation of artwork, and impact access to the information contained therein. Even if you take a faded photograph down and store it in the dark, it will not return to its original appearance and will continue to fade when taken out again.

If no light or UV meter is available, it is possible to estimate the damage that might result to an artifact from particular intensities of light and lengths of exposure. This can be done using the ISO’s Blue Wool standard cards, available from a number of conservation suppliers.

More than other measurements, the Blue Wool cards visibly demonstrate the destructive powers of light. Because these cards provide a standard against which subsequent fading can be judged, they can be used to convince skeptics that light really is a problem. Each Blue Wool standard contains eight samples of blue-dyed wool. Sample 1 is extremely light sensitive, while sample 8 is the most stable dye available (although not permanent). Sample 2 takes twice as long to fade as sample 1, sample 3 takes twice as long as sample 2, and so forth. For more information, see “Light, Ultraviolet and Infrared” by Stephan Michalski in Resources.

To demonstrate the degree of fading caused by the intensity of light in a particular location, cover half of the card with a light-blocking material to protect it completely from light damage (or cut the card up into strips reserving one as a control). Note the date and set out the Blue Wools in the desired location. Check periodically (every couple of weeks) to determine how long it takes the various samples to fade. Since the sensitivity of the first few samples on the card corresponds to light sensitive materials such as watercolors and textiles, the results will give you a general idea of the amount of damage you might expect if materials were exhibited for the same period of time at the current light level in that location.

There are two sources of light: sunlight and electrically produced light. As a primary light source, sunlight is not recommended. It is too intense, causes extensive fading, and has a high UV component, which also causes damage at the chemical level. Different types of electrical lighting may be required for storage, staff, public, and exhibition spaces within libraries, museums, and archives. It is helpful to understand the available options and characteristics to select the best option for lighting these spaces. The most common lamps found, especially in storage and exhibit spaces, are:

Since UV radiation is the most energetic, and thus the most destructive, it is easy to assume that if UV radiation is eliminated, damage will cease. Unfortunately, this is not the case; visible light also causes damage. While exposure to UV can be eliminated from exhibit and storage areas (and diminished in public spaces with filtering and lamp selection), reducing visible light requires different strategies.

Protect any materials that may be particularly susceptible to light damage, such as framed color photographs or watercolors, by displaying away from any direct light (sunlight and spotlights) and glazing with UV blocking glass or Plexiglas or by displaying good quality facsimiles.

mounted inside the window from hooks, magnets, or a separate frame (the panel must be cut larger than the window glass, so that all light passes through it).

While on exhibit, collections are most susceptible to light damage and care should be taken to protect these materials. The intensity of light and the length of time the materials will be on display are the primary factors and need to be considered together.

If the light levels are to be higher than 50-150 lux, the length of time on exhibit needs to be decreased accordingly. When making the decision about time on exhibit and light levels, be aware that low light levels for extended periods of time cause as much damage as high light levels for short periods. We can measure the damage to materials in direct proportion to the light level multiplied by the time of exposure, measured in lux hours (lx h). For example, an object lit for 10 hours a day at 50 lux for 100 days would have a light dosage of 50,000 lx h. Ideally, light-sensitive materials would only have an annual exposure of 50,000 lx h, regardless of whether they will be displayed annually or not. When considering how much and how often an item is to be on display, always keep in mind that light damage is cumulative and irreversible.

Using lux hours to track light exposure provides useful and concrete information on how bright exhibition lighting can be by clearly showing that the same amount of expected damage occurs with brighter light and short time as dimmer light and long time. In order to use this principle effectively, good records of exhibition durations and actual light levels must be kept.

All light is energy and the energy that light provides fuels destructive chemical reactions that contribute to the deterioration of collections in libraries, archives, and museums. Light also damages bindings, photographic emulsions, and other media, including the inks, dyes, and pigments used in many library and archival materials.

So if the fear of the mere possibility of burn-in is your primary concern, the decision is simple: Buy an LCD-based display instead. But know that you"re sacrificing the best picture quality that money can buy. Here are some points to keep in mind:

To repeat, you can watch those channels, play games or whatever else to use your TV as a TV, your phone as a phone, etc. You just shouldn"t watch only those channels, all day every day. And if that sounds extreme, know that emails I"ve gotten from readers about burn-in always have some variation on "well I only watched that channel for 5 hours a day." If that sounds like you, get an LCD.

To remove image retention, the TVs can also perform "refreshers" on a daily or longer-term basis. On Sony TVs the feature is called "Panel Refresh," and LG calls it "Pixel Refresher." It can be run manually if you notice image retention or, in the case of LG, you"ll get a reminder to run it after 2,000 hours.

With TVs, beyond the methods outlined above, there"s not much you can do to reverse burn-in. In theory, I suppose, you could create an inverse image using Photoshop and run that on your screen for a while. This could age the rest of the panel to more evenly match the "burned in" area. Figuring out how to do this is well beyond the scope of this article, and you"d need to be pretty well versed in Photoshop to even attempt it.

The most comprehensive independent tests for burn-in on TVs was run by the aforementioned review site RTings. In August 2017 they began a burn-in torture test with LCD and OLED TVs, followed by a "real life" torture test in 2018. They stopped regularly updating the test in 2020, but that was after the equivalent of 5 years of normal use on multiple TVs, and still they felt that most people will never have an issue with burn-in.

Before you check it out, keep in mind what they"re doing is not normal use. You"d have to be trying to wreck a TV to make it look that bad, which is literally what they"re trying to do. That said, the information is still valuable, and the main takeaway is that OLED is indeed more susceptible to burn-in than LCD.

With OLED TVs, it"s something to keep in mind if you"re a TV news junkie, or only ever play one video game. Keep an eye out for image retention or uneven wear. If you spot it, perhaps switch up your viewing habits, adjust the TV"s settings, or run the pixel refresher a few times. And if you watch content with hours of the same static image each day, or just keep CNN, Fox or CNBC on in the background all day, you should probably get an LCD TV.

NOTE: This article provides information about common issues that are seen on LCD screens. It is not something specific to a particular Dell computer but is something that can be seen on any LCD screen by any manufacturer.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey