silicon display screens quotation

![]()

“Ecstatic technology isn"t limited to silicon chips and display screens. As John Lilly"s early research established, it"s the knowledge of how to tweak the knobs and levers in our brain. When we get it right, it produces those invaluable sensations of selflessness, timelessness, effortlessness, and richness.”

![]()

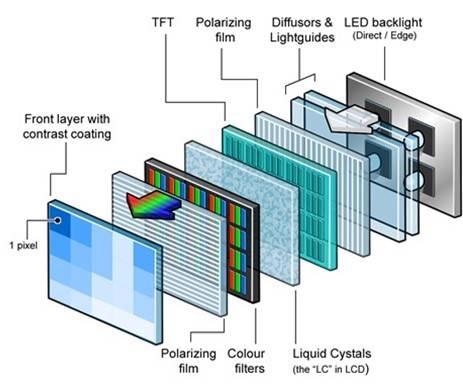

adhesive spacers provide thin liquid-crystal cell gap control <2.5µm with excellent uniformity (±100nm) for glass-on-glass and glass-on-silicon assemblies. The resin is

Some friends rail at the hypocrisy of those interviewed — among them a former executive assistant at Facebook. Others get defensive as they acknowledge that they too have a strict time limit on screens of any kind — despite the nature of their own employment.

When friends compare tricks for avoiding theirs (lock it in a cupboard after 8pm, set the display to greyscale, delete social media apps), I stay out of the conversation. Even so, I took note when the unwelcome weekly iPhone stats showed that I was spending lockdown looking at my phone for more than five hours every day.

Remote work, school and socialising have forced many of us to stare at our screens more than ever — whether we like it or not. Evan Spiegel, co-founder of addictive social messaging platform Snapchat, made headlines two years ago when he told the FT that his young stepson was only allowed an hour and a half of screen time each week. At the recent FT Weekend Festival, he was asked how this policy had fared during the pandemic. Not well, as it turned out.

This sounds like bad news for me — even if I’m not a child aged six to 17. But I’ve accepted constant screens as the price to pay for seeing interesting content. The only thing I plan on turning off is my screen-time notifications.

Digital graphic touch screen overlays transform any large display into a state-of-the-art interactive touch screen and whiteboard. Touch Screen Overlays attach to the front of your existing LCD, TFT, or Plasma display monitor giving it instant touch interaction with your device transforming your display into a Human Machine Interface. Touch Screen Overlays can provide an excellent way to seal your display from dust, particulate contaminants, and moisture ingress up to IP67 with proper design.

In addition to our many product capabilities, at Dyna-Graphics, we provide fully customized touchscreen panel overlays for your interactive touchscreen needs. Our capacitive and resistive touch screen overlay systems allow for complete interactive capabilities with any type of Plasma, TFT, or LCD display monitor.

Touch Screen overlays incorporate sophisticated optical imaging technology and a robust design to provide a durable touch solution perfect for high-traffic public applications. The hard coated plastic overlay preserves the displays optics and protects it from damage or abuse. Touch Screen overlays are easy to install and use, making it easy to take your standard display screen and convert it to touch screen HMI capable. In addition, overlay tough technology is designed with a wealth of features to ensure long-lasting durability and functionality. Give us a call at 800-959-0108 to discuss your project requirements.

Dyna-Graphics utilizes hard coated lenses in all our custom touch screen overlays and panel displays. These lenses enhance incandescent, LED, fluorescent gas, and liquid crystal displays for superior visibility. Light sources can be exposed or totally sealed, as your application requires.

Two options are available for lighted displays: always on, or “dead front” (viewable only when on or activated). Dead front displays can be adjusted for the strength of the light source. We can also install multiple light sources in the same switch panel. We can include individual LEDs, fluorescent gas displays, and digital LED displays, as needed.

The new 8K 3D display from BOE is unique in that the images on the screen can be viewed by multiple people and experienced in 3D from any angle without using any extra equipment. BOE"s new 3D display offers a refresh rate of 120Hz and a 3D viewing distance of 1.5 meters. Part of the technology that BOE utilizes for the monitor is lens array technology that is paired with QD (Quantum Dot) Mini LED backlighting.

PPDS, the global distributing arm of Philips Professional Displays, has unveiled its Tableaux line of zero-power e-Paper displays, according to a press release. Boasting full color, the Android-based system-on-a-chip displays are designed capable of 24/7 content display without being plugged into a power source, aiming at cutting energy use and operating costs while boosting sustainability.

Seoul Viosys has succeeded in improving the brightness of micro-LED displays to 4,000 nits via WICOP Pixel technology. This is deemed to be the highest level in the category of one-chip-based displays. Seoul Viosys will showcase its WICOP Pixel solutions at a separate micro-LED booth in the ISE exhibition center. WICOP Pixel refers to the world’s first full-color one-chip technology characterized by no-wire, no-package, no-lens, and vertically stacked three (RGB) micro-LEDs.

LG’s massive 272″ LG MAGNIT 8K Micro LED is making its debut at ISE. The enormous Micro LED leverages millions of self-emissive micrometre-scale pixels to create images of exceptional vibrancy and depth, while its 8K resolution (7,680 x 4,320) delivers razor-sharp detail. LG MAGNIT 8K also offers impressive colour consistency and a wide viewing angle. LG’s 8K Micro LED also synchronises with 56 Transparent OLED Signage displays, covering both sides of the LG exhibition hall’s entrance.

Coherent announced that it introduced its new HyperRapid NXT industrial picosecond laser, with 10 W of average output power in the deep-ultraviolet (DUV), that enables ultraprecise edge ablation around OLED displays. The new HyperRapid NXT from Coherent is the industry’s first laser-based solution capable of ablating a microscopic channel around OLED displays while leaving adjacent areas intact.

Korean display makers are investing more into high-tech small-scale displays as Apple Inc. has announced that it’ll adopt micro light emitting diodes for its new wrist watches. A microLED is a display technology that uses 100 micrometer- or smaller “micro” LEDs. When placed on a printed circuit board, these tiny LEDs form pixels. They can create natural colors and are reportedly more efficient at high resolutions compared to organic LEDs. The technology enables versatile sizes, shapes or resolutions.

Digital graphic touch screen overlays transform any large display into a state-of-the-art interactive touch screen and whiteboard. Touch Screen Overlays attach to the front of your existing LCD, TFT, or Plasma display monitor giving it instant touch interaction with your device transforming your display into a Human Machine Interface. Touch Screen Overlays can provide an excellent way to seal your display from dust, particulate contaminants, and moisture ingress up to IP67 with proper design.

In addition to our many product capabilities, at Dyna-Graphics, we provide fully customized touchscreen panel overlays for your interactive touchscreen needs. Our capacitive and resistive touch screen overlay systems allow for complete interactive capabilities with any type of Plasma, TFT, or LCD display monitor.

Touch Screen overlays incorporate sophisticated optical imaging technology and a robust design to provide a durable touch solution perfect for high-traffic public applications. The hard coated plastic overlay preserves the displays optics and protects it from damage or abuse. Touch Screen overlays are easy to install and use, making it easy to take your standard display screen and convert it to touch screen HMI capable. In addition, overlay tough technology is designed with a wealth of features to ensure long-lasting durability and functionality. Give us a call at 800-959-0108 to discuss your project requirements.

Dyna-Graphics utilizes hard coated lenses in all our custom touch screen overlays and panel displays. These lenses enhance incandescent, LED, fluorescent gas, and liquid crystal displays for superior visibility. Light sources can be exposed or totally sealed, as your application requires.

Two options are available for lighted displays: always on, or “dead front” (viewable only when on or activated). Dead front displays can be adjusted for the strength of the light source. We can also install multiple light sources in the same switch panel. We can include individual LEDs, fluorescent gas displays, and digital LED displays, as needed.

(A) Schematic description of a transparent display, (B) Calculated cross-section profiles for Si-SiO2 nanoparticles in a periodic structure (nanoparticle radius is 45 nm, the period is 301.7 nm) and (C) Calculated cross-section profiles for Si-SiO2 nanoparticles with random distribution of particles with radius between 40 and 50 nm (Paliks data

Equation (7), shows that the FOM is maximum for minimum absorption cross-section (in the range 390 nm to 750 nm), maximum for high scattering cross section in the desired wavelength and low in other wavelengths. On the other hand, introducing a very sharp scattering profile is critical in transparent monitor design. The numeral 2 used in the denominator is a weighing factor chosen to balance sharp scattering and low absorption. The absolute value of the cross-section per period of the periodic structure is less important here because one can adjust the 2-D density of the nanoparticles on the screen; thus the FOM is defined as a ratio. Also, in order to have a colorless transparent screen, we prefer a flat absorption spectrum. So we use max {σabs} rather than \({\bar{{\sigma }}}_{abs}\). One can also consider imposing a wavelength-dependent weight on the cross-sections to account for the spectral sensitivity of human eyes, but we omit this weight for simplicity. With this definition for FOM, we performed numerical optimizations on the proposed structures of spherical silicon nanoparticles, embedded in a transparent medium of silica. Emission and absorption cross-sections are calculated with the FDTD method, using experimental values of the dielectric function for silica and silicon. Data for the cross-section of structures optimized to scatter monochromatic light at 445 nm (blue), 526 nm (green), and 636 nm (red) and the corresponding particle sizes and FOMs are listed in Table 1.

For comparison between the performances of Si-SiO2 nanoparticles as transparent monitor and Ag nanoparticles (reported by Hsu et al.4 shows, the Si-SiO2 nanoparticles exhibit very sharp emissions compared with Ag nanoparticles in a perfect array, in quasi-array forms, and even in random distribution. Accordingly, the brightness is higher in the display made from Si-SiO2 nanoparticles. At the same time, the Si/SiO2 nanoparticles very probably show better performance than Ag nanoparticles in a transparent display. This can be concluded from the highly dispersive permittivity (Palik data) of the Si-SiO2 nanoparticles compared with the Ag particles (uniform permittivity in visible band). Interference between scattered light is thus very destructive for Si-SiO2 and instructive in the Ag case. Thus, for Si-SiO2, we can expect higher intensity and narrow bands.

Figure 8 represents the indexed powder XRD pattern of the synthesized Si-SiO2 core-shell nanocrystals. The signals at 2ϴ = 28, 47.305, 56.102, and 69.171 can be attributed to silicon in agreement with the JCPDS Card (7440-21-3) for silicon (cubic Fd-3m, a = 5.430 Å). All other signals can be related to SiO2 (hexagonal, P3221, a = b = 4.91344 Å and c = 5.40524 Å)

After characterization of the nanoparticles and considering the mentioned procedure for making a transparent display, nanoparticles in the colloidal form spin-coated on 18 × 18 cm2 glass screen. After drying the polystyrene including nanoparticles on the glass, the following experiments did on it. In the first part, Fig. 15, we examined transparency of the display on white light.

Images of ASEPE logo on the transparent display under illuminations by blue, Green and Red lights are examined. The results declared that the monitor only is excited by the blue light (Fig. 16). As Fig. 16 shows, the contrast of the image in dark media is high; however, in white light (normal ambient light), the image is distinguishable too. In both Green and Red illuminations actually, there is no image on the screen. For a comparison between white paper as a screen and transparent display, we presented an image on white paper too.

(A) Scattering of blue light from the whole transparent screen, (B), projecting OIC logo on transparent display and (C) projecting OIC in white light ambient.

Amorphous Silicon is a highly flexible material that has the potential to be used in solar cells. Its high refractoriness and excellent transmission characteristics make it an ideal material for solar cells. Amorphous silicon can be used in solar cells at a high efficiency rate, and the main component of a p-i-n cell is three layers of p-doped material. Other materials for solar cells include amorphous silicon and n-doped silicon.

Amorphous silicon is a good material for solar cells because it can be shaped to meet the needs of the module. The crystalline silicon is more stable at lower temperatures, while amorphous silicon is more malleable at higher temperatures. However, this material is limited in use in solar cells. The use of Amorphous Silicon in solar cells is becoming more popular. In recent years, more manufacturers are embracing the material as a viable alternative.

In the past few years, researchers have been investigating amorphous silicon for solar cells. They have developed a shunt-free contacting method on non-planar fabrics. Although transmission losses in a 10 nm titanium layer limit the short-circuit current density to 3.7 mA/cm, this material offers a high fill factor, and achieved efficiencies of 1.4%. The use of a transparent conductive oxide in the p-type layer will enable the material to achieve a higher efficiency.

Researchers at Heriot Watt University are also working on amorphous silicon for solar cells. They are developing thin film solar cells on textile substrates, where they can benefit from the scattering properties of the material. Ultimately, these solar cells can be used in disaster relief shelters, agriculture and architecture. For the time being, however, they are only being tested in laboratories. Further research will need to be conducted in this area.

Amorphous silicon thin-film transistors can be fabricated on polyimide foil, which is 25 mm thick and flexible. It is capable of being bent at radii of curvature as small as 0.5 mm without changing its electrical properties. The best performing thin-film transistors are those made of amorphous silicon. Here is a description of how amorphous silicon thin-film transistors work.

Amorphous silicon has many benefits over crystalline silicon. It is cheaper and has more crystalline grains, which make them good candidates for flexible image sensors and flat panel displays. Amorphous silicon can also detect individual X-rays or neutrons. The amorphous nature of amorphous silicon makes it ideal for thin-film transistor elements in LCDs. The deposition process of amorphous silicon makes it possible to fabricate image sensor arrays on plastic substrates.

While amorphous silicon thin-film transistors are a popular choice for liquid-crystal displays and other large-area electronics, they have a number of fundamental limitations associated with their performance. Using plasma-enhanced chemical vapor deposition, for example, is a good way to create large displays. Using this method allows for exceptional reproducibility and uniformity. In addition, engineering solutions are also available to mitigate amorphous silicon"s limitations.

In 1979, the RCA group led by Weimer reported the first pixel switching devices. This breakthrough was not used until material was available for the fabrication of large-area flat panel displays. LeComber and Spear"s experiments were cited as the most important breakthrough in flat panel technology. However, the invention of the amorphous silicon TFT is credited to another RCA group.

Compared to conventional X-ray imagers, amorphous silicon arrays exhibit improved pixel design. They are composed of a continuous layer above the readout structures, and their geometry extends beyond the mesa isolated structure. When used with conversion phosphor, these new imagers offer better sensitivity to X-ray illumination and visible light. However, the current technology has certain drawbacks.

The technology behind X-ray imagers for spherical amorphous silicon is relatively new, but the underlying physics is very similar. Amorphous silicon is an analog of CCD detectors and does not degrade under x-ray exposure. Thus, it is suitable for a wide range of applications, including medical imaging. The advantage of using amorphous silicon is that it is inexpensive, and there are many applications for this material.

Amorphous silicon imagers have improved low-contrast performance compared with amorphous selenium detectors for doses up to 135 uGy. For higher-dose phantoms, the amorphous silicon detector was superior. However, the difference between the two systems was not statistically significant. If you"re looking for an amorphous silicon imager for use in radiology, you"ve come to the right place.

Amorphous silicon imagers are becoming increasingly popular, and this technology is ready for mass production. X-ray imagers for amorphous silicon will enable large-area detectors and be more flexible. Unlike conventional detectors, amorphous silicon is cheaper than crystalline silicon. Its larger size makes it a more cost-effective option in the long run.

Amorphous Silicon liquid crystal displays have several advantages over their glassy counterparts. The lack of crossovers in the array reduces the overall capacitance of the display, making them faster to address. The top and bottom transparent plates are polarized. This polarization is in line with the type of liquid crystal display material 120. This method also improves the overall structure of the display. The result is a more compact display.

The display of the present invention includes an insulative substrate, a first electrode, and a second electrode formed on the insulative substrate. The pixel electrodes are separated by a first isolation device, which is insulated from the first electrode, and are electrically connected to a second electrode formed on the first pixel electrode. The electrodes are in a row and column arrangement, with the second pixel being spaced apart and substantially parallel to the first one. The light-influencing material is disposed between these two electrodes.

In the 1980s, a group of researchers at Dundee University demonstrated the use of amorphous silicon field-effect transistors to switch liquid crystal arrays. They did so while other semiconductor thin film materials were deemed unsuitable for large-area substrates. These results laid the groundwork for the commercial development of flat-panel television displays. The displays will be mounted on an outside wall of the building. A plaque commemorating the development of amorphous silicon liquid crystal displays will be erected on the wall, making it visible to visitors to the campus.

Despite the advantages of Amorphous Silicon liquid crystal displays, they do not have the same drawbacks as the traditional polycrystalline counterparts. Their high sensitivity and low energy consumption make them suitable for most applications. Amorphous silicon is ideal for LCDs and thin-film transistors for the LCD. Amorphous silicon displays have the potential to be more powerful than polycrystalline ones, and are expected to become the most widely used flat-panel displays.

In the past few years, TFT-LCDs made of amorphous silicon have been the focus of research and development. These displays can be extremely thin, which is an excellent fit for mobile phones. Amorphous silicon can be made into thin, flexible panels with an extremely high resolution. However, this technology may not be appropriate for all mobile devices. Some applications are more suitable for thinner displays than others, so a hybrid solution may be the best option.

Amorphous silicon TFT-LCDs operate by controlling the brightness of RGB sub-pixels. Because these pixels do not produce light, they require LED backlights for illumination. Unlike conventional LCDs, TFT screens can be adjusted for nighttime or sunlight readability. In addition, all TFTs are active matrix displays, which means that the individual pixels do not fade while waiting for the next cycle.

Low-temperature Poly-silicon TFT-LCDs have the advantage of being less susceptible to degradation. Moreover, the LTPS technology can reduce the number of components and connections in the LCD by more than half. This technology fosters greater reliability and flexibility. It can also be fabricated on glass substrates, making it an excellent choice for mobile devices. LTPS technology also offers higher resolution and picture quality, as well as lower power consumption and fewer connections.

Amorphous silicon has the same advantages as crystalline-silicon, including low cost and plentiful supply. However, its low electron mobility makes it incompatible for high refresh rates. Currently, new materials, including metal oxide and low-temperature polysilicon, are replacing amorphous silicon for LCDs and OLEDs. Despite its limitations, amorphous silicon remains an excellent option for liquid-crystal displays.

Bertram Gilfoyle, known simply to his group as Gilfoyle, is really an enigma. As the senior security architect for Pied Piper on the HBO series Silicon Valley, he has a highly inflated ego (though he’s able to back it up with stellar work), and he seemingly finds joy in, well, nothing. Except when sparring with Dinesh, that is.

A parody of the bustling tech hub of Silicon Valley, California, the HBO series Silicon Valley, which has aired five seasons to date with a sixth coming in 2020, has captured viewers’ attention for its hilariously exaggerated (but also somewhat realistic) interpretations of what it’s like to work in tech.

One of the hottest and most exciting products for the Visual Merchandising world is (SEG)Silicone Edged Fabric Graphics for Tension Fabric structures. QCI is pleased to offer several different brands of hardware and even more importantly QCI can print and finish stunning high impact graphics for virtually any brand of silicone edged tension fabric structures whether we carry the framing system or not. QCI’s sewing department expertly custom sews silicon edging that easily inserts into the grooves of the tension structure, allowing the fabric graphic to stretch across the frame for a tight wrinkle free fit. QCI combines the brilliant colors of our Dye Sublimation printing technique with this framing system for incredible versatility and high impact appeal. With an impressive range of formats from 2’ x 2’ to 10’ x 40’ the resultant impact on the marketplace has seen a growing accumulation of applications. Please contact our Customer Service Team for more information at 800-543-8883.

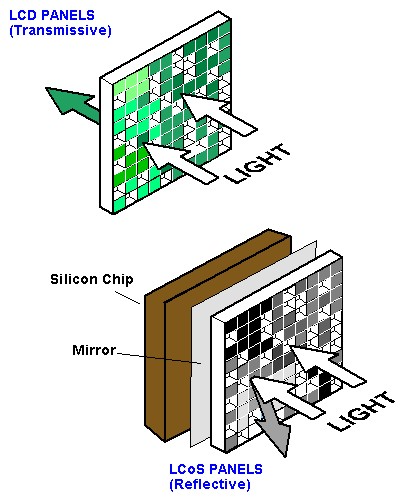

Silicon Micro Display (SMD) is dedicated towards providing low-cost microdisplay component and subsystem solutions for research and product development community. SMD will sustain the low-cost structure by limiting trade-show promotion and dedicated engineering support. Instead, we will rely on open forum inquiries and information exchange to provide the necessary support and improvements. SMD will provide access to continued hardware/firmware upgrades through low annual-maintenance subscription following the first year of support with the initial purchase.

Silicon Micro Display (SMD) was formed in 2009 with the objective of developing highest performing microdisplays for the emerging AR/VR industry. Since introducing the ST1080 head-mounted-display, the world"s first compact head-mounted-display satisfying the visual acuity based on a pair of 1080p Liquid-Crystal-on-Silicon (LCoS) microdisplays at CES 2012, SMD has been committed to developing microdisplay and driver technology to continually satisfy the human visual perception as the field-of-view (FOV) requirement for Near-Eye Displays (NEDs) widens. The result is a 4k UHD native resolution (4096 x 2240) microdisplay and a driver board system fully capable of operating as a color microdisplay in field-sequential-color (FSC) mode.

In 2014, SMD was awarded the Navy Rapid Innovation Fund (RIF) project to develop a low-latency helmet-mounted-display for the domeless fighter jet training system. SMD also has an on-going extended program with the Air Force to develop a compact 4k UHD microdisplay module and driver that satisfies the latency, high-frame-rate, color-break-up reduction, and high-dynamic-range (HDR) support in an effort continue to push the microdisplay technology to meet all aspects of human visual perception.

Currently, SMD is exploring other applications of microdisplay technology while continuing the effort to push the microdisplay backplane technology to go beyond 4k UHD resolution to satisfy the visual acuity requirement for the entire FOV of the human visual system within a manageable bandwidth budget.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey