ascii lcd display manufacturer

Winstar offers a wide range of standard Character LCD modules for customers" application. Our LCD character displays are available from 8x2, 12x2, 16x1, 16x2, 16x4, 20x2, 20x4, 24x2 through to 40x4 formats with 5x8 dot matrix characters. The LCD panel technologies include TN, STN, FSTN, FFSTN types and also with polarizer positive mode and negative mode options. There are different LED backlights are available in various colors including yellow/green, white, red, blue, green, amber, and RGB LEDs as well as no backlight option.

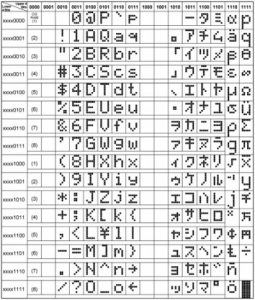

To meet the demands of customer applications, these character LCD displays are available with viewing angles of 6:00, 12:00, 3:00, and 9:00 o"clock. Winstar offers various IC options of character fonts including English/Japanese, western European, eastern European, Scandinavian European, Cyrillic (Russian), and Hebrew/Arabic. These LCD character module and LCM Modules can be used on industrial and consumer"s applications including entrance guard"s equipment, telegram, medical device, car and home audio, white goods, game machine, toys and etc.

LCD character modules are “characteristically” simple display devices known for their very low power consumption, low cost and long-term reliability. They are designed to display alpha-numeric characters in preset patterns and do not have much. In most cases, they are small displays with only 8 or 16 or 32 characters, utilized for status reports and simple communication. It is the most popular display for hobbyist because of its ease of operation.

Orient Display offers many standard sizes including (characters x lines) 8×1, 8×2, 16×2, 16×4 , 20×2, 20×4 , 24×4, 40×4, and many more. Orient Display’s character LCD displays cover small LCD character display modules for tiny devices to large character LCD displays for medical equipments.

Orient Display character LCD modules use industrial standard Hitachi HD44780 controller or compatible controllers such as Sitronix ST7066U, Samsung S6A0069, so they can be quickly integrated into a new product or used as a replacement in your existing products.

The LCD panel technologies include TN, STN, FSTN, FFSTN or VA (Vertical Alignment) types and also with positive mode and negative mode and options of reflective, transflective or transmissive polarizers. There are different LED backlights available in various colors including yellow-green, white, red, blue, green, amber, and RGB LEDs as well as no backlight option.

The viewing angles for these character LCD displays are available with 6:00, 12:00, 3:00, and 9:00. Orient Display offers various IC options of character fonts including English/Japanese, western European, eastern European, Scandinavian European, Cyrillic (Russian), and Hebrew/Arabic. These LCD character modules and LCD modules can be used on industrial and consumer’s applications including printers, microwaves, water machines, medical devices, car and home audio, white goods, game machines, toys, industrial meters, etc.

Please see our character LCD display list here. If you can’t find any in the list, please check with our engineers to search our factory database or have a custom-made option.

This is20×4 Character LCD Displaywith Blue Backlight ASCII Alphanumeric Character. 20×4 character LCD Display can be Interface with almost All Digital Microcontroller such as Arduino, 8051, PIC, AVR, ARM, MSP, COP8, STM, Raspberry Pi etc. 4x20 Display also used in Industrial Research and Development R&D, Student Hobby DIY Project. About20×4 Character LCD Display: 20×4 LCD is a basic 20 character by 4 line display Blue White Back light.

Utilizes the extremely common AIP31066 interface chipset. You will need 7 general I/O pins (If use in 4-bit Mode) to interface to this LCD screen. Includes LED Backlight. Features of 20×4 LCD Display : Commonly Used in: Student Project, Collage, copiers, fax machines, laser printers, industrial test equipment, networking equipment such as routers and storage devices.SIZE: 20×4 (4 Rows and 20 Characters per Row), Can display 4-lines X 20-characters. Operate with 5V DC, Wide viewing angle and high contrast. Built-in industry standard HD44780 equivalent LCD controller. LCM type: Character, Package Contents: 1 X LCD 20×4.

This is not official manufacturer"s information. It is distilled from information on many different data sheets and from my own experience. I have never used some of these displays. I have extrapolated what I know about the displays that I have used to the ones that I have just read about. I welcome any suggestions and corrections. Contact information is at the bottom of the page.

The HD44780 type controller chip is used with a wide variety of Liquid Crystal Displays. These LCDs come in many configurations each with between 8 and 80 viewable characters arranged in 1, 2, or 4 rows.

The problem is that there is no way to inform the controller of the configuration of the display that it is driving. The controller operates exactly the same way for all displays and it is up to the programmer of the device that is controlling the LCD controller (usually a host microcontroller) to deal with this situation.

The controller contains 80 bytes of Display Data Random Access Memory which is usually referred to as DDRAM. When the controller is used with a 40 x 2 display (forty characters on each of two rows) the operation is quite straightforward and that operation will be explained first. Each of the other configurations introduces one or more quirks so it is best to understand the operation of the 40 x 2 before proceeding to the description of the operation of any of the others.

Each of these DDRAM memory addresses corresponds to a character position on an attached display, but the specific position varies depending on the configuration of that display. As part of the initialization sequence the display is cleared by storing the ASCII code for a space in each of the 80 memory locations. Subsequently if a different ASCII code is stored in any of those memory locations then the character corresponding to that ASCII code is automatically displayed at a specific location on the display.

You can tell the controller where you want the first ASCII character that you send it to be stored, this is usually address 00h. After receiving that character it will automatically update its address pointer and put the next ASCII character you send into an adjacent memory location with no more addressing work on your part. You can specify whether to increment or decrement the address counter but normally it is incremented, so the next character will be put into address 01h. The LCD controller automatically accounts for the gap in addresses and after storing an ASCII code in address 27h it puts the next code in address 40h. Similarly it increments from address 67h back to 00h.

Here is a simplified diagram of the display on a 40 x 2 LCD Module. Each of the boxes in the diagram represents a location where a character can be displayed.

Here is a copy of the memory map of the controller. Remember, each of the memory locations in the controller chip is directly associated with one of the character locations on the display.

By some miracle of modern technology there is actually a one for one relationship between these two diagrams. If an ASCII code is stored at address 00h in memory the corresponding character will appear at the left end of the top row of the display. If an ASCII code is stored at address 63h in memory the corresponding character will appear five locations in from the right end of the second row of the display.

Here is a diagram showing how the two rows of the display are mapped into the two lines of memory. It is basically a combination of the two diagrams just above.

When the host controller wants to display a string of characters on the display all it has to do is specify a starting DDRAM address and then start sending the string of ASCII codes corresponding to the desired characters to the LCD controller, one after another. The LCD controller takes the first code that it receives, stores it at the specified address, and simultaneously displays the corresponding character on the display. It then increments it"s internal address counter and stores the next ASCII code that it receives in the next DDRAM location which causes the corresponding character to appear in the next location on the display. As mentioned before the LCD controller automatically accounts for the gap in addresses and after storing an ASCII code in address 27h it puts the next code in address 40h. Similarly it increments from address 67h back to 00h.

This display also has 80 characters, but the relationship between the DDRAM addresses and the character locations on the LCD is not quite as straightforward as the LCD with two rows of 40 characters. Here is a diagram of the device.

The memory map is always the same regardless of the display configuration, but in this drawing I have shown a small space between addresses 13h and 14h on the first line and another between addresses 53h and 54h on the second line.

Here is the same memory map, rearranged this time to show how the memory addresses relate to the character positions on a 20 x 4 LCD. Note how the right half of the previous diagram is now below the left half and note the resulting sequence of starting addresses for each display row (00h, 40h, 14h, 54h).

Remember that the LCD controller still considers this to be two lines of RAM. It is important to understand that this way of picturing the DDRAM addresses helps relate the memory addresses to the character locations but does not change the fact that as far as the controller is concerned there are only two lines of memory. In other words, although this diagram shows the DDRAM differently than before, the actual DDRAM configuration and operation is exactly the same as described above for the 40 x 2 display since there is no way of telling the LCD controller that there are now 4 rows of 20 characters instead of 2 rows of 40 characters.

When a long string of ASCII codes is sent to this LCD controller the action is not quite as simple as for the 40 x 2 display. After the first row is full the characters will continue on to the third row. The normal automatic incrementing from 27h to 40h will then cause the display to continue on the second row, and from there it will continue to the fourth row. After that the following characters will appear back on the first row, and so on.

In order to get a coherent display on sequential rows it is necessary to compensate for the design of the LCD controller when programming the host microcontroller. Basically the program on the host microcontroller can keep track of the DDRAM addresses, and when appropriate it can set up a new starting DDRAM address.

For each of the above displays there are 80 addresses in memory and there are 80 character locations on the display so it should be obvious that any time you send an ASCII code to the controller the corresponding character will show up somewhere on the display. If you mess up the address the character may not show up where you expected it, but it will be visible somewhere. If you work back from where it actually appears you can usually figure out where you made your mistake. All of the displays that follow have fewer character locations on the display than memory addresses in the controller. This makes the operation somewhat more complicated and troubleshooting more difficult.

This can be thought of as a truncated 40 x 2 display, but there are some ramifications of this truncation that may not be readily apparent. Here is a drawing of the device.

It is important to understand that, although this diagram shows only the part of the DDRAM that is normally used to display information on the 20 x 2 LCD, the actual memory map and controller operation is exactly the same as described above for the previous displays. Again that is because there is no way of telling the LCD controller that there are only 40 characters on the attached display.

Here is a drawing of the complete memory map. Note that this drawing is the same as the one for the 20 x 4 display except that the addresses on the right side are greyed out.

Although this display has only 40 characters there are still 80 bytes of DDRAM and they are still configured the same as they were before. The greyed out addresses are the locations in DDRAM that do not have corrresponding locations on the display. Any ASCII codes that are written to those locations are not lost, and it is possible to display them by "shifting" the display window, but in normal use as described here they are simply not displayed.

When a long string of ASCII codes is sent to this LCD controller the action is not quite as simple as for either of the 80 character displays. Assume that the host controller is sending a string of characters as described above. Consider what happens after the LCD controller stores an ASCII code in address 13h and displays the corresponding character at the right end of the top row on the LCD. It then stores the next ASCII code in address 14h, which has no corresponding location on this 20x2 display. As more ASCII codes are sent to the LCD controller they are stored in the DDRAM but do not appear on the display until the LCD controller finally increments it"s address counter from 27h to 40h at which time subsequent characters start to appear on the second row of the display. As far as a viewer of the display is concerned there is a gap of 20 missing characters. The same thing will happen on the second row when ASCII codes are stored in addresses 54h - 67h.

In order to prevent any missing characters the program on the host microcontroller can keep track of the DDRAM addresses, and when appropriate it can set up a new starting DDRAM address. On the other hand the display can be shifted to display those missing characters, but the techniques to do that will not be covered here.

This is a commonly found configuration and its operation is almost identical to that of the 20 x 2. The relationship between the DDRAM addresses and the character locations on the LCD is a subset of the example shown above. Here is a drawing of the device.

Once again it is important to understand that although this diagram shows only the part of the DDRAM that is normally used to display information on the 16 x 2 LCD the actual DDRAM configuration and operation is exactly the same as described above for the 40 x 2 display. This is because there is no way of telling the LCD controller that there are only 32 characters on the attached display.

Here is a drawing of the complete memory map. Note that this drawing is the same as the one for the 20 x 2 display except that a different range of addresses on the right side are greyed out.

The operation of this display when a long string of characters is sent to it is that same as described for the 20 x 2 display except that there is a gap of 24 missing characters at the end of each line (instead of 20).

There are actually two different varieties of 16 x 1 LCD displays and the initialization and operation of each is different so it is important to determine which one you have.

When power is first applied to any of the multi-row LCD modules and before the controller is initialized you will see that the character locations corresponding to the first line of memory are dark and the others are light (assuming that the contrast adjustment is properly set). If you apply power to a 16 x 1 LCD module and only the left 8 character locations are dark you have what I will call a type 1 module. If only the right 8 character locations are dark this is also a type 1 module but it is upside down! If all 16 character locations are dark then it is what I will call a type 2 module. This is my own terminology used only for the purpose of keeping them differentiated while describing their operation. The type 1 modules will have only one IC on the back of the pcb while the type 2 will have 2 (I guess this tidbit gives away the source of my "type" designations). This distinction may apply to newer devices with epoxy blobs instead of ICs, but I believe that sometimes one blob may cover more than one equivalent IC function.

From this you can see that although the display has only a single row of characters, as far as the LCD controller is concerned it is using two lines of memory and it must be considered to be a 2 line device when initializing the controller.

Here is a drawing of the complete memory map. Note that this drawing is the same as the one for the 20 x 2 and 16 x 2 displays except that a different range of addresses on the right side are greyed out.

Here you can see that if the host controller sends a long string of characters without periodically adjusting the DDRAM starting address then after each 8 characters are displayed the next 32 will "disappear".

Also, to display a message of more than 8 characters on the 16 character display the host controller will have to readjust the DDRAM address after displaying the first 8 characters.

Here is a drawing of the complete memory map. Note that this memory map is different than all of the previous ones. This is the only device described here that is a true "one-line" display (see note 2) and as such it has a different memory map.

Here you can see that if the host controller sends a long string of characters after the first 16 characters are displayed the next 64 will "disappear".

At the expense of an extra IC you get some slightly easier programming since, in order to display a message of more than 8 characters on the 16 character display, the host microcontroller does not have to readjust the DDRAM address after displaying the first 8 characters.

Since only one line of memory is in use this LCD module should be configured as a 1-line device. As far as I can determine, this changes the multiplex frequency which changes the display brightness and/or contrast. Also, there are some single row LCDs that are capable of displaying a larger 5x10 font instead of the more common 5x7 font.

Here is the same memory map, rearranged this time to show how the memory addresses relate to the character positions on a 16 x 4 LCD. Note how the center of the previous diagram is now below the left part, the right part is missing, and the resulting sequence of starting addresses for each display row is different than for the 20 x 4 (00h, 40h, 10h, 50h).

Here you can see that if the host controller sends a long string of characters without periodically adjusting the DDRAM starting address then after the first row is full the characters will continue on to the third row. After the third row is full the next eight characters "disappear". The normal automatic incrementing from 27h to 40h will then cause the display to continue on the second row, and from there it will continue to the fourth row. After the fourth row is full the next eight characters will "disappear" and then it"s back to the first row.

The 40 x 4 LCD is treated essentially as two 40 x 2 devices stacked one on top of another in the same glass enclosure. Electrically it uses what amounts to two HD44780 controller chips and it therefore has two separate memory maps each with the same address range. One is used for the top two lines and the other is used for the bottom two lines. The memories are accessed individually by strobing the desired Enable pin of which there are now two. Here is a diagram of the device.

To display a really long string of characters on this display the host controller would start out just like it did for the 40 x 2 display. It would specify a starting DDRAM address (typically 00h) and then start sending the string of ASCII codes corresponding to the desired characters to the LCD controller, one after another, making sure to strobe the enable pin associated with the upper memory bank. After storing an ASCII code in address 67h the LCD controller will automatically increment to address 00h as before and at this time the host controller must stop strobing the enable pin for the upper bank and start strobing the one for the lower bank.

There are other LCD configurations available but I believe that any of them can be handled by a technique similar to one of the examples above. If you have a display that seems to be considerably different from any of these I would like to hear from you.

(1) The mysterious gap is due to considerations resulting from the multiplexing of the display. The DDRAM addressing uses seven bit addressing and the highest bit signifies which row of memory is involved. If you compare the addresses in the first row with those just below in the second row you will see that the only difference is in that one bit.

(2) As implied above the number of rows of characters that can be displayed on the LCD is not the same as the number of lines of memory used by its controller. Only some of the 16x1 displays use "one line" of memory, all of the other displays including most 16x1 displays, use "two lines" of memory.

Nextion is a Human Machine Interface (HMI) solution combining an onboard processor and memory touch display with Nextion Editor software for HMI GUI project development.

Using the Nextion Editor software, you can quickly develop the HMI GUI by drag-and-drop components (graphics, text, button, slider, etc.) and ASCII text-based instructions for coding how components interact on the display side.

Nextion HMI display connects to peripheral MCU via TTL Serial (5V, TX, RX, GND) to provide event notifications that peripheral MCU can act on, the peripheral MCU can easily update progress, and status back to Nextion display utilizing simple ASCII text-based instructions.

Data Care Systems Pvt. Ltd. was established in the year 1989. We are one of the leading manufacturer and supplier of Digital Clocks, Data Transmission Systems, Nurse Call Systems, Display Systems, Annunciator Panels, Data Communication Systems, etc. promoted by technocrats with extensive expertise and over a decade of experience in R & D establishment. Started with the objective of Designing, Developing and Manufacturing user friendly Data Communication products committed to provide state-of-art world class equipments.

An LCD (Liquid Crystal Display) is a great way to display information in our Arduino Uno controller. We will be wiring and programming an alphanumeric, two rows with 16 characters on each row. The display has an LED (Light Emitting Diode) backlight with adjustable contrast.

This white and blue LCD will display “Hello World!” on the top line and temperature on the bottom line. The thermistor temperature circuit created last time will be displayed in both Celsius and Fahrenheit degrees. Let’s get started.

When you look at an LCD display, it is made up of a series of dots or pixels. Each of these pixels is a liquid crystal. If electricity flows through the liquid crystal it will change its structure and be more rigid. This rigidity will look darker than if no electricity is applied. If we use a light behind this LCD then the backlight will make the pixels more pronounced. So electricity on the pixel will block the light and no electricity will allow the light through. This contrast is what we see using an LCD display.

This first part will set up the library and declare the variables for the LCD display unit. Using the Steinhart-Hart Equation we declare our variables and set the coefficients for the equation.

The LCD is set up with 16 characters and 2 lines. The cursor for the LCD display is set for the first character on the first line by default. We then print the message “ Hello, World!”.

The program will calculate the temperature in Celsius (T) and in Fahrenheit (TF). The LCD cursor is then set to the second row and column 0. We can then print our temperatures and units of measure.

You will see the ‘Hello World!’ and the current temperature in two units of measure displayed on the LCD. Hold the thermistor between your fingers to see how rapidly the temperature can be read.

If you’re like most of my readers, you’re committed to learning about technology. Numbering systems used in PLCs are not difficult to learn and understand. We will walk through the numbering systems used in PLCs. This includes Bits, Decimal, Hexadecimal, ASCII, and Floating Point. To get this free article, subscribe to my free email newsletter.First Name:

Text LCD displays are among the simplest. They are popular for their ease of operation and programming thanks to the HD44780 LCD controller and their analogs with the built-in set of characters including ASCII characters. Text displays consist of a matrix of dots combined into rows and columns. Formats of rows and columns are standardized by manufacturers and can be 8x1, 8x2, 10x1, 10x2, 16x1, 16x2, 16x4, 20x1, 20x2, 20x4, 24x1, 24x2. Each LCD controller is capable of operating up to 80 characters so the text LCD display with the 20x4 format is the largest. There are even larger text LCD displays such as 40x4 using several LCD controllers but they are too rare.

Initially, text LCD displays communicate with microcontrollers such as Arduino using parallel 4 or 8-bit interfaces. Some manufacturers add shift registers and port expanders to the display, making it possible to control via I2C or SPI bus. It is done for connecting convenience and reducing the number of mounting wires.

These nodes contain everything you need to start working with displays. You only have to connect your display to the microcontroller and set up proper connection parameters.

If the display communicates via an I2C bus the input parameter is the device address. Put the I2C address value of the byte type to the ADDR pin field.

If the display is controlled using a parallel interface fill in the pin values RS, EN, D4, D5, D6, D7 according to the microcontroller ports through which the display is connected.

The L input pins of the string type have indexes from 1 to 4 and correspond to the lines on your text display. The boolean value at the ACT pin is responsible for updating the display screen if the incoming string values change. Versions controlled by the I2C bus have an additional BL pin which turns on and off the display backlight.

Here is a simple example of using quick start nodes. For the example we use a 16x2 format display controlled by I2C. Connect the display to the microcontroller. Create an empty patch and put the text-lcd-i2c-16x2 quick start node onto it. The LCD screen from this example has the 38 I2C address so we put the 38h value to the ADDR pin.

Let’s print the “HELLO” word on the first line of the text display. Add a constant-string node onto the patch, fill it with the "HELLO" string value, and then link it with the L1 input pin of the quickstart node denoting the first line of the display.

A text can be entered directly into a value field of the input pin. To demonstrate it, let’s print the “WORLD” word on the second line of the display. Put the "WORLD" string value into the L2 pin of the text-lcd-i2c-16x2 quick start node.

Try a more dynamic example. Let’s display the system time, it is the time that has passed since the start of the program. To obtain the time value use the system-time node from the core library.

Remove the "WORLD" value from the L2 pin of the quickstart node and change the text inside of the constant string node to "Time: ". In XOD you can add different strings together or combine a string with a value of another data type using concat or join nodes. Put the concat node onto the patch to unite the static "Time: " text with a value received from the system-time node. To display the combined string on the first line of the display link the output pin of the concat node with the L1 pin of the quickstart node.

If the quickstart node doesn’t suit your task or the display is of a non-common format try to operate some developer nodes from the library xod-dev/text-lcd library.

Define the display you want to use to start working with it in XOD. Find out how your display communicates and place the appropriate device node from the xod-dev/text-lcd library. These nodes construct and output an lcd-device custom type value which is necessary for further work.

Use the text-lcd-parallel-device node if the display is controlled using a parallel interface. This node allows the display connection only through a 4-bit parallel interface. Here enter the pin values RS, EN, D4, D5, D6, D7. These values correspond to the microcontroller ports through which the display is connected.

Use the text-lcd-i2c-device node if the display communicates via an I2C bus. For this node, the input parameter is the device address. Enter the I2C address of your display to the ADDR pin value.

When the device is initialized, you can display text on it. To output text, use the print-at node. It fits any type of LCD device because it is generic.

The input values of the print-at nodes determine what text to display and where it should be on the display screen. Text to display is set at the VAL pin value. The ROW and POS field values set the cell coordinates on the display for the first character. That’s the place where your text begins. The LEN pin value sets the number of character cells for the text to reserve. The text can’t go beyond the boundaries you specify. It is useful, for example, when the length of your text changes during the program or you want to organize free space between several text parts. Printing is performed when the DO pin receives a pulse.

At first, let’s make a patch to print the "HELLO" text. Put the text-lcd-i2c-device node onto the patch and fill it with parameters. According to the format of the display, the number of columns is 20 and the number of rows is 4. The I2C address of the used display is 0x39 so put the 39h byte to the ADDR pin. Add the print-at node and link it with the device node. Put the HELLO to the VAL input pin.

Add one more print-at node and link with the LCD device bus. Put the "WORLD" word into the VAL field. The new text is on the same line as the previous one so set the ROW value to 1. The POS value now should be calculated. The “HELLO” word begins from the cell with index 4 and occupies 5 cells. By adding one empty cell for space and the “HELLO” word length to the previous text position you can get the POS for the new text: it is 10. Link the input DO pin of the new node with output DONE pin of the previous to execute printing sequentially.

Text displays contain a table of images for each character in their memory. These tables are used to generate letters, numbers and other symbols. Almost always a full list of all available characters can be found in the manufacturer’s datasheet. To display a specific symbol, it is necessary to transfer its hexadecimal number from the sign generator table. Use the \x## sequence to embed the character code in the string.

For example, the display that is used for this example contains five symbols which can indicate a battery capacity level. Hexadecimal codes for these symbols are 9B,9C,9D,9E, and 9F. Let’s try to display these symbols on the 3rd line of the display. Let’s change the previous example patch. Leave one print-at node and set up new printing coordinates. Put the 2 value into the ROW pin and let the POS be 7. Then, put the "\x9B\x9C\x9D\x9E\x9F" sequence of the character codes into the VAL pin…

Make your project or device more attractive and informative with a text display. Get started with quickstart nodes from the xod-dev/text-lcd library. Combine strings using concat. For non-standard cases, dive deeper into the library. Use a device node together with various action nodes, such as set-backlight and clear.

In this tutorial I am going to explain about the pin out, working and control systems of character lcd’s. Character lcd’s comes in many sizes for example 8×1, 8×2, 8×4, 16×1, 16×2, 20×1, 20×2, 20×4, 24×1, 24×2, 24×4, 32×1, 32×2, 40×1, 40×2 and 40×4. In these MxN dimensions, M represents number of coulombs & N represents number of rows.

All these Lcd’s available in market have 14 or 16 pins depending on the vendor/supplier. Also they all contains a same lcd controller in them which controls all their activities. Talks to external peripherals(like microcontrollers) receives data from external devices and displays them on lcd display screen. Generally every character lcd has HD44780 controller in it which controls every operation of character lcd. Some variants and competitors of HD44780 also placed step in embedded market but they are not popular for exampleAIP31066 , KS0066 , SPLC780 and ST7066 lcd controller.

In these 14 pins, 8 are data pins(FromDB-0toDB-7). Three are lcd control pinsRS(Register Select),R/W(Read-Write) &En(Enable). Two are lcd power pinsVcc(+5v)Vss(Gnd). The last pin islcd contrast pin(V0).

If lcd contains 16 pins than the extra 2 pins are LED+ and LED- pins. LED+ and LED- are for lcd’s back light, if you want to switch on the back light of lcd then use these pins other wise leave them void.

Character lcd’s which have pins arranged in two lines like headers, their pin-out is given below. Female header pin-out is shown below. Vendors for ease pre-solder the lcd pins and provide a female header for connections.

Mostly character lcds contains HD44780U lcd controller in them. HD44780 was developed by Hitachi. A single HD44780 can handle up to 80 characters. In 40×4 lcd display total characters which we can display on lcd are 40×4=160. So to control 160 characters we need two HD44780 controllers. To work with two HD44780 controllers we need an extra pin to energize the second controller.

Lcd contrast pin is same like fine tuning your television. In televisions we fine tune stations using remote but in character lcd’s we have to manually do it by varying the resistance. Varying the resistance means we control the input current to lcd. Varying resistance will fade or brighten the characters or data appearing on lcd screen.

Character Lcd’s can be interfaced in 8-bit and 4-bit mode with external controllers. In 8-bit mode all the data lines(DB0-DB7) of lcd are utilized. In 4-bit mode only four data pins of lcd are utilized (DB7-DB4). In 4-bit mode first the 8-bit ASCII value is divided in to two nibbles, first the upper nibble is send on data line and then the lower nibble. 4-bit mode is used when we want to save GPIO pins of our external device like microcontoller. An example of lcd connection with remote controller is shown in the picture below.

I prepared a good tutorial on interfacing character lcd in 8-bit and 4-bit mode with microcontrollers. Demo codes are also presented and explained in the post. Click the below button to take the tutorial.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey