multiplexing lcd displays factory

Liquid Crystal Displays or more commonly known as LCDs are one of the most common electronic components which help us interact with an equipment or a device. Most personal portable equipment and even gigantic industrial equipment utilize a custom segment display to display data. For many portable consumer electronics, a segment LCD display is one of the biggest contributors to the overall cost of the device, hence designing a custom segment display can drive the cost down while also utilizing the display area in the most optimum manner. These displays have the lowest cost per piece, low power requirements, and a low tooling fee too.

At first thought, designing a custom segment LCD might look like a Herculean task, but trust me that it is easier than it seems. In this article, we have summarised and compared the display types and available technologies which are required to construct a custom segment LCD. We have also provided a flowchart that can act as a step-by-step guide while you design your own custom LCD. We have also provided the process we followed, a require gathering sheet we used for communicating our needs to the manufacturer, and a few other data and the quotation we received from the manufacturer.

LCD Bias– It denotes the number of different voltage levels used in driving the segments, static drives (explained later in this article) only have 2 voltage levels or 2 bias voltage while multiplex drives have multiple voltage levels. For example, 1/3 will have 4 bias voltages.

LCDs utilizes the light modulating properties of liquid crystals which can be observed by using polarizing filters. Polarizing filters are special materials that have their molecules aligned in the same direction. If the light waves passing through polarisers have the same orientation as the filter, then the molecules of lights are absorbed by the filter, hence reducing the intensity of light passing through it, making it visible.

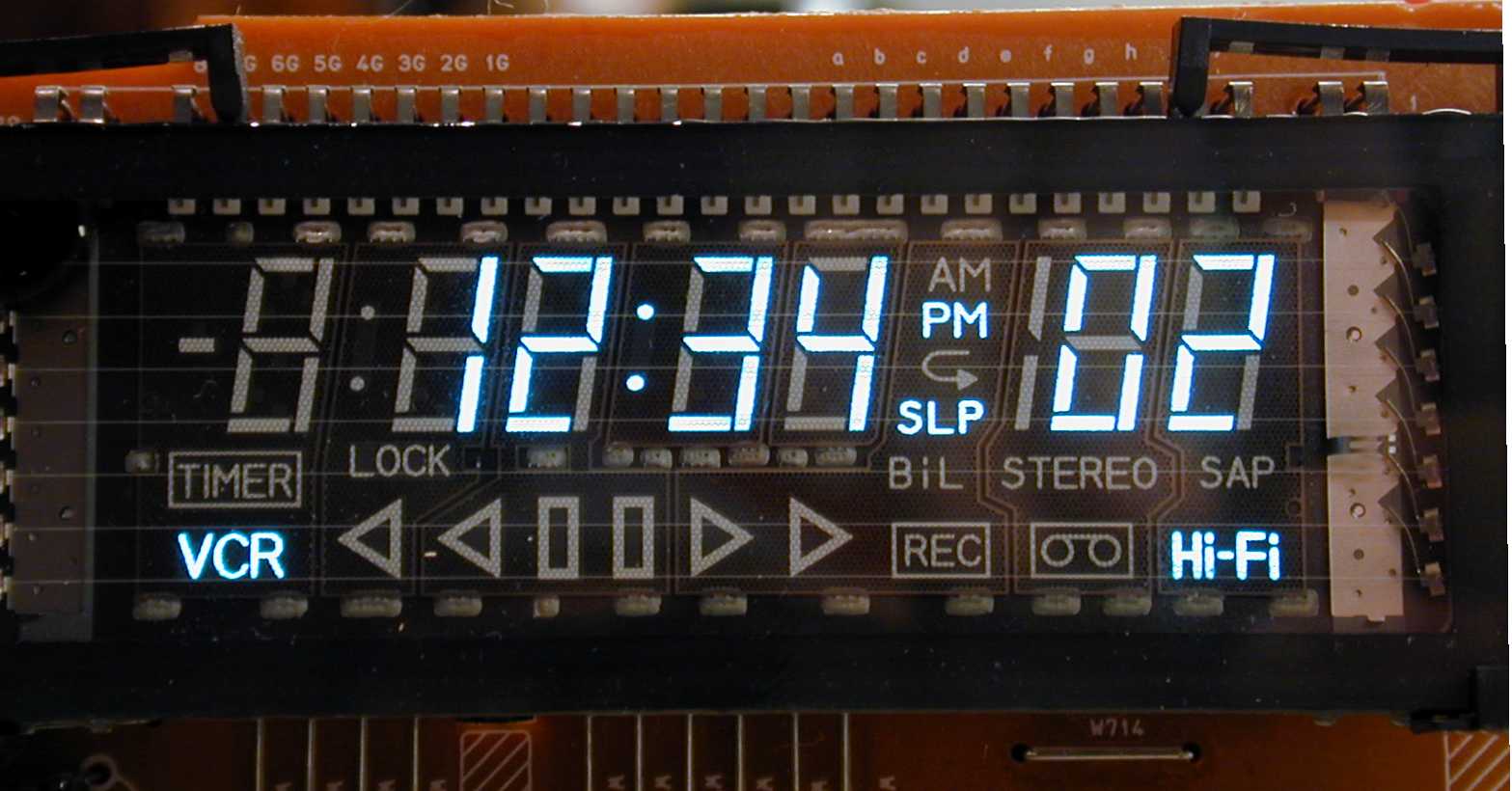

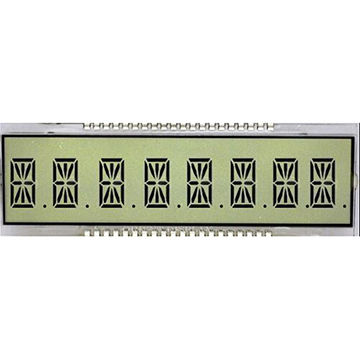

A custom LCD is important for maximizing the efficiency of the display area by adding custom symbols and characters. It also helps in reducing the cost and improving energy efficiency of the product. A higher number of custom symbols and specified placement of numerical and alphanumerical characters make the display more informative and readable for the user. This makes it look better than the plain old boring displays we get in the market. Furthermore, we can specify the viewing angle, contrast, and other specifications which can increase durability or give a better value for money for our intended usage. A typical Custom Segment display is shown below, we will also show you how to design and fabricate the same further in the article.

The LCD display doesn’t emit any light of its own, therefore it requires an external source of illumination or reflector to be readable in dark environments.

While designing a custom segment LCD display, we have the leverage of choosing a lot of parameters that affect the final product. From the color of the display to the illumination technique and color of illumination as well as the type of input pins. Some important considerations we need to take while designing a custom 7 segment display are - the type of display, i.e. positive or negative, illumination method, driving technique, polarising type, and connection method. All these design criteria are explained below:

Positive and negative displays can be easily distinguished by the colour of the background and characters. Some common differences between the positive and negative displays are:

So, which one should you choose? When the displays are to be used in areas with higher ambient light, we should select positive segment LCD display as it has better visibility than negative segment LCD displays without using a backlight.

As we know that LED displays don’t emit any light, hence to illuminate it and make it visible in a dark environment, we can use different methods of illumination. The most common LCD Illumination methods are compared below:

For displays that need to be used for budget-friendly devices that should be small and rugged, LED lights are preferred for the displays due to the high durability and low cost of operations. For high brightness, CCFL and Incandescent lights can be used.

A polarizer film is the most important component of an LCD display, which makes it possible to display characters by controlling the light. There are 3 types of polarizers that can be used in the LCD display, the properties and difference are given below:

Displays can be categorized into two types, passive displays, and active display, passive displays are simpler to construct as they have 2 connections at each segment, the conductors comprise of an Indium Tin Oxide to create an image, whereas the active displays use thin-film transistors (TFT) arranged in a grid. The name is due to its ability to control each pixel individually.

If your displays have fewer segments, then static LCD drive is preferred as it is easier to control and cheaper to construct, and has a better contrast ratio. But let’s say that if the number of segments in the display are more than 30-40 then a multiplex LCD drive should be preferred as it has multiple common pins, hence reducing the total number of pins required to drive the display.

Choosing a connector type!!! For the prototyping phase or if you need to connect your LCD display on a Microcontroller directly, a pin type connector is the best and most economical option you have. If you need to connect your LCD display in a final product with a high volume of production which also requires to be extremely durable, but at the same time should not take up a lot of space, a Flex type LCD Connector will work best for you

LCDs have limited viewing angles and when seen from an angle they lose contrast and are difficult to be observed. The viewing angle is defined by the angles perpendicular to the center of the display towards its right, left, up, and down which are denoted by the notations 3:00, 9:00, 12:00, and 6:00 respectively. The viewing angle of LCD can be defined as the angle w.r.t. to the bias angle at which the contrast of segments is legible.

To improve the viewing angle in an LCD, a Bias is incorporated in the design which shifts the nominal viewing angle with an offset. Another technique is to increase the Voltage, it affects the bias angle, making the display crisper when viewed from a direction.

For example, the viewing angle of a TN type TFT LCD is 45-65 degrees. Extra-wide polarising film (EWP) can increase the viewing angle by 10 degrees, using an O film polariser can make the viewing angles 75 degrees but these come at a cost of reduced contrast.

LCD Control chip or LCD driver chips can be mounted on the flex cable, display, or externally on a PCB. The placement of LCD control chip can affect the cost and size of the display. The 2 most common methods of chip placement are-Chip of Board (COB)and Chip on Glass(COG) which are described below:

We planned to design an air quality monitoring system for which we needed a custom segment LCD panel for an air quality monitoring device. Our product needs to display the following data: 2.5-micron and 10-micron particulate matter (PM) suspended in the air; the units should be in parts per million (PPM). CO2 in the air in PPM along with total volatile organic compounds present in the air in parts per billion (PPB). To make the product more usable, we included time in 24-hour format, Temperature in ºC, Battery status, loudspeaker status, Bluetooth status, and Wi-Fi status. And for some personal touch, we also added how good the air quality in the room is by using 3 different smileys.

We realized that it was impossible to provide all these data in a generic LCD available in the market, thus decided to build a custom LCD for our project.

A step-by-step flowchart is shown below to walk you through each and every step of selecting components and getting your custom segment LCD manufactured.

Usually, the displays are mounted at a height of 4.5 feet from the ground, thus the viewing direction was selected to be 12"O clock with an operating frequency of 64Hz. We selected a Transmissive polarizer for the front glass and a reflective polarizer for the rear glass so that the natural light can pass through the front panel and the display can achieve the maximum contrast without the need for backlighting and we opted for the pin type connectors as they are easy for prototyping and are suitable for harsh environment with a lot of vibrations and shocks which best suited our purpose.

We mailed our requirements to multiple LCD manufacturers, (you will find a lot of LCD manufacturers on the Internet). Most LCD manufacturers have competitive pricing, and reply within a week. A sample requirement sheet is shown above which a customer needs to fill to specify all the details to the manufacturer.

This is a sample Custom Segment LCD quotation we got from one of the manufacturers. As you can see, the cost is based on the quantity. Higher the quantity, lower the cost. Apart from the cost per quantity, there is one more component called tooling fees. Tooling fee is a one-time fee charged by the manufacturer. It is for the technical design, support, and customization of the product. Customization of PCB or tooling of LCD can drive the tooling price higher or lower.

A custom segment LCD can help you personalize your product while also saving the overall cost of your product. The whole process will take you around 2-3 months, which will include the designing phase, prototyping phase, and getting your custom segment LCDs delivered to your doorstep. Higher ordering quantity will reduce the cost per piece of each unit, thus driving down the cost of your final product.

Golden View Display wants you to make an informed choice among our LCD products. The tech center provides you with most of the information you will need to understand liquid crystal displays.

The configuration for Liquid Crystal Display Static Drive technique is that one side of all of the Liquid Crystal Display segments are tied to a common, or backplane, and the other side of each of the segments are routed to individual connection points that are tied to the driver control circuitry. This method uses a large number of interconnects and is not feasible for complex displays, but it does produce the best looking display

LCD’s require an AC drive voltage with virtually no DC component. Segments are controlled by the magnitude of the AC voltage across the LCD segment, but there must always be AC voltage across ALL segments of the LCD. Prolonged DC operation may cause electrochemical reactions inside the displays which will cause significantly reduced life. The initial indications of display degradation because of excessive DC current is a loss of alignment along the edges of some of the characters. The visual indication will be a “fuzzy” appearance of some of the characters.

The TN LCD is an RMS voltage responsive device, that is, the contrast of a given segment is dependent upon the RMS value of the applied voltage across it, measured with respect to the common plane. This fact, which seems obvious now, is very important when discussing drive schemes.

Drive frequencies for direct drive displays are typically between 30Hz and 100Hz. Depending on the display size and design, displays can be operated at higher frequencies, but this will result in increased power consumption. LCDs portray a capacitive load, which reduces the load impedance as frequency increases. However, operation below 30Hz typically results in display flicker

LCD’s can be overdriven by a combination of voltage and frequency, which will result in cross talk or “ghosting”. Ghosting is the appearance or partial activation of an “off” segment. This condition occurs when high drive voltage and frequency are applied. Since the current is directly proportional to the frequency, there is a voltage-frequency product which must not be exceeded. These values are very dependent on the design and layout of any given part, so proper display design and choice of driving conditions is important. It is also very important that all unused segments be connected to the backplane, and not allowed to float.

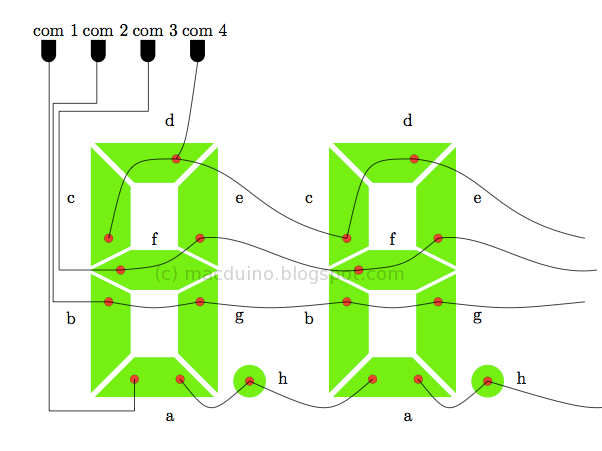

The configuration for Liquid Crystal Display Multiplex Drive technique differs from a Static Drive technique is that it uses more than a single”backplane” or segment common. With this configuration, each segment control line can be connected to as many segments as there are backplanes, providing that each of the segments that it is connected to are tied to a separate backplanes. This method “Multiplexes” each of the segment control lines and minimizes the number of interconnects. This is the method used with complex displays that have limited interconnection surface area or available drive circuits. This reduction in the number of external connections enhances device reliability and increases the potential display density. The liability of a higher multiplex rate will effect display quality, operational temperature range, and the increased complexity of drive circuitry (or perhaps microprocessor software) may necessary for their operation.

The method of drive for multiplexed displays is essentially a time division multiplex with the number of time divisions equal to twice the number of common planes used in a given format. As is the case with conventional LCDs, in order to prevent irreversible electrochemical action from destroying the display, the voltage at all segment locations must be caused to reverse polarity periodically so that zero net DC voltage is applied. This is the reason for the doubling in time divisions: Each common plane must be alternately driven with a voltage pulse of opposite polarity.

As is the case with non multiplexed displays, the drive frequency should be chosen to be above the flicker-fusion rate, i.e. >30 Hz. Since increasing the drive frequency significantly above this value increases current demand by the CMOS drive electronics, and to prevent problems due to the finite conductivity of the display segment and common electrodes, an upper drive frequency limit of 60-90 Hz is recommended.

Segmented LCDs and graphic displays are a popular choice among products such as thermostats, kitchen appliances, medical devices, industrial meters, and more. A segmented LCD is an ideal solution for products that require a customizable cost-effective, low-power display option. Displaytech offers custom 7 segment displays in static or multiplex drive.

Segmented LCDs are monochrome liquid crystal displays where the elements on the panel are divided into segments which can either be visible (on) or hidden (off).

A 7-segment LCD is a cost-effective, low-power display option to use within your product design. At Displaytech, we are here to help you choose the best LCD solution for your product.

Focus Display Solutions offers its LCD design guide series as an online resource for design engineers and product managers. For additional technical journals, visit our LCD Journal page.

As the popularity of 3V, 3.3V and battery powered products increases, so has the demand for smaller, low power LCD modules. Segmented LCD glass continues to be a popular option for its low tooling cost, low MOQ (Minimum Order Quantities) and conservative power budget.

Note: UWVDis an excellent option for a negative mode segment or character LCD display but not for a graphic display. DFSTN is an excellent option for a negative mode dot matrix/graphic module.Q: What is the minimum spacing between segments or icons on a segment LCD Display?

The below photo of a negative mode UWVD LCD. It illustrates a very small gap between the segments of a bar graph. Although this tiny of a gap will allow multiple segments when used on a bar graph configuration, this spacing between numbers or characters can make the display difficult to read.

A: The minimum distance on a segmented LCD can be as little as 1.3mm, but we recommend a buffer of 1.5mm to 2.0mm between the edge of the segment and the edge of ITO (Indium-Tin Oxide) glass.

There are many different display technologies such as LCD, OLED, EPD, and ECD. They are all based on fundamentally different technologies with various driving requirements. That being said, all of them share some basic ideas of how to drive them. In this article, I will explain some fundamentals in display driving. This information is relevant whether you are a professional engineer designing display applications, a hacker exploring seven segment displays for your Arduino projects, or simply if you are just interested in this topic.

There are two main categories of displays; segmented (left picture) or graphical (right picture). In a segmented display, the content on the display has to be predetermined (it can be numbers, seven segment displays, symbols, characters), while a graphical display is generic and can represent any given picture. The segmented displays are generally cheaper (even if they are custom made) while graphical displays offer more flexibility in terms of the content displayed.

Direct drive is a common driving method for segmented displays such as seven segment displays. It is a very simple option where each display segment is connected to a pin. A segment is addressed simply by setting a voltage to the targeted segment. In some cases, this type of display can be driven directly from many microcontrollers, eliminating the need for a dedicated display driver. This, in turn, reduces the cost of the overall system. This is the case for the Rdot display which can be connected to practically any MCU with accurate driving voltage. An advantage with direct drive is the possibility to address all the pixels at the same time. For LCDs, direct drive is the driving method that offers the highest contrast.

To solve the issue with an unreasonable amount of electrodes, the segments, or pixels, has to be arranged in a structure according to the figure below. This can be done with both segmented and graphical displays. For example, addressing pixel 2 (P2) is done by addressing column 2 (C2) and row 1 (R1).

In a passive matrix display, pixels are addressed row by row, this is called time multiplexing. That means that all pixels on row 1 are updated first, then all pixels on row 2, etc.. meaning that for a display with three rows, each row is only addressed ⅓ of the total time. On retro displays, it is sometimes possible to see this effect as a continuous sweeping across the screen. For LCDs, this reduces the contrast of the display which, in turn, limits the total number of rows possible. This method is often called multiplex driving for segmented displays. Passive matrix drive is a cost-effective method to drive displays as it doesn"t require any additional hardware. However, just a few display technologies have the characteristics required for passive matrix drive.

By adding transistors to the pixel, it can more easily be controlled. This is partly because transistors offer a threshold voltage which is an important feature for a display matrix to function properly. A capacitor, on the other hand, functions as an energy storage when the pixel is not addressed. In this way, all pixels can maintain their state even for a large number of rows. The Apple iMac display, for example, can in this way achieve 2880 rows without a problem. The drawback with active matrix is the high price point since the fabrication requires expensive deposition processes. For that reason, active matrix is mainly suitable for high-end displays.

There are two main display types; segmented and graphical. Direct drive is not suitable for graphical displays due to the high number of interconnections between the display and the controller. Matrix drive solves this problem with time multiplexing. There are two types of matrix drive; passive or active. Active drive is only suitable for high-end displays as it is an expensive technology. Passive matrix is a very inexpensive technology, but so far no high-resolution displays based on passive matrix have been demonstrated. Rdot will revolutionize the display industry during 2019 by introducing a passive matrix display that is both flexible and low-cost.

A pixel or segment in an LCD is turned on by an AC voltage applied to it. On a very simple display, such as a 7-segment display, each segment can be driven by its own AC voltage. In such a case there needs to be one connection from the LCD controller to the LCD for each segment. For simple displays with 100 or so segments, this method gives great performance. This is called 1/1 duty cycle, each segment is driven 100% of the time when it is on.

A modest 20×4 character display would require 3200 connections between the LCD controller and the LCD if it were to be driven at 1/1 duty cycle. It is not practical to route that many connections between the controller and the glass.

What is done is called “multiplexing” which combines multiple signals into a single signal and allows pixels or segments to be driven for some fraction of the time. Take the same 20×4 display driven at 1/32 duty cycle and the number of connections comes down to a much more reasonable 132 connections. Essentially, the display is divided into 32 “separate” displays–one per horizontal line. Each line is driven by its AC signal in its turn. That means that each “on” pixel gets driven 1/32 or 3.125% of the time.

TFT is an LCD Technology which adds a thin-film transistor at each pixel to supply common voltages to all elements. This voltage improves video content frame rates. Displays are predominantly utilizing color filter layers and white LED backlighting.

OLED Displays are emissive displays and do not utilize liquid crystal. Each pixel is emissive with light. Passive OLED displays multiplex power and logic through the IC. Active OLED displays add a transistor at each pixel to supply power directly to the pixels and the IC only performs logical functions.

Golden View Display wants you to make an informed choice among our LCD products. The tech center provides you with most of the information you will need to understand liquid crystal displays.

The configuration for Liquid Crystal Display Static Drive technique is that one side of all of the Liquid Crystal Display segments are tied to a common, or backplane, and the other side of each of the segments are routed to individual connection points that are tied to the driver control circuitry. This method uses a large number of interconnects and is not feasible for complex displays, but it does produce the best looking display

LCD’s require an AC drive voltage with virtually no DC component. Segments are controlled by the magnitude of the AC voltage across the LCD segment, but there must always be AC voltage across ALL segments of the LCD. Prolonged DC operation may cause electrochemical reactions inside the displays which will cause significantly reduced life. The initial indications of display degradation because of excessive DC current is a loss of alignment along the edges of some of the characters. The visual indication will be a “fuzzy” appearance of some of the characters.

The TN LCD is an RMS voltage responsive device, that is, the contrast of a given segment is dependent upon the RMS value of the applied voltage across it, measured with respect to the common plane. This fact, which seems obvious now, is very important when discussing drive schemes.

Drive frequencies for direct drive displays are typically between 30Hz and 100Hz. Depending on the display size and design, displays can be operated at higher frequencies, but this will result in increased power consumption. LCDs portray a capacitive load, which reduces the load impedance as frequency increases. However, operation below 30Hz typically results in display flicker

LCD’s can be overdriven by a combination of voltage and frequency, which will result in cross talk or “ghosting”. Ghosting is the appearance or partial activation of an “off” segment. This condition occurs when high drive voltage and frequency are applied. Since the current is directly proportional to the frequency, there is a voltage-frequency product which must not be exceeded. These values are very dependent on the design and layout of any given part, so proper display design and choice of driving conditions is important. It is also very important that all unused segments be connected to the backplane, and not allowed to float.

The configuration for Liquid Crystal Display Multiplex Drive technique differs from a Static Drive technique is that it uses more than a single”backplane” or segment common. With this configuration, each segment control line can be connected to as many segments as there are backplanes, providing that each of the segments that it is connected to are tied to a separate backplanes. This method “Multiplexes” each of the segment control lines and minimizes the number of interconnects. This is the method used with complex displays that have limited interconnection surface area or available drive circuits. This reduction in the number of external connections enhances device reliability and increases the potential display density. The liability of a higher multiplex rate will effect display quality, operational temperature range, and the increased complexity of drive circuitry (or perhaps microprocessor software) may necessary for their operation.

The method of drive for multiplexed displays is essentially a time division multiplex with the number of time divisions equal to twice the number of common planes used in a given format. As is the case with conventional LCDs, in order to prevent irreversible electrochemical action from destroying the display, the voltage at all segment locations must be caused to reverse polarity periodically so that zero net DC voltage is applied. This is the reason for the doubling in time divisions: Each common plane must be alternately driven with a voltage pulse of opposite polarity.

As is the case with non multiplexed displays, the drive frequency should be chosen to be above the flicker-fusion rate, i.e. >30 Hz. Since increasing the drive frequency significantly above this value increases current demand by the CMOS drive electronics, and to prevent problems due to the finite conductivity of the display segment and common electrodes, an upper drive frequency limit of 60-90 Hz is recommended.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey