lcd display arduino wiring brands

In this article I am going to interface a 16x2 I2C LCD with Arduino Uno. In my previous article is discuss aboutinterfacing of 16x2 LCD with Arduino Uno. The difference is in number of wires. There we need more than 12 wires. But here only use just 4 wires. How ?!!!!!! Before I use parallel communication method for interfacing LCD with Arduino. But now I am using I2C Communication.

Here I use the same 16X2 LCD in my previous article. But additionally attach a I2C Module to the 16x2 LCD. It work as an inter mediator between the LCD and MCU (here Arduino).

It is also known as I2C Module. It has total of 20 male pins. 16 pins are faced to rear side and 4 pins faced towards front side. The 16 pins for connect to 16x2 LCD and the 2 pins out of 4 pins are SDA and SCL. SDA is the serial data pin and SCL is the clock pin. The rest 2 pins for power supply (Vcc and ground).There is a POT on the I2C Module. We can control the contrast of the LCD display by rotating this POT. And there is a jumber fixed on the module. When we remove the jumber, the backlight of the LCD display will go OFF.

You can see three solder pads on the I2C module. which is labeled as A0, A1 and A2. This is Address selectors. ie, each solder pads have one upper potion and a one lower potion. if, there is a connection between upper potion with lower connection it is called "Connected" otherwise it is called "Not connected". When A0, A1, A2 are in "Not Connected" condition ( A0 = 0, A1 = 0, A2 = 0) the address would be 0x27. In default the A0, A1, A2 are in "Not connected" condition. And some time default address is 0x3F. There is no need to change the address of the I2C module when we use only one LCD. But when we use more than one LCD, need to change the address. Because two or more different device can"t communicate with the same address. For more address see the table given below.

In some cases A0, A1, A2 are "Not connected" state, but the address is not 0x27. We can"t communicate with this address. So we need to find the original address of that device. For that we need to run the Arduino with "I2C Scanner" code.

Next open Serial monitor from the icon on top right corner of Arduino IDE. And set the baud rate as 9600. Please ensure the correct port. Then you can see the address of LCD in serial monitor like shown below

Before that need to add a library to Arduino IDE. Go to thelinkand download the library Arduino-LiquidCrystal-I2C-library. Then open Arduino IDE and go toSketch>Include Library> Add.ZIP Library. Next select the downloaded ZIP file and clickopen.

Next create a sketch. First I include the header "Wire.h". This library help to communicate with I2C device. Then include "LiquidCrystal_I2C.h" for better communication with display.#include

Next set the address, number of column and number of rows using the function "LiquidCrystal_I2C lcd(). The address is 0x27 (discovered using the I2C Scanner Code). Number of columns is 16 and number of rows is 2. After this, we can call the display using "lcd". You can also use multiple I2C LCDs with Arduino Uno. But set different addresses and variable for each display.LiquidCrystal_I2C lcd(0x27, 16, 2);

Now the LCD is ready to print. The cursor is at 4th column(count from 0), and 0th row(count from 0). Then print the Message "Hackster" by the function "lcd.print()".lcd.print("Hackster");

The programming is completed. Upload the sketch to Arduino and see the message on LCD.The complete code is given in the Code section of this article.Please don"t copy-paste my code. Try to understand the code line by line and create your own sketch.

Looks like the HD44780 (or equivalent) controller is driving the panel in 1x16 mode, with 5x8 black pixel grid for each character. Those are the initial, default settings before the display has been configured. So this indicates that the panel is receiving power. But there could be problems with the contrast, the interface, the timing, etc.

When the LCD panel shows either a "ghost grid" where all the pixels are barely visible, or a dark grid (like in the photo) where all of the pixels are dark, that suggests a problem with LCD contrast. This is also affected by viewing angle. Normally you would have to adjust the trimpot until there is good contrast between the pixels.

But, this problem is more difficult if the panel hasn"t been successfully initialized yet -- the panel may be displaying a blank grid, and it"s hard to properly adjust contrast unless you know some pixels are "on" and some are "off". So you may have to try adjusting the contrast after every experiment, because you can"t tell whether it"s blank because of a contrast problem or an initialization problem. If you run the "hello world" program (see below) that should give you a visible pattern for contrast adjustment.

Some panels require negative voltage for contrast, but most modern panels use contrast between the VDD/GND supply rails. You can find out if the display has a datasheet, but if it"s something from a sketchy "marketplace" like alibaba or amazon marketplace (not amazon itself) or banggood or ebay, these vendors often don"t include datasheets. If you"re going to try testing negative contrast, use a large value resistor in series (like 100k) to protect against excessive current -- if it"s not a negative voltage panel, applying negative bias (without current limiting) could damage the panel.

You"ve got the R/W control line tied to ground, so it"s a read-only interface. Sometimes firmware designers do this to save a pin, but it has another cost: you can"t read back anything from the display. No way to read the ready/busy status, so the firmware has to wait the maximum time for each command. And there"s no way for the firmware to detect whether or not the display is connected, without the R/W control line.

Since you"ve got the R/W control line tied to ground, there"s no way to read the LCD ready/busy status... it"s a write-only configuration... so timing problems are likely unless you allow sufficient time before and after each command; 1.0usec would be generous. You"re using an Arduino UNO, which is a pretty slow microcontroller board.

The Adafriut "LiquidCrystal Library - Hello World" that comes with the Arduino platform (Examples - LiquidCrystal - Hello World) uses nybble mode; it runs slow enough on stock Arduino UNO, and is a good place to start, given that you"re using a solderless breadboard.

I don"t recognize any logos on your display panel; it"s not optrex or any other brand-name panel. For a one-off prototype that you"re not selling, it"s probably ok, but it"s anyone"s guess whether it works. No refunds.

The Adafriut "LiquidCrystal Library - Hello World" that comes with the Arduino platform (Examples - LiquidCrystal - Hello World) is a good working example to start with. You may have to verify that the rs,en,d4,d5,d6,d7 pin assignments match up with what you"ve wired in your hardware.

The LCD 16x2 are often setup to operate at 4-bit mode to save the number of GPIO pins required for interfacing with the LCD. For some reason, you seems to want to use 8-bit mode and choose to explicitly set the mode by your class instantiation. In this case, the function prototype according to the library source code would be:

Noticed that the first argument in the class instantiation specify whether you"d want to setup the display to operate at 4-bit mode or 8-bit mode, so if you want to use the 8-bit mode, the instantiation should be:

The LCD 16x2 are often setup to operate at 4-bit mode to save the number of GPIO pins required for interfacing with the LCD. For some reason, you seems to want to use 8-bit mode and choose to explicitly set the mode by your class instantiation. In this case, the function prototype according to the library source code would be:

Noticed that the first argument in the class instantiation specify whether you"d want to setup the display to operate at 4-bit mode or 8-bit mode, so if you want to use the 8-bit mode, the instantiation should be:

In this digital age, we come across LCDs all around us from simple calculators to smartphones, computers and television sets, etc. The LCDs use liquid crystals to produce images or texts and are divided into different categories based on different criteria like type of manufacturing, monochrome or colour, and weather Graphical or character LCD. In this tutorial, we will be talking about the 16X2 character LCD Modules.

The 16x2 LCDs are very popular among the DIY community. Not only that, but you can also find them in many laboratory and industrial equipment. It can display up to 32 characters at a time. Each character segment is made up of 40 pixels that are arranged in a 5x8 matrix. We can create alphanumeric characters and custom characters by activating the corresponding pixels. Here is a vector representation of a 16x2 LCD, in which you can see those individual pixels.

As the name indicates, these character segments are arranged in 2 lines with 16 characters on each line. Even though there are LCDs with different controllers are available, The most widely used ones are based on the famous HD44780 parallel interface LCD controller from Hitachi.

Vo / VEE Contrast adjustment; the best way is to use a variable resistor such as a potentiometer. The output of the potentiometer is connected to this pin. Rotate the potentiometer knob forward and backwards to adjust the LCD contrast.

The 16x2 LCD modules are popular among the DIY community since they are cheap, easy to use and most importantly enable us to provide information very efficiently. With just 6 pins, we can display a lot of data on the display.

The module has 16 pins. Out of these 16 pins, two pins are for power, two pins are for backlight, and the remaining twelve pins are for controlling the LCD.

If you look at the backside of the module you can simply see that there are not many components. The main components are the two controller chips that are under the encapsulation. There is an onboard current limiting resistor for the backlight. This may vary from different modules from different manufacturers. The only remaining components are a few complimentary resistors for the LCD controller.

In the module PCB, you may have noticed some unpopulated footprints. These footprints are meant for charge pump circuits based on switched capacitor voltage converters like ICL7660 or MAX660. You can modify your LCD to work with 3.3V by populating this IC and two 10uF capacitors to C1 and C2 footprint, removing Jumper J1 and adding jumper J3. This modification will generate a negative contrast voltage of around 2.5V. This will enable us to use the LCD even with a VCC voltage of 3.3V.

To test whether a 16x2 LCD works or not, connect the VDD, GND and backlight pins to 5v and GND. Connect the centre terminal of a 10K variable resistor to the VEE pin. Connect the other two terminals to VCC and GND. Simply rotate the variable resistor you will see that the contrast will be adjusted and small blocks are visible. If these rectangles are visible, and you were able to adjust the contrast, then the LCD is working

There are 16 pins on the display module. Two of them are for power (VCC, GND), one for adjusting the contrast (VEE), three are control lines (RS, EN, R/W), eight pins are data lines(D0-D7) and the last two pins are for the backlight (A, K).

The 16x2 LCD has 32 character areas, which are made up of a 5x8 matrix of pixels. By turning on or off these pixels we can create different characters. We can display up to 32 characters in two rows.

Yes, we can. We can store up to eight custom characters in the CGRAM (64 bytes in size) area. We can create load the matrix data for these characters and can recall when they need to be displayed.

Controlling the LCD module is pretty simple. Let’s walk through those steps. To adjust the contrast of the LCD, the Vo/ VEE pin is connected to a variable resistor. By adjusting the variable resistor, we can change the LCD contrast.

The RS or registry select pin helps the LCD controller to know whether the incoming signal is a control signal or a data signal. When this pin is high, the controller will treat the signal as a command instruction and if it’s low, it will be treated as data. The R/W or Read/Write pin is used either to write data to the LCD or to read data from the LCD. When it’s low, the LCD module will be in write mode and when it’s high, the module will be in reading mode.

The Enable pin is used to control the LCD data execution. By default, this pin is pulled low. To execute a command or data which is provided to the LCD data line, we will just pull the Enable pin to high for a few milliseconds.

To test the LCD module, connect the VDD, GND, and backlight pins to 5v and GND. Connect the center terminal of a 10K variable resistor to the VEE pin. Connect the other two terminals to VCC and GND as per the below connection diagram-

Simply rotate the variable resistor you will see that the contrast will be adjusted and small blocks are visible. If these rectangles are visible, and you were able to adjust the contrast, then the LCD is working.

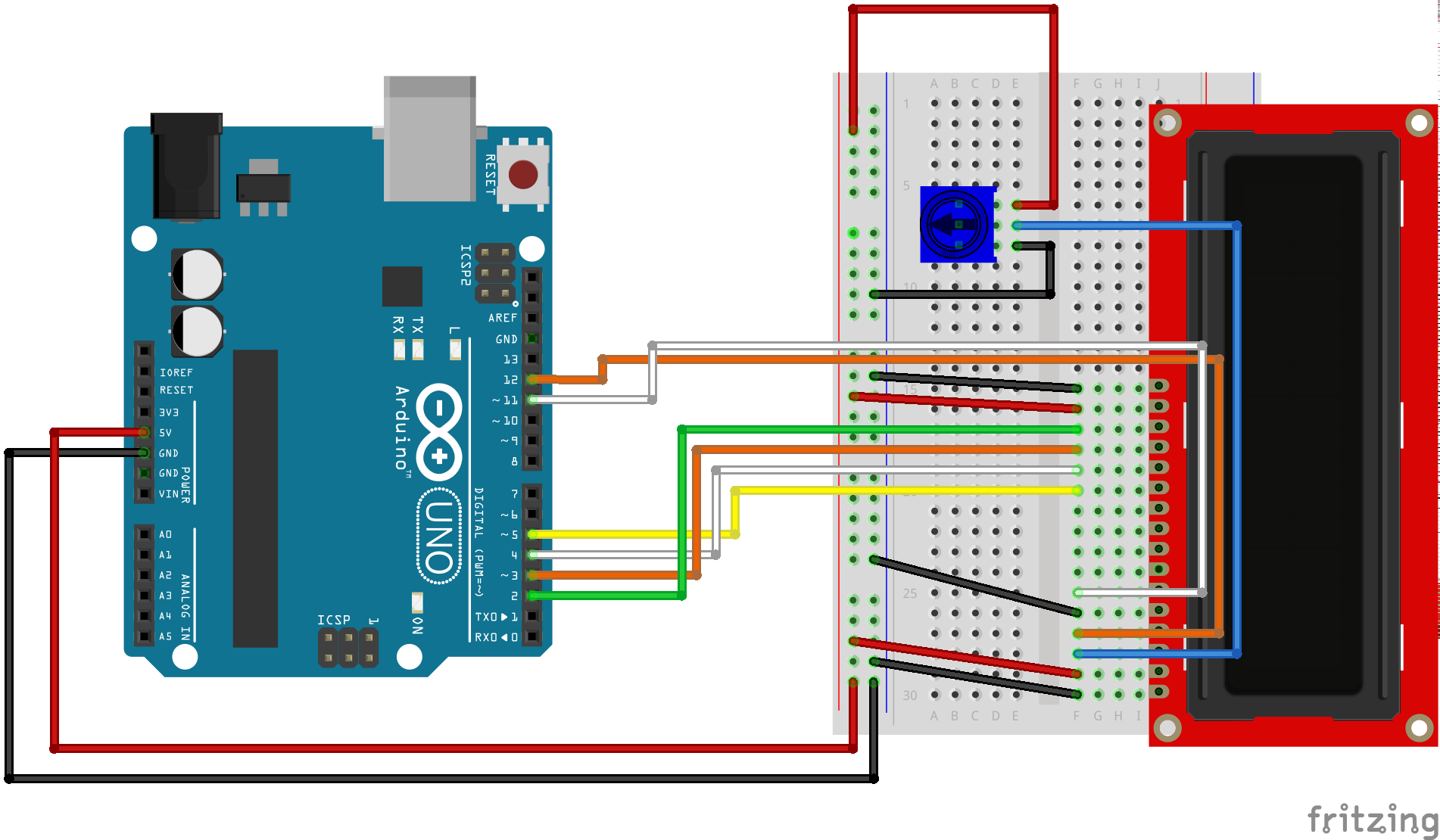

Let’s see how to connect the LCD module to Arduino. For that first, connect the VSS to the GND and VDD to the 5V. To use the LCD backlight, connect the backlight Anode to the 5V and connect the backlight cathode to the GND through a 220Ωresistor. Since we are not using the read function connect the LCD R/W pin to the GND too. To adjust the contrast, connect the centre pin of a 10KΩ trimmer resistor to the VEE pin and connect the side pins to the VCC and GND. Now connect the registry select pin to D12 and Enable pin to D11.

Now let’s connect the data pins. The LCD module can work in two modes, 8-bit and 4-bit. 8-bit mode is faster but it will need 8 pins for data transfer. In 4-bit mode, we only need four pins for data. But it is slower since the data is sent one nibble at a time. 4-bit mode is often used to save I/O pins, while the 8-bit mode is used when speed is necessary. For this tutorial, we will be using the 4-bit mode. For that connect the D4, D5, D6 and D7 pins from the LCD to the D5, D4, D3 and D2 pins of the Arduino.

The following Arduino 16x2 LCD code will print Hello, World! on the first line of the display and the time the Arduino was running in seconds on the second line.

Now let’s discuss the code. As usual, the sketch starts by including the necessary libraries. For this tutorial, we will be including the LiquidCrystal library from Arduino. This library is compatible with LCDs based on the Hitachi HD44780, or any compatible chipset. You can find more details about this library on the Arduino website.

Let’s create an object to use with the LiquidCrystal library. The following line of code will create an object called lcd. We will be using this object in the entire code to access the library functions. The object is initialized with the pin numbers.

Now let’s look at the setup()function. The lcd.begin function is used to initialize the LCD module. This function will send all the initialization commands. The parameters used while calling this function are the number of columns and the number of rows. And the next function is lcd.print. with this function, we have printed the word Circuit Digest! to the LCD. Since the LCD cursor is set to home position within the lcd.begin, we don’t need to set any cursor position. This text will stay there for two seconds. After that, the text will scroll from left to right until the entire text is out of the display. To scroll the display to the right, we have used the function lcd.scrollDisplayRight. After that, to clear display, we used lcd.clear, this will clear any characters on the display.

Now let’s look at theloop function. The for loop will count from 0 to 9, and when it reaches 9, it will reset the count and repeat the process all over again. lcd.setCursor is used to set the cursor position. lcd.setCursor(8, 1) will set the LCD cursor to the eighth position in the second row. In the LCD, the first row is addressed as 0 and the second row is addressed as 1. And the lcd.print(i) will print the count value stored in the variable i to the display.

Wrong characters are displayed: This problem occurs usually when the LCD is not getting the correct data. Make sure you are sending the correct ASCII value. If you are sending the correct ASCII characters, but still showing the wrong one on the LCD, check your connections for loose contact or short circuits.

Display shows Black boxes or does not show anything: First thing to do in these situations is to adjust the contrast voltage by rotating the variable resistor. This will correct the contrast value and will give you a visible readout.

Contrast is Ok, but still no display: Make sure to provide a sufficient time delay in between sending each character. Because if you don’t give enough time to process the data the display will malfunction.

Contrast and delay are ok, but still no display: Make sure you are powering the LCD from a 5V source. By default, these displays won’t work with a supply voltage below 5V. So if you are using the display with a 3.3V microcontroller make sure to power the display from 5V and use level shifters in between the display and the microcontroller.

In this project we will provide the input voice using Google Voice Keyboard via a Android App (BlueTerm) and print the text on 16x2 LCD using Raspberry Pi.

In this tutorial we are interfacing a Liquid Crystal Display (LCD) module with the Raspberry Pi Pico using Micropython to display strings, and characters on the LCD.

We used some Python scripts to find the local IP address of your Raspberry Pi on the network and display it on the 16x2 LCD Screen. We also added the script in the Crontab so that it can be run on every 10 minutes and we will have the updated IP address every time.

Printing “Hello, world!” is usually the first thing that programming tutorials will have you do in a new language. This guide starts by blinking an LED, but now we’re going to print out real text using a Liquid Crystal Display (LCD).

Character LCDs are designed to show a grid of letters, numbers and a few special characters. This makes them great for printing data and showing values. When current is applied to this special kind of crystal, it turns opaque. This is used in a lot of calculators, watches and simple displays. Adding an LCD to your project will make it super portable and allow you to integrate up to 32 characters (16 x 2) of information.

Pin 3 on the LCD controls the contrast and brightness of the LCD. Using a simple voltage divider with a potentiometer, the contrast can be adjusted. As you rotate the knob on the potentiometer, you should notice that the screen will get brighter or darker and that the characters become more visible or less visible. The contrast of LCDs is highly dependent on factors such as temperature and the voltage used to power it. Thus, external contrast knobs are needed for displays that cannot automatically account for temperature and voltage changes.

If you look closely at the characters on the LCD, you will notice that they are actually made up of lots of little squares. These little squares are called pixels. The size of displays is often represented in pixels. Pixels make up character space, which is the number of pixels in which a character can exist.

The LCD has 16 pins, and it is polarized. The pins are numbered from left to right, 1 through 16. The LCD utilizes an extremely common parallel interface LCD driver chip from Hitachi called the HD44780. Thankfully, the Arduino community has developed a library to handle a great deal of the software-to-hardware interface. Below is a list of each of the pins on the LCD.

If you are not seeing any characters, are seeing barely visible characters, or see just white rectangles, then you need to adjust the contrast. Twist the potentiometer very slowly until you can clearly read the display. If you reach the end of the potentiometer"s rotation, try twisting in the opposite direction.

“Begin” the LCD. This sets the dimensions of the LCD that you are working with (16 x 2). It needs to be called before any other commands from the LCD library are used.

Move the cursor to the first space of the lower line lcd.setCursor(0,1);, then print the number of seconds that have passed since the RedBoard was last reset.

LiquidCrystal LCD_name(RS_pin, enable_pin, d4, d5, d6, d7);As with servos, you need to create an LCD object and give it a name (you can make more than one). The numbers in the brackets are pins on the RedBoard that connect to specific pins on the LCD.

lcd.setCursor(0,0);Move the cursor to a point on the 16x2 grid of characters. Text that you write to the LCD will start from the cursor. This line is starting back at position (0,0).

Show hours, minutes and secondsTry adding some code so that the display shows the hours, minutes and seconds that have passed since the RedBoard was last reset.

Count button pressesBy adding a button to the circuit, you can count the number of times the button was pressed or have the button change what the LCD is displaying. There could be many pages of information.

Rectangles in first rowIf you see 16 rectangles (like “█”) on the first row, it may be due to the jumper wires being loose on the breadboard. This is normal and can happen with other LCDs wired in parallel with a microcontroller. Make sure that the wires are fully inserted into the breadboard, then try pressing the reset button and adjusting the contrast using the potentiometer.

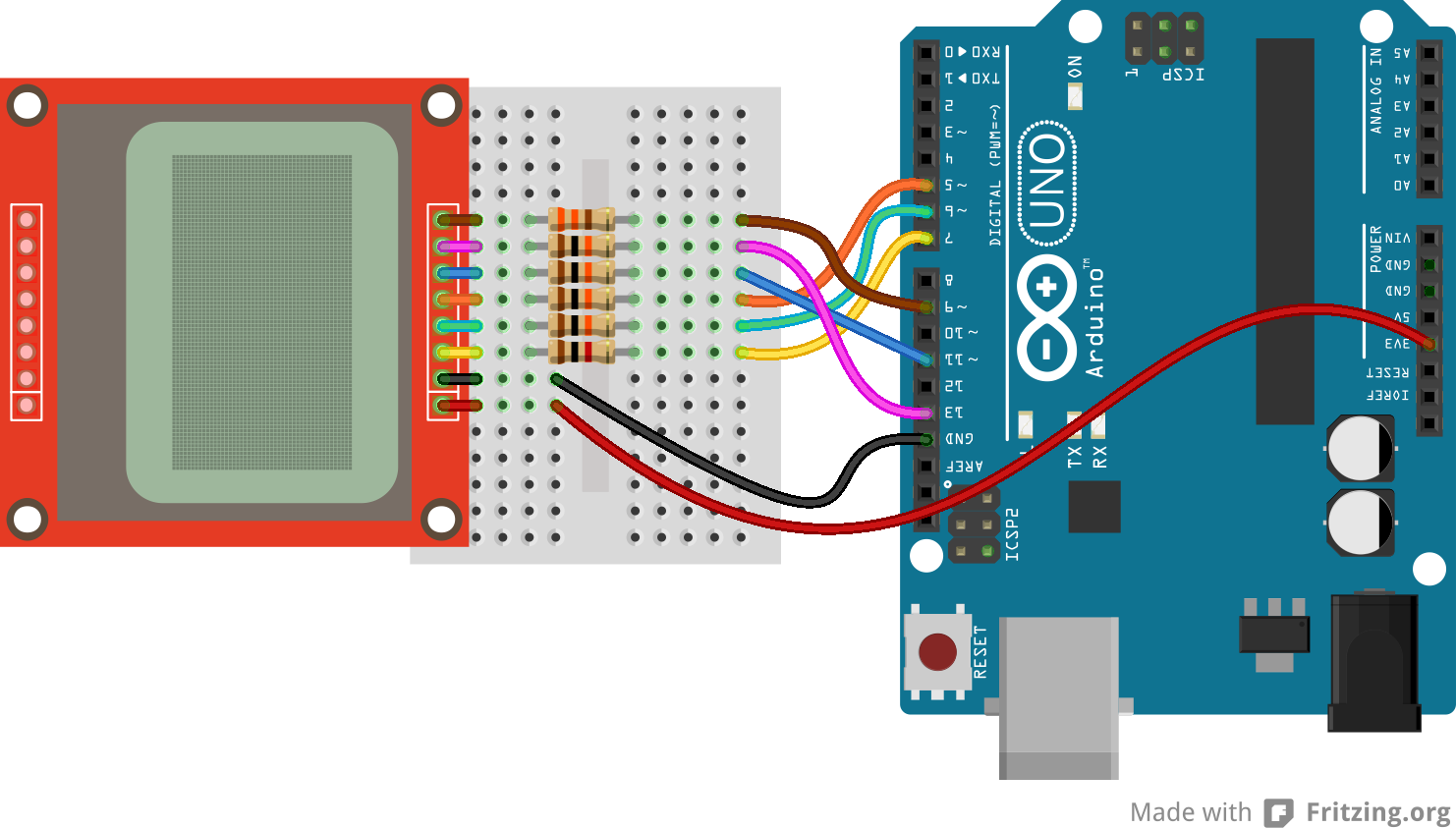

As a 2inch IPS display module with a resolution of 240 * 320, it uses an SPI interface for communication. The LCD has an internal controller with basic functions, which can be used to draw points, lines, circles, and rectangles, and display English, Chinese as well as pictures.

The 2inch LCD uses the PH2.0 8PIN interface, which can be connected to the Raspberry Pi according to the above table: (Please connect according to the pin definition table. The color of the wiring in the picture is for reference only, and the actual color shall prevail.)

The LCD supports 12-bit, 16-bit, and 18-bit input color formats per pixel, namely RGB444, RGB565, and RGB666 three color formats, this demo uses RGB565 color format, which is also a commonly used RGB format.

For most LCD controllers, the communication mode of the controller can be configured, usually with an 8080 parallel interface, three-wire SPI, four-wire SPI, and other communication methods. This LCD uses a four-wire SPI communication interface, which can greatly save the GPIO port, and the communication speed will be faster.

Note: Different from the traditional SPI protocol, the data line from the slave to the master is hidden since the device only has display requirement.

Framebuffer uses a video output device to drive a video display device from a memory buffer containing complete frame data. Simply put, a memory area is used to store the display content, and the display content can be changed by changing the data in the memory.

2.We use Dev libraries by default. If you need to change to BCM2835 or WiringPi libraries ,please open RaspberryPi\c\Makefile and modify lines 13-15 as follows:

If you need to draw pictures, or display Chinese and English characters, we provide some basic functions here about some graphics processing in the directory RaspberryPi\c\lib\GUI\GUI_Paint.c(.h).

Set points of the display position and color in the buffer: here is the core GUI function, processing points display position and color in the buffer.

The fill color of a certain window in the image buffer: the image buffer part of the window filled with a certain color, usually used to fresh the screen into blank, often used for time display, fresh the last second of the screen.

Display time: in the image buffer,use (Xstart Ystart) as the left vertex, display time,you can choose Ascii visual character font, font foreground color, font background color.;

2. The module_init() function is automatically called in the INIT () initializer on the LCD, but the module_exit() function needs to be called by itself

Python has an image library PIL official library link, it do not need to write code from the logical layer like C, can directly call to the image library for image processing. The following will take 1.54inch LCD as an example, we provide a brief description for the demo.

Note: Each character library contains different characters; If some characters cannot be displayed, it is recommended that you can refer to the encoding set ro used.

We come across Liquid Crystal Display (LCD) displays everywhere around us. Computers, calculators, television sets, mobile phones, and digital watches use some kind of display to display the time.

An LCD screen is an electronic display module that uses liquid crystal to produce a visible image. The 16×2 LCD display is a very basic module commonly used in DIYs and circuits. The 16×2 translates a display of 16 characters per line in 2 such lines. In this LCD, each character is displayed in a 5×7 pixel matrix.

Contrast adjustment; the best way is to use a variable resistor such as a potentiometer. The output of the potentiometer is connected to this pin. Rotate the potentiometer knob forward and backward to adjust the LCD contrast.

A 16X2 LCD has two registers, namely, command and data. The register select is used to switch from one register to other. RS=0 for the command register, whereas RS=1 for the data register.

Command Register: The command register stores the command instructions given to the LCD. A command is an instruction given to an LCD to do a predefined task. Examples like:

Data Register: The data register stores the data to be displayed on the LCD. The data is the ASCII value of the character to be displayed on the LCD. When we send data to LCD, it goes to the data register and is processed there. When RS=1, the data register is selected.

Generating custom characters on LCD is not very hard. It requires knowledge about the custom-generated random access memory (CG-RAM) of the LCD and the LCD chip controller. Most LCDs contain a Hitachi HD4478 controller.

CG-RAM address starts from 0x40 (Hexadecimal) or 64 in decimal. We can generate custom characters at these addresses. Once we generate our characters at these addresses, we can print them by just sending commands to the LCD. Character addresses and printing commands are below.

LCD modules are very important in many Arduino-based embedded system designs to improve the user interface of the system. Interfacing with Arduino gives the programmer more freedom to customize the code easily. Any cost-effective Arduino board, a 16X2 character LCD display, jumper wires, and a breadboard are sufficient enough to build the circuit. The interfacing of Arduino to LCD display is below.

The combination of an LCD and Arduino yields several projects, the most simple one being LCD to display the LED brightness. All we need for this circuit is an LCD, Arduino, breadboard, a resistor, potentiometer, LED, and some jumper cables. The circuit connections are below.

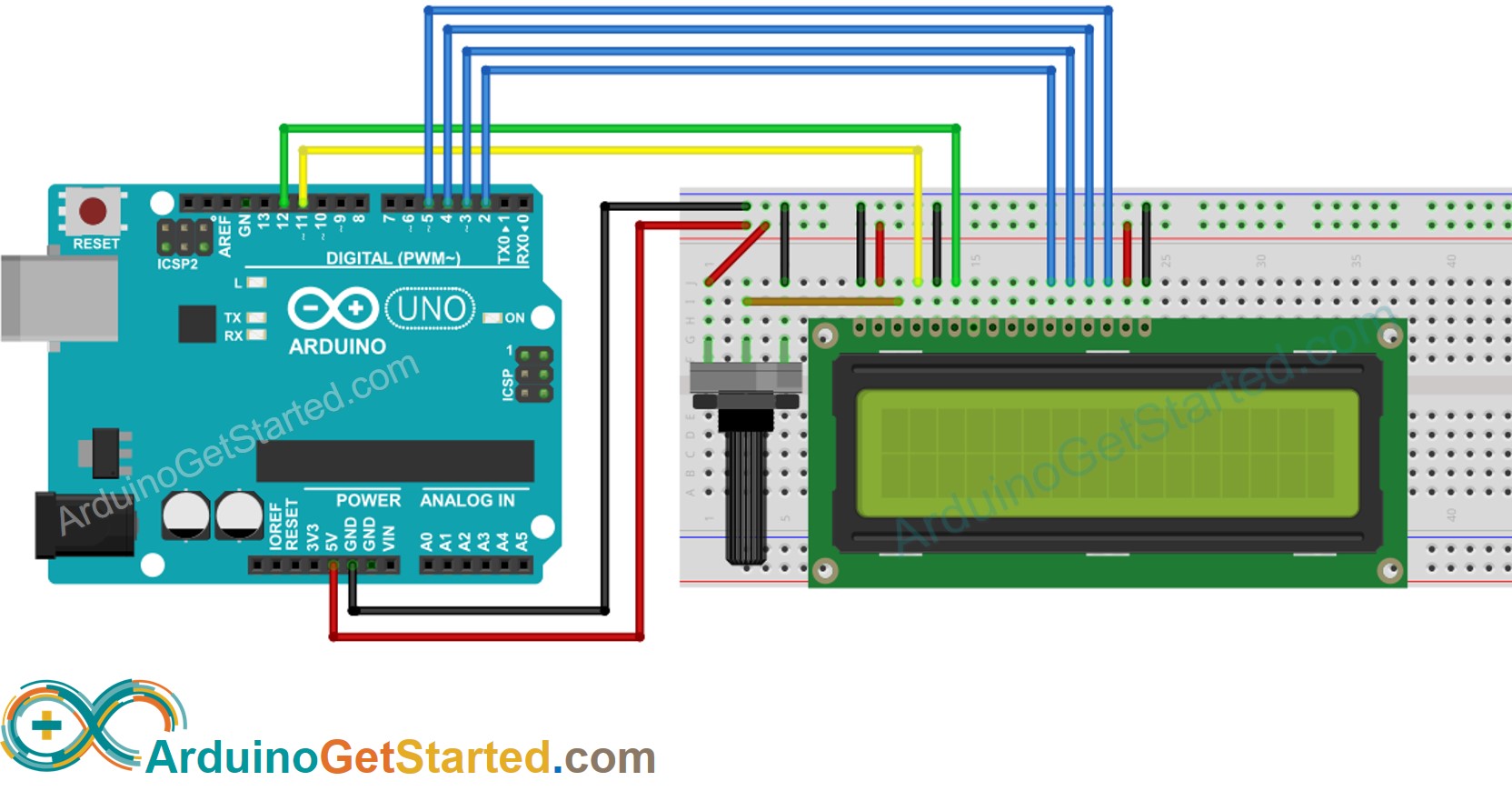

In this Arduino LCD I2C tutorial, we will learn how to connect an LCD I2C (Liquid Crystal Display) to the Arduino board. LCDs are very popular and widely used in electronics projects for displaying information. There are many types of LCD. This tutorial takes LCD 16x2 (16 columns and 2 rows) as an example. The other LCDs are similar.

In the previous tutorial, we had learned how to use the normal LCD. However, wiring between Arduino and the normal LCD is complicated. Therefore, LCD I2C has been created to simplify the wiring. Actually, LCD I2C is composed of a normal LCD, an I2C module and a potentiometer.

lcd.print() function supports only ASCII characters. If you want to display a special character or symbol (e.g. heart, angry bird), you need to use the below character generator.

Depending on manufacturers, the I2C address of LCD may be different. Usually, the default I2C address of LCD is 0x27 or 0x3F. Try these values one by one. If you still failed, run the below code to find the I2C address.

ArduinoGetStarted.com is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to Amazon.com, Amazon.it, Amazon.fr, Amazon.co.uk, Amazon.ca, Amazon.de, Amazon.es and Amazon.co.jp

In this article, you will learn how to use TFT LCDs by Arduino boards. From basic commands to professional designs and technics are all explained here.

In electronic’s projects, creating an interface between user and system is very important. This interface could be created by displaying useful data, a menu, and ease of access. A beautiful design is also very important.

There are several components to achieve this. LEDs, 7-segments, Character and Graphic displays, and full-color TFT LCDs. The right component for your projects depends on the amount of data to be displayed, type of user interaction, and processor capacity.

TFT LCD is a variant of a liquid-crystal display (LCD) that uses thin-film-transistor (TFT) technology to improve image qualities such as addressability and contrast. A TFT LCD is an active matrix LCD, in contrast to passive matrix LCDs or simple, direct-driven LCDs with a few segments.

In Arduino-based projects, the processor frequency is low. So it is not possible to display complex, high definition images and high-speed motions. Therefore, full-color TFT LCDs can only be used to display simple data and commands.

In this article, we have used libraries and advanced technics to display data, charts, menu, etc. with a professional design. This can move your project presentation to a higher level.

In electronic’s projects, creating an interface between user and system is very important. This interface could be created by displaying useful data, a menu, and ease of access. A beautiful design is also very important.

There are several components to achieve this. LEDs, 7-segments, Character and Graphic displays, and full-color TFT LCDs. The right component for your projects depends on the amount of data to be displayed, type of user interaction, and processor capacity.

TFT LCD is a variant of a liquid-crystal display (LCD) that uses thin-film-transistor (TFT) technology to improve image qualities such as addressability and contrast. A TFT LCD is an active matrix LCD, in contrast to passive matrix LCDs or simple, direct-driven LCDs with a few segments.

In Arduino-based projects, the processor frequency is low. So it is not possible to display complex, high definition images and high-speed motions. Therefore, full-color TFT LCDs can only be used to display simple data and commands.

In this article, we have used libraries and advanced technics to display data, charts, menu, etc. with a professional design. This can move your project presentation to a higher level.

Size of displays affects your project parameters. Bigger Display is not always better. if you want to display high-resolution images and signs, you should choose a big size display with higher resolution. But it decreases the speed of your processing, needs more space and also needs more current to run.

After choosing the right display, It’s time to choose the right controller. If you want to display characters, tests, numbers and static images and the speed of display is not important, the Atmega328 Arduino boards (such as Arduino UNO) are a proper choice. If the size of your code is big, The UNO board may not be enough. You can use Arduino Mega2560 instead. And if you want to show high resolution images and motions with high speed, you should use the ARM core Arduino boards such as Arduino DUE.

In electronics/computer hardware a display driver is usually a semiconductor integrated circuit (but may alternatively comprise a state machine made of discrete logic and other components) which provides an interface function between a microprocessor, microcontroller, ASIC or general-purpose peripheral interface and a particular type of display device, e.g. LCD, LED, OLED, ePaper, CRT, Vacuum fluorescent or Nixie.

The display driver will typically accept commands and data using an industry-standard general-purpose serial or parallel interface, such as TTL, CMOS, RS232, SPI, I2C, etc. and generate signals with suitable voltage, current, timing and demultiplexing to make the display show the desired text or image.

The LCDs manufacturers use different drivers in their products. Some of them are more popular and some of them are very unknown. To run your display easily, you should use Arduino LCDs libraries and add them to your code. Otherwise running the display may be very difficult. There are many free libraries you can find on the internet but the important point about the libraries is their compatibility with the LCD’s driver. The driver of your LCD must be known by your library. In this article, we use the Adafruit GFX library and MCUFRIEND KBV library and example codes. You can download them from the following links.

You must add the library and then upload the code. If it is the first time you run an Arduino board, don’t worry. Just follow these steps:Go to www.arduino.cc/en/Main/Software and download the software of your OS. Install the IDE software as instructed.

By these two functions, You can find out the resolution of the display. Just add them to the code and put the outputs in a uint16_t variable. Then read it from the Serial port by Serial.println(); . First add Serial.begin(9600); in setup().

First you should convert your image to hex code. Download the software from the following link. if you don’t want to change the settings of the software, you must invert the color of the image and make the image horizontally mirrored and rotate it 90 degrees counterclockwise. Now add it to the software and convert it. Open the exported file and copy the hex code to Arduino IDE. x and y are locations of the image. sx and sy are sizes of image. you can change the color of the image in the last input.

Upload your image and download the converted file that the UTFT libraries can process. Now copy the hex code to Arduino IDE. x and y are locations of the image. sx and sy are size of the image.

In this template, We converted a .jpg image to .c file and added to the code, wrote a string and used the fade code to display. Then we used scroll code to move the screen left. Download the .h file and add it to the folder of the Arduino sketch.

In this template, We used sin(); and cos(); functions to draw Arcs with our desired thickness and displayed number by text printing function. Then we converted an image to hex code and added them to the code and displayed the image by bitmap function. Then we used draw lines function to change the style of the image. Download the .h file and add it to the folder of the Arduino sketch.

In this template, We created a function which accepts numbers as input and displays them as a pie chart. We just use draw arc and filled circle functions.

In this template, We added a converted image to code and then used two black and white arcs to create the pointer of volumes. Download the .h file and add it to the folder of the Arduino sketch.

In this template, We added a converted image and use the arc and print function to create this gauge. Download the .h file and add it to folder of the Arduino sketch.

In this template, We display simple images one after each other very fast by bitmap function. So you can make your animation by this trick. Download the .h file and add it to folder of the Arduino sketch.

In this template, We just display some images by RGBbitmap and bitmap functions. Just make a code for touchscreen and use this template. Download the .h file and add it to folder of the Arduino sketch.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey