tft lcd backlight engineerign firm brands

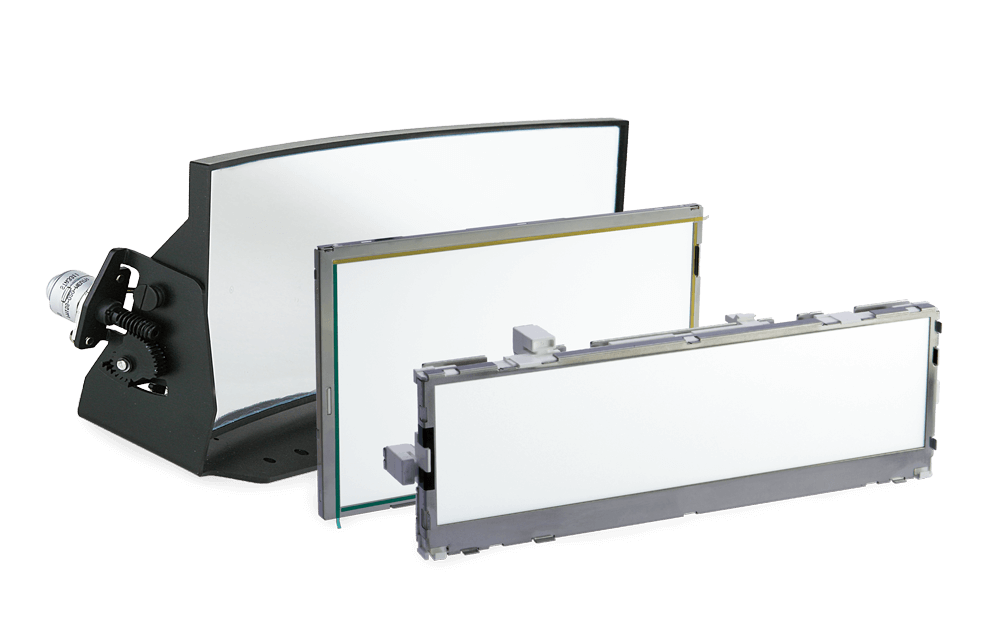

Distributor of component LCDs for equipment which provide high-contrast ratio, color saturation, luminance and performance enhancements such as advanced wide viewing (AWV) for true color fidelity, super-high brightness (SHB) and wide temperature range. Focus on industrial, instrumentation, hand-helds, medical and other low-to-medium volume markets. High-bright LED backlights for outdoor use. LVDS interfaces decrease EMI. Factory installed touch screen solutions. 3.5" to 12.1" QVGA, HVGA, VGA, WVGA, SVGA, XGA, WXGA. Also distributes other related products including LED drivers, lamps, indicators, LED assemblies, segment displays, LED mounts, LEDs, and light pipes. Distributor of electronic components, hardware and fasteners and provides design/value engineering support, fulfillment strategies, procurement services and transactional models to meet specific needs and priorities.

Our new line of 10.1” TFT displays with IPS technology are now available! These 10.1” IPS displays offer three interface options to choose from including RGB, LVDS, and HDMI interface, each with two touchscreen options as capacitive or without a touchscreen.

The new line of 3.5” TFT displays with IPS technology is now available! Three touchscreen options are available: capacitive, resistive, or without a touchscreen.

“Blanview” is Toppan’s unique TFT-LCD technology enabling the display to create high contrast and crisp images even in bright circumstances where a sunlight hit to display surface directly.

With leveraging Toppan’s high-quality amorphous silicon (a-Si) technology “HAST” (Hyper Amorphous Silicon TFT), which has been fostered in our 40-years-long display expertise, Toppan succeeded in generating new type TFT-LCD with a good balance between 2 values - “Sunlight Readable” and “Low Power Consumption”

Transmissive-typeis the most common LCD technology that is widely used in many electrical devices. Transmissive can provide clear images in indoor and dark situations, but meanwhile its display readability gets worse in bright outdoor situations. Backlight power increase can improve the display visibility somewhat, but it lead to boost total power consumption; this may be critical impact to battery-driven handheld devices.

Transflective-typeis suitable LCD technology to outdoor applications. Transflective has pixels divided into 2 areas, Transmission and Reflection area; the reflection area (reflective electrode) takes a role to reflect incident light from outside. This can give a clear display readability as well as low power consumption; however, the panel transmittance (backlight efficiency) becomes rather lower due to a 2-divided pixel structure. As a result, Transflective inherently has a drawback of large power consumption in indoor or dark conditions. Complex pixel structure furthermore cause a problem that a color level changes indoors and outdoors; generally white color tends to gain yellowish outdoors.

Transmissive with high light transmittance can utilize backlight efficiently for good display quality; on the other hand, it has little functionality to make use of incident light from outside. Transmissive eventually is not possible to secure good display visibility in outdoor bright situations, unless increasing backlight (= power consumption increase).

Transflective can reflect more incident light with a large size reflection area (reflective electrode), but meanwhile, its backlight use efficiency rather decreases due to a smaller size of transmission area. Transflective requires to consume lots of power in darker environment.

Blanview succeeds in taking an ideal balance between a reflection of incoming light and high backlight usage efficiency. Toppan realized this unique characteristics by a combination of i) high aperture ratio pixel design and manufacturing technology, ii) optical design optimization (optical films, color filter, etc), and iii) reflective layer layout to the locations where not block a backlight light path.

This unique technology enables us to take a “hybrid use” of backlight and incident light from outside. Blanview succeeded in not only ensuring superior display readability in any situations, but also decreasing total power consumption.

This chart shows backlight power consumption required to secure enough display readability with transmissive LCD, transflective LCD and Blanview LCD respectively.

Blanview TFT-LCD is most appropriate display to electronic equipment, facilities and devices which may be used in “sometimes outdoor, sometimes indoor”. Low-Power-Consumption advantage will extend a battery life of handheld devices.

We have thousands of standard products that are in stock and available from our Seattle, WA and Hong Kong warehouses to support fast product development and preproduction without MOQ. The stock covers TN, STN LCD display panels, COB, COG character LCD display, graphic LCD display, PMOLED, AMOLED display, TFT display, IPS display, high brightness and transflective, blanview sunlight readable display, super high contrast ratio display, lightning fast response displays, efficient low power consumption display, extreme temperature range display, HMI display, HDMI display, Raspberry Pi Display, Arduino display, embedded display, capacitive touch screen, LED backlight etc. Customers can easily purchase samples directly from our website to avoid time delays with setting up accounts and credit terms and shipping within 24 hours.

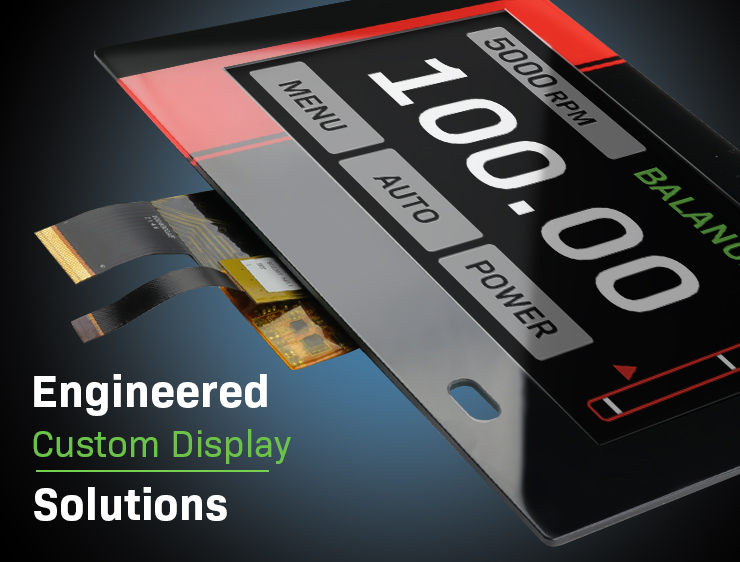

Many of our customers require customized OEM display solutions. With over two decades of experience, we apply our understanding of available display solutions to meet our customer’s requirements and assist from project concept to mass production. Using your ideas and requirements as a foundation, we work side by side with you to develop ideas/concepts into drawings, build prototypes and to final production seamlessly. In order to meet the fast changing world, we can provide the fastest turnaround in the industry, it takes only 3-4 weeks to produce LCD panels samples and 4-6 weeks for LCD display module, TFT LCD, IPS LCD display, and touch screen samples. The production time is only 4-5 weeks for LCD panels and 5-8 weeks for LCD display module, TFT LCD, IPS LCD display, and touch screen.

a line of extreme and ultra-narrow bezel LCD displays that provides a video wall solution for demanding requirements of 24x7 mission-critical applications and high ambient light environments

![]()

One of the things that sets us apart from other touchscreen display manufacturers is the level of customization we offer. Our product portfolio includes a wide range of TFT & Monochrome LCDs, OLED, touch sensor and glass technologies, which we can provide stand-alone or integrated into complete assemblies.

Yeebo Group was established in 1988, and principally has been engaging in developing, manufacturing and marketing of high quality Monochrome LCD and LCD Modules. Yeebo’s products have a strong global presence in key electronic market sectors including Automotive indumenta, Telecommunications, Medical equipment and Electronic consumable products such as Audio, White products, Watches and Electronic notebooks.

Yeebo Group is a publicly held company listed on the Stock Exchange of Hong Kong. With headquarter located in Hong Kong, our manufacturing activities operate with one each LCD manufacturing plant and LCM assembly plant in Jiangmen, Guangdong. Our LCD foundry and LCM assembly facilities are equipped with multiple, highly automated production lines which have latest state-of-the-art equipment to produce ITO coated glass. Lately the group successfully developed OLED, together with Tsinghua University and has invested in Kunshan Visionox Technology Company Ltd. who specialized at OLED manufacturing.

Yeebo Group was established in 1988, and principally has been engaging in developing, manufacturing and marketing of high quality Monochrome LCD and LCD Modules. Yeebo’s products have a strong global presence in key electronic market sectors including Automotive indumenta, Telecommunications, Medical equipment and Electronic consumable products such as Audio, White products, Watches and Electronic notebooks.

Yeebo Group is a publicly held company listed on the Stock Exchange of Hong Kong. With headquarter located in Hong Kong, our manufacturing activities operate with one each LCD manufacturing plant and LCM assembly plant in Jiangmen, Guangdong. Our LCD foundry and LCM assembly facilities are equipped with multiple, highly automated production lines which have latest state-of-the-art equipment to produce ITO coated glass. Lately the group successfully developed OLED, together with Tsinghua University and has invested in Kunshan Visionox Technology Company Ltd. who specialized at OLED manufacturing.

The HMI small touchscreen features 5.7inch backlight LED color TFT LCD display, supports 320 x 240 pixels QVGA resolution. This touch panel screen has 65536 colors with 50,000 hours of backlight lifespan. It supports Korean, Chinese (simplified Chinese), Japanese (ANK, Kanji), ASCII and Taiwanese (traditional Chinese) character fonts. The analogue touch panel with 16 levels brightness provides four viewing angles 60° left, 60° right, 40° top, 60° bottom in horizontal x vertical. Its dimensions are 163mm (width) x 129.4mm (depth). It weighs 0.405kg. It is suitable for use with small machines, HVAC, pumping and packaging applications. The integrated design of Harmony SCU delivers maximum functionality while keeping installation easy. The Harmony SCU (formerly known as Magelis SCU) is designed to operate with the EcoStruxure Machine Expert, delivers adequate functionality for control of small machines.

This product is part of the Harmony SCU range, an offer of HMI controllers from 3.5 to 5.7inch colour screens. The HMI small touchscreen features 3.5inch QVGA backlit LED colour TFT LCD display and supports 320 x 240 pixels resolution. It supports Korean, Chinese (simplified Chinese), Japanese (ANK, Kanji), ASCII and Taiwanese (traditional Chinese) character fonts. It supports 65536 colours with 50000 hours of backlight lifespan. The analogue touch panel with 16 levels brightness provides four viewing angles 60° left, 60° right, 40° top, 60° bottom in horizontal x vertical. Its dimensions are 97.6mm (width) x 80mm (depth) and weighs 0.53kg. The integrated design of Harmony SCU delivers maximum functionality while keeping installation easy. Designed for small machines and simple processes control, its state-of-the-art display provides clear readability. The Harmony SCU (formerly known as Magelis SCU) is designed to operate with EcoStruxure™ Machine Expert. It offers functionality for control of small machines and simple processes, while saving up to 30% in installation and ownership costs.

Take 240*128 graphic LCD module for example. There are 240 dots horizontally, 128 dots vertically. Outer dimension 170.0×93.4 mm and active area 120.0×64.0 mm. When you develop a custom dot matrix LCD module, it can be any length and width, resolution, but it takes a lot of time and great efforts to develop it. The most widely used dot matrix LCD modules with specific sizes were made public and it is very convenient for everyone to get them with no tooling fee. You will not have a lot of options when you choose a graphic LCD module, a custom dot matrix LCD module is still your first choice.

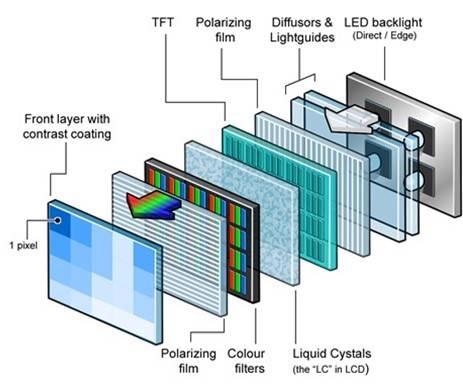

A liquid-crystal display (LCD) is a flat panel display or other electronically modulated optical device that uses the light-modulating properties of liquid crystals. Liquid crystals do not emit light directly, instead using a backlight or reflector to produce images in color or monochrome.

They’re everywhere! In your living room, at the ATM, on your desk, and most especially as part of your automation and control system. Taking form most commonly as LCDs (liquid crystal displays), flat panels have finally made it to the big time, replacing with ever-increasing frequency those bulky, heavy CRTs (cathode ray tubes) with sleek and slender units that boast many benefits beyond being fashionably thin.

LCDs have been around for many years. In fact, the phenomenon of liquid crystals was identified more than 100 years ago. Not until the 1970s, however, did the technology develop to the point of being applied to display products. And only in the past decade have these products begun to proliferate, as quality increases and mass production drives down costs and makes them an attractive choice for both new and replacement human-machine-interface (HMI) applications.

In the 1990s, flat panel computers and monitors were very expensive, observes Bobby Dixon, strategic accounts manager for GE Fanuc Embedded Systems. “We had to explain what an LCD was, why its features were better than a CRT. Now it’s the de facto standard. It used to be difficult to interface an LCD with your electronics. There was little standardization in terms of connectors, types of interface signals, etc. Today, there’s more quality and more consistency.”

Flat panel LCDs offer several benefits over CRT technology. They are lightweight, offer higher resolution, and use about a third of the power of CRT deplays. Touchscreen capabilities are easily incorporated due to the flat nature of digital displays. “Viewing text on a flat panel display is the closest thing you’ll achieve to actually reading printed text on a piece of paper,” observes Jim Muta, engineering manager for Samsung.

Flat panels come in a variety of shapes, sizes, and types. At this time, the most common appears to be the TFT (thin-film transistor), or active matrix LCD using twisted nematic (TN) or super-twisted nematic (STN) technology. Other types include IPS (in-plane switching), MVA (multiple domain vertical alignment), and PVA (pattern multiple domain vertical alignment).

“Each sub-pixel in an LCD is capable of turning on or off ,” explains Muta, “to provide clarity, extremely high contrast, and improved sharpness/focus compared to a CRT. Those features are the driving factors of the flat panel. They substantially improve front-of-screen performance over the CRT. The only area in which CRTs are still superior to flat panels is with motion, in video, and that’s because of their very fast response time.”

LCD front-of-screen performance, or how well a device displays an image, embraces the four primary characteristics—brightness, contrast, viewing angle, and response time—that distinguish one LCD from another. “The demand for front-of-screen performance is becoming more and more of an issue,” says Muta. “Manufacturers are striving for optimum performance in all four areas. Until now, that hadn’t been achieved. There were always tradeoffs. Now all the best attributes of these four factors are finally coming together in a single product.”

Simply, flat panels are easier to see. Explains Dale Maunu, director of channel sales and customer support for Optrex America, “It is easier to control ambient light with an LCD. A traditional CRT is actually spherical. In terms of the optics, if you watch a CRT-based television, a light bulb in the room will be reflected back to the viewer perfectly in the TV screen. Because of its spherical shape, there is always some angle at which the light will be reflected back to the eye. If the glass were truly flat, you’d have to be at a very specific angle for that to happen. The amount of reflection in a flat panel is much less. A viewer, or operator, can more easily find a comfortable place to view the screen.”

Light and lighter Transflective backlighting uses both a backlight and surrounding light to display an image. Portable devices such as color-display cellular phones and PDAs are typically transflective. (Illustration courtesy of GE Fanuc Embedded Systems.)

Front-of-screen performance characteristics are not the only factors influencing the growing popularity of flat panel displays. Progress in backlighting has also been significant. Early flat panels had very short backlight life. Today’s technology offers backlights that last 50,000 hours or more. In addition, backlight replacement kits are typically available and can be retrofit into a display.

Several technologies are available for backlighting an LCD. Common methods include molded light pipes, electroluminescence (EL), fiber optics, and cold cathode fluorescent tubes (CCFT). Some panels have no light source. A reflective display has a mirror to capture and use the surrounding light source, as opposed to transmissive displays that use a backlight. Color cell phones and PDAs are typically transreflective , using both a backlight and surrounding light to display an image (see illustration).

Strong backlighting is one way to overcome sunlight and improve readability. Today, coatings added to the front of the display reduce glare, explains GE Fanuc’s Dixon. “Films inserted inside the display actually make use of sunlight and reflect it back to the display surface, making the image brighter in the sunlight than it would be inside. These measures increase readability without adding heat-generating, power-consuming backlights.”

“What is the longevity of the backlighting?” is a legitimate question to ask when specifying an LCD, suggests Dixon. “Backlighting longevity,” he says, “has increased dramatically.” Adds Shalli Kumar, president and CEO of AVG/EZAutomation, “There are backlight panels that last 100,000 hours and researchers are still looking for more longevity. In 1995, backlight life was around 5,000 hours. Ten years later, minimum life is up to 40,000 hours, a significant increase. To expect more increases is not unrealistic.”

Beyond the panel and backlighting, a flat panel display requires a third element: a method for converting the analog signal from either a PLC or PC to a digital signal that the LCD can understand. “Our controller cards work with just about any flat panel,” says Dusty Perryman, director of sales for Digital View, a manufacturer of flat panel controllers. “Controller manufacturers are typically brand-independent and therefore can provide relatively unbiased information about the best way to drive a flat panel.”

Advantages of an LCD to an HMI are obvious to Perryman. “A CRT is still somewhat cheaper,” he notes, “but the advantages of a flat panel are tremendous. Ability to package an LCD to fit environmental constraints is tremendous.” He cautions, however, scaling images to fit a specific panel is totally different with LCD technology than with CRTs, unless steps are taken to accommodate a change. “A 15-in. LCD with a native resolution of 1,024 by 768 pixels must operate within that resolution to maintain that specified clarity,” he says. “However, we can equip a panel so that one can input a higher resolution, say 1,600 by 1,200 pixels, than the technology on the circuit board is designed for and scale those pixels to fit into the 1,024 by 768 native mode. Such flexibility extends a product’s life span.”

“You can’t mount a CRT on the side of a forklift, but you can put an LCD there,” says Digital View’s Perryman. His words sum up one of the primary reasons for the increasing application of flat panel displays. Adds Rob Rawlyk, application manager at Beckhoff, “The flat panel has freed the HMI system to go where it hasn’t been able to go before. Now we can put a display screen wherever an operator needs one.”

Flat panels have few drawbacks. Their use is already commonplace and continuing to increase. They incorporate the best features of a CRT (fast response time, color uniformity) with the best of the LCD (high clarity, contrast, sharpness). And, the technology is still changing and improving. “We’re seeing panel improvements every couple of years or so in all the critical areas: resolution, viewing angle, brightness, response time,” says AVG/EZAutomation’s Kumar.

Still in the experimental stage, OLED (organic light emitting diode) technology is very expensive and not yet practical. But prototypes have already been built, and Muta expects OLED technology to be an area of growth. “OLED displays will have the look and feel of an LCD,” he predicts, “but we’re a few years away from seeing these devices in the mainstream. You’ll see more activity in LCD backlighting improvement before you’ll see OLEDs on the market.”

Optrex’ Maunu agrees that OLED has a long way to go and forecasts a bright outlook for LCDs. “OLED materials are maturing,” he observes. “We’re seeing 10,000 hour lifetimes now. But there aren’t any good manufacturing tools for making these devices, and according to recent estimates there won’t be any before 2006 or 2007. The volume isn’t there. OLEDs will show up in areas where they make sense, in automotive and some handheld applications. Vendors have some $35 billion invested in LCD TFT technology and production. And LCD technology keeps improving. Performance is getting better and better. Neither vendors nor users are going to walk away from that.”

What is an LCD? Among the most common type of flat panel, the TN TFT LCD is an active matrix technology that provides a clear, sharp image. (Illustration courtesy of Samsung.)

In simplest terms, a liquid crystal display, or LCD, is a light valve. Two sheets of polarizing material sandwich a solution of liquid crystal molecules. An electric current passing through the liquid causes the crystals to align so that light cannot pass through. Manipulating the molecules in this way permits or blocks the passage of light.

There are various types of LCD screens. Among the most common and popular are twisted nematic thin-film transistor (TN-TFT), or active-matrix, technology. Three transistors control every pixel to achieve high-resolution RGB color.

Beyond the screen, every display includes backlighting and a controller. Controller circuit boards convert analog signals from a PLC or PC to a digital signal that the LCD can understand. Backlighting brings the image to the screen surface and may be done in any of a number of ways, among them electroluminescence (EL), molded light pipes, fiber optics, and cold cathode fluorescent tubes (CCFT). Backlighting must be intensely bright, as only a small amount of light—in some cases as little as 6%—finds its way through the panel to the display screen surface. Transmissivity in a typical flat panel is 4% to 8%.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey