2.4 tft lcd shield pinout factory

In this tutorial, you will learn how to use and set up 2.4″ Touch LCD Shield for Arduino. First, you’ll see some general information about this shield. And after learning how to set the shield up, you’ll see 3 practical projects.

The role of screens in electronic projects is very important. Screens can be of very simple types such as 7 Segment or character LCDs or more advanced models like OLEDs and TFT LCDs.

One of the most important features of this LCD is including a touch panel. If you are about to use the LCD, you need to know the coordinates of the point you touch. To do so, you should upload the following code on your Arduino board and open the serial monitor. Then touch your desired location and write the coordinates displayed on the serial monitor. You can use this coordination in any other project.

To display pictures on this LCD you should save the picture in 24bit BMP colored format and size of 240*320. Then move them to SD card and put the SD card in the LCD shield. we use the following function to display pictures. This function has 3 arguments; the first one stands for the pictures name, and the second and third arguments are for length and width coordinates of the top left corner of the picture.

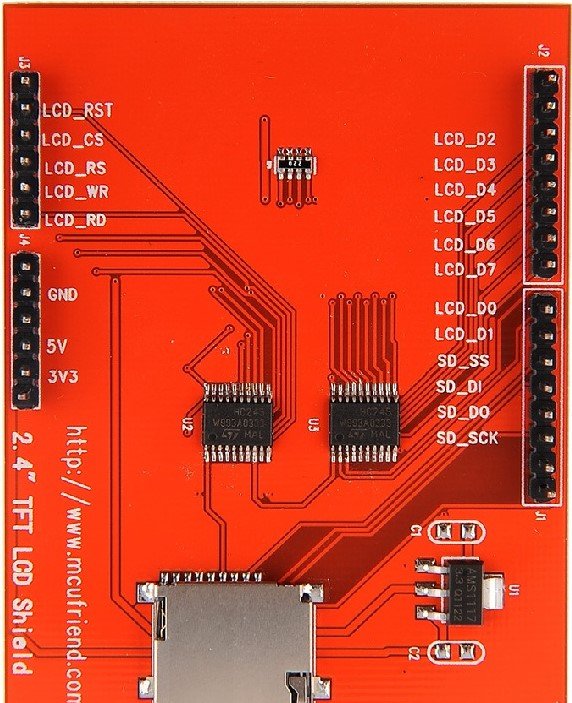

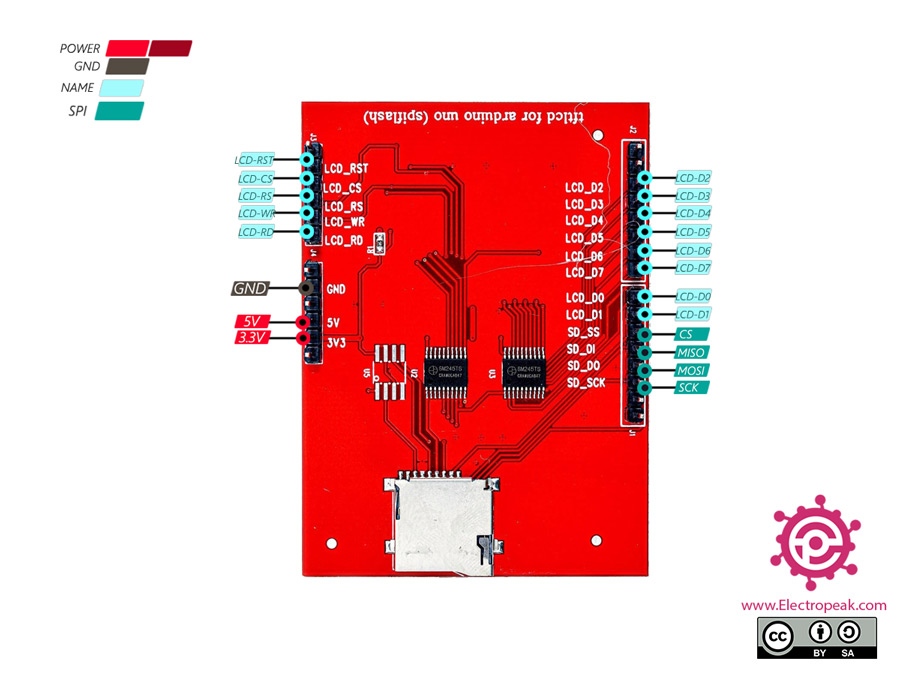

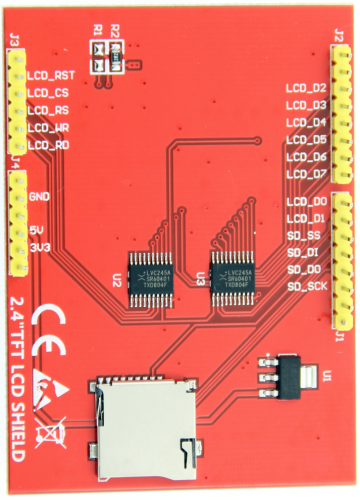

This module is a 2.4-inch TFT LCD module with “320X240” resolution and 65K color display. It is suitable for Arduino Uno and Mega2560 development boards, and also supports SD card expansion function. It uses 8-bit parallel port communication, and the driver IC is ILI9341.

The 2.4-inch display is a ready-made shield for Arduino Uno, which can also be placed on the Arduino Mega. The pins of this shield are designed to be easily installed on the Arduino. The bad point about these modules is that they use all Arduino Uno pins.

The 2.4 ” tft lcd touch screen shield for Arduino can be used in a number of applications. However many of the shields available on the market are cloned versions which usually give many hobbyists hard time to use because they do not work properly with the common libraries for running TFT displays.

If you try uploading any of the examples in the Adafruit_GFX library for example the “graphicstest”, the lcd will just give a white screen. Nothing is displayed on the screen!

This problem is mainly due to using a newer version of the Adafruit GFX library. The 1.5.4 release of the Adafruit_GFX library broke compatibility with the Adafruit_TFTLCD library. So you have to roll back to Adafruit_GFX 1.5.3:

Another problem you may encounter with this tft lcd shield is the poor fuctioning of the touch screen. You may find the stylus pen is not well aligned with the content you are writing on the screen.

You can keep on adjusting the values of before x and y until you get an ideal point that works best for your tft lcd. Mine worked fine with return TSPoint(x, 1105-y, z)

Voltage type: 5v or 3v voltage input voltage,input is selectable. Because TFT can only work under 3.3 V voltage, so when the input voltage VIN is 5V, need through the 3.3 V voltage regulator IC step down to 3.3V , when the input voltage of 3.3 V, you need to use the zero resistance make J2 short , is equivalent to not through the voltage regulator IC for module and power supply directly.

A 2.4” TFT LCD module consists of a bright backlight (4 white LEDs) and a colourful 240X320 pixels display. It also features individual RGB pixel control giving a much better resolution than the black and white displays. A resistive touch screen comes pre-installed with the module as a bonus and hence you can easily detect your finger presses anywhere on the screen.

The TFT comes with an auto-reset circuit which gets active on every breakout. However, a user can reset the module using this pin also, in case setup is not resetting clean.

The TFT comes with an auto-reset circuit which gets active on every breakout. However, a user can reset the module using this pin also, in case setup is not resetting clean.

Resistive Touch Pins – Y+, X+, Y-, and X- are the 4 resistive touch pins which require analog pins to read and determine touch pins. Their overlay is fixed at the top of the module which makes them electrically separate from the TFT. They can be used is 8-bit as well as SPI mode.

The 2.4” TFT LCD module supports many modes. However, two of them are very popular among users – “SPI mode” and “8-bit mode”. The display contains pins on both sides required for a mode and a user can switch easily between them by simply rewiring the display. It should be noted that only one mode can be used at a time.

A 2.4” TFT module has a very flexible usage. It is compatible with all your DIY projects where you want to add a bright, colourful, and touchscreen enabled display.

Spice up your Arduino project with a beautiful touchscreen display shield with built in microSD card connection. This TFT display is 2.4" diagonal and colorful (18-bit 262,000 different shades)! 240x320 pixels with individual pixel control. As a bonus, this display has a optional capacitive touch panel and resistive touch panel with controller XPT2046 attached by default.

The shield is fully assembled, tested and ready to go. No wiring, no soldering! Simply plug it in and load up our library - you"ll have it running in under 10 minutes! Works best with any classic Arduino (UNO/Due/Mega 2560).

This display shield has a controller built into it with RAM buffering, so that almost no work is done by the microcontroller. You can connect more sensors, buttons and LEDs.

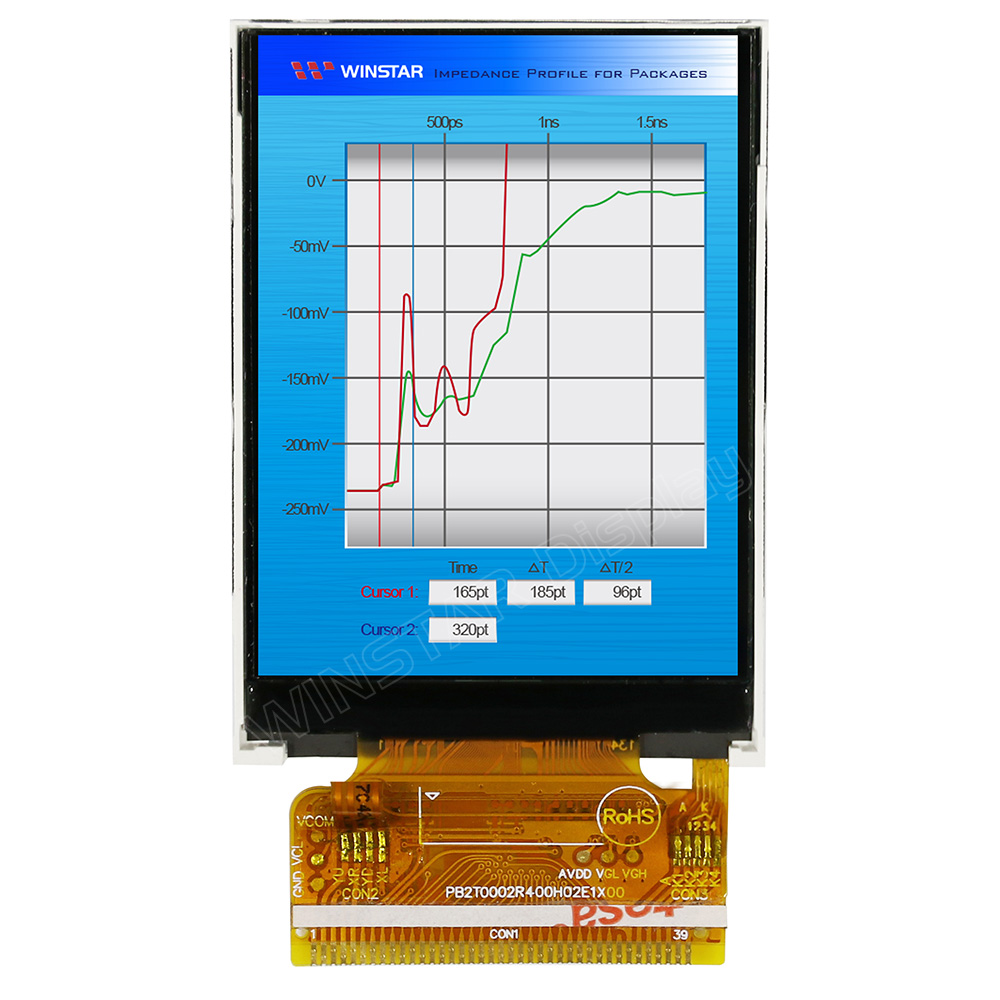

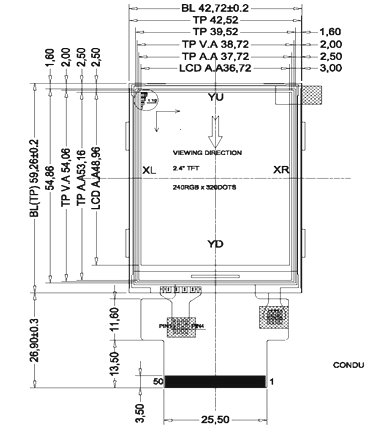

Winstar WF24H is a 2.4 inch diagonal full color 240x320 TFT display module. This 2.4 inch TFT LCD display is built in with ILI9341V IC; it supports 8/16-bit 8080-series Parallel MCU Interface. WF24H model is having module dimension of 42.72 x 60.26 mm and Active area size of 36.72 x 48.96 mm; it integrated ILI9341V controller on module, logic supply voltage range from 2.4V to 3.3V.

This 2.4" TFT LCD module is portrait mode, if you would like to use landscape mode please contact with us for more technical support. This 2.4" TFT Display is featured with brightness up to 500 cd/m2(typical value), it can be operating at temperatures from -20℃ to +70℃; its storage temperatures range from -30℃ to +80℃. It is very suitable for smart home applications, medical devices, portable devices, wearable devices, energy controls, telecoms and data transfers etc.

Search keyword: tft 2.4, tft 2.4", 2.4 tft lcd, 2.4" tft lcd, 2.4 inch tft lcd, tft lcd 2.4, 2.4 tft display, 2.4" tft display, 2.4 inch tft display, tft display 2.4, tft display 2.4"

In this tutorial, you will learn how to use and set up 2.4″ Touch LCD Shield for Arduino. First, you’ll see some general information about this shield. And after learning how to set the shield up, you’ll see 3 practical projects.

The role of screens in electronic projects is very important. Screens can be of very simple types such as 7 Segment or character LCDs or more advanced models like OLEDs and TFT LCDs.

One of the most important features of this LCD is including a touch panel. If you are about to use the LCD, you need to know the coordinates of the point you touch. To do so, you should upload the following code on your Arduino board and open the serial monitor. Then touch your desired location and write the coordinates displayed on the serial monitor. You can use this coordination in any other project./*TFT LCD - TFT Touch CoordinateBased on Librery Examplemodified on 21 Feb 2019by Saeed Hosseinihttps://electropeak.com/learn/*/#include

Displaying Text and Shapes on Arduino 2.4 LCD/*TFT LCD - TFT Simple drivingmodified on 21 Feb 2019by Saeed Hosseinihttps://electropeak.com/learn/*/#include

Displaying BMP pictures/*This code is TFTLCD Library Example*/#include

To display pictures on this LCD you should save the picture in 24bit BMP colored format and size of 240*320. Then move them to SD card and put the SD card in the LCD shield. we use the following function to display pictures. This function has 3 arguments; the first one stands for the pictures name, and the second and third arguments are for length and width coordinates of the top left corner of the picture.bmpdraw(“filename.bmp”,x,y);

Create A Paint App w/ Arduino 2.4 Touchscreen/*This code is TFTLCD Library Example*/#include

Hello, I have a few 2.4" touch screens used to be connected to verious Adruino boards. A little search I found taht they could be used on Pi as well. The trouble is I don"t know which pin on the display goes to which Pi"s GPIO. Whould be nice to have a diagram or chart to indicate that. does anyone knows a goo linke for that? Thanks.

It appears you have an Arduino "shield" version of the display. Arduinos use 5V logic and Raspberry Pis use 3.3V logic. As far as I know, you can"t mix them without level translators. It"s also an 8-bit parallel interface. An RPi could potentially control it, but it"s easier to work with 4-wire SPI displays like this one:

bitbank wrote:It appears you have an Arduino "shield" version of the display. Arduinos use 5V logic and Raspberry Pis use 3.3V logic. As far as I know, you can"t mix them without level translators. It"s also an 8-bit parallel interface. An RPi could potentially control it, but it"s easier to work with 4-wire SPI displays like this one:

This 240x320 resolution LCD TFT is a standard display with 8-bit/16-bit Parallel interface, offering 262K colors and a 6:00 optimal view. This Liquid Crystal Display has a built-in ST7789Vi controller, FFC ZIF I/O connection, is RoHS compliant and does not come with a touchscreen.

Adjust the length, position, and pinout of your cables or add additional connectors. Get a cable solution that’s precisely designed to make your connections streamlined and secure.

The 2.4 inch TFT LCD Touch Display Shield is a Bright, 4 white-LED backlight, on by default but you can connect the transistor to a digital pin for backlight control. So spice up your Arduino UNO project is a beautiful large touchscreen display shield with a built-in microSD card connection. This TFT display is big (2.4″ diagonal) bright (4 white-LED backlights) and colorful (18-bit 262,000 different shades)!

2.4 inch TFT LCD Touch Display Shield for ArduinoUno is fully assembled, tested and ready to go. Add the touch display without wiring, no soldering! Simply plug it in and load up a library – you ‘ll have it running in under 10 minutes! Works best with any classic Arduino ATMEGA328 Board.

The 2.4 inch TFT LCD Touch Display comes with 240×320 pixels with individual pixel control. It has way more resolution than a black and white 128×64 display. As a bonus, this display has a resistive touchscreen attached to it already, so you can detect finger presses anywhere on the screen.

A thin-film-transistor liquid-crystal display (TFT LCD) is a variant of a liquid-crystal display that uses thin-film-transistor technologyactive matrix LCD, in contrast to passive matrix LCDs or simple, direct-driven (i.e. with segments directly connected to electronics outside the LCD) LCDs with a few segments.

In February 1957, John Wallmark of RCA filed a patent for a thin film MOSFET. Paul K. Weimer, also of RCA implemented Wallmark"s ideas and developed the thin-film transistor (TFT) in 1962, a type of MOSFET distinct from the standard bulk MOSFET. It was made with thin films of cadmium selenide and cadmium sulfide. The idea of a TFT-based liquid-crystal display (LCD) was conceived by Bernard Lechner of RCA Laboratories in 1968. In 1971, Lechner, F. J. Marlowe, E. O. Nester and J. Tults demonstrated a 2-by-18 matrix display driven by a hybrid circuit using the dynamic scattering mode of LCDs.T. Peter Brody, J. A. Asars and G. D. Dixon at Westinghouse Research Laboratories developed a CdSe (cadmium selenide) TFT, which they used to demonstrate the first CdSe thin-film-transistor liquid-crystal display (TFT LCD).active-matrix liquid-crystal display (AM LCD) using CdSe TFTs in 1974, and then Brody coined the term "active matrix" in 1975.high-resolution and high-quality electronic visual display devices use TFT-based active matrix displays.

The circuit layout process of a TFT-LCD is very similar to that of semiconductor products. However, rather than fabricating the transistors from silicon, that is formed into a crystalline silicon wafer, they are made from a thin film of amorphous silicon that is deposited on a glass panel. The silicon layer for TFT-LCDs is typically deposited using the PECVD process.

Polycrystalline silicon is sometimes used in displays requiring higher TFT performance. Examples include small high-resolution displays such as those found in projectors or viewfinders. Amorphous silicon-based TFTs are by far the most common, due to their lower production cost, whereas polycrystalline silicon TFTs are more costly and much more difficult to produce.

The twisted nematic display is one of the oldest and frequently cheapest kind of LCD display technologies available. TN displays benefit from fast pixel response times and less smearing than other LCD display technology, but suffer from poor color reproduction and limited viewing angles, especially in the vertical direction. Colors will shift, potentially to the point of completely inverting, when viewed at an angle that is not perpendicular to the display. Modern, high end consumer products have developed methods to overcome the technology"s shortcomings, such as RTC (Response Time Compensation / Overdrive) technologies. Modern TN displays can look significantly better than older TN displays from decades earlier, but overall TN has inferior viewing angles and poor color in comparison to other technology.

The transmittance of a pixel of an LCD panel typically does not change linearly with the applied voltage,sRGB standard for computer monitors requires a specific nonlinear dependence of the amount of emitted light as a function of the RGB value.

Less expensive PVA panels often use dithering and FRC, whereas super-PVA (S-PVA) panels all use at least 8 bits per color component and do not use color simulation methods.BRAVIA LCD TVs offer 10-bit and xvYCC color support, for example, the Bravia X4500 series. S-PVA also offers fast response times using modern RTC technologies.

TFT dual-transistor pixel or cell technology is a reflective-display technology for use in very-low-power-consumption applications such as electronic shelf labels (ESL), digital watches, or metering. DTP involves adding a secondary transistor gate in the single TFT cell to maintain the display of a pixel during a period of 1s without loss of image or without degrading the TFT transistors over time. By slowing the refresh rate of the standard frequency from 60 Hz to 1 Hz, DTP claims to increase the power efficiency by multiple orders of magnitude.

Due to the very high cost of building TFT factories, there are few major OEM panel vendors for large display panels. The glass panel suppliers are as follows:

External consumer display devices like a TFT LCD feature one or more analog VGA, DVI, HDMI, or DisplayPort interface, with many featuring a selection of these interfaces. Inside external display devices there is a controller board that will convert the video signal using color mapping and image scaling usually employing the discrete cosine transform (DCT) in order to convert any video source like CVBS, VGA, DVI, HDMI, etc. into digital RGB at the native resolution of the display panel. In a laptop the graphics chip will directly produce a signal suitable for connection to the built-in TFT display. A control mechanism for the backlight is usually included on the same controller board.

The low level interface of STN, DSTN, or TFT display panels use either single ended TTL 5 V signal for older displays or TTL 3.3 V for slightly newer displays that transmits the pixel clock, horizontal sync, vertical sync, digital red, digital green, digital blue in parallel. Some models (for example the AT070TN92) also feature input/display enable, horizontal scan direction and vertical scan direction signals.

New and large (>15") TFT displays often use LVDS signaling that transmits the same contents as the parallel interface (Hsync, Vsync, RGB) but will put control and RGB bits into a number of serial transmission lines synchronized to a clock whose rate is equal to the pixel rate. LVDS transmits seven bits per clock per data line, with six bits being data and one bit used to signal if the other six bits need to be inverted in order to maintain DC balance. Low-cost TFT displays often have three data lines and therefore only directly support 18 bits per pixel. Upscale displays have four or five data lines to support 24 bits per pixel (truecolor) or 30 bits per pixel respectively. Panel manufacturers are slowly replacing LVDS with Internal DisplayPort and Embedded DisplayPort, which allow sixfold reduction of the number of differential pairs.

Kawamoto, H. (2012). "The Inventors of TFT Active-Matrix LCD Receive the 2011 IEEE Nishizawa Medal". Journal of Display Technology. 8 (1): 3–4. Bibcode:2012JDisT...8....3K. doi:10.1109/JDT.2011.2177740. ISSN 1551-319X.

K. H. Lee; H. Y. Kim; K. H. Park; S. J. Jang; I. C. Park & J. Y. Lee (June 2006). "A Novel Outdoor Readability of Portable TFT-LCD with AFFS Technology". SID Symposium Digest of Technical Papers. AIP. 37 (1): 1079–82. doi:10.1889/1.2433159. S2CID 129569963.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey