apple lcd panel manufacturer factory

As Apple mainly relies on Samsung and LG to manufacture its OLED panels for the iPhone, another Chinese factory wants a piece of Cupertino’s company money. As reported by

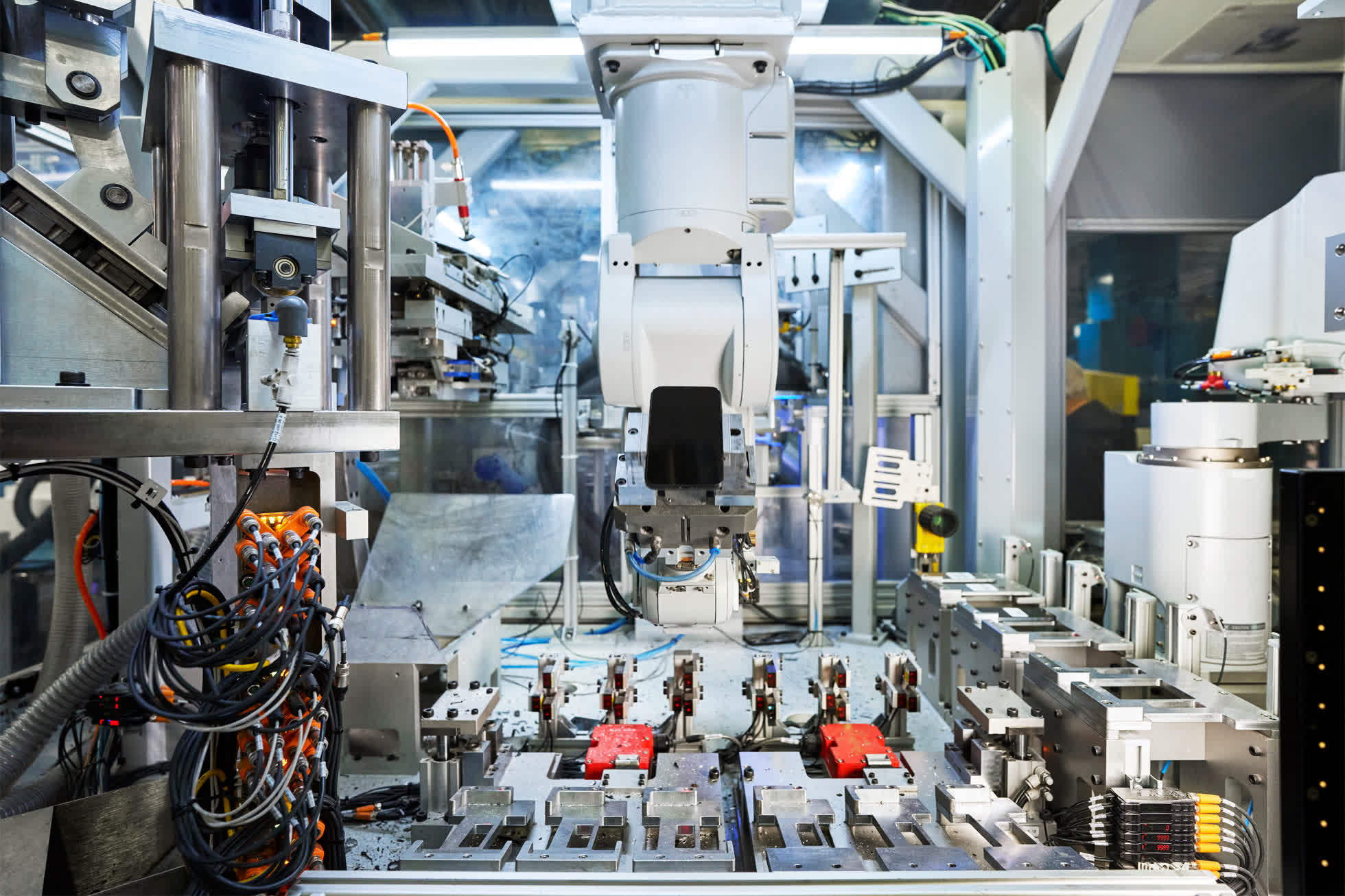

CSOT, together with Apple, first review the OLED panel produced from its T4 factory at Wuhan, China, sources said. The factory is designed to house three phases for a total capacity of 45,000 substrates per month. Two phases are currently live.

As of now, the Chinese company had supplied OLED panels for Samsung’s Galaxy M models in 2021. CSOT will also supply OLED panels for Galaxy A73 this year, The Elecreports.

The publication notes that it won’t be an easy path for CSOT, as China’s largest display panel maker BOE had failed “multiple times in Cupertino’s evaluation processes before finally being able to supply OLED panels to the iPhone maker.”

As 9to5Mac reported earlier this week, BOE, which currently manufactures OLED panels for iPhone 12 and iPhone 13 – and will do the same for this year’s iPhone 14 – will try to supply displays for iPhone 15 Pro as well.

Although Apple has a very high standard on its supply chains, having more options is good. As The Elec notes, “Cupertino can also already use BOE to pressure Samsung Display and LG Display into lowering their unit prices. BOE’s OLED production capacity will also expand to 144,000 substrates per month by the end of this year or early next year, triple that of the maximum capacity at CSOT’s T4 factory.”

The problems faced by tertiary Apple display supplier BOE appear to have gone from bad to worse, according to a new report. The company is now in danger of losing all orders for the iPhone 14.

Too many of the company’s displays were failing to pass quality control checks, and BOE reportedly tried to solve this by quietly changing the specs – without telling Apple …

Chinese display manufacturer BOE was only ever third-placed in Apple’s supply chain, behind Samsung and LG, but was still hoping to make as many as 40M OLED screens this year for a range of iPhone models.

The biggest issue is not with CPUs and GPUs, but far more mundane chips like display drivers and power management systems. These relatively low-tech chips are used in a huge number of devices, including Apple ones.

Yield rates are always a challenge for Apple suppliers, as the company’s specs are often tighter than those set by other smartphone makers. Even Samsung Display, which has the most-advanced OLED manufacturing capabilities, has at times had yield rates as low as 60% for iPhone displays.

The company was caught having changed the circuit width of the thin film transistors on the OLED panels it made for iPhone 13 earlier this year, people familiar with the matter said.

The Chinese display panel sent a C-level executive and employees to Apple’s headquarters following the incident to explain why they changed the circuit width of the transistors.

They also asked the iPhone maker to approve the production of OLED panels for iPhone 14, but didn’t receive a clear response from Apple, they also said.

Cupertino seems poised to give the order for around 30 million OLED panels it intended to give BOE before the incident to Samsung Display and LG Display instead.

The struggling Apple partner was first said to be considering a sale of the plant in 2019 in an effort to pay back its debts to Apple, which funded the construction of the facility with a $1.5 billion "prepayment" to the display maker.

Now, Nikkei reports that Japan Display plans to finalize the deal to sell the factory and the land it occupies to Sharp, a subsidiary of Apple supplier Foxconn. The sale is estimated to be worth about 40 billion yen (about $375 million).

The Hakusan plant, located in the Ishikawa Prefecture of Japan, is equipped to produce LCD smartphone displays. It has been left idle since July 2019, a casualty of Japan Display"s reported lack of preparation for the iPhone"s shift to OLED.

In March, Japan Display was said to have sold about $200 million worth of LCD manufacturing equipment from the facility to a customer believed to be Apple. Nikkei"s report on Thursday suggests that Japan Display has sold a total of $281 million worth of equipment to that customer.

Sharp, for its part, plans to use the facility to consolidate its production of LCD panels for Apple iPhone while renting the manufacturing equipment from Apple. A Sharp facility in Kameyama, Japan, will reportedly shift to producing panels for customers in areas such as automotive or medical equipment. The facility can produce up to 7 million display panels per month.

Japan Display originally planned to sell the plant, that Apple assisted build by pre-funding it for 170 billion yen, by the end of March, but the global coronavirus pandemic snarled negotiations.

In total, the sale of the factory to Sharp and equipment to the unnamed customer could net Japan Display about 70 billion yen. As of March 2020, Japan Display was said to still owe about $800 million to Apple.

While Samsung will continue to supply approximately 80 per cent of iPhone displays, rumours claim that a little-known company called BOE looks set to become Apple’s second-largest OLED supplier. Not only is this a sign that Apple’s lowest-cost iPhone 12 model will likely make the leap from LCD to OLED this year, but it’s also a sign that Apple is looking to diversify which manufacturers it uses, and potentially looking to ready itself for a move into the display market itself.

You, like many of us when we first read the rumours, are probably wondering who the hell BOE is, and how it managed to score such a big deal despite its relatively unknown status. However, BOE is, in fact, the largest display manufacturer in China, supplying screens for smartphones, TVs and other electronic devices and home appliances.

The company, which was founded in Bejing in 1993 and acquired SK Hynix"s STN-LCD and OLED businesses back in 2001, is ranked second in the world when it comes to flexible OLED shipments, holding a market share of 11 per cent during the first quarter of this year. It, naturally, is still a long way behind market leader Samsung, which owned 81 per cent market share of the OLED market in the same quarter. Still, with a sizable chunk of the OLED market already under its belt, it perhaps won’t come as too much of a surprise – now, at least – that the firm already has some big-name allies.

BOE’s display technology is currently being utilised in Huawei"s most popular smartphone models, including the high-end P and Mate series, and it reportedly will manufacturer the palm-stretching screen set to appear on this year’s Huawei Mate 40.

BOE’s surprising alliance with Apple isn’t the only time the two companies have worked together, either; the Chinese manufacturer already makes LCD screens for Apple"s older iPhones, and its tiny OLED panels are currently used in some Apple Watch models. It’s unclear how much BOE and Apple’s latest deal is worth, but it’s likely in the billions. According to online reports, Samsung’s deal with the iPhone maker is thought to be worth around $20 billion annually, so if BOE manages to secure 20 per cent of Apple’s display orders going forward, such a deal could be worth as much as $4bn.

Although BOE has managed to muscle its way into Apple’s exclusive list of OLED suppliers, and has invested heavily in facilities and equipment in order to meet the firm’s demands, the new partnership hasn’t got off to a flying start. According to reports, the company’s flexible OLED panels have not yet passed Apple’s final validation. This means, according to rumours, that BOE’s screens might not show up in the first batch of iPhone 12 models, and will instead start shipping on handsets at the beginning of 2021, with Apple instead set to re-increase its reliance on LG in the short term.

Scenarios like this, along with the fact that Apple is clearly looking to lessen its reliance on big-name display makers, makes us think that it won’t be long until the company ultimately stops relying on others altogether; after all, it’s no secret that Apple wants to control every aspect of its hardware development.

The display market could be Apple’s next target. Not only does the company already manufacturer screen technology in the form of its Pro Display XDR, but a recent Bloomberg report claims that Apple is “designing and producing its own device displays” and is making a “significant investment” in MicroLED panels. This technology utilises newer light-emitting compounds that make them brighter, thinner and less power-intense than the current OLED displays.

Apple’s efforts in MicroLED are reportedly in the “advanced stages”; the company has applied for more than 30 patents, and recent rumours suggest the firm is also considering investing over $330 million in a secretive MicroLED factory with the goal of bringing the technology to its future devices.

Chinese display manufacturer Beijing Oriental Electronics (BOE) could lose out on 30 million display orders for the upcoming iPhone 14 after it reportedly altered the design of the iPhone 13’s display to increase yield rate, or the production of non-defective products, according to a report from The Elec (via 9to5Mac).

Apple tasked BOE with making iPhone 13 displays last October, a short-lived deal that ended earlier this month when Apple reportedly caught BOE changing the circuit width of the iPhone 13’s display’s thin-film transistors without Apple’s knowledge. (Did they really think Apple wouldn’t notice?).

This decision could continue to haunt BOE, however, as Apple may take the company off the job of making the OLED display for the iPhone 14 as well. According to The Elec, BOE sent an executive to Apple’s Cupertino headquarters to explain the incident and says it didn’t receive an order to make iPhone 14 displays. Apple is expected to announce the iPhone 14 at an event this fall, but The Elec says production for its display could start as soon as next month.

In place of BOE, The Elec expects Apple to split the 30 million display order between LG Display and Samsung Display, its two primary display providers. Samsung will likely produce the 6.1 and 6.7-inch displays for the upcoming iPhone 14 Pro, while LG is set to make the 6.7-inch display for the iPhone 14 Pro Max.

According to MacRumors, BOE previously only manufactured screens for refurbished iPhones. Apple later hired the company to supply OLED displays for the new iPhone 12 in 2020, but its first batch of panels failed to pass Apple’s rigorous quality control tests. Since the beginning of this year, BOE’s output has also been affected by a display driver chip shortage.

Foxconn, one of the electronics manufacturers that makes Apple"s iPhones, revealed plans today to build a factory in Wisconsin to produce flat-screen displays. Foxconn"s total investment in the Wisconsin factory amounts to $10 billion, more than the original $7 billion that Foxconn had been talking about investing in US manufacturing since Donald Trump took office as President. The factory will create at least 3,000 jobs and upwards of 13,000 jobs, as well as up to 22,000 induced jobs in other parts of Wisconsin. President Trump praised the deal at the press event, claiming it was a win for anyone who "believes in the label "Made in the USA.""

Foxconn will build flat-screen LCD display panels at the new factory under the Sharp brand, which the company bought in 2016 for $1.5 billion. At the press event, Gou and Governor Walker emphasized LCD display manufacturing for the automotive, healthcare, and other industries, rather than OLED display manufacturing.

Currently iPhones still use LCD displays, which means the Wisconsin factory could potentially provide LCD panels for those handsets. However, Sharp President Tai Jeng-wu has suggested in the past that Apple could use OLED displays in the future. There have also been rumors of OLED displays being used in forthcoming iPhone 8 models, but nothing has been confirmed. Currently there"s no official word that any panels made in the new Wisconsin factory will be used in Apple products going forward.

Don"t expect Apple to fully produce iPhones in the US anytime soon either. President Trump announced this week that Apple plans to build three "big" manufacturing plants in the US, but Apple did not announce that with him, nor did the company comment publicly on that notion. There are a number of incentives keeping iPhone production in China, including tax breaks and subsidies. Even if the incentives provided to Foxconn in Wisconsin are a step in a new direction, much more negotiation and work would need to be done before iPhones or any Apple products are completely "made in the USA."

Flat-panel displays are thin panels of glass or plastic used for electronically displaying text, images, or video. Liquid crystal displays (LCD), OLED (organic light emitting diode) and microLED displays are not quite the same; since LCD uses a liquid crystal that reacts to an electric current blocking light or allowing it to pass through the panel, whereas OLED/microLED displays consist of electroluminescent organic/inorganic materials that generate light when a current is passed through the material. LCD, OLED and microLED displays are driven using LTPS, IGZO, LTPO, and A-Si TFT transistor technologies as their backplane using ITO to supply current to the transistors and in turn to the liquid crystal or electroluminescent material. Segment and passive OLED and LCD displays do not use a backplane but use indium tin oxide (ITO), a transparent conductive material, to pass current to the electroluminescent material or liquid crystal. In LCDs, there is an even layer of liquid crystal throughout the panel whereas an OLED display has the electroluminescent material only where it is meant to light up. OLEDs, LCDs and microLEDs can be made flexible and transparent, but LCDs require a backlight because they cannot emit light on their own like OLEDs and microLEDs.

Liquid-crystal display (or LCD) is a thin, flat panel used for electronically displaying information such as text, images, and moving pictures. They are usually made of glass but they can also be made out of plastic. Some manufacturers make transparent LCD panels and special sequential color segment LCDs that have higher than usual refresh rates and an RGB backlight. The backlight is synchronized with the display so that the colors will show up as needed. The list of LCD manufacturers:

Organic light emitting diode (or OLED displays) is a thin, flat panel made of glass or plastic used for electronically displaying information such as text, images, and moving pictures. OLED panels can also take the shape of a light panel, where red, green and blue light emitting materials are stacked to create a white light panel. OLED displays can also be made transparent and/or flexible and these transparent panels are available on the market and are widely used in smartphones with under-display optical fingerprint sensors. LCD and OLED displays are available in different shapes, the most prominent of which is a circular display, which is used in smartwatches. The list of OLED display manufacturers:

MicroLED displays is an emerging flat-panel display technology consisting of arrays of microscopic LEDs forming the individual pixel elements. Like OLED, microLED offers infinite contrast ratio, but unlike OLED, microLED is immune to screen burn-in, and consumes less power while having higher light output, as it uses LEDs instead of organic electroluminescent materials, The list of MicroLED display manufacturers:

LCDs are made in a glass substrate. For OLED, the substrate can also be plastic. The size of the substrates are specified in generations, with each generation using a larger substrate. For example, a 4th generation substrate is larger in size than a 3rd generation substrate. A larger substrate allows for more panels to be cut from a single substrate, or for larger panels to be made, akin to increasing wafer sizes in the semiconductor industry.

"Samsung Display has halted local Gen-8 LCD lines: sources". THE ELEC, Korea Electronics Industry Media. August 16, 2019. Archived from the original on April 3, 2020. Retrieved December 18, 2019.

"TCL to Build World"s Largest Gen 11 LCD Panel Factory". www.businesswire.com. May 19, 2016. Archived from the original on April 2, 2018. Retrieved April 1, 2018.

"Panel Manufacturers Start to Operate Their New 8th Generation LCD Lines". 대한민국 IT포털의 중심! 이티뉴스. June 19, 2017. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"TCL"s Panel Manufacturer CSOT Commences Production of High Generation Panel Modules". www.businesswire.com. June 14, 2018. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"Samsung Display Considering Halting Some LCD Production Lines". 비즈니스코리아 - BusinessKorea. August 16, 2019. Archived from the original on April 5, 2020. Retrieved December 19, 2019.

Herald, The Korea (July 6, 2016). "Samsung Display accelerates transition from LCD to OLED". www.koreaherald.com. Archived from the original on April 1, 2018. Retrieved April 1, 2018.

"China"s BOE to have world"s largest TFT-LCD+AMOLED capacity in 2019". ihsmarkit.com. 2017-03-22. Archived from the original on 2019-08-16. Retrieved 2019-08-17.

Nowadays, LCD panels for smartphone displays are taking the back seat while tech companies move towards OLED screens, including Apple. Samsung Display, one of Apple’s suppliers for iPhone, iPad and Apple Watch displays, announced today that it is going to end LCD production in its China-based and South Korean factories by the end of 2020.

Reuters now reports that Samsung is moving on with its factories, but will still supply LCD display orders until the end of the year. The company has two LCD production lines in South Korea and two LCD-dedicated factories in China.

The production of LCD displays by Samsung has already been in decline since last year, as demand for LCD screens is continuously decreasing. In October, Samsung closed one of its LCD production lines in South Korea. Additionally, the company stated that it will invest around $10.72 billion in research and improvements for their production lines of quantum dot screens.

Samsung Display is once again dominating the panel shipment for iPhones, reported Ross Young from DSCC (Display Supply Chain Consultants). According to internal info, Apple procured 82% of panels from Samsung, 12% from the Korean company LG Display and the other 6% from the Chinese BOE.

The iPhone 14 Pro Max units will have only Samsung panels at the beginning, the report revealed. Apparently, LG is struggling to keep up with the demand and has “technical challenges”, and will begin providing screens as early as September.

The Chinese maker BOE is on the other end - it is capable of manufacturing in great volumes but Apple has limited the purchases to the iPhone 14 series, with no Pro in sight. Samsung’s share is similar to what it was in the iPhone 13 series when it provided 83% of all panels.

Detailed info from Young, shipments from display factories to assembling plants were 1.8 million in June, 5.35 million in July, over 10 million in August and over 16.5 million in September. This means Apple is preparing to have at least 34 million units for the first three months of iPhone 14 sales.

We have thousands of standard products that are in stock and available from our Seattle, WA and Hong Kong warehouses to support fast product development and preproduction without MOQ. The stock covers TN, STN LCD display panels, COB, COG character LCD display, graphic LCD display, PMOLED, AMOLED display, TFT display, IPS display, high brightness and transflective, blanview sunlight readable display, super high contrast ratio display, lightning fast response displays, efficient low power consumption display, extreme temperature range display, HMI display, HDMI display, Raspberry Pi Display, Arduino display, embedded display, capacitive touch screen, LED backlight etc. Customers can easily purchase samples directly from our website to avoid time delays with setting up accounts and credit terms and shipping within 24 hours.

Many of our customers require customized OEM display solutions. With over two decades of experience, we apply our understanding of available display solutions to meet our customer’s requirements and assist from project concept to mass production. Using your ideas and requirements as a foundation, we work side by side with you to develop ideas/concepts into drawings, build prototypes and to final production seamlessly. In order to meet the fast changing world, we can provide the fastest turnaround in the industry, it takes only 3-4 weeks to produce LCD panels samples and 4-6 weeks for LCD display module, TFT LCD, IPS LCD display, and touch screen samples. The production time is only 4-5 weeks for LCD panels and 5-8 weeks for LCD display module, TFT LCD, IPS LCD display, and touch screen.

Apple has begun considering new OLED display designs from manufacturer BOE Technology for its iPhone 14 display, as per a report by The Elec. The tech giant had earlier suspended orders from the Chinese manufacturer owing to the unauthorised design changes the company is said to have made to the displays, which ended on millions of iPhone 14 OLED screen orders to be scrapped. BOE had reportedly faced some production issues earlier in February 2022 also and the unauthorised manufacturing change caused Apple to ultimately suspend the orders it had placed with the Chinese electronic component maker.

Now, BOE is reportedly ready with new samples of the iPhone 14 display design and Apple is said to evaluate them this week. The ultimate decision on whether or not to finalise the new design could take place this month itself which means that production could start by July or August, added the report. The report also said that Apple will currently evaluate the new display samples only for the iPhone 14 base model and not the Pro models.

Earlier, BOE is said to have "expanded the circuit width of the thin-film transistor" used in the panels for the iPhone 13 orders it received, without Apple’s knowledge.

Among the world famous brands, the screen of South Korea"s samsung and LG is known to be produced and sold by themselves.Display screens of other niche brands, and those brands capable of self-production and self-marketing, also have an unassailable position in their own segments, facing various brands.For buyers, how to find suitable suppliers from these LCD panel manufacturers?

The world-renowned LCD panel production line is mainly controlled by several enterprises: au optronics in Taiwan;Chi mei electronics in Taiwan, China;Sharp, Japan;South Korea samsung, South Korea LG;Philips;Boe, etc.These companies supply the world"s main demand for liquid crystal displays.

LG Display is currently the world"s first LCD panel manufacturer. It is affiliated to LG group and headquartered in Seoul, South Korea.Its subsidiaries are: LG electronics, LG display, GS caltex, LG chemistry, LG life and health, etc., covering the fields of chemical energy, electronics and appliances, communication and service.LG Display"s customers include Apple, HP, DELL, SONY, Toshiba, PHILIPS, Lenovo, Acer and other world-class consumer electronics manufacturers.LG"s manufacturing base in China is in nanjing, shenyang.

Innolux is a tft-lcd panel manufacturing company founded by foxconn technology group in 2003.The factory is located in longhua foxconn technology park in shenzhen.Innolux has a strong display technology research and development team, coupled with foxconn"s strong manufacturing capacity, to effectively play the vertical integration benefits, to improve the level of the world plane display industry will have a pointer contribution.In March 2010, it merged with chi mei electronics and tong bao optoelectronics.

Au optronics, formerly known as acer technology, was founded in August 1996. It was renamed au optronics after the merger of au optronics and united optronics in 2001.Au optronics is the world"s first tft-lcd design, manufacturing and development company to be publicly listed on the New York stock exchange (NYSE).

Au optronics is the first manufacturer in the world to obtain ISO50001 energy management system certification and ISO14045 product system certification for ecological benefit assessment. Au optronics has been included in the dow Jones world sustainability index in 2010/2011 and 2011/2012, setting an important milestone for the industry.

Boe, founded in April 1993, is the largest display panel manufacturer in China and a provider of Internet of things technology, products and services.At present, boe has reached the world"s first place in the field of notebook LCD, flat LCD and mobile LCD. With its success in joining the apple supply chain, boe will become the world"s top three LCD panel manufacturers in the near future.

Sharp is known as "the father of LCD panel".Since its founding in 1912, sharp corporation has been developing the world"s first calculator and liquid crystal display, represented by the live pencil, which is the name of the company. At the same time, sharp corporation has been actively expanding new fields, contributing to the improvement of human living standards and social progress.Sharp is already owned by foxconn.

The company has set up tft-lcd key materials and technology national engineering laboratory, national enterprise technology center, post-doctoral mobile workstation, and undertakes national development and reform commission, ministry of science and technology, ministry of industry and information technology and other major national special projects.The company"s strong technology and scientific research capabilities become the cornerstone of the company"s sustainable development.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey