ascii lcd display brands

In this case, D500 is the MRR that the OIT has been configured to poll once every 200 milliseconds. When input coil X1 is activated, the controller puts the decimal number 30 into the MRR. The OIT then sees the number 30 in the MRR and Displays Screen #30

Maple Systems OITs can be programmed to send the number representing the screen currently Displayed on the OIT to a register in the controller called the Current Message Register (CMR). The CMR can be used by the controller to determine which screen is currently being Displayed on the OIT, whether Displayed due to MRR, Set Point Limit, Function Key, etc. This might be used to determine which screen an OIT operator sees in a chained sequence.

Clear Alarm is monitored by the OIT to allow the controller to clear the currently Displayed alarm. When the controller sets this coil, the OIT cancels the alarm in progress.

The controller"s discrete and register memory can be monitored, Displayed, and updated by the OIT. This can be done by configuring the OIT"s screens to Display the controller"s discrete and register memory as embedded data fields (register monitors). When the OIT Displays a screen containing a register monitor, the OIT reads the specified memory address in the controller and then Displays the data. If the register monitor has been configured as read/write, when the operator changes the data in the register monitor on the OIT"s Display, the OIT writes the change to the controller"s memory.

In this case, D500 is the MRR that the OIT has been configured to poll once every 200 milliseconds. When input coil X1 is activated, the controller puts the decimal number 30 into the MRR. The OIT then sees the number 30 in the MRR and displays Screen #30

Maple Systems OITs can be programmed to send the number representing the screen currently displayed on the OIT to a register in the controller called the Current Message Register (CMR). The CMR can be used by the controller to determine which screen is currently being displayed on the OIT, whether displayed due to MRR, Set Point Limit, Function Key, etc. This might be used to determine which screen an OIT operator sees in a chained sequence.

Clear Alarm is monitored by the OIT to allow the controller to clear the currently displayed alarm. When the controller sets this coil, the OIT cancels the alarm in progress.

If a limit is exceeded, the associated screen is displayed Set points have a variety of uses: system warnings or alarms, restarting a recipe after a given number of units have been batch processed, or providing the operator with a choice of actions when a trip point has been exceeded.

The controller"s discrete and register memory can be monitored, displayed, and updated by the OIT. This can be done by configuring the OIT"s screens to display the controller"s discrete and register memory as embedded data fields (register monitors). When the OIT displays a screen containing a register monitor, the OIT reads the specified memory address in the controller and then displays the data. If the register monitor has been configured as read/write, when the operator changes the data in the register monitor on the OIT"s display, the OIT writes the change to the controller"s memory.

Select from 20 presets or define your own OITs allow controller"s registers and coils to be displayed or modified using number keys, the Toggle key, and ? + / ? - keys.

OLEDs contain organic compounds made of carbon and other substances to light up (Illuminate) and display characters, icons and graphics in a wide variety of colors that are readable in daylight and nighttime. Since they generate their own illumination, they are called an emissive display.

The word ‘matrix’ just means how the display is driven. Below is a rough drawing of a matrix of pixels. Each pixel is either on or off to generate an image.

Passive displays control/refresh one row at a time. Once that row is refreshed, the control moves to the next row and so on. That means that the rows are on a small percentage of time which limits their size.

The lower the duty cycle, the more time before the display is refreshed, the more power required to illuminate the pixel, and the duller the contrast.

If your display has 5 rows, then you need to make the pixel 5 times brighter which equates to 5 times more power. This increased brightness reduces the display’s half-life.

Half-life is the amount of time in hours for the display to be half as bright as when first turned on. This is not the amount of time for it to burn out, but just to grow dim.

The capacitors increase complexity and therefore, AMOLED’s are more expensive, but requires much less power and can produce larger displays than PMOLED modules.

LCDs can independently control each pixel, but not the brightness of that pixel. The brightness is control by the LED backlight that sits behind all the pixels.

OLEDs offer a much wider viewing angle than TFTS and LCDs (Liquid Crystal Displays). LCDs (FSTN) can provide up to a 120-degree viewing angle, but there will be a viewing bias. That is, one of the four views (top, bottom, left or right) will have the sharpest viewing angle.

Character OLEDs can display letters, numbers and punctuation marks. They contain a controller driver with a built-in character table that reduces programing steps when developing the display’s firmware.

Displaying a letter is as easy as sending the ASCII number to the controller. The controller than draws the letter at the specified location and automatically refreshes each character to maintain a sharp contrast.

OLEDs are an emissive technology, meaning that the characters/segments glow when the display is on. This is also known as a negative mode display meaning the background is dark and the letters/segments are light colored.

Negative mode modules stand out to catch the user’s attention and allow the display to be readable at night but draw additional current than a Liquid Crystal Display.

LCDs do not glow and without a backlight they can operate on as little as 1mA. The addition of a LED backlight is necessary for nighttime operation but will increase current by 15mA to 90mA depending on the number of LEDs and how brightly they are driven.

Graphic OLEDs can display letter, numbers, images, video etc. They use dots (pixels) in a matrix pattern. The dots are turned on and off by the customer’s firm wear.

Graphic displays are identified by the size of the glass that is measured, in inches, along the diagonal. Common sizes include .91”, 1.54”, 2.42” and others.

The resolution of graphic displays is measured by the number of dots along the horizon (X-axis) by the number of dots along the vertical (Y-axis). The more dots, the sharper the contrast. Examples are 320x240, 180x180 etc.

Most people think all OLEDs as a multi-color displays that can generate between 64K to 64M unique colors from the combination of Red, Green and Blue pixels.

But there is a demand for monochrome displays because they produce one color background (normally black for an OLED) and a different color character, normally white for OLEDs but can be other colors.

Monochrome displays produce a sharp contrast that makes it easy them easy to read. Many non-consumer industries such as industrial, construction, test and measurement and even medical applications use monochrome to provide the sharpest image possible.

Enclose the display in something that retains heat. Wind blowing across an unprotected display quickly lowers the temperature that results in poor performance.

One of the oldest, but still best methods to generate heat is to outline the display with ¼ watt, through hole resistors. They generate heat and last many years. One major downside is their power consumption and is not recommended for battery power products.

If you need a very bright, multi-color graphics display, TFTs may be your best option since they can be modified to produce brightness in excess of 1K Nits.

Dark mode is where OLEDs can turn off individual pixels to save power. This is one key power saving advantage that OLEDs have over LCDs (Liquid Crystal Displays). LCDs are not able to turn off an independent pixel.

OLEDs are available in SPI, I2C and 8080 4-bit/8-bit and other interfaces. Many displays will accept more than one interface (bus). SPI is the most popular option though not the best for fast frame rate.

Many medical product incorporate OLEDs since the displays are rigorous and must perform in a demanding environment. These displays are readable in low light and high brightness locations. Their wide viewing angles making them an idea solution for outdoor and indoor environments.Anti-reflective coatings can be applied to improve readability in direct sunlight locations.

OLEDs with low power backlights extend the battery life of the product. They are highly durable to withstand extreme temperature shock and vibration. Handheld products integrating OLEDs include data loggers, instrument displays, handheld meters (measuring anything from light to temperature to gas composition) to handheld thermometers.

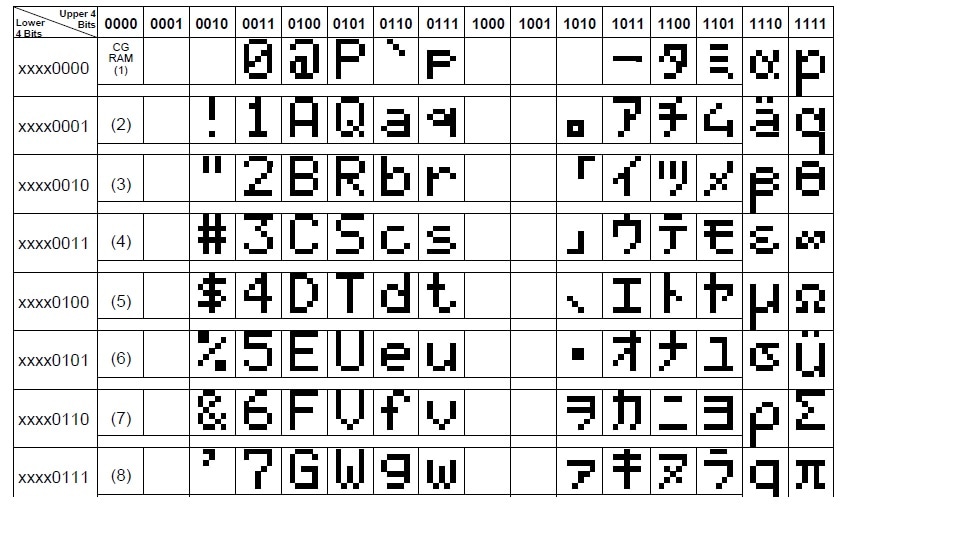

In this tutorial i am going to print/display ASCII characters on 16×2 lcd using pic16f877 microcontroller. Lcd is interfaced with pic microcontroller in 8-bit mode. Code is written in c language. High tech c compiler is used to compile code and code is written in Mp-lab ide. Interfacing 16×2 lcd with pic microcontroller and displaying characters on lcd is very easy. Only the portion which is little bit complex is how to generate/display ASCII characters on lcd. Well you don’t need to generate ASCII characters they are already present in the 16×2 lcd controller (HD44780) Ram, like other characters and numbers. You just need to know how to invoke the ASCII characters to be displayed on the lcd screen.

If you are new in the field of microcontrollers and lcd’s and don’t know about lcd pin out, working and internal structure of lcd then please go through the following tutorials. They will clear you about the working of 16×2 lcd. You will learn how to display characters on lcd? Difference between commands and data send to lcd? It will also explain you about how to use lcd in 4-bit and 8-bit mode.

The circuit diagram of the project is given below. Port-B of Pic16f877 microcontroller is connected with data pins of 16×2 lcd. It means Port-B is used to send commands and data to 16×2 lcd. Lcd control signals(read/write, enable, register select) are provided using individual bits of Port-D. All the other connections are normal connections applying +5 volts to microcontroller and lcd. You can see the circuit diagram given below. Rs(Register select) is connected to Port-D Pin#6. En(Enable) is connected to Port-D Pin#7. Read/Write pin is grounded. Lcd will always remain in write state since we made the R/W pin ground.

Coming to the code portion, I first include the header file htc.h. If you are using high tech c compiler always include this library, this library is necessary to be included in every project that is going to be compiled with high tech c compiler. It contains the compilers directives etc. Then the frequency of the oscillator is defined which is 20 MHz. Then individual pins of Port-D are defined. These pins are used to provide control signals to lcd. delay() function is used to generate some arbitrary delay where necessary. lcdcmd() function is sending commands to lcd with control signals. display() function is sending data to lcd with control signals. lcdint() function is initializing our lcd(8-bit mode, display on ,cursor off etc).

In the main function two instructions are invoking ascii characters. The instructioni=j/10; wherej is integer(int) and i is character(char). Now when we divide two integers and save result in character(char) variable. The result is stored in ascii format. Sincej is 0 and dividing 0 by 10 gives 0. So icontains 0, ASCII value of zero.

The ascii character 0 is present at address 0x30. To go to address 0x00 negate 0x30 from 0x30. The instruction i=i-0x30; is doing the same job. First i contains 0x30 after executing i=i-0x30 i contains 0x00. Hence we are at starting address of ascii characters. Now increment the address one by one and display the ascii character associated with that address on the lcd screen.

Notethat the ascii characters of the HD44780 controller differs from the standard ascii characters. The HD44780 controller contains ascii characters in the format given on the right side. Some addresses are also void. So don’t get confused when you see the characters like below displayed on your lcd screen.

Total digits in ram of 16×2 lcd are 256. So i decided to display them all. It contains ASCII, numeric, alphabet and special characters(Chinese). Some address are void so nothing will display on the lcd screen across these addresses.

We come across Liquid Crystal Display (LCD) displays everywhere around us. Computers, calculators, television sets, mobile phones, and digital watches use some kind of display to display the time.

An LCD screen is an electronic display module that uses liquid crystal to produce a visible image. The 16×2 LCD display is a very basic module commonly used in DIYs and circuits. The 16×2 translates a display of 16 characters per line in 2 such lines. In this LCD, each character is displayed in a 5×7 pixel matrix.

Contrast adjustment; the best way is to use a variable resistor such as a potentiometer. The output of the potentiometer is connected to this pin. Rotate the potentiometer knob forward and backward to adjust the LCD contrast.

A 16X2 LCD has two registers, namely, command and data. The register select is used to switch from one register to other. RS=0 for the command register, whereas RS=1 for the data register.

Command Register: The command register stores the command instructions given to the LCD. A command is an instruction given to an LCD to do a predefined task. Examples like:

Data Register: The data register stores the data to be displayed on the LCD. The data is the ASCII value of the character to be displayed on the LCD. When we send data to LCD, it goes to the data register and is processed there. When RS=1, the data register is selected.

Generating custom characters on LCD is not very hard. It requires knowledge about the custom-generated random access memory (CG-RAM) of the LCD and the LCD chip controller. Most LCDs contain a Hitachi HD4478 controller.

CG-RAM address starts from 0x40 (Hexadecimal) or 64 in decimal. We can generate custom characters at these addresses. Once we generate our characters at these addresses, we can print them by just sending commands to the LCD. Character addresses and printing commands are below.

LCD modules are very important in many Arduino-based embedded system designs to improve the user interface of the system. Interfacing with Arduino gives the programmer more freedom to customize the code easily. Any cost-effective Arduino board, a 16X2 character LCD display, jumper wires, and a breadboard are sufficient enough to build the circuit. The interfacing of Arduino to LCD display is below.

The combination of an LCD and Arduino yields several projects, the most simple one being LCD to display the LED brightness. All we need for this circuit is an LCD, Arduino, breadboard, a resistor, potentiometer, LED, and some jumper cables. The circuit connections are below.

It depends on the exact model of LCD you are using. Or more exactly, on the Dot Matrix Liquid Crystal Display Controller/Driver, like the Hitachi HD44780U that is used in many 16x2 LCD.

In this table, the char "°" is at col 0b1101, row 1111, (0xDF, or 223). But, you have to cast that value to a char before displaying, otherwise you will get the value (223), not the symbol.

Want to display sensor readings in your ESP32 projects without resorting to serial output? Then an I2C LCD display might be a better choice for you! It consumes only two GPIO pins which can also be shared with other I2C devices.

True to their name, these LCDs are ideal for displaying only text/characters. A 16×2 character LCD, for example, has an LED backlight and can display 32 ASCII characters in two rows of 16 characters each.

If you look closely you can see tiny rectangles for each character on the display and the pixels that make up a character. Each of these rectangles is a grid of 5×8 pixels.

At the heart of the adapter is an 8-bit I/O expander chip – PCF8574. This chip converts the I2C data from an ESP32 into the parallel data required for an LCD display.

If you are using multiple devices on the same I2C bus, you may need to set a different I2C address for the LCD adapter so that it does not conflict with another I2C device.

An important point here is that several companies manufacture the same PCF8574 chip, Texas Instruments and NXP Semiconductors, to name a few. And the I2C address of your LCD depends on the chip manufacturer.

So your LCD probably has a default I2C address 0x27Hex or 0x3FHex. However it is recommended that you find out the actual I2C address of the LCD before using it.

Connecting I2C LCD to ESP32 is very easy as you only need to connect 4 pins. Start by connecting the VCC pin to the VIN on the ESP32 and GND to ground.

After wiring up the LCD you’ll need to adjust the contrast of the display. On the I2C module you will find a potentiometer that you can rotate with a small screwdriver.

Plug in the ESP32’s USB connector to power the LCD. You will see the backlight lit up. Now as you turn the knob on the potentiometer, you will start to see the first row of rectangles. If that happens, Congratulations! Your LCD is working fine.

The I2C address of your LCD depends on the manufacturer, as mentioned earlier. If your LCD has a Texas Instruments’ PCF8574 chip, its default I2C address is 0x27Hex. If your LCD has NXP Semiconductors’ PCF8574 chip, its default I2C address is 0x3FHex.

So your LCD probably has I2C address 0x27Hex or 0x3FHex. However it is recommended that you find out the actual I2C address of the LCD before using it. Luckily there’s an easy way to do this. Below is a simple I2C scanner sketch that scans your I2C bus and returns the address of each I2C device it finds.

After uploading the code, open the serial monitor at a baud rate of 115200 and press the EN button on the ESP32. You will see the I2C address of your I2C LCD display.

But, before you proceed to upload the sketch, you need to make a small change to make it work for you. You must pass the I2C address of your LCD and the dimensions of the display to the constructor of the LiquidCrystal_I2C class. If you are using a 16×2 character LCD, pass the 16 and 2; If you’re using a 20×4 LCD, pass 20 and 4. You got the point!

First of all an object of LiquidCrystal_I2C class is created. This object takes three parameters LiquidCrystal_I2C(address, columns, rows). This is where you need to enter the address you found earlier, and the dimensions of the display.

In ‘setup’ we call three functions. The first function is init(). It initializes the LCD object. The second function is clear(). This clears the LCD screen and moves the cursor to the top left corner. And third, the backlight() function turns on the LCD backlight.

After that we set the cursor position to the third column of the first row by calling the function lcd.setCursor(2, 0). The cursor position specifies the location where you want the new text to be displayed on the LCD. The upper left corner is assumed to be col=0, row=0.

lcd.scrollDisplayRight() function scrolls the contents of the display one space to the right. If you want the text to scroll continuously, you have to use this function inside a for loop.

lcd.scrollDisplayLeft() function scrolls the contents of the display one space to the left. Similar to above function, use this inside a for loop for continuous scrolling.

If you find the characters on the display dull and boring, you can create your own custom characters (glyphs) and symbols for your LCD. They are extremely useful when you want to display a character that is not part of the standard ASCII character set.

CGROM is used to store all permanent fonts that are displayed using their ASCII codes. For example, if we send 0x41 to the LCD, the letter ‘A’ will be printed on the display.

CGRAM is another memory used to store user defined characters. This RAM is limited to 64 bytes. For a 5×8 pixel based LCD, only 8 user-defined characters can be stored in CGRAM. And for 5×10 pixel based LCD only 4 user-defined characters can be stored.

After the library is included and the LCD object is created, custom character arrays are defined. The array consists of 8 bytes, each byte representing a row of a 5×8 LED matrix. In this sketch, eight custom characters have been created.

I answered a question from another user a while ago (here) that referenced the following doc: www.cloverlcd.com/pdf/S6A0069.pdf. You can get an idea as to how it may work from that link (at least for that example).

This is not official manufacturer"s information. It is distilled from information on many different data sheets and from my own experience. I have never used some of these displays. I have extrapolated what I know about the displays that I have used to the ones that I have just read about. I welcome any suggestions and corrections. Contact information is at the bottom of the page.

The HD44780 type controller chip is used with a wide variety of Liquid Crystal Displays. These LCDs come in many configurations each with between 8 and 80 viewable characters arranged in 1, 2, or 4 rows.

The problem is that there is no way to inform the controller of the configuration of the display that it is driving. The controller operates exactly the same way for all displays and it is up to the programmer of the device that is controlling the LCD controller (usually a host microcontroller) to deal with this situation.

The controller contains 80 bytes of Display Data Random Access Memory which is usually referred to as DDRAM. When the controller is used with a 40 x 2 display (forty characters on each of two rows) the operation is quite straightforward and that operation will be explained first. Each of the other configurations introduces one or more quirks so it is best to understand the operation of the 40 x 2 before proceeding to the description of the operation of any of the others.

Each of these DDRAM memory addresses corresponds to a character position on an attached display, but the specific position varies depending on the configuration of that display. As part of the initialization sequence the display is cleared by storing the ASCII code for a space in each of the 80 memory locations. Subsequently if a different ASCII code is stored in any of those memory locations then the character corresponding to that ASCII code is automatically displayed at a specific location on the display.

You can tell the controller where you want the first ASCII character that you send it to be stored, this is usually address 00h. After receiving that character it will automatically update its address pointer and put the next ASCII character you send into an adjacent memory location with no more addressing work on your part. You can specify whether to increment or decrement the address counter but normally it is incremented, so the next character will be put into address 01h. The LCD controller automatically accounts for the gap in addresses and after storing an ASCII code in address 27h it puts the next code in address 40h. Similarly it increments from address 67h back to 00h.

Here is a simplified diagram of the display on a 40 x 2 LCD Module. Each of the boxes in the diagram represents a location where a character can be displayed.

Here is a copy of the memory map of the controller. Remember, each of the memory locations in the controller chip is directly associated with one of the character locations on the display.

By some miracle of modern technology there is actually a one for one relationship between these two diagrams. If an ASCII code is stored at address 00h in memory the corresponding character will appear at the left end of the top row of the display. If an ASCII code is stored at address 63h in memory the corresponding character will appear five locations in from the right end of the second row of the display.

Here is a diagram showing how the two rows of the display are mapped into the two lines of memory. It is basically a combination of the two diagrams just above.

When the host controller wants to display a string of characters on the display all it has to do is specify a starting DDRAM address and then start sending the string of ASCII codes corresponding to the desired characters to the LCD controller, one after another. The LCD controller takes the first code that it receives, stores it at the specified address, and simultaneously displays the corresponding character on the display. It then increments it"s internal address counter and stores the next ASCII code that it receives in the next DDRAM location which causes the corresponding character to appear in the next location on the display. As mentioned before the LCD controller automatically accounts for the gap in addresses and after storing an ASCII code in address 27h it puts the next code in address 40h. Similarly it increments from address 67h back to 00h.

This display also has 80 characters, but the relationship between the DDRAM addresses and the character locations on the LCD is not quite as straightforward as the LCD with two rows of 40 characters. Here is a diagram of the device.

The memory map is always the same regardless of the display configuration, but in this drawing I have shown a small space between addresses 13h and 14h on the first line and another between addresses 53h and 54h on the second line.

Here is the same memory map, rearranged this time to show how the memory addresses relate to the character positions on a 20 x 4 LCD. Note how the right half of the previous diagram is now below the left half and note the resulting sequence of starting addresses for each display row (00h, 40h, 14h, 54h).

Remember that the LCD controller still considers this to be two lines of RAM. It is important to understand that this way of picturing the DDRAM addresses helps relate the memory addresses to the character locations but does not change the fact that as far as the controller is concerned there are only two lines of memory. In other words, although this diagram shows the DDRAM differently than before, the actual DDRAM configuration and operation is exactly the same as described above for the 40 x 2 display since there is no way of telling the LCD controller that there are now 4 rows of 20 characters instead of 2 rows of 40 characters.

When a long string of ASCII codes is sent to this LCD controller the action is not quite as simple as for the 40 x 2 display. After the first row is full the characters will continue on to the third row. The normal automatic incrementing from 27h to 40h will then cause the display to continue on the second row, and from there it will continue to the fourth row. After that the following characters will appear back on the first row, and so on.

In order to get a coherent display on sequential rows it is necessary to compensate for the design of the LCD controller when programming the host microcontroller. Basically the program on the host microcontroller can keep track of the DDRAM addresses, and when appropriate it can set up a new starting DDRAM address.

For each of the above displays there are 80 addresses in memory and there are 80 character locations on the display so it should be obvious that any time you send an ASCII code to the controller the corresponding character will show up somewhere on the display. If you mess up the address the character may not show up where you expected it, but it will be visible somewhere. If you work back from where it actually appears you can usually figure out where you made your mistake. All of the displays that follow have fewer character locations on the display than memory addresses in the controller. This makes the operation somewhat more complicated and troubleshooting more difficult.

This can be thought of as a truncated 40 x 2 display, but there are some ramifications of this truncation that may not be readily apparent. Here is a drawing of the device.

It is important to understand that, although this diagram shows only the part of the DDRAM that is normally used to display information on the 20 x 2 LCD, the actual memory map and controller operation is exactly the same as described above for the previous displays. Again that is because there is no way of telling the LCD controller that there are only 40 characters on the attached display.

Here is a drawing of the complete memory map. Note that this drawing is the same as the one for the 20 x 4 display except that the addresses on the right side are greyed out.

Although this display has only 40 characters there are still 80 bytes of DDRAM and they are still configured the same as they were before. The greyed out addresses are the locations in DDRAM that do not have corrresponding locations on the display. Any ASCII codes that are written to those locations are not lost, and it is possible to display them by "shifting" the display window, but in normal use as described here they are simply not displayed.

When a long string of ASCII codes is sent to this LCD controller the action is not quite as simple as for either of the 80 character displays. Assume that the host controller is sending a string of characters as described above. Consider what happens after the LCD controller stores an ASCII code in address 13h and displays the corresponding character at the right end of the top row on the LCD. It then stores the next ASCII code in address 14h, which has no corresponding location on this 20x2 display. As more ASCII codes are sent to the LCD controller they are stored in the DDRAM but do not appear on the display until the LCD controller finally increments it"s address counter from 27h to 40h at which time subsequent characters start to appear on the second row of the display. As far as a viewer of the display is concerned there is a gap of 20 missing characters. The same thing will happen on the second row when ASCII codes are stored in addresses 54h - 67h.

In order to prevent any missing characters the program on the host microcontroller can keep track of the DDRAM addresses, and when appropriate it can set up a new starting DDRAM address. On the other hand the display can be shifted to display those missing characters, but the techniques to do that will not be covered here.

This is a commonly found configuration and its operation is almost identical to that of the 20 x 2. The relationship between the DDRAM addresses and the character locations on the LCD is a subset of the example shown above. Here is a drawing of the device.

Once again it is important to understand that although this diagram shows only the part of the DDRAM that is normally used to display information on the 16 x 2 LCD the actual DDRAM configuration and operation is exactly the same as described above for the 40 x 2 display. This is because there is no way of telling the LCD controller that there are only 32 characters on the attached display.

Here is a drawing of the complete memory map. Note that this drawing is the same as the one for the 20 x 2 display except that a different range of addresses on the right side are greyed out.

The operation of this display when a long string of characters is sent to it is that same as described for the 20 x 2 display except that there is a gap of 24 missing characters at the end of each line (instead of 20).

There are actually two different varieties of 16 x 1 LCD displays and the initialization and operation of each is different so it is important to determine which one you have.

When power is first applied to any of the multi-row LCD modules and before the controller is initialized you will see that the character locations corresponding to the first line of memory are dark and the others are light (assuming that the contrast adjustment is properly set). If you apply power to a 16 x 1 LCD module and only the left 8 character locations are dark you have what I will call a type 1 module. If only the right 8 character locations are dark this is also a type 1 module but it is upside down! If all 16 character locations are dark then it is what I will call a type 2 module. This is my own terminology used only for the purpose of keeping them differentiated while describing their operation. The type 1 modules will have only one IC on the back of the pcb while the type 2 will have 2 (I guess this tidbit gives away the source of my "type" designations). This distinction may apply to newer devices with epoxy blobs instead of ICs, but I believe that sometimes one blob may cover more than one equivalent IC function.

From this you can see that although the display has only a single row of characters, as far as the LCD controller is concerned it is using two lines of memory and it must be considered to be a 2 line device when initializing the controller.

Here is a drawing of the complete memory map. Note that this drawing is the same as the one for the 20 x 2 and 16 x 2 displays except that a different range of addresses on the right side are greyed out.

Here you can see that if the host controller sends a long string of characters without periodically adjusting the DDRAM starting address then after each 8 characters are displayed the next 32 will "disappear".

Also, to display a message of more than 8 characters on the 16 character display the host controller will have to readjust the DDRAM address after displaying the first 8 characters.

Here is a drawing of the complete memory map. Note that this memory map is different than all of the previous ones. This is the only device described here that is a true "one-line" display (see note 2) and as such it has a different memory map.

Here you can see that if the host controller sends a long string of characters after the first 16 characters are displayed the next 64 will "disappear".

At the expense of an extra IC you get some slightly easier programming since, in order to display a message of more than 8 characters on the 16 character display, the host microcontroller does not have to readjust the DDRAM address after displaying the first 8 characters.

Since only one line of memory is in use this LCD module should be configured as a 1-line device. As far as I can determine, this changes the multiplex frequency which changes the display brightness and/or contrast. Also, there are some single row LCDs that are capable of displaying a larger 5x10 font instead of the more common 5x7 font.

Here is the same memory map, rearranged this time to show how the memory addresses relate to the character positions on a 16 x 4 LCD. Note how the center of the previous diagram is now below the left part, the right part is missing, and the resulting sequence of starting addresses for each display row is different than for the 20 x 4 (00h, 40h, 10h, 50h).

Here you can see that if the host controller sends a long string of characters without periodically adjusting the DDRAM starting address then after the first row is full the characters will continue on to the third row. After the third row is full the next eight characters "disappear". The normal automatic incrementing from 27h to 40h will then cause the display to continue on the second row, and from there it will continue to the fourth row. After the fourth row is full the next eight characters will "disappear" and then it"s back to the first row.

The 40 x 4 LCD is treated essentially as two 40 x 2 devices stacked one on top of another in the same glass enclosure. Electrically it uses what amounts to two HD44780 controller chips and it therefore has two separate memory maps each with the same address range. One is used for the top two lines and the other is used for the bottom two lines. The memories are accessed individually by strobing the desired Enable pin of which there are now two. Here is a diagram of the device.

To display a really long string of characters on this display the host controller would start out just like it did for the 40 x 2 display. It would specify a starting DDRAM address (typically 00h) and then start sending the string of ASCII codes corresponding to the desired characters to the LCD controller, one after another, making sure to strobe the enable pin associated with the upper memory bank. After storing an ASCII code in address 67h the LCD controller will automatically increment to address 00h as before and at this time the host controller must stop strobing the enable pin for the upper bank and start strobing the one for the lower bank.

There are other LCD configurations available but I believe that any of them can be handled by a technique similar to one of the examples above. If you have a display that seems to be considerably different from any of these I would like to hear from you.

(1) The mysterious gap is due to considerations resulting from the multiplexing of the display. The DDRAM addressing uses seven bit addressing and the highest bit signifies which row of memory is involved. If you compare the addresses in the first row with those just below in the second row you will see that the only difference is in that one bit.

(2) As implied above the number of rows of characters that can be displayed on the LCD is not the same as the number of lines of memory used by its controller. Only some of the 16x1 displays use "one line" of memory, all of the other displays including most 16x1 displays, use "two lines" of memory.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey