lcd display arduino wiring manufacturer

In electronics world today, Arduino is an open-source hardware and software company, project and user community that designs and manufactures single-board microcontrollers and microcontroller kits for building digital devices. Arduino board designs use a variety of microprocessors and controllers. The boards are equipped with sets of digital and analog input/output (I/O) pins that may be interfaced to various expansion boards (‘shields’) or breadboards (for prototyping) and other circuits.

The boards feature serial communications interfaces, including Universal Serial Bus (USB) on some models, which are also used for loading programs. The microcontrollers can be programmed using the C and C++ programming languages, using a standard API which is also known as the “Arduino language”. In addition to using traditional compiler toolchains, the Arduino project provides an integrated development environment (IDE) and a command line tool developed in Go. It aims to provide a low-cost and easy way for hobbyist and professionals to create devices that interact with their environment using sensors and actuators. Common examples of such devices intended for beginner hobbyists include simple robots, thermostats and motion detectors.

In order to follow the market tread, Orient Display engineers have developed several Arduino TFT LCD displays and Arduino OLED displays which are favored by hobbyists and professionals.

Although Orient Display provides many standard small size OLED, TN and IPS Arduino TFT displays, custom made solutions are provided with larger size displays or even with capacitive touch panel.

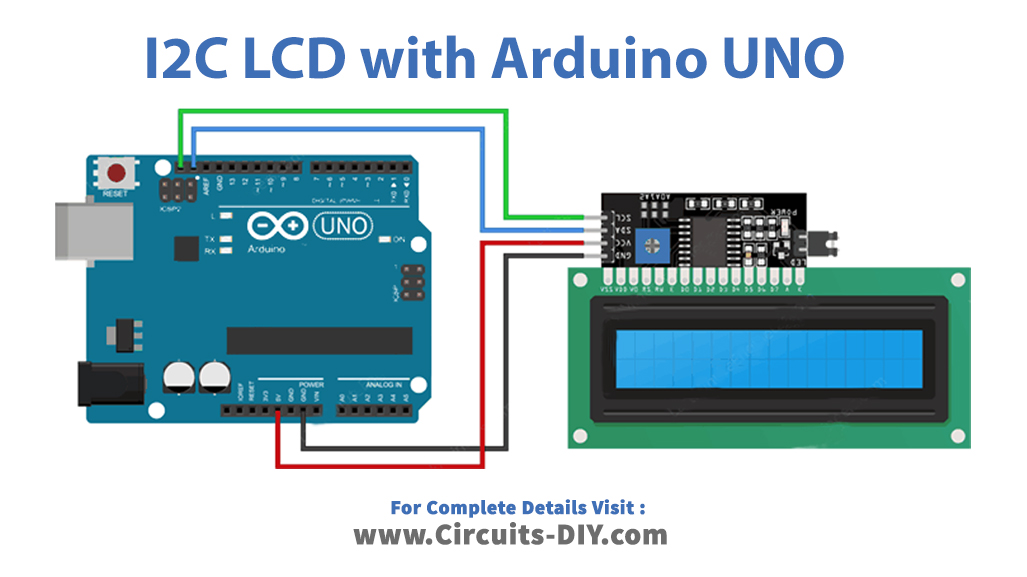

If you’ve ever tried to connect an LCD display to an Arduino, you might have noticed that it consumes a lot of pins on the Arduino. Even in 4-bit mode, the Arduino still requires a total of seven connections – which is half of the Arduino’s available digital I/O pins.

The solution is to use an I2C LCD display. It consumes only two I/O pins that are not even part of the set of digital I/O pins and can be shared with other I2C devices as well.

True to their name, these LCDs are ideal for displaying only text/characters. A 16×2 character LCD, for example, has an LED backlight and can display 32 ASCII characters in two rows of 16 characters each.

If you look closely you can see tiny rectangles for each character on the display and the pixels that make up a character. Each of these rectangles is a grid of 5×8 pixels.

At the heart of the adapter is an 8-bit I/O expander chip – PCF8574. This chip converts the I2C data from an Arduino into the parallel data required for an LCD display.

If you are using multiple devices on the same I2C bus, you may need to set a different I2C address for the LCD adapter so that it does not conflict with another I2C device.

An important point here is that several companies manufacture the same PCF8574 chip, Texas Instruments and NXP Semiconductors, to name a few. And the I2C address of your LCD depends on the chip manufacturer.

So your LCD probably has a default I2C address 0x27Hex or 0x3FHex. However it is recommended that you find out the actual I2C address of the LCD before using it.

Connecting an I2C LCD is much easier than connecting a standard LCD. You only need to connect 4 pins instead of 12. Start by connecting the VCC pin to the 5V output on the Arduino and GND to ground.

Now we are left with the pins which are used for I2C communication. Note that each Arduino board has different I2C pins that must be connected accordingly. On Arduino boards with the R3 layout, the SDA (data line) and SCL (clock line) are on the pin headers close to the AREF pin. They are also known as A5 (SCL) and A4 (SDA).

After wiring up the LCD you’ll need to adjust the contrast of the display. On the I2C module you will find a potentiometer that you can rotate with a small screwdriver.

Plug in the Arduino’s USB connector to power the LCD. You will see the backlight lit up. Now as you turn the knob on the potentiometer, you will start to see the first row of rectangles. If that happens, Congratulations! Your LCD is working fine.

To drive an I2C LCD you must first install a library called LiquidCrystal_I2C. This library is an enhanced version of the LiquidCrystal library that comes with your Arduino IDE.

The I2C address of your LCD depends on the manufacturer, as mentioned earlier. If your LCD has a Texas Instruments’ PCF8574 chip, its default I2C address is 0x27Hex. If your LCD has NXP Semiconductors’ PCF8574 chip, its default I2C address is 0x3FHex.

So your LCD probably has I2C address 0x27Hex or 0x3FHex. However it is recommended that you find out the actual I2C address of the LCD before using it. Luckily there’s an easy way to do this, thanks to the Nick Gammon.

But, before you proceed to upload the sketch, you need to make a small change to make it work for you. You must pass the I2C address of your LCD and the dimensions of the display to the constructor of the LiquidCrystal_I2C class. If you are using a 16×2 character LCD, pass the 16 and 2; If you’re using a 20×4 LCD, pass 20 and 4. You got the point!

First of all an object of LiquidCrystal_I2C class is created. This object takes three parameters LiquidCrystal_I2C(address, columns, rows). This is where you need to enter the address you found earlier, and the dimensions of the display.

In ‘setup’ we call three functions. The first function is init(). It initializes the LCD object. The second function is clear(). This clears the LCD screen and moves the cursor to the top left corner. And third, the backlight() function turns on the LCD backlight.

After that we set the cursor position to the third column of the first row by calling the function lcd.setCursor(2, 0). The cursor position specifies the location where you want the new text to be displayed on the LCD. The upper left corner is assumed to be col=0, row=0.

There are some useful functions you can use with LiquidCrystal_I2C objects. Some of them are listed below:lcd.home() function is used to position the cursor in the upper-left of the LCD without clearing the display.

lcd.scrollDisplayRight() function scrolls the contents of the display one space to the right. If you want the text to scroll continuously, you have to use this function inside a for loop.

lcd.scrollDisplayLeft() function scrolls the contents of the display one space to the left. Similar to above function, use this inside a for loop for continuous scrolling.

If you find the characters on the display dull and boring, you can create your own custom characters (glyphs) and symbols for your LCD. They are extremely useful when you want to display a character that is not part of the standard ASCII character set.

CGROM is used to store all permanent fonts that are displayed using their ASCII codes. For example, if we send 0x41 to the LCD, the letter ‘A’ will be printed on the display.

CGRAM is another memory used to store user defined characters. This RAM is limited to 64 bytes. For a 5×8 pixel based LCD, only 8 user-defined characters can be stored in CGRAM. And for 5×10 pixel based LCD only 4 user-defined characters can be stored.

Creating custom characters has never been easier! We have created a small application called Custom Character Generator. Can you see the blue grid below? You can click on any 5×8 pixel to set/clear that particular pixel. And as you click, the code for the character is generated next to the grid. This code can be used directly in your Arduino sketch.

After the library is included and the LCD object is created, custom character arrays are defined. The array consists of 8 bytes, each byte representing a row of a 5×8 LED matrix. In this sketch, eight custom characters have been created.

This module works with at least the LiquidCrystal I2C and LiquidCrystal_PCF8574 libraries available in the Arduino library manager. Address 0x3F worked for me since the A0, A1, and A2 jumpers are not shorted.

Recently purchased unit has a different address than the same part number purchased a year ago. It seems that if the small board is marked MH, the address is not going to be 0x27 or 0x20 but 0x3F. With that change of address, this display works and looks great.

Google for LCM1602 and you will find many pages that mention the board - including the pinouts stated above and sample programs using the Arduino library.

I liked the idea of the 4-wire interface, but I was disappointed that no documentation was available for this part. However after a night of hacking I got it to work with my Arduino Uno. I thought Id pass along the following information to spare others the trouble.

On the software side, you have to download and install a new LiquidCrystal_I2C library for Arduino, which has the capability to talk to the LCD display over the I2C bus. Heres a link to the library. Follow the example code for the DFRobot board, which turns out to have the same configuration as this LCD, and it should fire right up for you. The LCD has white characters on a backlit blue background, and looked great.

You are aware of various pros of an LCD (liquid crystal display) and its ability to perform and therefore in this Arduino LCD tutorial of arduinomylifeup, we will learn how to connect a simple 16×2 LCD up to the Arduino with this good little device.

If you had some experience with the LCD boards, you must be aware of the fact that they are not assembled with header pins and hence, will need to be soldered on. With the availability of header pins, you can perhaps skip soldering but getting a worthy connection to the board will be challenging. The potentiometer in the circuit is used to control the brightness of the screen.

The equipment used for this project are Arduino Uno, 16×2 LCD Board, 16x Header pins (if LCD display has no pins), Breadboard, Breadboard wire, 10k ohm Potentiometer and Arduino LCD Circuit. Moreover, the circuit for the Arduino liquid crystal display is amazingly easy.

Solder the header pins one by one so the short side sticks up through the holes on the display and also to ensure that you don’t accidentally connect two up. Once done it’s ready for use.

Now to hook up the display, use the full circuit diagram given below or follow the instruction. Start with hooking the 5V pin from the Arduino to the positive line on the breadboard, which is followed by hooking of the ground pin to the ground rail on the breadboard. Next, the potentiometer is connected to the breadboard and wire the positive pin the positive rail. Also, wire the ground pin to the ground rail.

The code for communicating with the display is actually pretty straight forward. If you want to see how it is all done, then check out the video and other details in the following link.

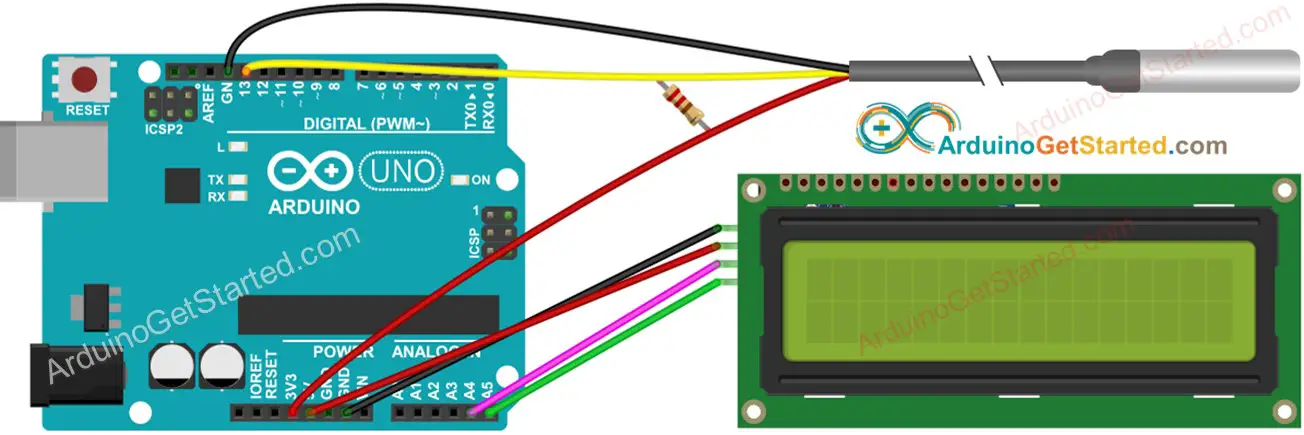

An LCD (Liquid Crystal Display) is a great way to display information in our Arduino Uno controller. We will be wiring and programming an alphanumeric, two rows with 16 characters on each row. The display has an LED (Light Emitting Diode) backlight with adjustable contrast.

This white and blue LCD will display “Hello World!” on the top line and temperature on the bottom line. The thermistor temperature circuit created last time will be displayed in both Celsius and Fahrenheit degrees. Let’s get started.

When you look at an LCD display, it is made up of a series of dots or pixels. Each of these pixels is a liquid crystal. If electricity flows through the liquid crystal it will change its structure and be more rigid. This rigidity will look darker than if no electricity is applied. If we use a light behind this LCD then the backlight will make the pixels more pronounced. So electricity on the pixel will block the light and no electricity will allow the light through. This contrast is what we see using an LCD display.

The LiquidCrystal.zip file came on the disk with the Arduino UNO R3 super starter kit. It can also be downloaded from the link below with the program. Select this library and then select open. This will add the library to the Arduino IDE (Integrated Development Environment).

This first part will set up the library and declare the variables for the LCD display unit. Using the Steinhart-Hart Equation we declare our variables and set the coefficients for the equation.

The LCD is set up with 16 characters and 2 lines. The cursor for the LCD display is set for the first character on the first line by default. We then print the message “ Hello, World!”.

The program will calculate the temperature in Celsius (T) and in Fahrenheit (TF). The LCD cursor is then set to the second row and column 0. We can then print our temperatures and units of measure.

You will see the ‘Hello World!’ and the current temperature in two units of measure displayed on the LCD. Hold the thermistor between your fingers to see how rapidly the temperature can be read.

To establish a good communication between human world and machine world, display units play an important role. And so they are an important part of embedded systems. Display units - big or small, work on the same basic principle. Besides complex display units like graphic displays and 3D dispays, one must know working with simple displays like 16x1 and 16x2 units. The 16x1 display unit will have 16 characters and are in one line. The 16x2 LCD will have 32 characters in total 16in 1st line and another 16 in 2nd line. Here one must understand that in each character there are 5x10=50 pixels so to display one character all 50 pixels must work together. But we need not to worry about that because there is another controller (HD44780) in the display unit which does the job of controlling the pixels. (you can see it in LCD unit, it is the black eye at the back ).

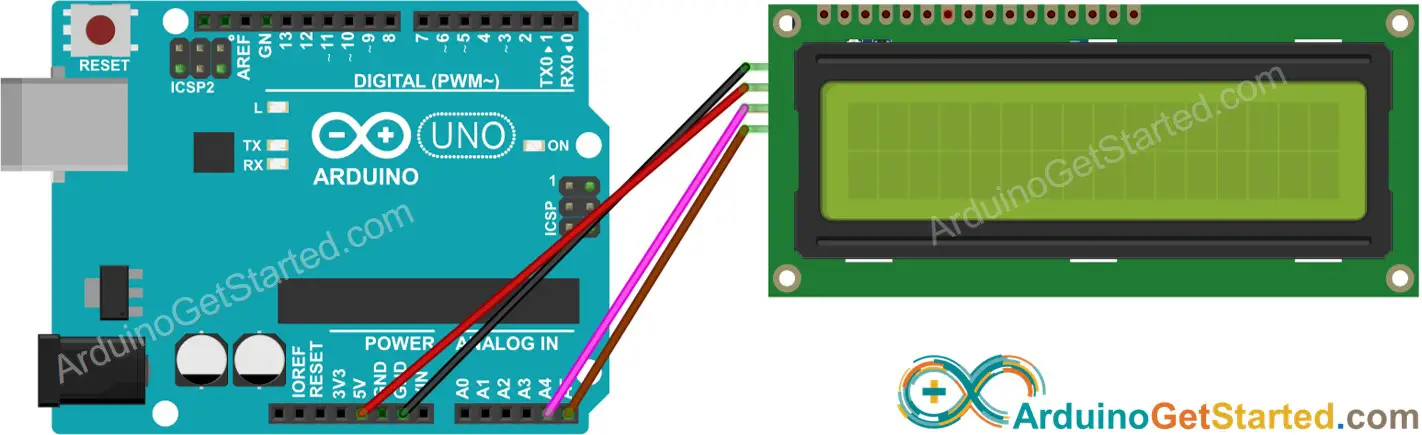

In this tutorial, we are going to interface a 16x2 LCD with ARDUINO UNO. Unlike normal development boards interfacing an LCD to an ARDUINO is quite easy. Here we don’t have to worry about data sending and receiving. We just have to define the pin numbers and it will be ready to display data on LCD.

Note:We updated this tutorial and added some more additional information along with a step-by-step guide to interface 16x2 LCD withArduino. You can follow the below link for an updated tutorial.

In 16x2 LCD there are 16 pins over all if there is a back light, if there is no back light there will be 14 pins. One can power or leave the back light pins. Now in the 14 pins there are 8 data pins (7-14 or D0-D7), 2 power supply pins (1&2 or VSS&VDD or GND&+5v), 3rd pin for contrast control (VEE-controls how thick the characters should be shown), and 3 control pins (RS&RW&E).

In the circuit, you can observe I have only took two control pins, this gives the flexibility. The contrast bit and READ/WRITE are not often used so they can be shorted to ground. This puts LCD in highest contrast and read mode. We just need to control ENABLE and RS pins to send characters and data accordingly.

The ARDUINO IDE allows the user to use LCD in 4 bit mode. This type of communication enables the user to decrease the pin usage on ARDUINO, unlike other the ARDUINO need not to be programmed separately for using it in 4 it mode because by default the ARDUINO is set up to communicate in 4 bit mode. In the circuit you can see we have used 4bit communication (D4-D7).

First we need to enable the header file (‘#include

Second we need to tell the board which type of LCD we are using here. Since we have so many different types of LCD (like 20x4, 16x2, 16x1 etc.). Here we are going to interface a 16x2 LCD to the UNO so we get ‘lcd.begin(16, 2);’. For 16x1 we get ‘lcd.begin(16, 1);’.

In this instruction we are going to tell the board where we connected the pins. The pins which are connected need to be represented in order as “RS, En, D4, D5, D6, D7”. These pins are to be represented correctly. Since we have connected RS to PIN0 and so on as show in the circuit diagram, we represent the pin number to board as “LiquidCrystal lcd(0, 1, 8, 9, 10, 11);”. The data which needs to be displayed in LCD should be written as “ cd.print("hello, world!");”. With this command the LCD displays ‘hello, world!’.

As you can see we need not to worry about any thing else, we just have to initialize and the UNO will be ready to display data. We don’t have to write a program loop to send the data BYTE by BYTE here.

In this Instructables lesson, displaying texts and featuring them on a 16 by 2 LCD using Arduino is demonstrated. Let"s get started and I hope you enjoy!

Arduino is a device that is widely used by students for various robotics projects and sensors to detect heart-rate, temperature, air pressure ... Arduino is an open-source hardware and software company, project and user community that designs and manufactures single-board micro controllers and micro controller kits for building digital devices and interactive objects that can sense and control both physically and digitally. Basically Arduino is capable to store codes inserted from Arduino IDE using C and C++ coding languages from a computer to manipulate the functions that are assigned for the device to do. LCD (Liquid Crystal Display) screen is an electronic display module and find a wide range of applications. A 16x2 LCD display is very basic module and is very commonly used in various devices and circuits. A 16x2 LCD means it can display 16 characters per line and there are 2 such lines. The LCD has 16 pins. Starting from left to right, the first pin is GND (ground). The second pin is the VCC (5 volts) pin which is connected to the Arduino board. The third pin is the Vo (display contrast) pin which can be connected to a potentiometer to adjust the display contrast. Fourth pin is the RS (register select) pin used for selecting the commands/data sent to the LCD using methods defined in the Arduino Liquid Crystal packages. Fifth one is the R/W (read/write) pin which selects the mode whether we read or write on the LCD. Sixth pin is the E (enable) pin which enables writings to the registers. The next 8 pins are data pins D0 to D7 that registers are written in using binary numbers according to the ASCII Table. The fifteenth pin is the A (anode) , and the last one is K (cathode).

The IDE Now that we have a little undrestanding of what Arduino and the LCD are, let"s jump ahead into the Arduino IDE and install that on our computer. Arduino IDE can be downloaded from Or from the windows store on windows 8. The IDE is the place where coding takes place. Here, the codes are written in C and C++. After compiling the code and troubleshooting the mistakes, the complied code is sent to the Arduino Board using the USB 2 cable. After installing the IDE we implement the Liquid Crystal package as shown below. Liquid Crystal Package implementation... Installing LiquidCrystal package opens our access to use the methods and implementations defined in the specific package regarding to the LCD on our IDE to be compiled and stored into the Arduino board. After package installation, the setup and loop are written in the IDE. Follow the above and copy the parameters to make a connection between the board and the LCD.

Compiling and Storing the Code into the Arduino For the last step, connect the Arduino to the computer using a USB-2 cable. compile the code and select the Arduino UNO on the IDE and store the code into the Arduino by clicking on the horizontal arrow on the top left corner of the IDE.

The note "Arduino" should be appearing on your LCD. Congratulations !!! You have made your first text on the LCD... Now if you want to go the extra mile, www.arduino.cc has all the methods and explanations that can be used to use on your text for further design and change, move, personalize your own text. Above are some of the example codes found in the website. Try them yourself.

This article includes everything you need to know about using acharacter I2C LCD with Arduino. I have included a wiring diagram and many example codes to help you get started.

In the second half, I will go into more detail on how to display custom characters and how you can use the other functions of the LiquidCrystal_I2C library.

Once you know how to display text and numbers on the LCD, I suggest you take a look at the articles below. In these tutorials, you will learn how to measure and display sensor data on the LCD.

Each rectangle is made up of a grid of 5×8 pixels. Later in this tutorial, I will show you how you can control the individual pixels to display custom characters on the LCD.

They all use the same HD44780 Hitachi LCD controller, so you can easily swap them. You will only need to change the size specifications in your Arduino code.

The 16×2 and 20×4 datasheets include the dimensions of the LCD and you can find more information about the Hitachi LCD driver in the HD44780 datasheet.

Note that an Arduino Uno with the R3 layout (1.0 pinout) also has the SDA (data line) and SCL (clock line) pin headers close to the AREF pin. Check the table below for more details.

After you have wired up the LCD, you will need to adjust the contrast of the display. On the I2C module, you will find a potentiometer that you can turn with a small screwdriver.

The LiquidCrystal_I2C library works in combination with the Wire.h library which allows you to communicate with I2C devices. This library comes pre-installed with the Arduino IDE.

To install this library, go to Tools > Manage Libraries (Ctrl + Shift + I on Windows) in the Arduino IDE. The Library Manager will open and update the list of installed libraries.

Note that counting starts at 0 and the first argument specifies the column. So lcd.setCursor(2,1) sets the cursor on the third column and the second row.

Next the string ‘Hello World!’ is printed with lcd.print("Hello World!"). Note that you need to place quotation marks (” “) around the text since we are printing a text string.

The example sketch above shows you the basics of displaying text on the LCD. Now we will take a look at the other functions of the LiquidCrystal_I2C library.

This function turns on automatic scrolling of the LCD. This causes each character output to the display to push previous characters over by one space.

If the current text direction is left-to-right (the default), the display scrolls to the left, if the current direction is right-to-left, the display scrolls to the right.

I would love to know what projects you plan on building (or have already built) with these LCDs. If you have any questions, suggestions or if you think that things are missing in this tutorial, please leave a comment down below.

ERM2004FS-3 is small size 20 characters wide,4 rows character lcd module,SPLC780C controller (Industry-standard HD44780 compatible controller),6800 4/8-bit parallel interface,single led backlight with white color included can be dimmed easily with a resistor or PWM,fstn-lcd positive,black text on the white color,high contrast,wide operating temperature range,wide view angle,rohs compliant,built in character set supports English/Japanese text, see the SPLC780C datasheet for the full character set, It"s optional for pin header connection,5V or 3.3V power supply and I2C adapter board for arduino.

It"s easily controlled by MCU such as 8051,PIC,AVR,ARDUINO,ARM and Raspberry Pi.It can be used in any embedded systems,industrial device,security,medical and hand-held equipment.

Looks like the HD44780 (or equivalent) controller is driving the panel in 1x16 mode, with 5x8 black pixel grid for each character. Those are the initial, default settings before the display has been configured. So this indicates that the panel is receiving power. But there could be problems with the contrast, the interface, the timing, etc.

When the LCD panel shows either a "ghost grid" where all the pixels are barely visible, or a dark grid (like in the photo) where all of the pixels are dark, that suggests a problem with LCD contrast. This is also affected by viewing angle. Normally you would have to adjust the trimpot until there is good contrast between the pixels.

But, this problem is more difficult if the panel hasn"t been successfully initialized yet -- the panel may be displaying a blank grid, and it"s hard to properly adjust contrast unless you know some pixels are "on" and some are "off". So you may have to try adjusting the contrast after every experiment, because you can"t tell whether it"s blank because of a contrast problem or an initialization problem. If you run the "hello world" program (see below) that should give you a visible pattern for contrast adjustment.

Some panels require negative voltage for contrast, but most modern panels use contrast between the VDD/GND supply rails. You can find out if the display has a datasheet, but if it"s something from a sketchy "marketplace" like alibaba or amazon marketplace (not amazon itself) or banggood or ebay, these vendors often don"t include datasheets. If you"re going to try testing negative contrast, use a large value resistor in series (like 100k) to protect against excessive current -- if it"s not a negative voltage panel, applying negative bias (without current limiting) could damage the panel.

You"ve got the R/W control line tied to ground, so it"s a read-only interface. Sometimes firmware designers do this to save a pin, but it has another cost: you can"t read back anything from the display. No way to read the ready/busy status, so the firmware has to wait the maximum time for each command. And there"s no way for the firmware to detect whether or not the display is connected, without the R/W control line.

Since you"ve got the R/W control line tied to ground, there"s no way to read the LCD ready/busy status... it"s a write-only configuration... so timing problems are likely unless you allow sufficient time before and after each command; 1.0usec would be generous. You"re using an Arduino UNO, which is a pretty slow microcontroller board.

The Adafriut "LiquidCrystal Library - Hello World" that comes with the Arduino platform (Examples - LiquidCrystal - Hello World) uses nybble mode; it runs slow enough on stock Arduino UNO, and is a good place to start, given that you"re using a solderless breadboard.

I don"t recognize any logos on your display panel; it"s not optrex or any other brand-name panel. For a one-off prototype that you"re not selling, it"s probably ok, but it"s anyone"s guess whether it works. No refunds.

The Adafriut "LiquidCrystal Library - Hello World" that comes with the Arduino platform (Examples - LiquidCrystal - Hello World) is a good working example to start with. You may have to verify that the rs,en,d4,d5,d6,d7 pin assignments match up with what you"ve wired in your hardware.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey