tft display interface with stm32 factory

Before I start, I want to mention that I did not write this code. This is a PORT from the mcufriend’s arduino code, which can be found HERE. I merely made some changes, so that it can be used with the CubeMx with a little modifications.

Now comes the part for setting up the Pins for the display. As, we are using the parallel connection, there are 8 DATA Pins and 5 CONTROL Pins. It would be really easy, if you connect all the data pins to thesame PORTand in the same order.

According to the Setup, the LCD_D2 is connected to the PA15. So if I want to write the DATA to the LCD_D2 pin, first I will select the 2nd bit of the data (d & (1<<2)), and than shift this by 13 using <<13. This will be like adding 2 with 13 to make a total of 15, and that’s where the LCD_D2 is connected to.

After all the Pins work is done, we still need to select the delays according to our clock frequency. As I am using STM32F103C8 at72 MHz, I am going to uncomment the respective code as shown below.

This guide is about DWIN HMI Touch Screen TFT LCD Display. HMI Means Human-Machine Interface. DWIN is specialized in making HMI Touch screen displays that are compatible with all microcontrollers like Arduino, STM32, PIC, and 8051 families of Microcontrollers.

This is a Getting Started tutorial with 7-inch DWIN HMI TFT LCD Display. We will see the architecture, features, board design, components, and specifications. We will also learn about the TTL & RS232 interfaces. Using the DGUS software you can create UI and with SD Card you can load the firmware on display memory.

You can change the TTL Interface mode or RS232 mode from here. Just solder these two terminals as shown here to enable TTL Interface. By default, the module is in RS232 Interface.

One of the method to load the firmware to the T5L DWIN LCD Display is by using the SD Card. An SD Card of up to 16GB can be used to download the firmware files. We can easily insert the Micro SD card into the SD Card slot on the backside.

After copying the file, remove the SD Card from your computer and insert it into the SD Card slot of DWIN LCD Display. Then power the display using the USB Cable. The firmware downloading process will start automatically.

The next part of this tutorial includes creating UI and interfacing DWIN LCD Display with Arduino. For that you can follow the DWIN LCD Arduino Interfacing Guide.

Our enhancement depends around the sophisticated devices ,exceptional talents and repeatedly strengthened technology forces for Stm32 Tft Lcd Tutorial, Interactive Touch Panel, Lcd Inverter, Tft Display Interface,Small Touchscreen Monitor. We attend seriously to produce and behave with integrity, and by the favor of customers at home and abroad in the xxx industry. The product will supply to all over the world, such as Europe, America, Australia,Amsterdam, Turkmenistan,Austria, Jordan.Our company is working by the operation principle of "integrity-based, cooperation created, people oriented, win-win cooperation". We hope we can have a friendly relationship with businessman from all over the world.

Established in 2015, Shenzhen Hongshuyuan Technology Co.,Ltd.(LAFVIN) is a professional manufacturer and exporter that is concerned with design, development and production of aduino board,sensor modules,robot car,3d printer etc. STEM items.

We have been ready to share our knowledge of internet marketing worldwide and recommend you suitable merchandise at most aggressive rates. So Profi Tools present you very best price of money and we are ready to develop alongside one another with Stm32 Spi Lcd Example, Lcd Panel Construction, Lcd Screen, Touch Displays,Lcd Graphic Module. Our products are widely used in many industrial fields. Our Company Services Division in good faith for the purpose of the quality of survival. All for customer service. The product will supply to all over the world, such as Europe, America, Australia,London, Slovakia,Bulgaria, Durban.With the superior and exceptional service, we"ve been well developed along with our customers. Expertise and know-how ensure that we are always enjoying the trust from our customers in our business activities. "Quality", "honesty" and "service" is our principle. Our loyalty and commitments remain respectfully at your service. Contact Us Today For further information, contact us now.

This 7 inch TFT LCD display module has super stability. The module uses the driving scheme of CPLD + SDRAM, which far more superior than SSD1963 and RA8875. Solve the problem of bad immunity, death and white screen from SSD1963.

This 7 inch TFT LCD display module has good simplicity. Not need an initializer, what have to do is reset. You can use 5 register command to control it. Greatly thin the code, reducing the debugging difficult and error rate.

This 7 inch TFT LCD display module has good speed. The respond speed of W/R cycle can be up to 200ns. The fastest full screen refresh rate is 13 frames. 8M SDRAM correspond to 8 pages display cache. The display registers and RW one is set independently. Display page and RW page also can be in which data can be written in the background. Just using one command to change screenful display data instantly. Far more superior than RA8875.

LED_A: backlight control (factory default backlight is controlled by program,0-16 Adjustable backlight brightness, without LED_A control, if required by the LED_A manual control on the module Backlight Control Department to modify resistor pad jumpers can be changed manually LED_A control, manual control when, LED_A access high-back light, then lower the backlight off, the PWM signal is adjustable brightness)

The board offers additional and independent GPIOs over a 40pin, 1.27mm male header. It provides direct access to the below GPIOs of MCU STM32H747XIH6, that makes it possible to be easily extended by an addon board for specific application.

SWD connector allows to program STM32 and QSPI with customer’s applications. Riverdi developed the ST-LINK programming cable that is included in the STM32 Embedded Display sample package (single packing).

In some applications there might be a need to connect a second display in one device. With the STM32 Embedded Display line it is very easy as these displays are equipped with Master RiBUS connector – universal interface to Riverdi’s intelligent displays. In this way, the second display does nots need an external host controller and 2 independent displays can be controlled by one STM32.

The board is equipped with a separate 512Mb flash memory. It can store pictures, music, video, fonts, etc. QSPI can be accessed over the SWD interface on the board with any official ST programmer.

Power supply voltage ranges from 6.0 V- 36.0V. A wide power supply comes with a wide range of application. Reverse polarity protection which ensures that the device is not damaged if the power supply polarity is reversed. Module also can be powered from interface connectors: RS232, RS485, 2xCAN FDs. They are internally connected.

PoE stands for Power over Ethernet and refers to the ability to use an Ethernet cord to carry network data and electrical power to connected devices. The 2 x 20-pin, 1.27 mm, pin sockets, are used to connect the Riverdi PoE Add-on Board. The Riverdi PoE Add-on Board features 10/100M Ethernet Port with Power-Over-Ethernet enabled. It allows you to power the module through the Ethernet port.

STM32 Embedded boards were designed with special attention paid to electromagnetic compatibility, a design that has given them a high immunity to external electromagnetic signals which otherwise could have disturbing influence on their working correctly.

Board is equipped with low noise backlight converters thanks to which they produce low electromagnetic interference (EMI) to the surrounding space. In consequence, external electronic devices or circuits do not need special electromagnetic screening.

The EMC measurements held in a specialized laboratory confirmed low electromagnetic emissions of STM32 Embedded modules, even when displaying dynamic pictures.

Typical surface luminance for a high brightness, IPS TFT displays is 850 cd/m2 which means it is very bright even outdoors. The full viewing angles allow the user to interact with the display in a natural and intuitive way from every side. Please see the datasheet for more features.

Optical bonding is a process of affixing the touch panel (or just the protective glass) to the display using a liquid adhesive, gel or dry (film). In general, this process improves the parameters of the module – the optical performance, as well as durability.

The air-gap is the reason for the phenomena of reflection of sunlight. So, when the display is off, the Visual Area (V.A) is never black – it is gray.

The PCAP (Projected Capacity touch panel) is classified as ‘industrial’ (as opposed to ‘consumer’) when it is able to operate correctly in more demanding, harsh conditions (i.e. disturbing electromagnetic fields around causing interferences with panel controller, water droplets present in the surrounding area also on panel glass), and react properly when touched by hands in gloves. It can be tuned at the factory, detect touch through thicker glass layers than consumer panels (6mm thick glass layer was tested with success in the Riverdi lab) and it uses an industrial grade chip controller. Such controllers have industrial manufacturer’s guidelines implemented and are guaranteed to be manufactured typically from 10 to 15 years without any changes.

A uxTouch display is a specially designed LCD TFT display which has a Projected Capacitive Touch (PTC). They are the perfect choice for your project if you intend to have an interactive design and technology, thanks to their absolute flat design and multi-touch feature.

STM32 Embedded boards were designed with special attention paid to electromagnetic compatibility, a design that has given them a high immunity to external electromagnetic signals which otherwise could have disturbing influence on their working correctly.

Board is equipped with low noise backlight converters thanks to which they produce low electromagnetic interference (EMI) to the surrounding space. In consequence, external electronic devices or circuits do not need special electromagnetic screening.

The EMC measurements held in a specialized laboratory confirmed low electromagnetic emissions of STM32 Embedded modules, even when displaying dynamic pictures.

Typical surface luminance for a high brightness, IPS TFT displays is 800 cd/m2 which means it is very bright even outdoors. The full viewing angles allow the user to interact with the display in a natural and intuitive way from every side. Please see the datasheet for more features.

Optical bonding is a process of affixing the touch panel (or just the protective glass) to the display using a liquid adhesive, gel or dry (film). In general, this process improves the parameters of the module – the optical performance, as well as durability.

The air-gap is the reason for the phenomena of reflection of sunlight. So, when the display is off, the Visual Area (V.A) is never black – it is gray.

The PCAP (Projected Capacity touch panel) is classified as ‘industrial’ (as opposed to ‘consumer’) when it is able to operate correctly in more demanding, harsh conditions (i.e. disturbing electromagnetic fields around causing interferences with panel controller, water droplets present in the surrounding area also on panel glass), and react properly when touched by hands in gloves. It can be tuned at the factory, detect touch through thicker glass layers than consumer panels (6mm thick glass layer was tested with success in the Riverdi lab) and it uses an industrial grade chip controller. Such controllers have industrial manufacturer’s guidelines implemented and are guaranteed to be manufactured typically from 10 to 15 years without any changes.

A uxTouch display is a specially designed LCD TFT display which has a Projected Capacitive Touch (PTC). They are the perfect choice for your project if you intend to have an interactive design and technology, thanks to their absolute flat design and multi-touch feature.

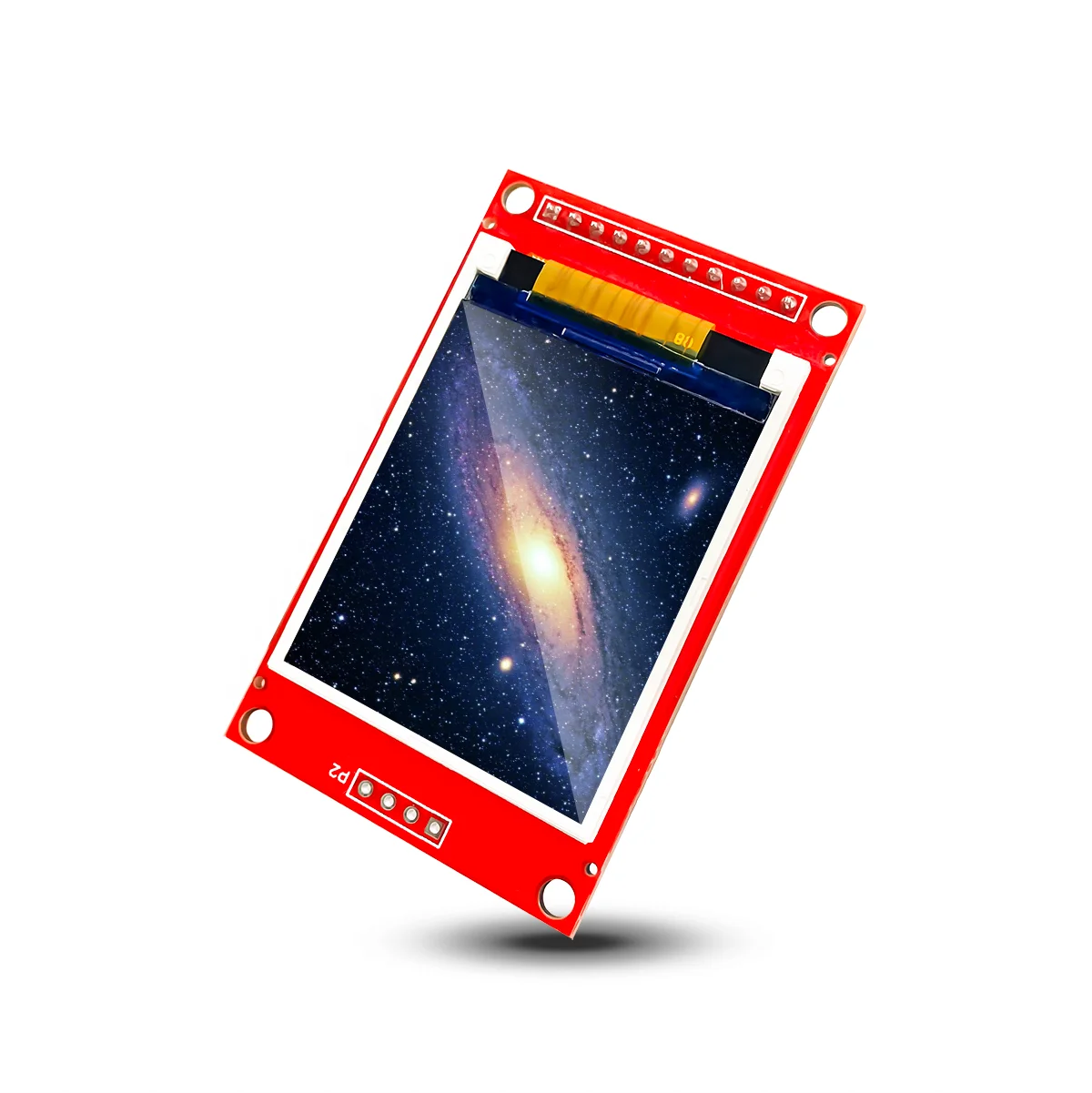

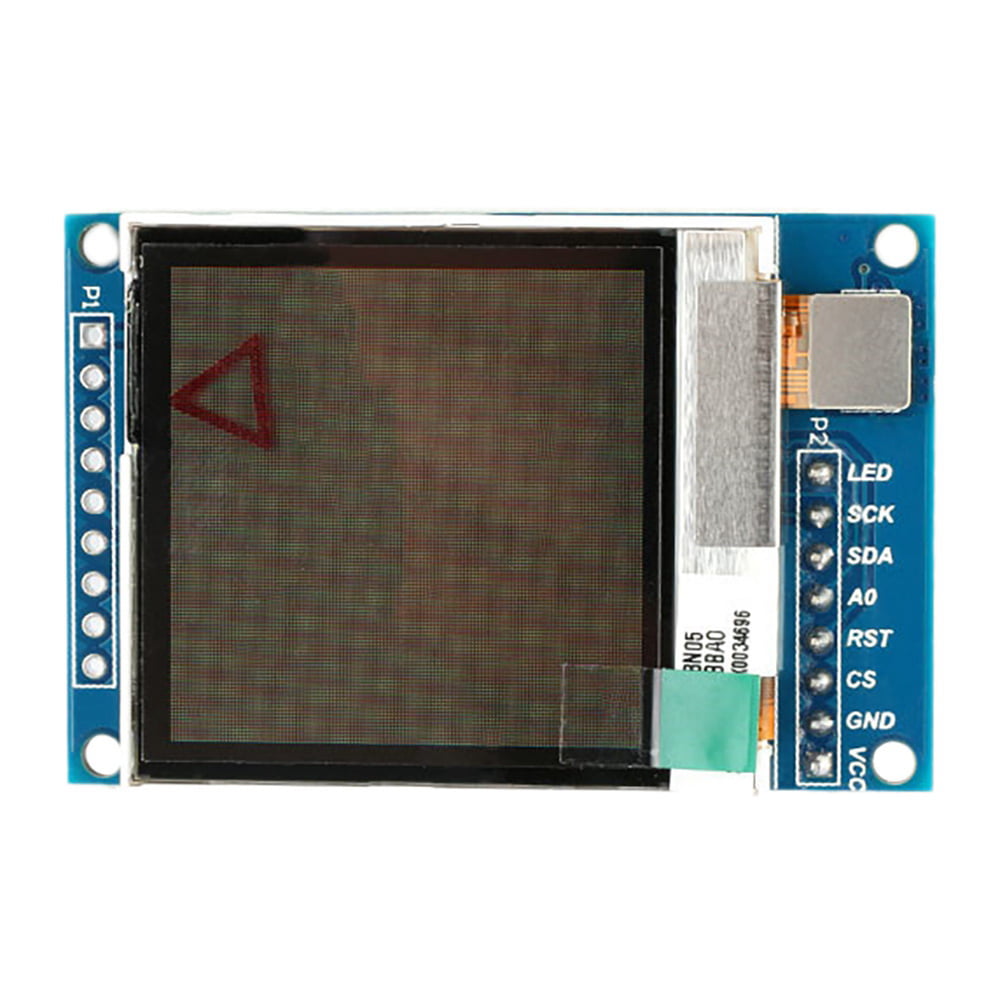

The LCD I am using is a 2.8″ TFT LCD with SPI communication. I also have another 16-bit Parallel TFT LCD but it will be another story for another time. For this post, let’s focus on how to display what you want on the 2.8″ LCD. You can find all details about this LCD from this page:http://www.lcdwiki.com/2.8inch_SPI_Module_ILI9341_SKU:MSP2807

First thing first, this LCD use SPI as the main communication protocol with your MCU. For STM32 users, HAL Library has already implemented this protocol which makes this project easier for us. But, a little knowledge about this protocol does not hurt anyone. SPI is short for Serial Peripheral Interface which, aside from two data lines, also has a clock line and select lines to choose between devices you want to communicate with.

This LCD uses ILI9341 as a single-chip SOC driver for a display with a resolution of 240×320. More details can be found in the official document of ILI9341. But the most important thing is that we have to establish astart sequencein order for this LCD to work. The “start sequence” includes many other sequences which are also defined in the datasheet. Each sequence starts when you send a command to ILI9341 and then some parameters to follow up. This sequence is applied for all communication between MCU and ILI9341.

For this project, I recommend using theSystem Workbench for STM32for coding and building the code. After installing and open the program, go to the source code you have just downloaded and double click the.cprojectfile. It will automatically be open in your IDE. Then build the program by right click on the folder you just open (TFTLCD) and chooseBuild Project. Wait for it to finish and upload it to the board by right clicking the folder, choose Run As and then clickAc6 STM32C/C++ Application. And that’s it for running the example.

The most important library for this project is obviously the ILI9341_Driver. This driver is built from the provided source code in the lcdwiki.com page. I only choose the part that we need to use the most in many applications like writing string, displaying image and drawing symbols. Another library from the wiki page is the TOUCH library. Most of the libraries I got from the Internet were not working properly due to some adjustments to the original one.

To draw symbols or even display images, we need a “byte array” of that image or symbol. As an illustration, to display an image from a game called Transistor, I have a “byte array” of that image stored in a file named transistor.h. You can find this file in the link below. Then, I draw each pixel from the image to the LCD by adding the code in the Display_Picture() function in the Display folder.void Display_Picture()

The above example is just only for displaying black and white image. In order to show a color image, we need to a little bit different. First, go tothis websiteto generate the array of the colour image. Remember to change your size to 320×240 and choose the 65K color option. Because it now takes up two bytes for one pixel, we need to send two bytes at once. You can check the Display_Color_Picture() function in the Display folder.void Display_Color_Picture()

As for the TOUCH feature, the way it works is that the screen will return the ADC value of the x or y coordinate of where you touch on the screen. The code I provided is a short version of the source code from the manufacturer and you can consider it as an extremely simple version of a touch screen feature. Because of that, the response time is very great. But for a simple application that doesn’t require drawing with your stylus, I think this works just fine. You just need to press on the screen long enough until it changes to a different layout.

This project shows how to use the STONE display, STM32 microcontroller, ultrasonic sensors, and a servo. The purpose of the project is to be able to display the distance measured by ultrasound in real-time through the STONE display.

Engineers can easily adopt the TFT-LCD color user interface and touch functions on various industrial devices and also reduce a lot of development time and cost.

Through the existing command set provided by the product, this TFT-LCD module can generate command transmission and recognition with the main controller. The main controller receives the commands from the TFT-LCD module to operate the industrial equipment.

Operating temperature. Because the Curie point of piezoelectric materials is generally high, especially with ultrasonic probe diagnosis, using less power, so the operating temperature is relatively low, it can work for a long time without failure. The temperature of medical ultrasound probes is relatively high and requires separate cooling equipment.

Servo (called Servo in English): It is a set of automatic control systems consisting of a DC motor, reduction gear set, sensor, and control circuit. By sending a signal, the output axis rotation angle is specified. Servo generally has a maximum rotation angle (such as 180 degrees.) The difference with ordinary DC motors is mainly in that DC motors rotate in a circle, and servos can only rotate within a certain angle, not in a circle (digital servos can switch between servo mode and motor mode without this problem). THE ordinary DC motor can not feedback the rotation angle information, while the servo can do it. The applications are also different, as ordinary DC motors are generally used for powering the whole rotation, while servos are used to control the rotation of an object at a certain angle (such as the joints of a robot).

When the servo receives a pulse that is less than 1.5ms, the output axis will counterclockwise rotate a certain angle with the middle position as the standard. The opposite case is received pulses greater than 1.5ms. Different brands, or even different servos of the same brand, will have different maximum and minimum values. Generally, the minimum pulse is 1ms and the maximum pulse is 2ms. As follows:

First of all, the servo leads, generally for three-wire control (No contact with a servo that is not a three-wire control), red for power, brown for ground, yellow for the signal. When controlling the servo, you need to constantly give PWM waves so that the servo has torque at a certain angle.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey